Patents

Literature

36 results about "MOX fuel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mixed oxide fuel, commonly referred to as MOX fuel, is nuclear fuel that contains more than one oxide of fissile material, usually consisting of plutonium blended with natural uranium, reprocessed uranium, or depleted uranium. MOX fuel is an alternative to the low-enriched uranium (LEU) fuel used in the light water reactors that predominate nuclear power generation.

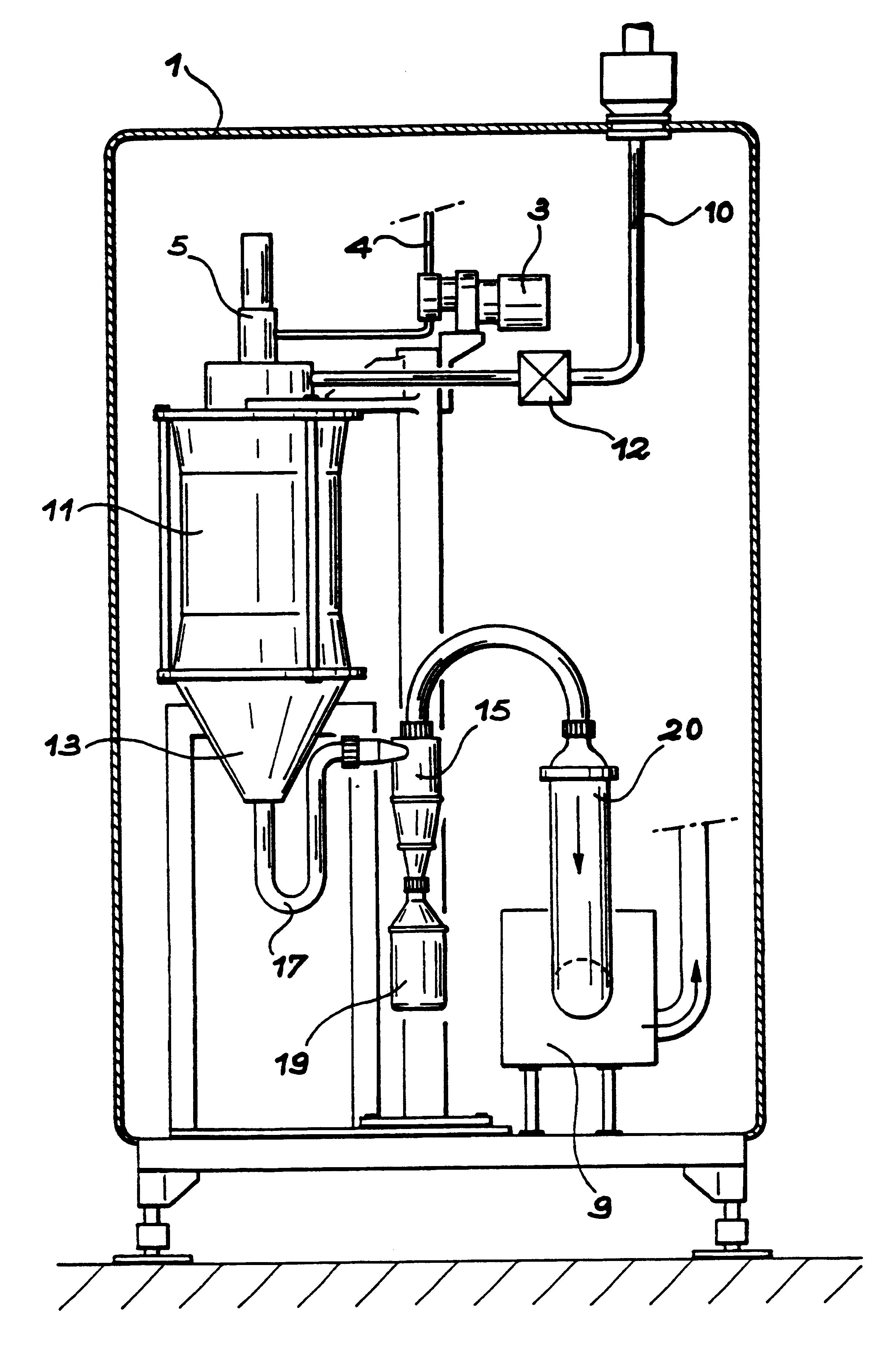

Preparation by spray-drying of a flowable uranium dioxide powder obtained by dry process conversion of UF6

InactiveUS6656391B1Lower levelMaintain good propertiesNuclear energy generationUranium dioxideUranium hexafluorideViscosity

The invention relates to a process for preparing a castable powder of uranium dioxide UO2, for use in the manufacture of MOX fuel.This process comprises the following stages:1) to prepare an aqueous suspension of a powder of UO2 obtained by dry process from uranium hexafluoride, said suspension comprising 50 to 80% by weight of UO2 and at least one additive chosen among deflocculation agents, organic binders, hydrogen peroxide H2O2 and a powder of U3O8, in such a quantity that the viscosity of the suspension does not exceed 250 mPa.sec, and2) to atomise this suspension and dry it in a hot gas, at a temperature of 150 to 300° C., to obtain a castable powder of UO2 with an average particle size of 20 to 100 mum.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

