Welding process for ultrahigh-strength steel plate with yield strength larger than or equal to 1250 MPa

A technology of yield strength and welding process, which is applied in the field of ultra-high-strength steel welding, can solve the problems of reducing joint strength, poor weldability, poor weld formation, etc., achieve good plastic toughness and crack resistance, no welding defects, The effect of strong solderability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0022] A welding process for ultra-high-strength steel plates with a yield strength ≧1250 MPa in this embodiment, wherein the chemical composition weight percentages of the ultra-high-strength steel plates are as follows: C: 0.2-0.5; Si: 0.1-0.4; Mn: 0.5-1.4; P: ≤0.015; S: ≤0.01; Cr: 0.5~0.8; Mo: 0.4~0.9; Ni: 0.2~0.8; the rest is Fe;

[0023] 1) Selection of welding consumables:

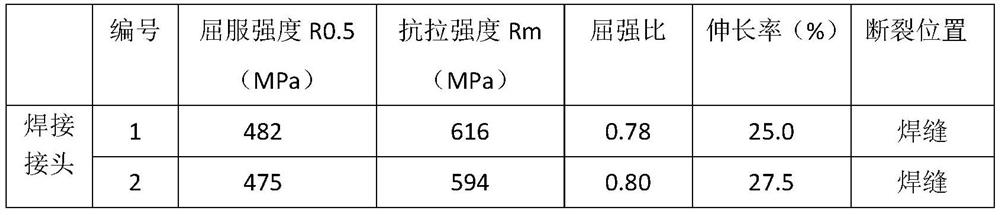

[0024] Considering the low bearing capacity of the weld area of the components welded by the steel plate, the austenitic stainless steel MIG welding wire, CHM-307Si, is selected. The cold crack sensitivity of the joints welded with this welding material will be greatly reduced and the weldability will be improved. DC reverse connection is adopted, the welding seam is fine and bright, the spatter is small and less, and the welding seam has good plasticity, toughnes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com