A special mold injection device for new energy vehicle interior

A new energy vehicle and interior decoration technology, which is applied in the field of mold injection molding, can solve the problems of the injected raw materials sticking to the inner wall of the hopper, and the hopper is easy to block, so as to achieve smooth circulation, ensure normal use, and prevent blockage

Active Publication Date: 2022-06-03

辽宁信兴汽车零部件有限公司

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The technical problem to be solved in the present invention is to provide a special mold injection molding device for new energy vehicle interior decoration, the purpose of which is to separate the Zusu raw material from the inner wall of the hopper, and solve the problem that the injected raw material adheres to the inner wall of the hopper, making it easy to block the hopper

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

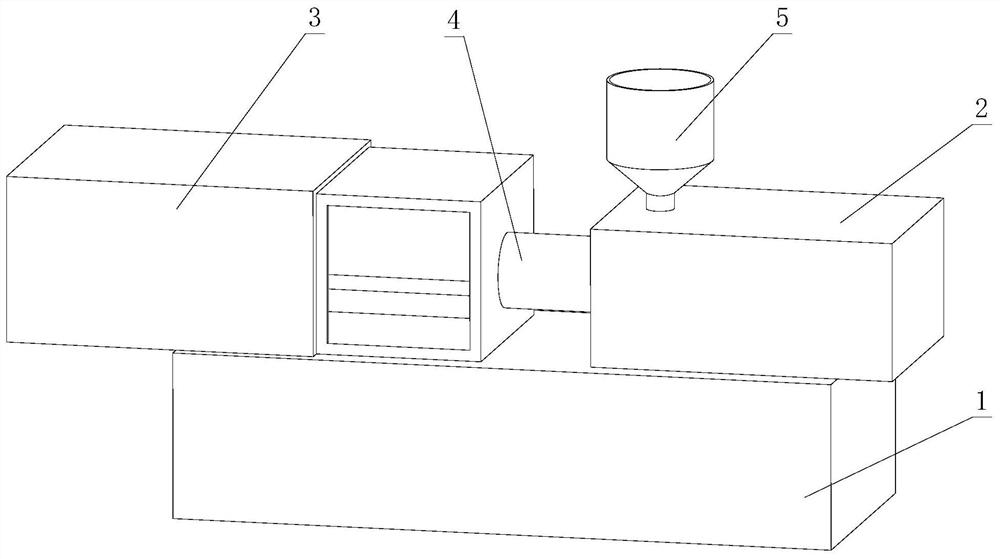

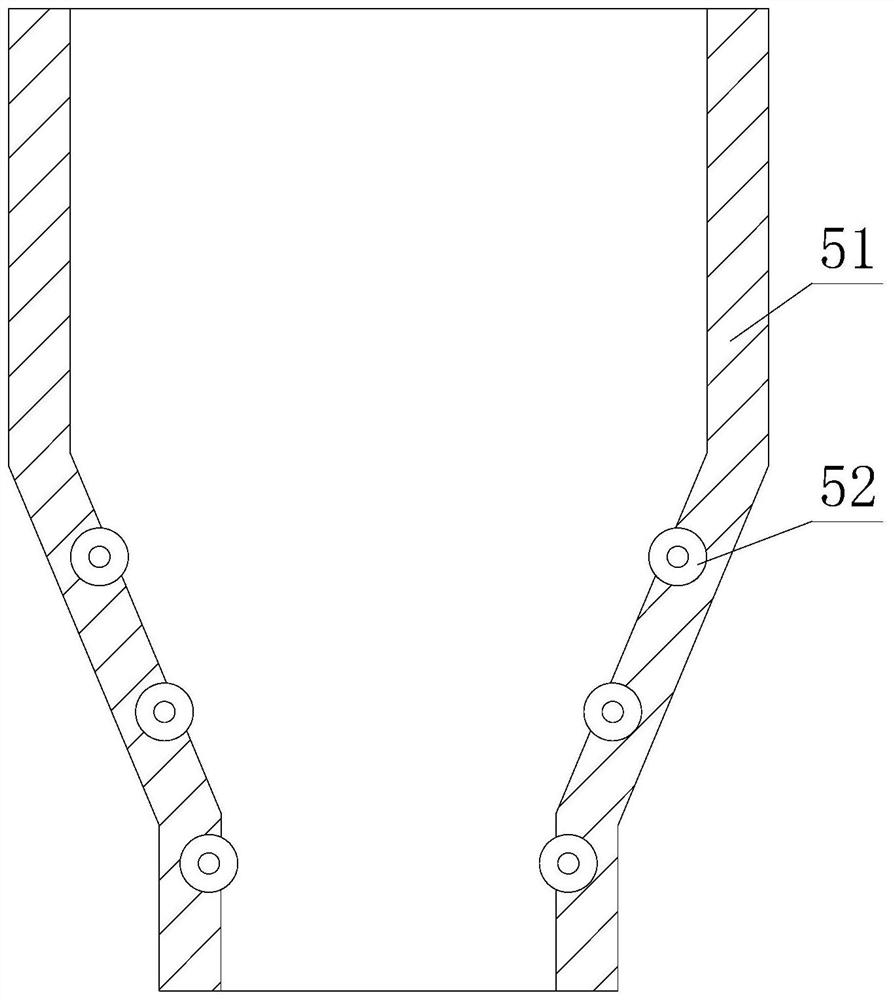

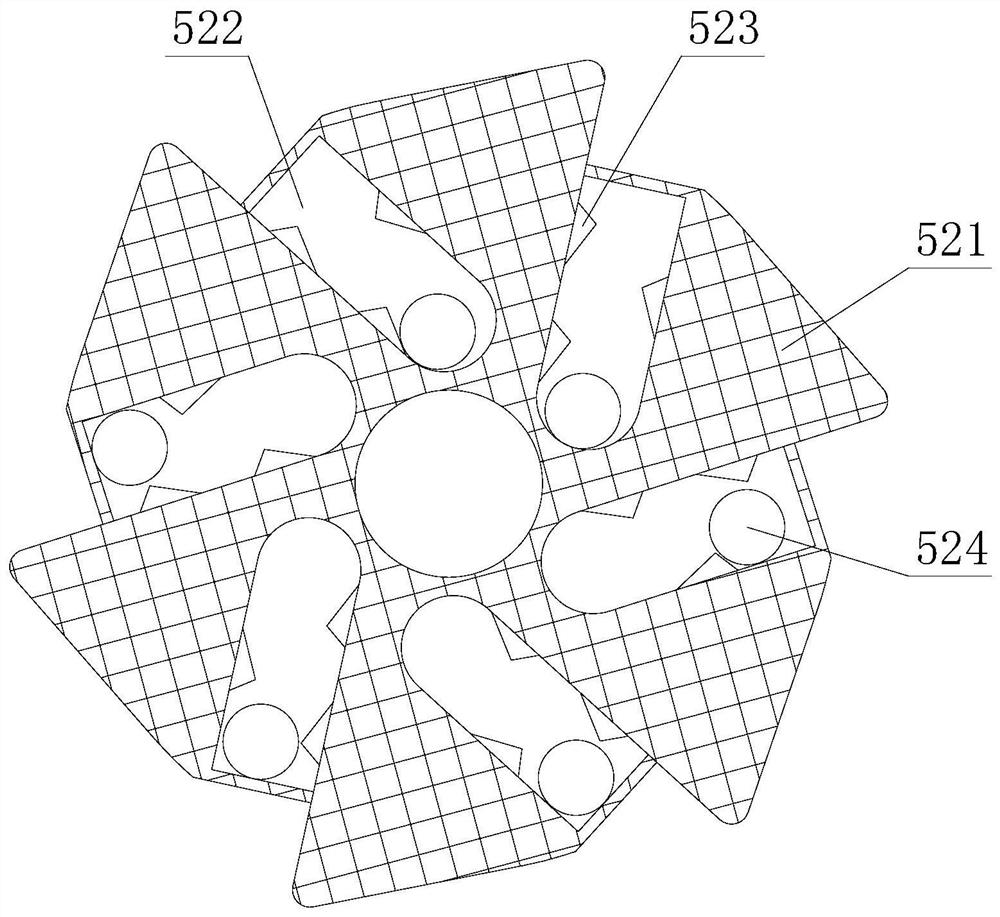

The invention discloses a special mold injection molding device for new energy automobile interior decoration, relates to the technical field of mold injection molding, and comprises a base, and the left and right sides of the upper end of the base are respectively provided with a matching mold structure and a feeding structure, and the mixing mold structure A heating structure is arranged between the feeding structure and a hopper is arranged on the upper end of the feeding structure close to the heating structure, and a silo is arranged inside the hopper. Through the design of the inner shock groove and the guide block, the present invention can make the vibration ball move in the inner shock groove when the wind wheel rotates, and