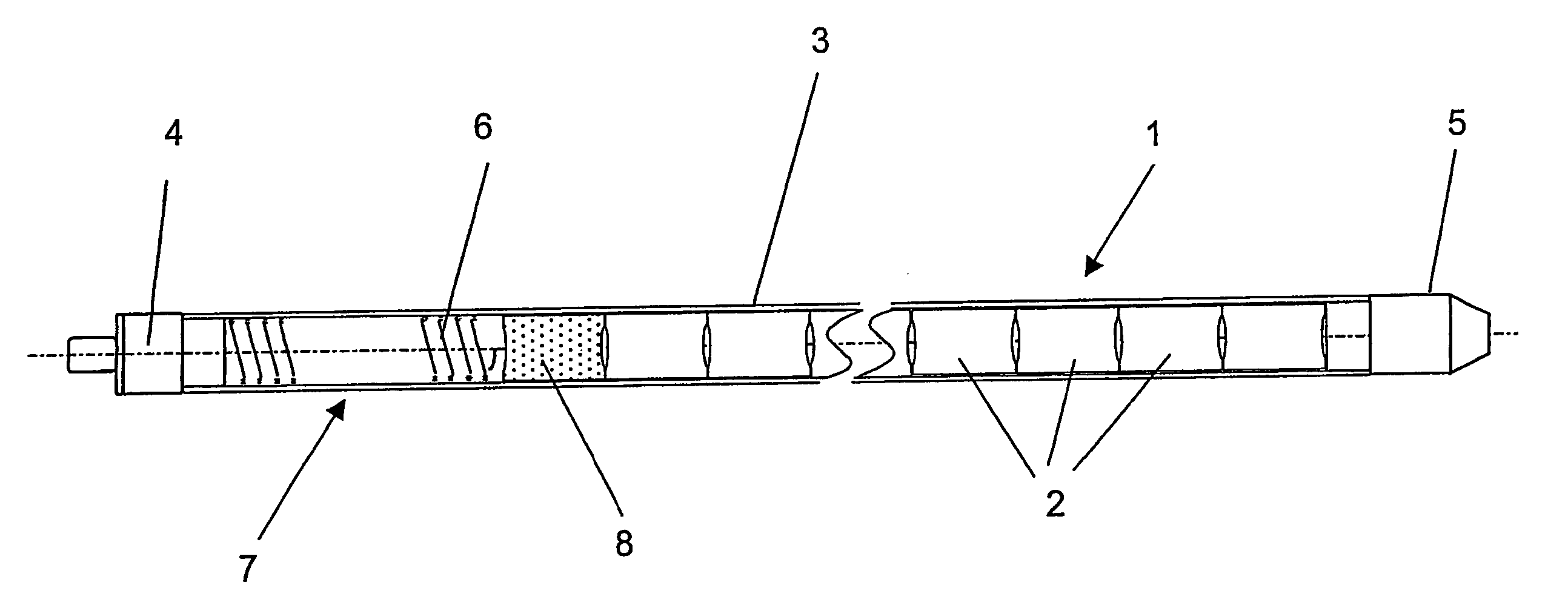

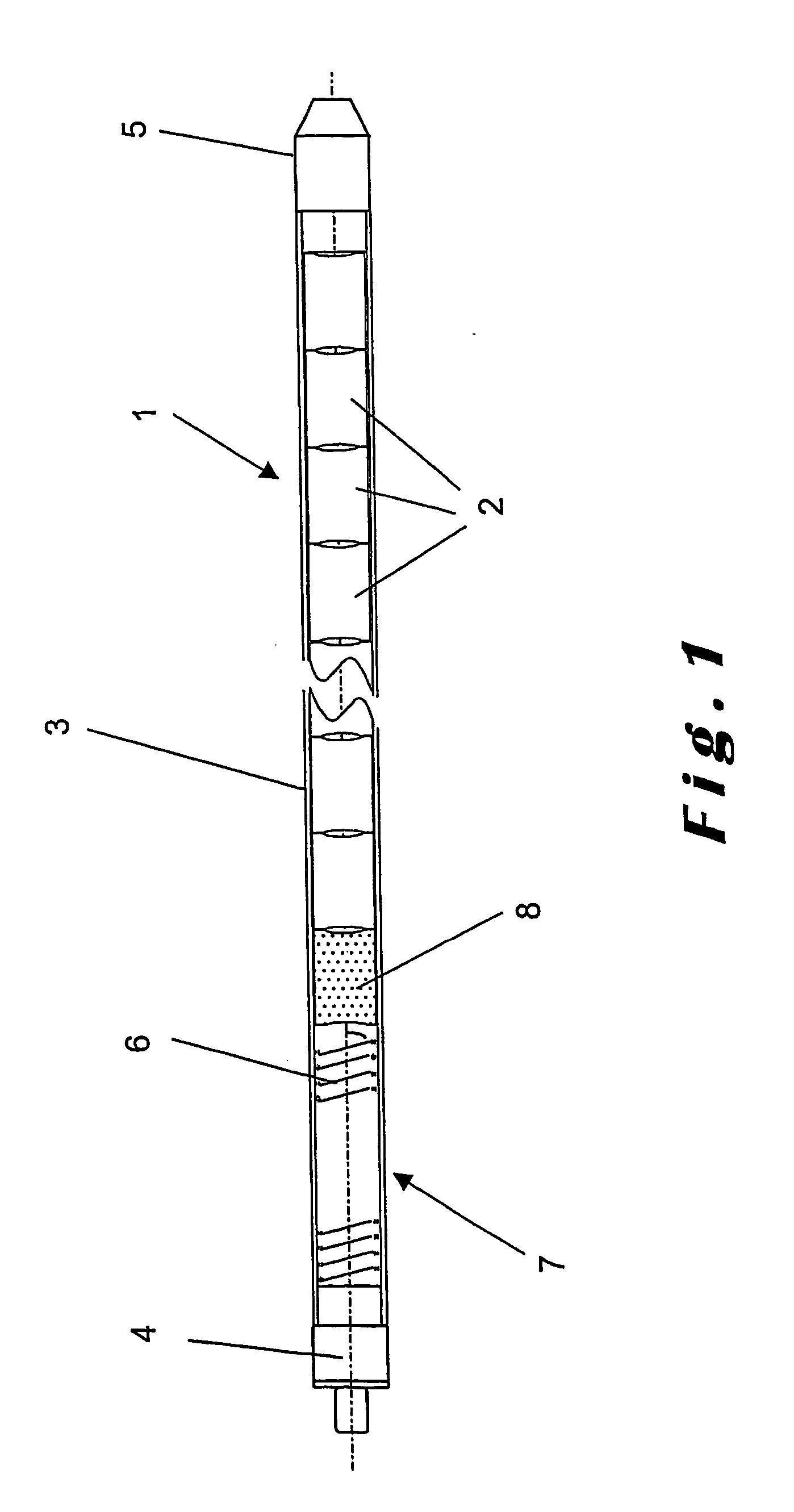

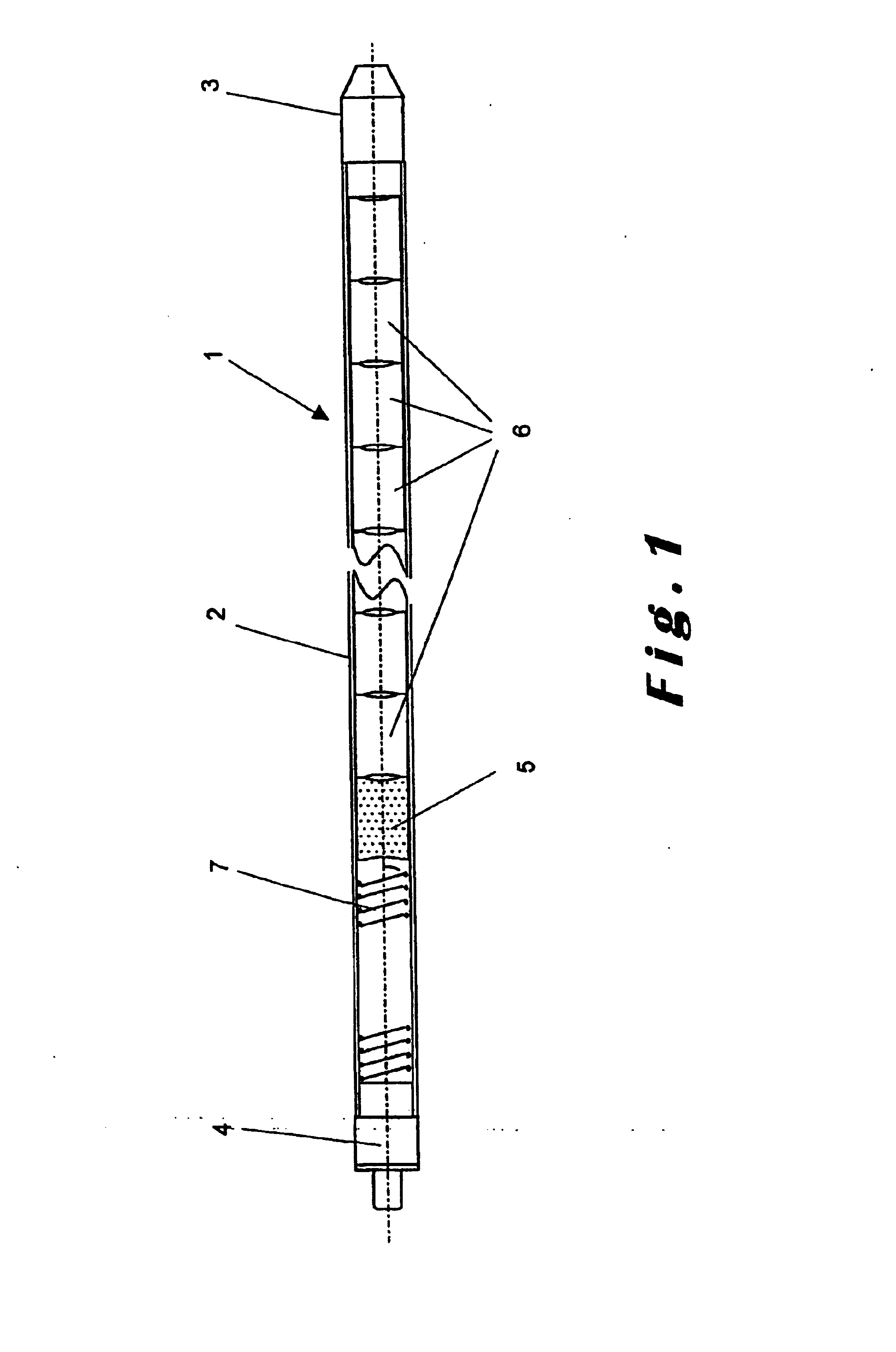

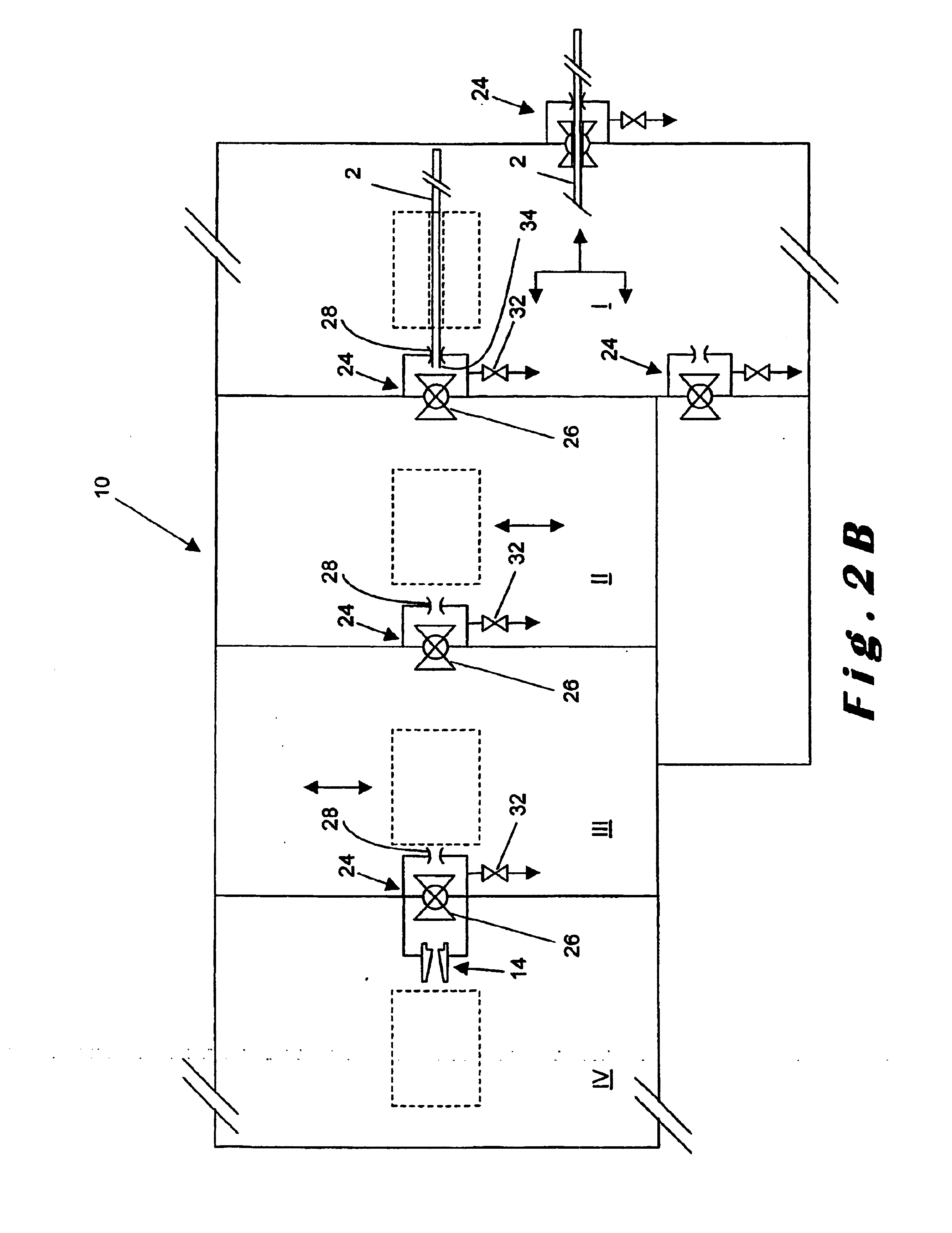

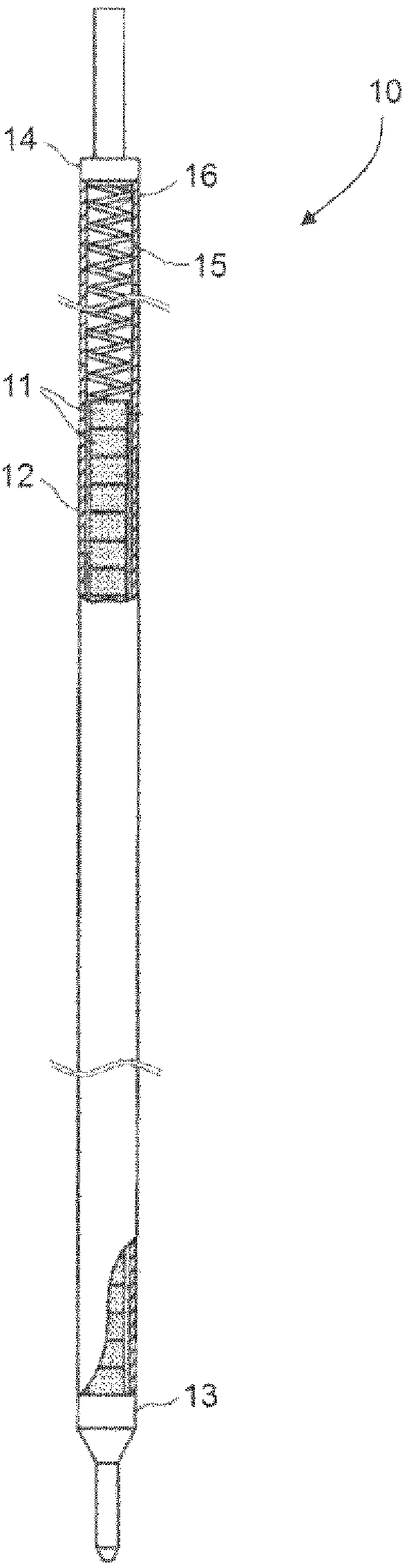

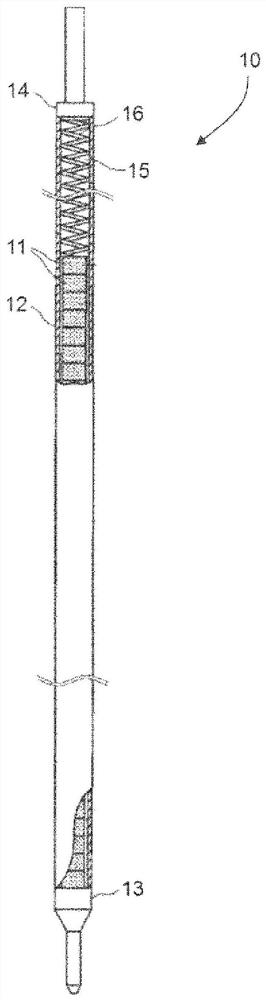

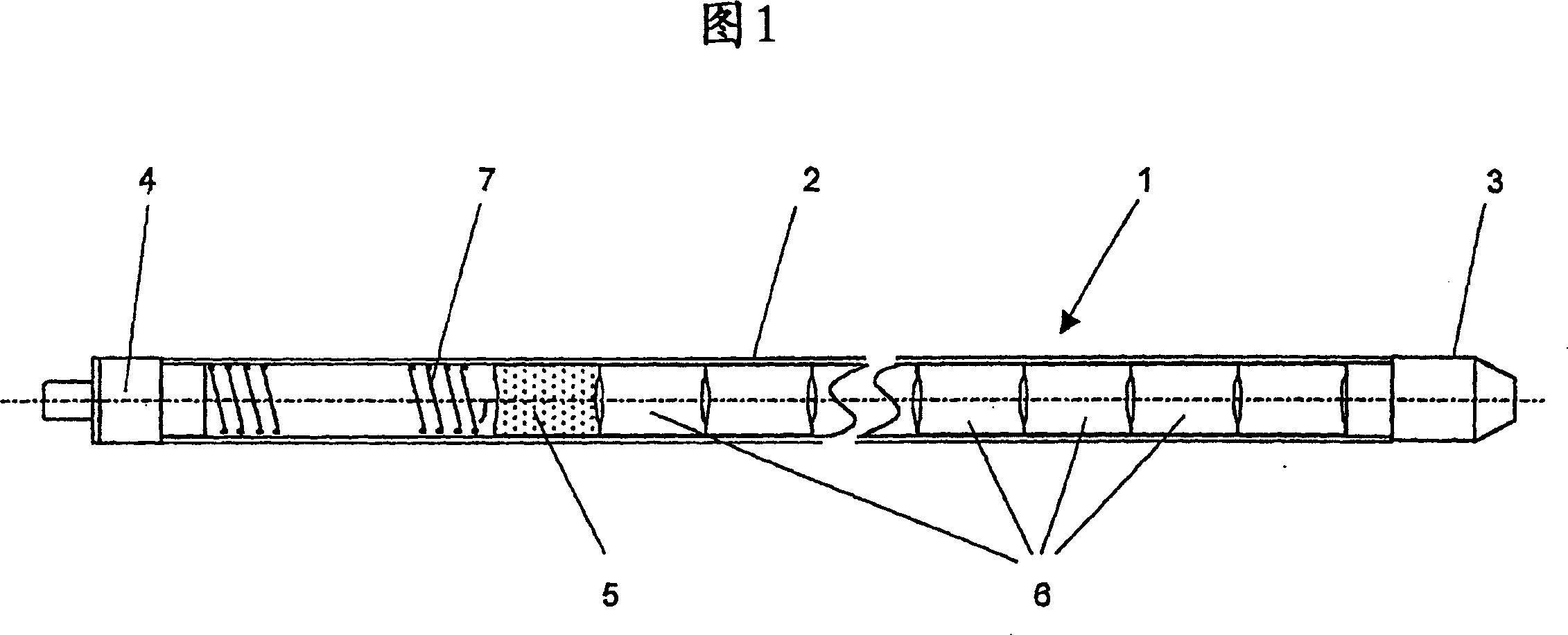

Method and apparatus for carrying out a mox fuel rod quality control

InactiveUS20060056566A1Nuclear energy generationNuclear monitoringQuality controlRadioactive contamination

