Steel bridge deck paving structure and construction method thereof

A construction method and technology for steel bridge decks, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of delamination and slippage between bridge deck and asphalt concrete surface, insufficient compliance of asphalt concrete surface deformation, and interlayer. Poor adhesion durability and other problems, to achieve the effect of good followability, strong deformation resistance and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The application will be further elaborated below in conjunction with the accompanying drawings and embodiments.

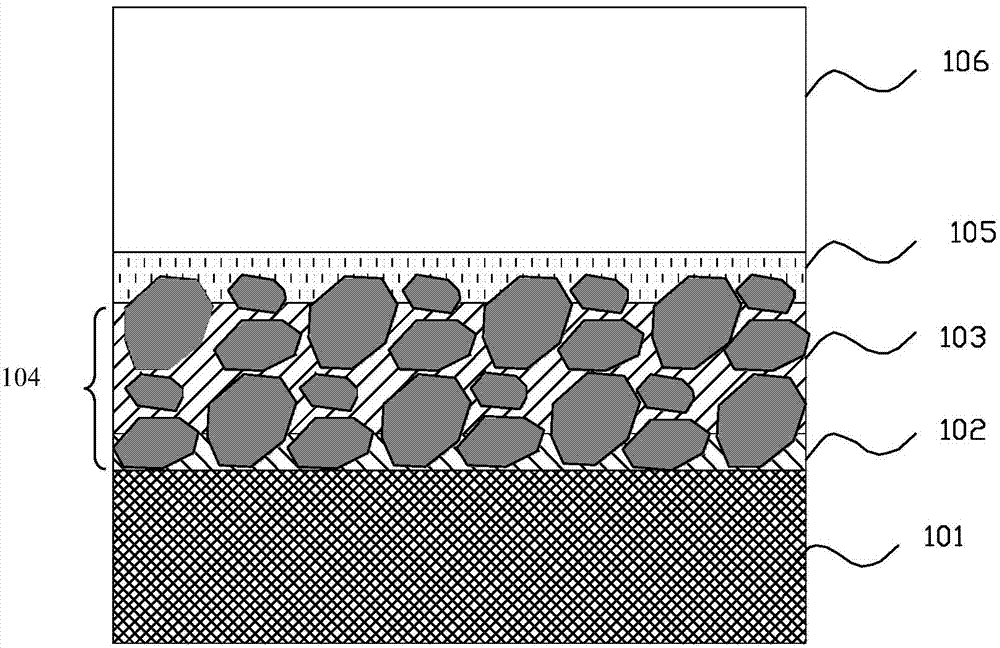

[0036] Such as figure 1 As shown, the steel bridge deck pavement structure of the present invention, according to the order from top to bottom, includes an ultra-high viscosity modified asphalt mastic macadam layer 106, an adhesive material 105, a combined connecting layer 104, an ultra-high viscosity The modified asphalt mastic macadam layer and the combined connecting layer are bonded with an adhesive material; The stone layer 103 is formed and directly arranged on the steel plate 101 of the bridge deck.

[0037] 1. Material requirements

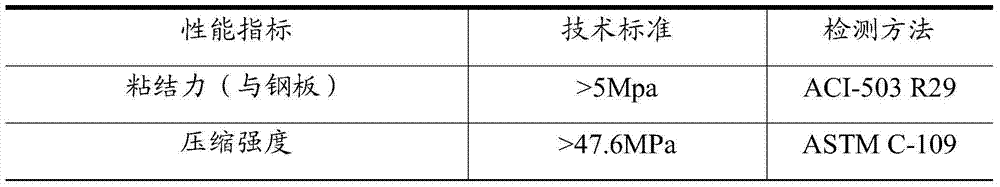

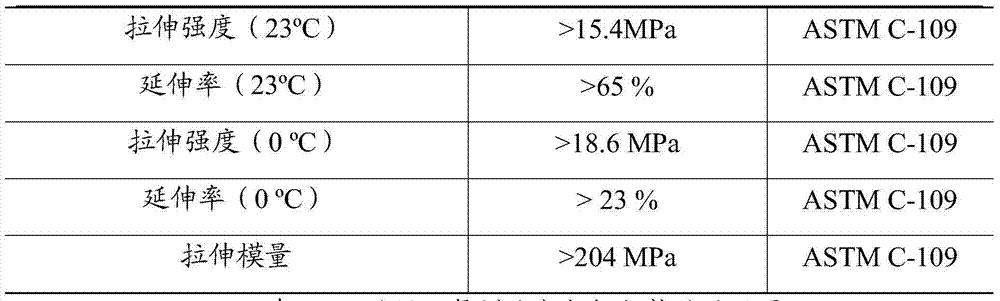

[0038] (1) Modified epoxy resin: The polymer resin material produced by the American Dow Chemical Company (DOW) is preferred. Its main component is a binary hybrid polymer resin. The formula does not contain any fillers and volatile solvents. The hybrid polymer system can provide superior low temperature flexibility a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com