when the vibration ball moves to the surface of the guide block, the vibration ball moves in an inclined direction, so that The vibrating ball hits the side wall of the wind wheel to generate vibration. Through the different rotation positions of the inner shock groove, the moving speed of the vibrating ball is different. After the vibration ball hits the wind wheel after moving, the vibration is generated, so that the wind wheel adheres The injection molding raw material is separated from the surface of the wind wheel to prevent clogging and make the injection molding raw material flow smoothly.

Description

A special mold injection device for new energy vehicle interior technical field The present invention relates to a kind of injection molding device, relate to the technical field of mold injection molding, be specifically related to a kind of new energy vehicle interior Special mold injection device for decoration. Background technique The sad interiors of new energy sources are mostly plastic products, so need to have injection molding impact to produce, to improve new energy sources Production efficiency of automotive interiors. The following problems exist for the prior art: 1. In the prior art, due to the transfer of heat and the high temperature generated during injection molding, the material is A part of the injection material in the hopper will become soft and melted, making the injection material stick to the inner wall of the hopper, making the injection not smooth. question; 2, in the prior art, for some production factories, production efficiency can...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B29C45/18B65D88/66

CPCB29C45/18B65D88/66Y02P70/10

Inventor 王然然

Owner 辽宁信兴汽车零部件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com