A method for carrying out a comprehensive quality control of MOX fuel rods, including measurement of plutonium content of pellets contained in the rod, check of internal structure and constituents in the rod, including the detection of rogue pellets, and measurement of dimensional characteristics and radioactive contamination along the rod surface, by moving the fuel rod axially, performing concurrently the measurements and checks along the fuel rod moved axially, using radiometry and radiography. An apparatus for carrying out the method.

Owner:BELGONUCLEAIRE SA

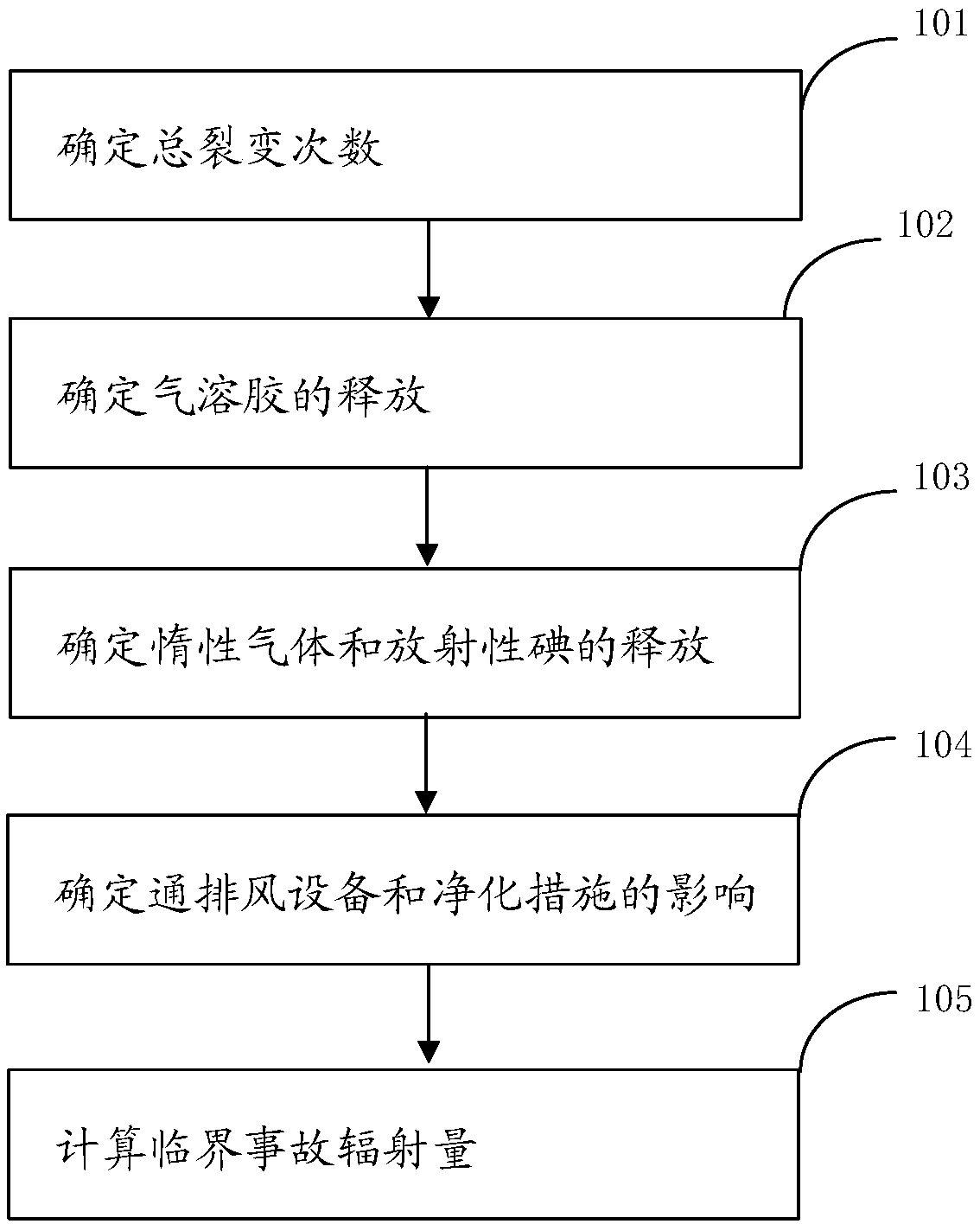

estimation method for a critical accident environment release source item of MOX fuel

The invention provides an estimation method for a critical accident environment release source item of MOX fuel. The method comprises the following steps: (1) determining the total number of fissures;(2) determining the release of aerosol; (3) determining the release of inert gas and radioactive iodine; (4) determining the influence of ventilation and exhaust equipment and purification measures;And (5) calculating the critical accident radiation quantity. The method provided by the invention can estimate the critical accident release amount of the MOX fuel.

Owner:CHINA INST FOR RADIATION PROTECTION

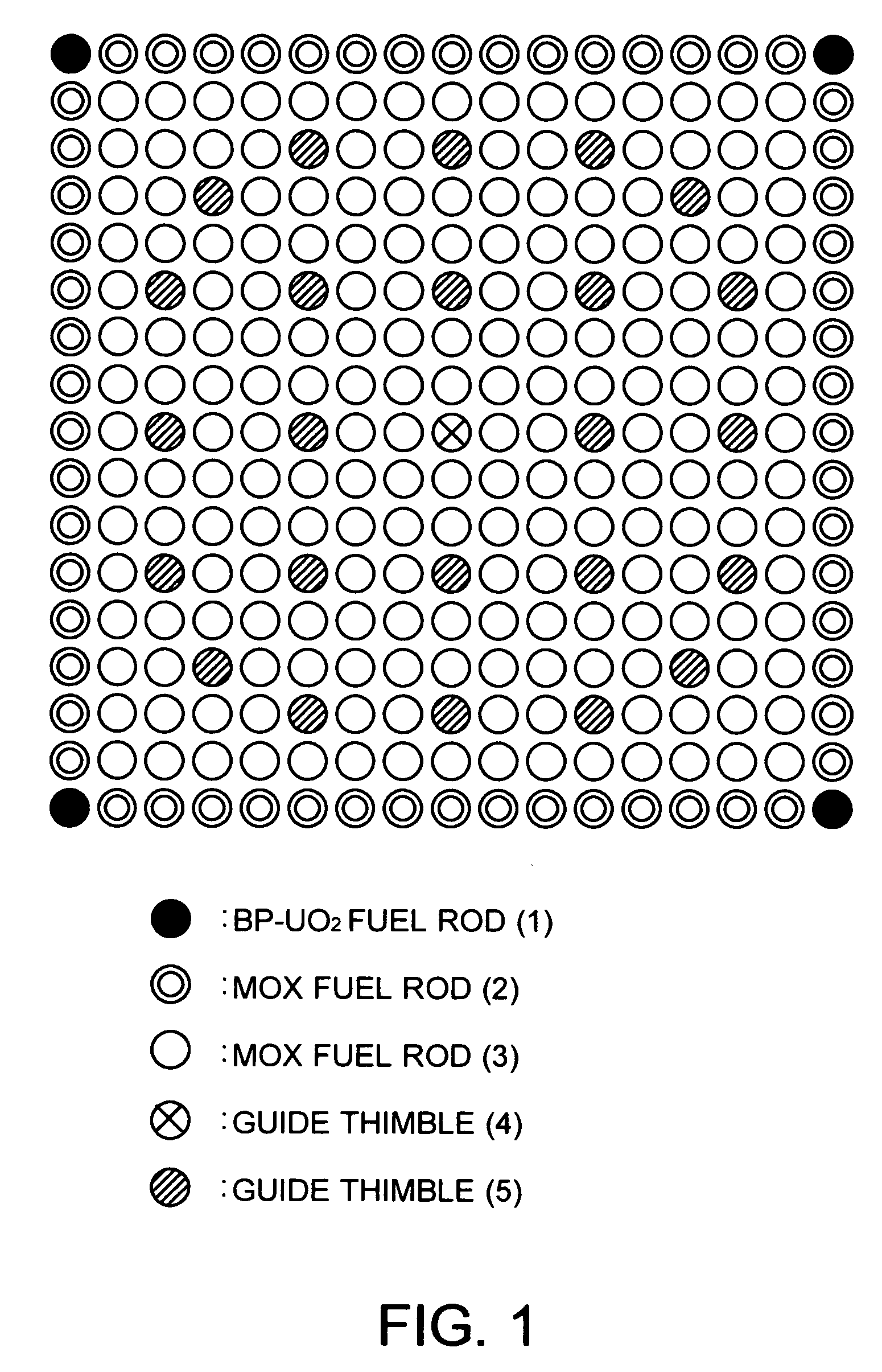

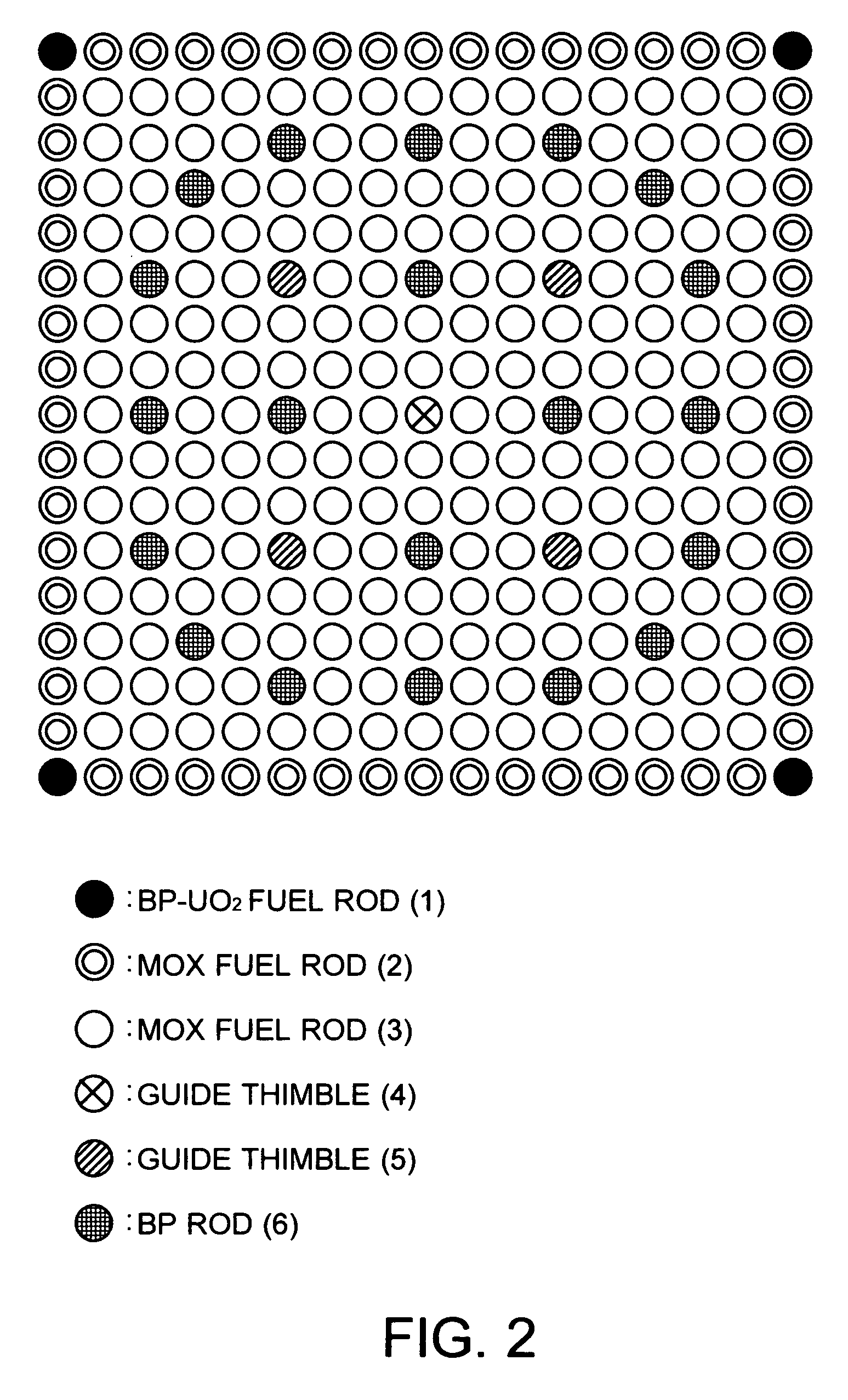

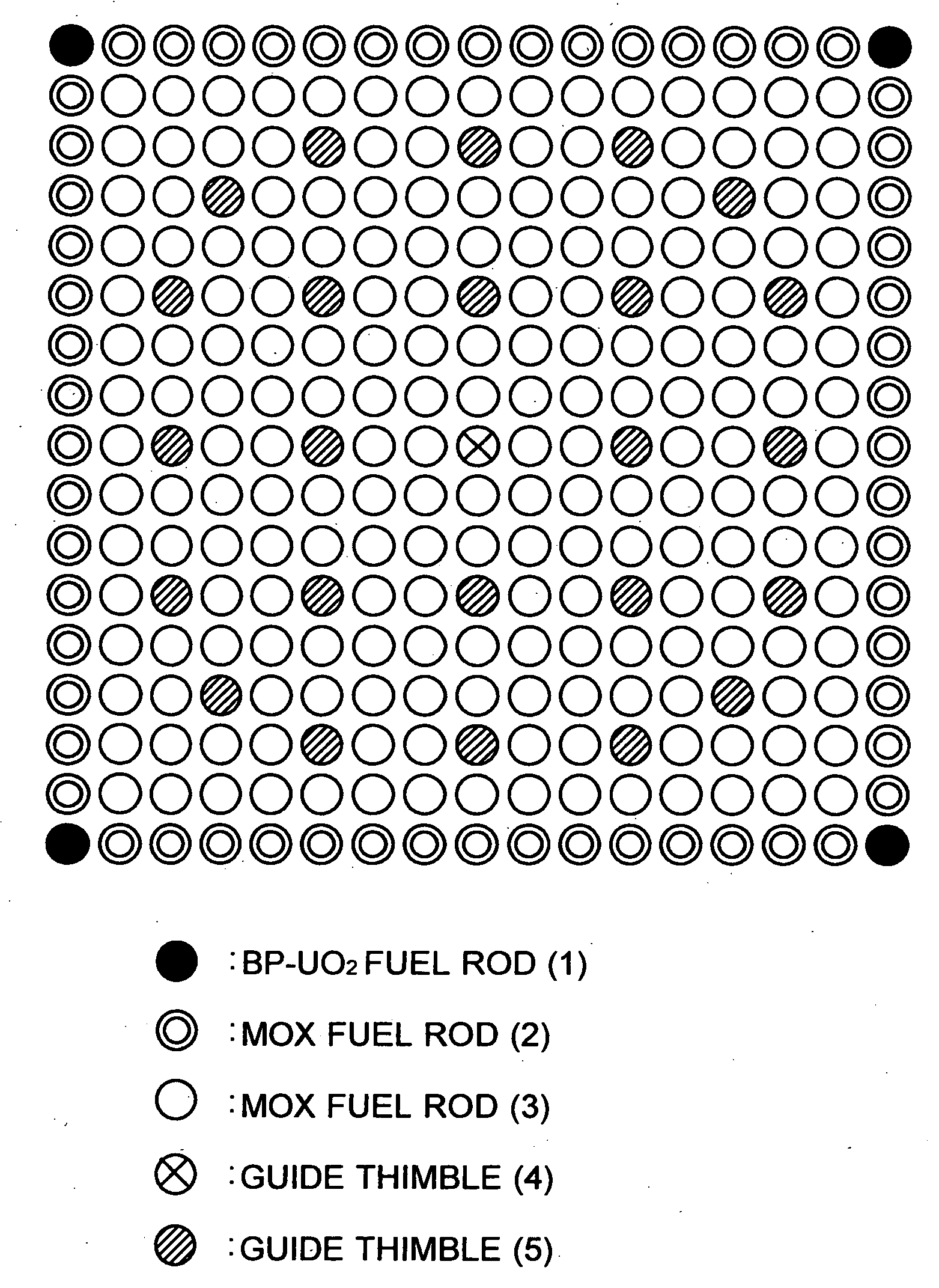

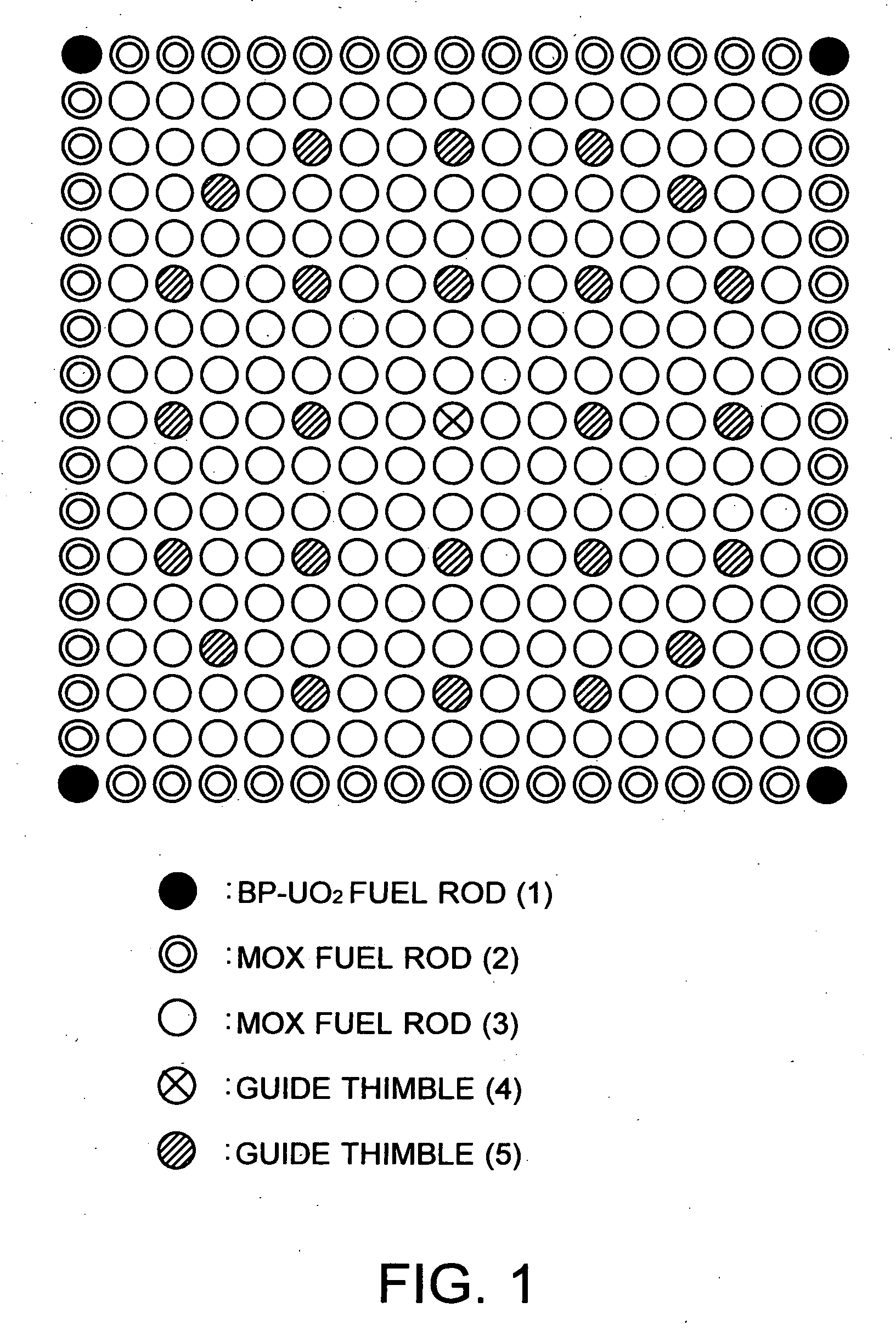

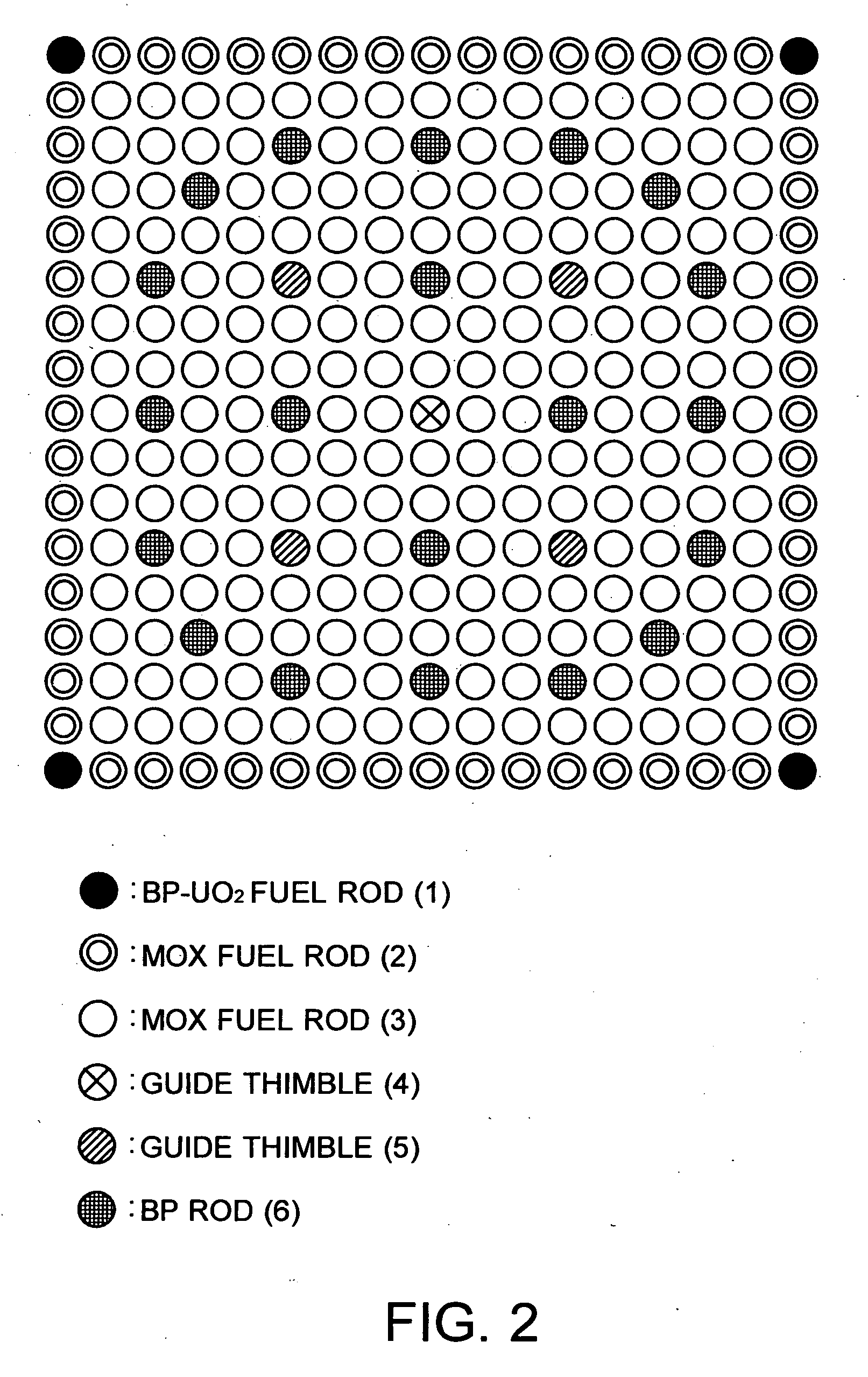

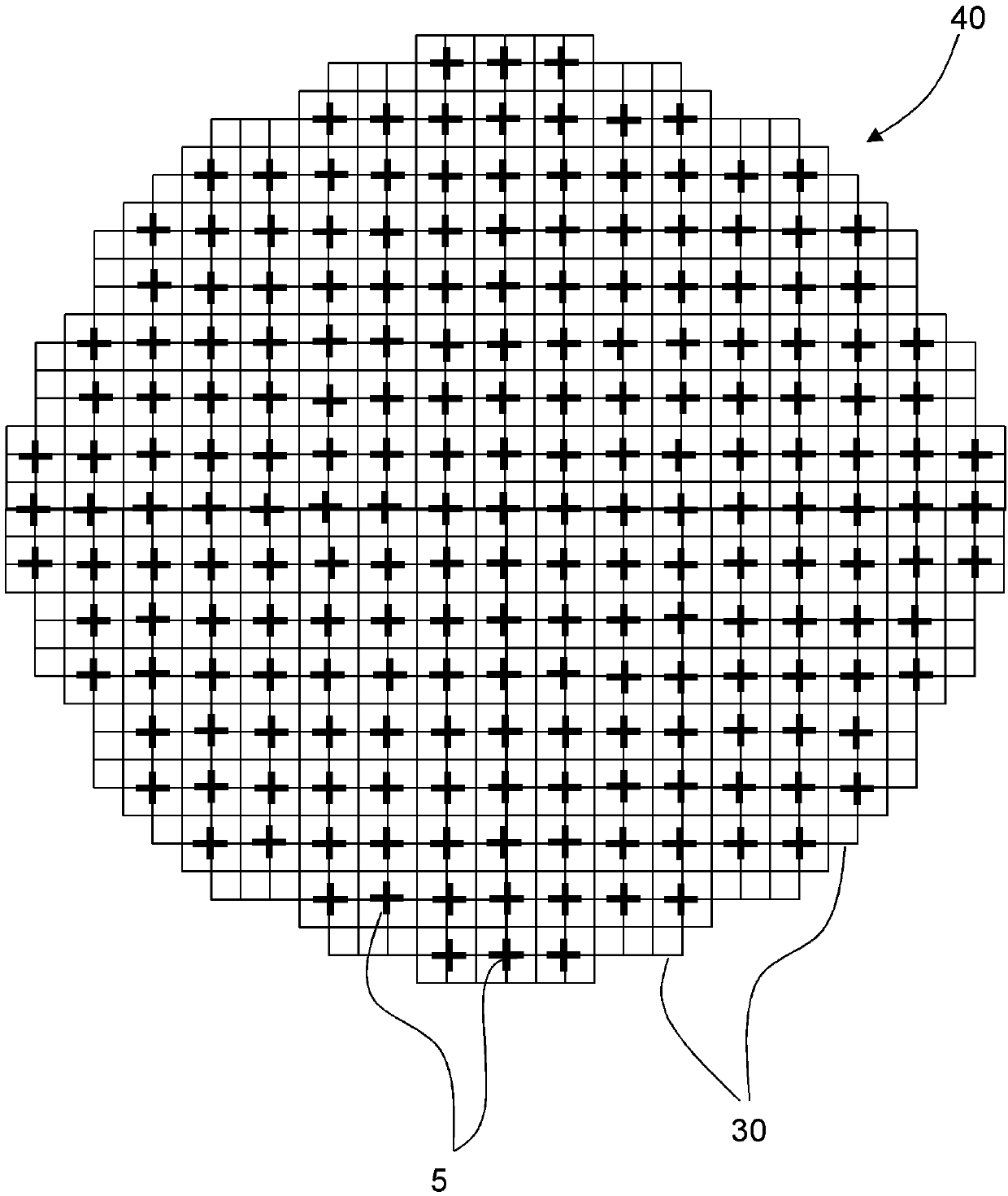

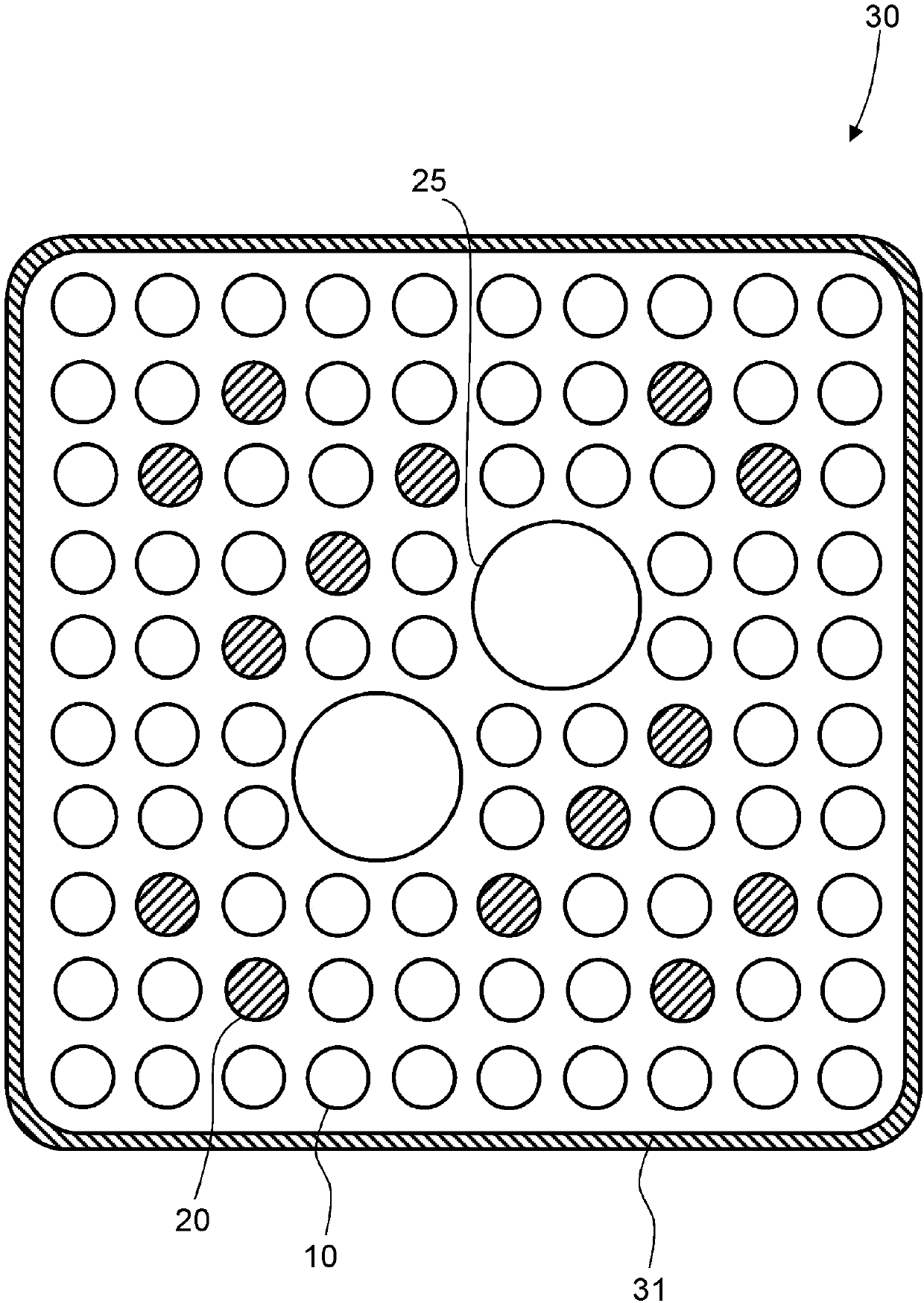

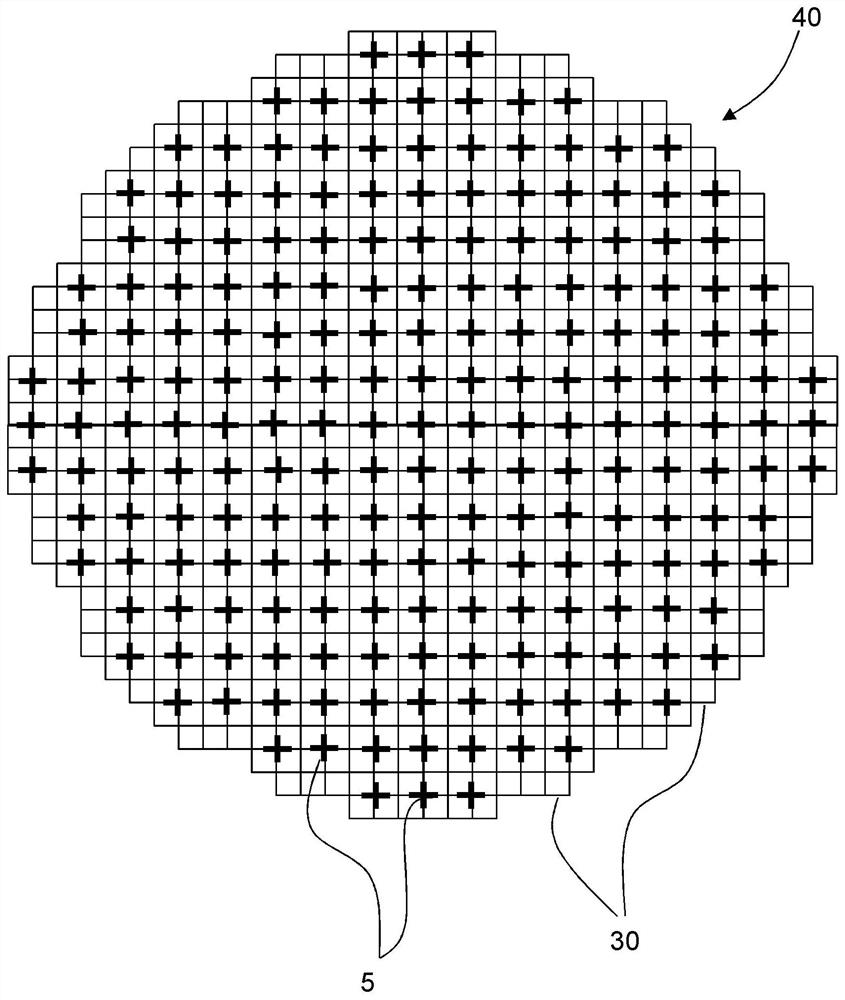

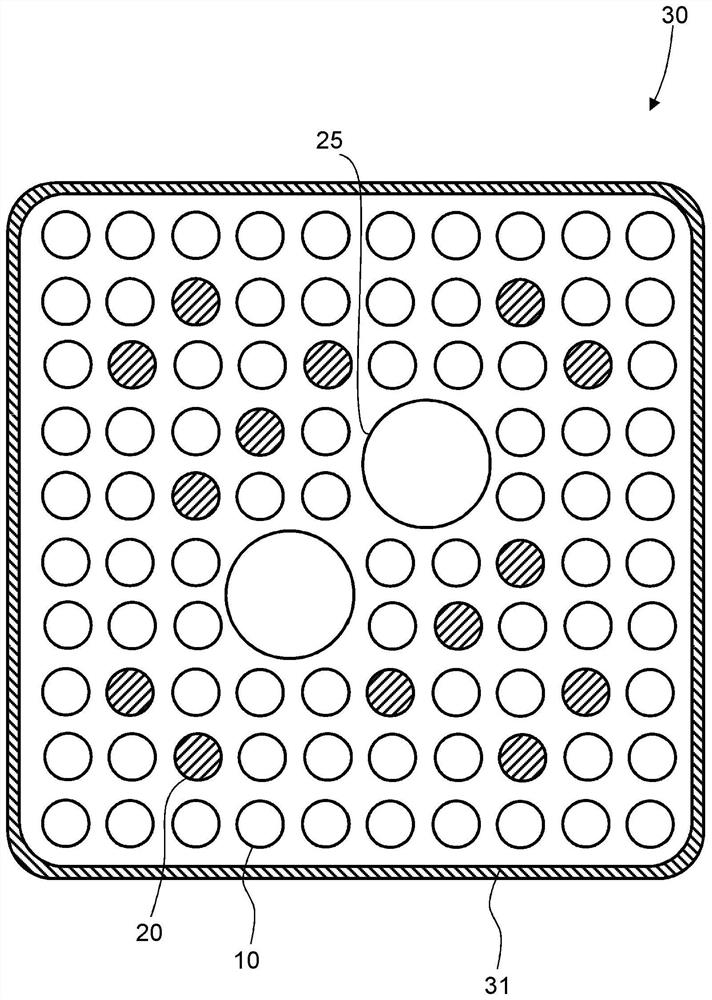

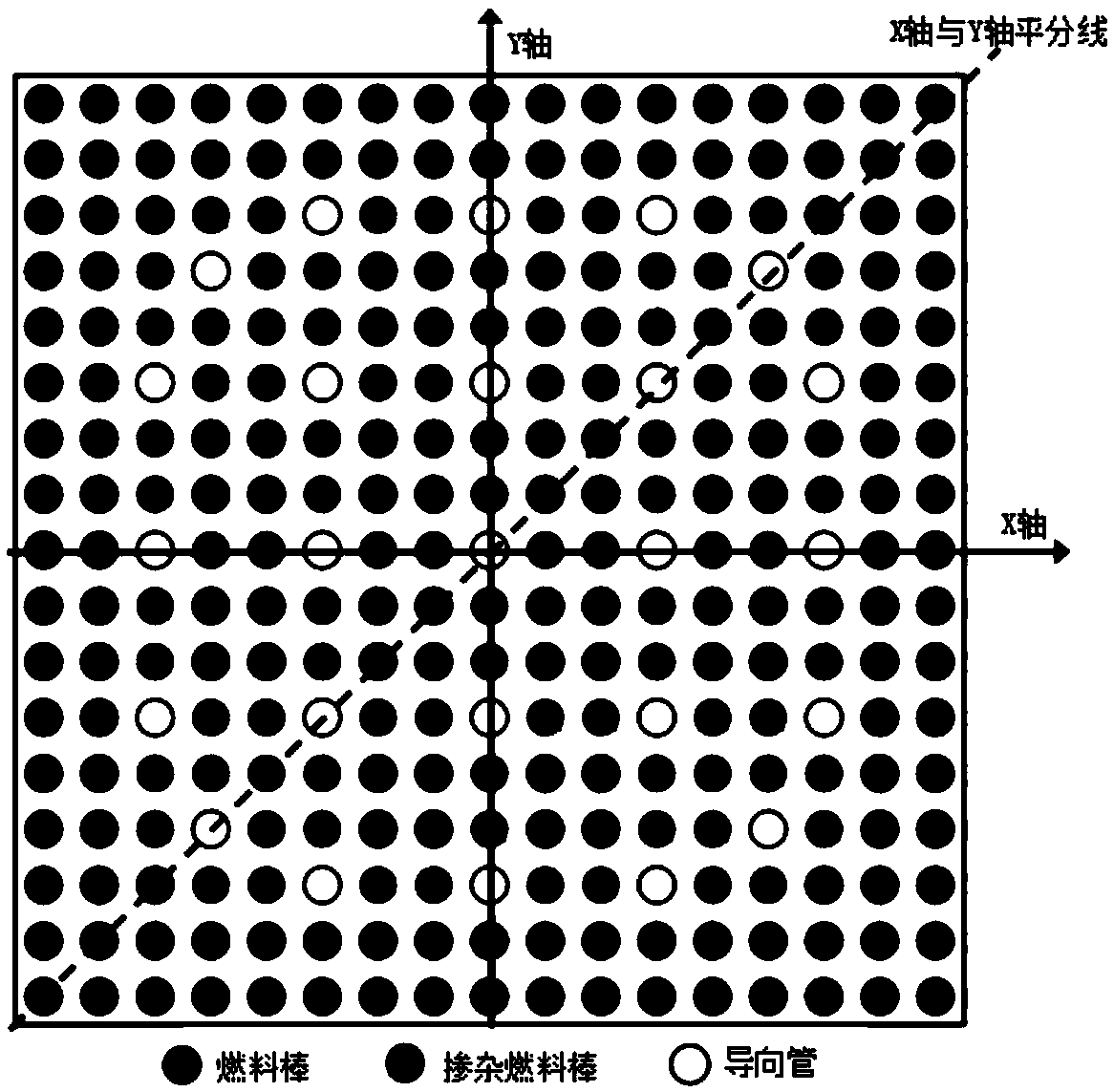

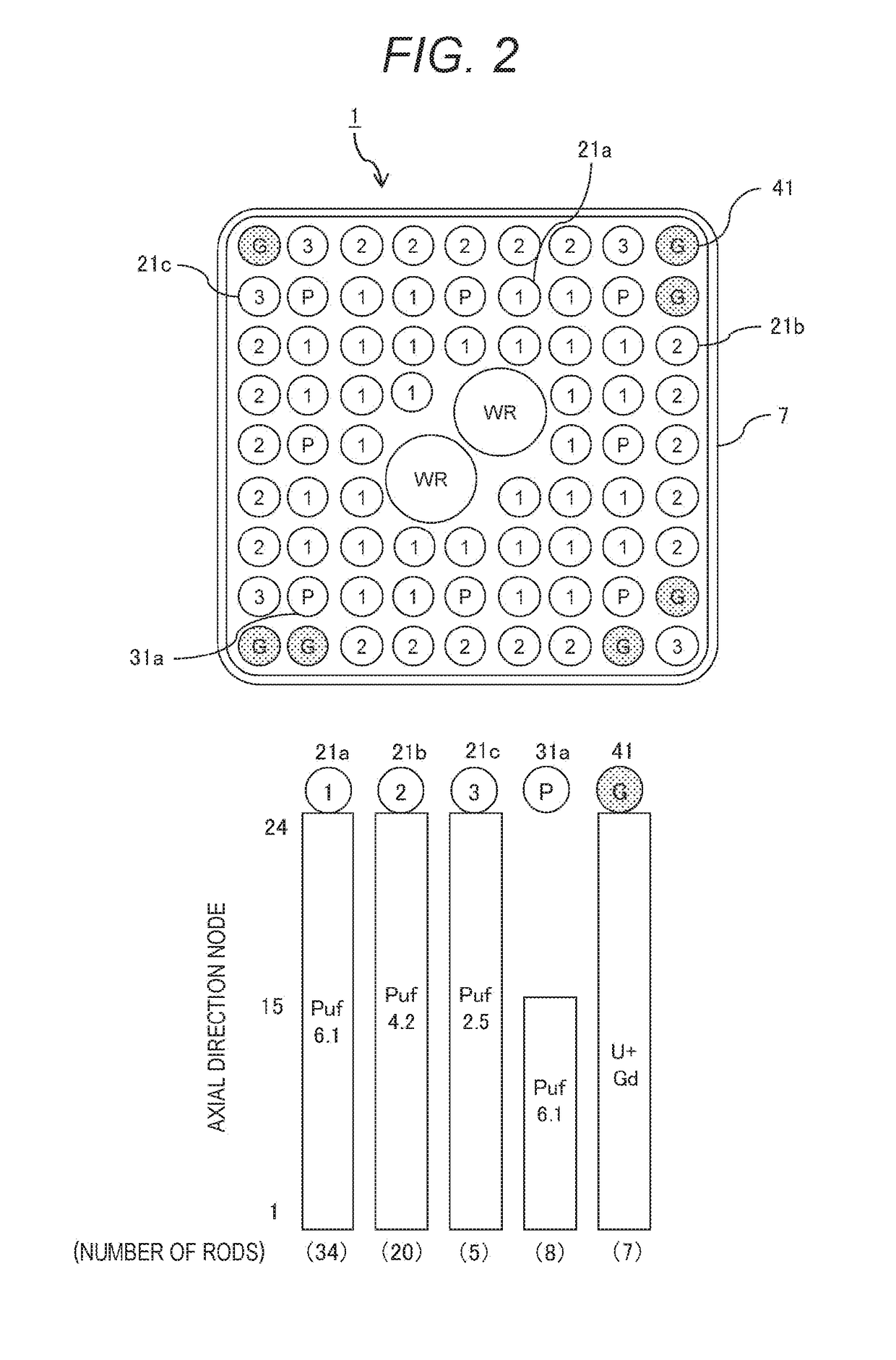

Mox fuel assembly for pressurized water reactors

InactiveUS20060269036A1Satisfactory controlEfficient use ofNuclear energy generationFuel element assembliesPressurized water reactorEngineering

This invention relates to a MOX fuel assembly for PWRs that enables satisfactorily suppressing a power peaking factor without the necessity of reducing the Pu content per fuel assembly. The MOX fuel assembly has a lattice arrangement in which one or more burnable poison contained UO2 fuel rods and a plurality of MOX fuel rods are disposed in an n-rows by n-columns (n×n) lattice array. The MOX fuel rod consists of at least two kinds of MOX fuel rods including a plurality of first MOX fuel rods and a plurality of second MOX fuel rods. The first MOX fuel rod has a predetermined Pu content and a predetermined Pu weight, and the second MOX fuel rod has substantially the same Pu content as that of the first MOX fuel rod and a different Pu weight from that of the first MOX fuel rod.

Owner:NUCLEAR FUEL INDS

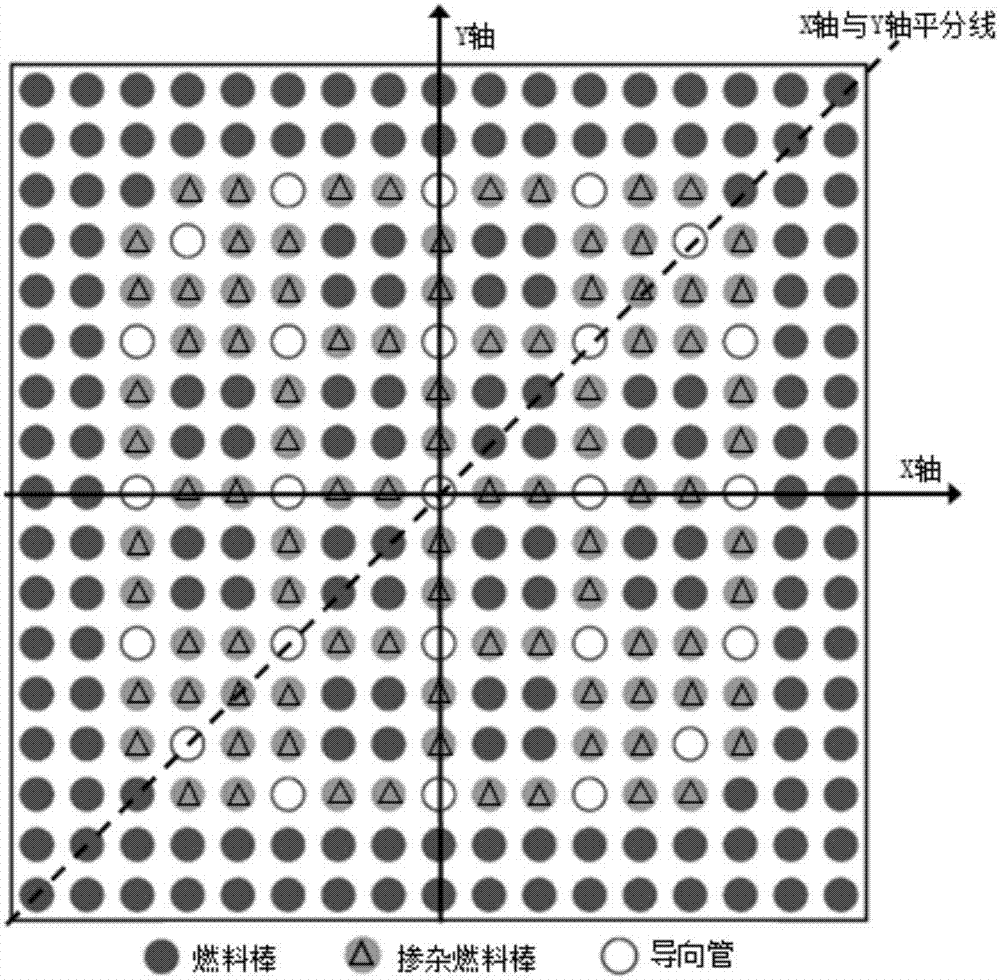

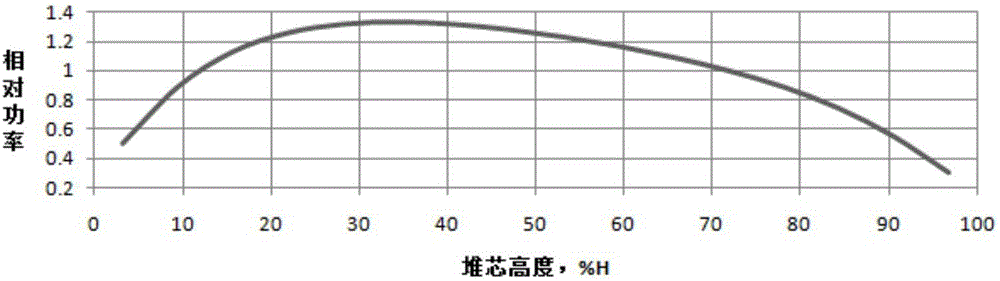

MOX fuel rod, MOX fuel assembly and method for flattening axial power

InactiveCN108550405AAxial power reductionAxial power up toFuel elementsNuclear energy generationCombustionNuclear engineering

The invention relates to an MOX fuel rod, an MOX fuel assembly and a method of flattening the axial power. The MOX fuel rod includes a doped fuel, the doped fuel is distributed in the axially middle part of the MOX fuel rod, and the doped fuel is a fuel doped with a long-lived minor actinide. The fuel in the axially middle part of the MOX fuel rod is the doped fuel, and the long-lived minor actinide in the doped fuel is transmuted in a neutron field to form a short-lived or stable nuclide, so the cost and the difficulty of final treatment of a spent fuel are reduced, and the treatment problemof the long-lived minor actinide in the spent fuel solved; and the transmutation of the long-lived minor actinide in the doped fuel, absorbing neutrons in the neutron field, is used to reduce the fission reaction rate of the doped fuel in order to reduce the original axial power and fuel consumption in the MOX fuel rod and the power and fuel consumption at a high combustion position, so the purposes of flattening the axial power of the MOX fuel rod, enhancing the reactor core safety and improving the fuel utilization rate are achieved.

Owner:SUN YAT SEN UNIV

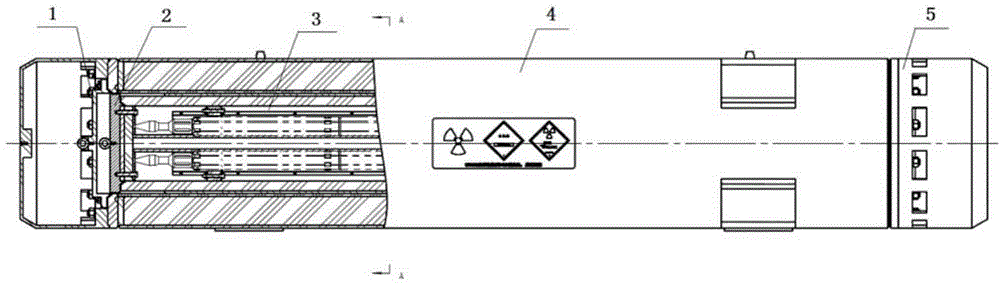

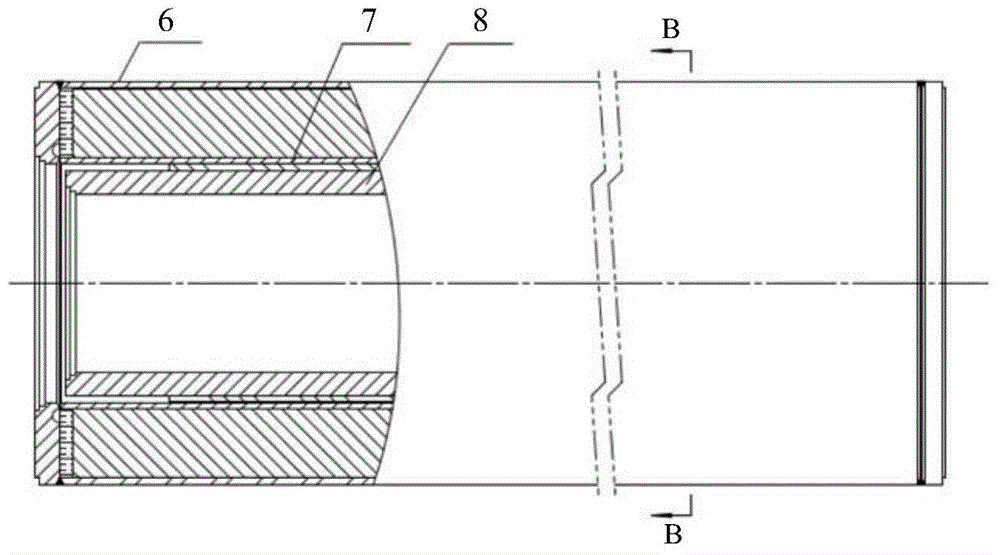

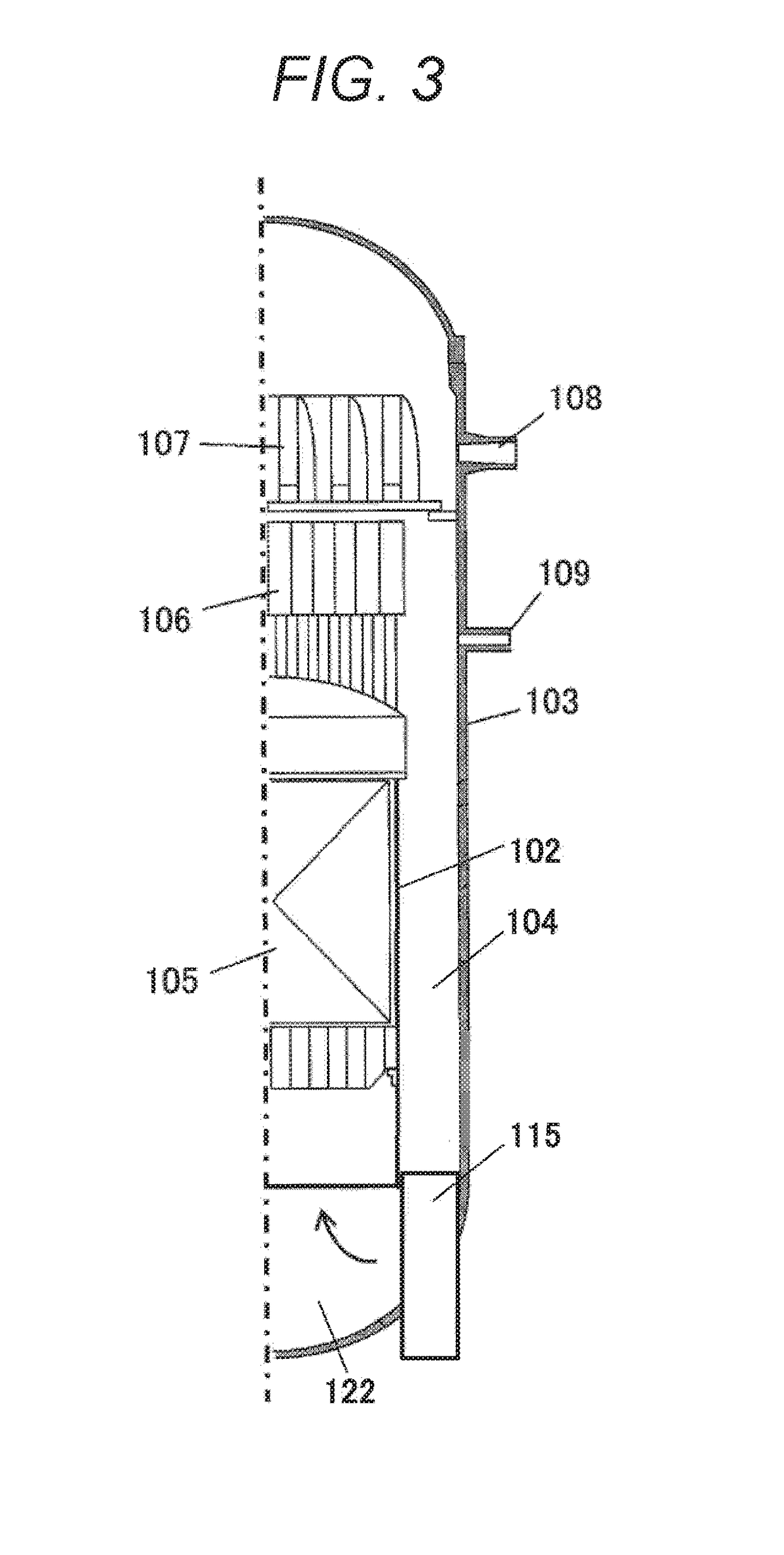

Conveying container for fast reactor MOX fuel component

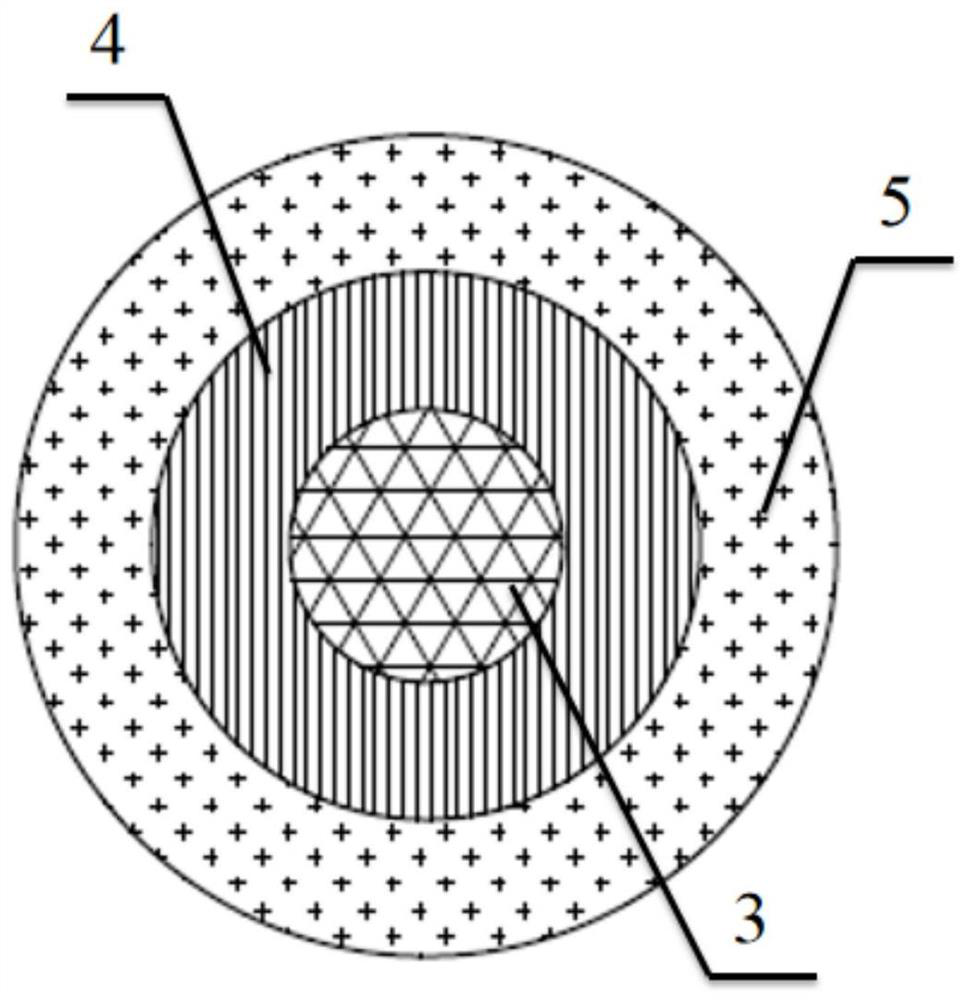

ActiveCN104575648AImprove stress statusImprove shielding effectPortable shielded containersRadioactive agentEngineering

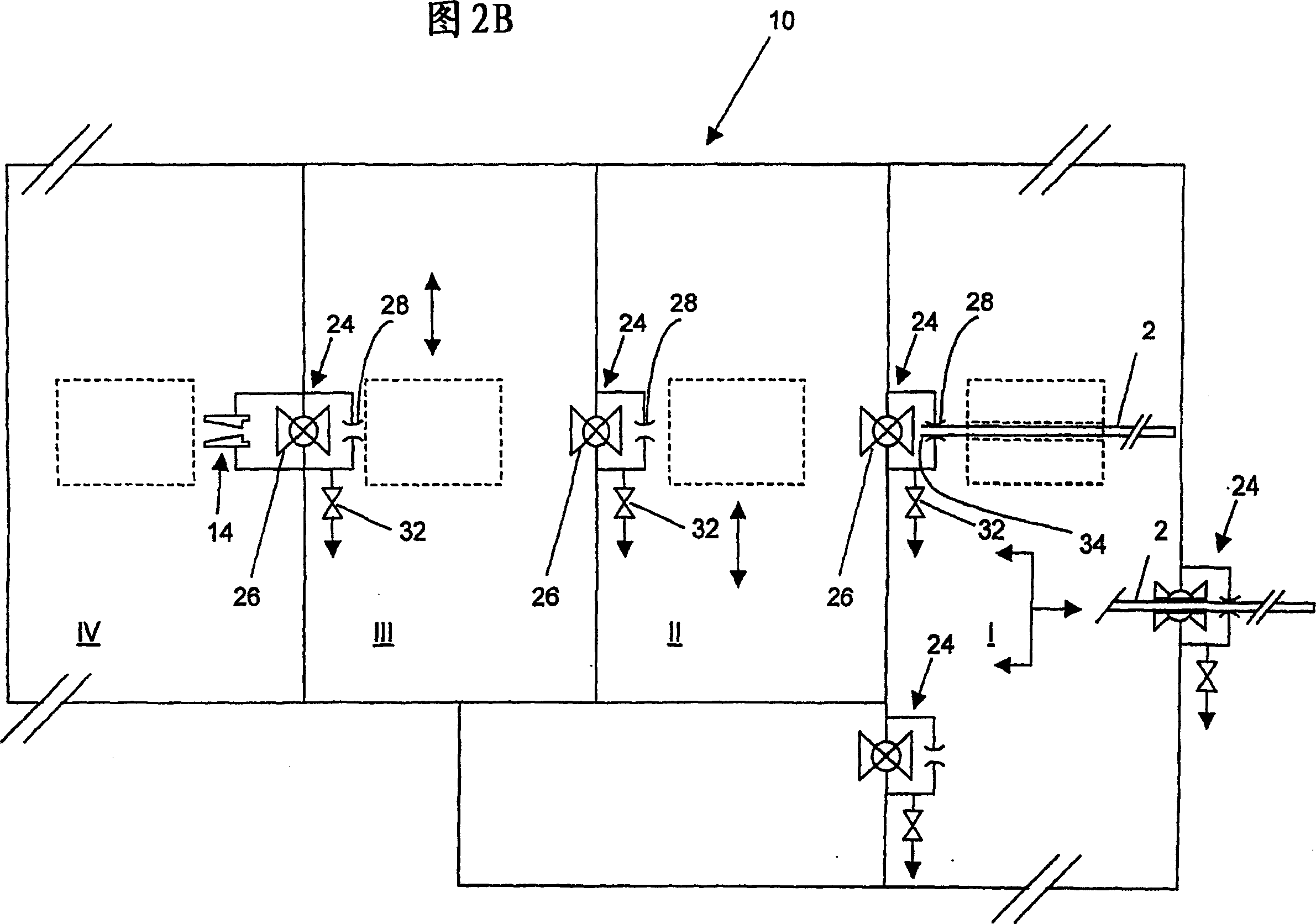

The invention relates to a conveying container of a fuel component, in particular to a conveying container for a fast reactor MOX fuel component. The conveying container structurally comprises a cylinder body component, wherein a middle penetrating component used for accommodating the fuel component is arranged in the cylinder body component; a compression end cover is arranged on the end part of the cylinder body component; the cylinder body component comprises an inner cylinder, a middle cylinder and an outer cylinder; the compression end cover is divided into two layers; the first layer of compression end cover is fixedly connected with the inner cylinder of the cylinder body component to form a first layer of containing boundary of radioactive substances; the second layer of compression end cover is fixedly connected with the middle cylinder of the cylinder body component to form a second layer of containing boundary of the radioactive substances; a shielding body and a heat isolating layer are arranged between the middle cylinder and the outer cylinder. The conveying container has better shielding property, containing property, buffering property and heat isolating property; the requirement on transportation of the radioactive substances by regulations can be met; in the whole transportation process, the MOX fuel component can be kept in a subcritical state.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Radiation protection method for MOX pellet preparation process

The invention belongs to the technical field of nuclear chemical radiation protection and in particular relates to a radiation protection method for an MOX pellet preparation process. Key equipment ona production line is enclosed by using glove boxes; the whole production line is formed by sequentially connecting a plurality of glove boxes; radioactive aerosol is used as an atmosphere in each glove box; each glove box is matched with an independent mechanical pump; the front end of the mechanical pump is designed to be provided with a filter-cloth-type efficient dust filter; the mechanical pump has the effect of making the average pressure inside each glove box smaller than the normal atmosphere pressure 300kPa; the glove box with the highest radiation level is placed in the middle of theproduction line; the radiation level of the glove box closer to the outer side is lower; the pressure of the glove box with a higher radiation level is lower; the pressure difference of the adjacentglove boxes is 20kPa; a sealing door with a sealing ring is designed at a junction between every two glove boxes; and the sealing door is closed under the condition that materials are not transferred.A whole set of radiation protection, detection and dirt removal method is established, the safety production of MOX fuel pellets is realized, and the safety of production operating personnel is guaranteed.

Owner:THE 404 COMPANY LIMITED CHINA NAT NUCLEAR

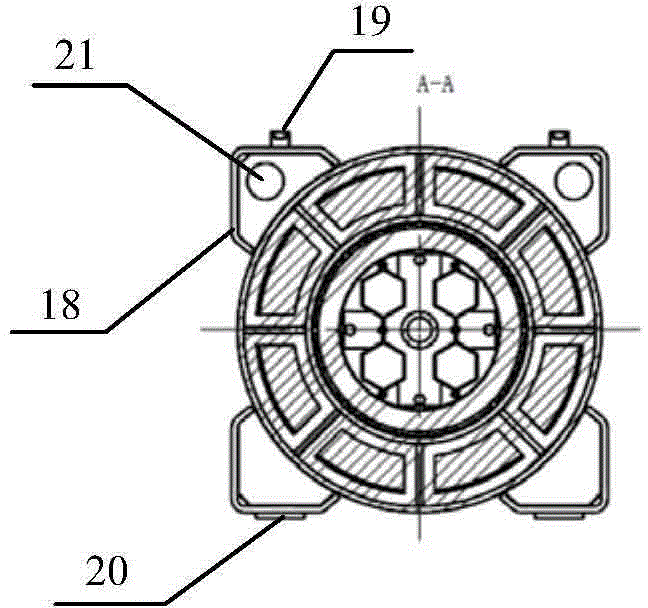

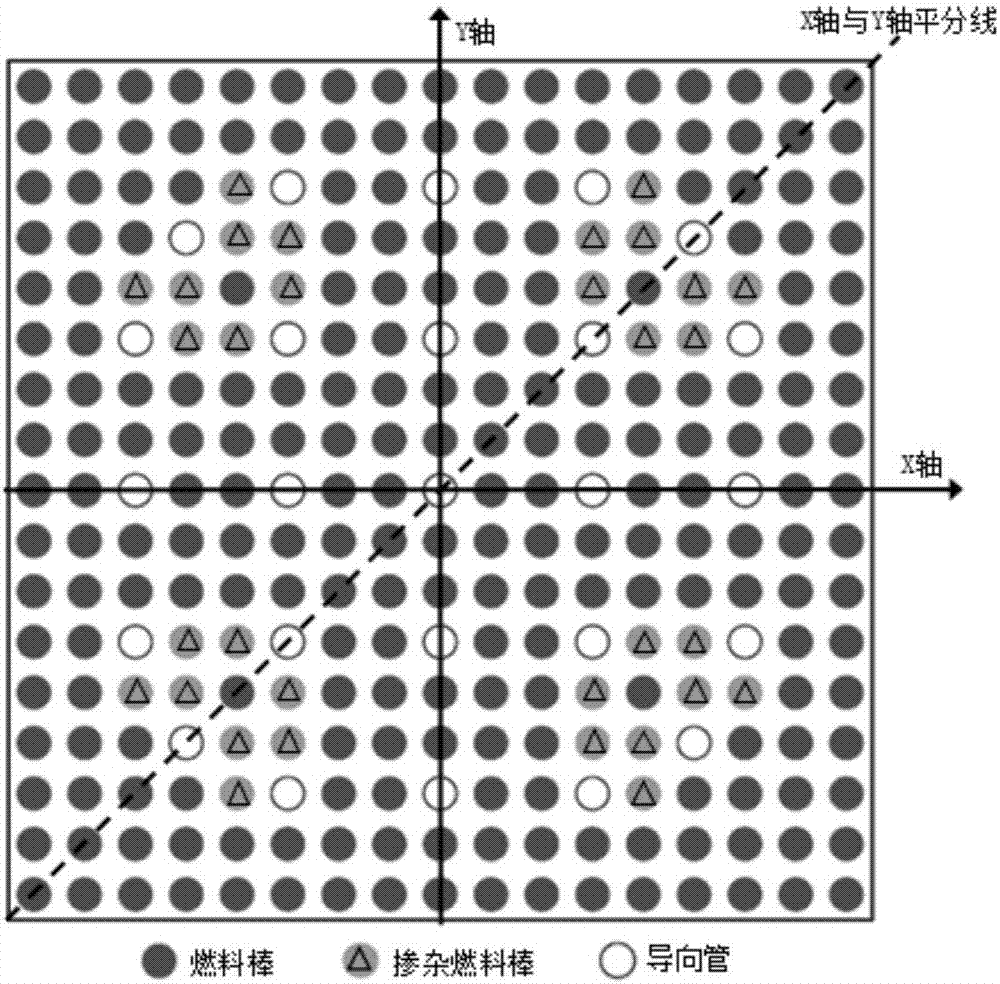

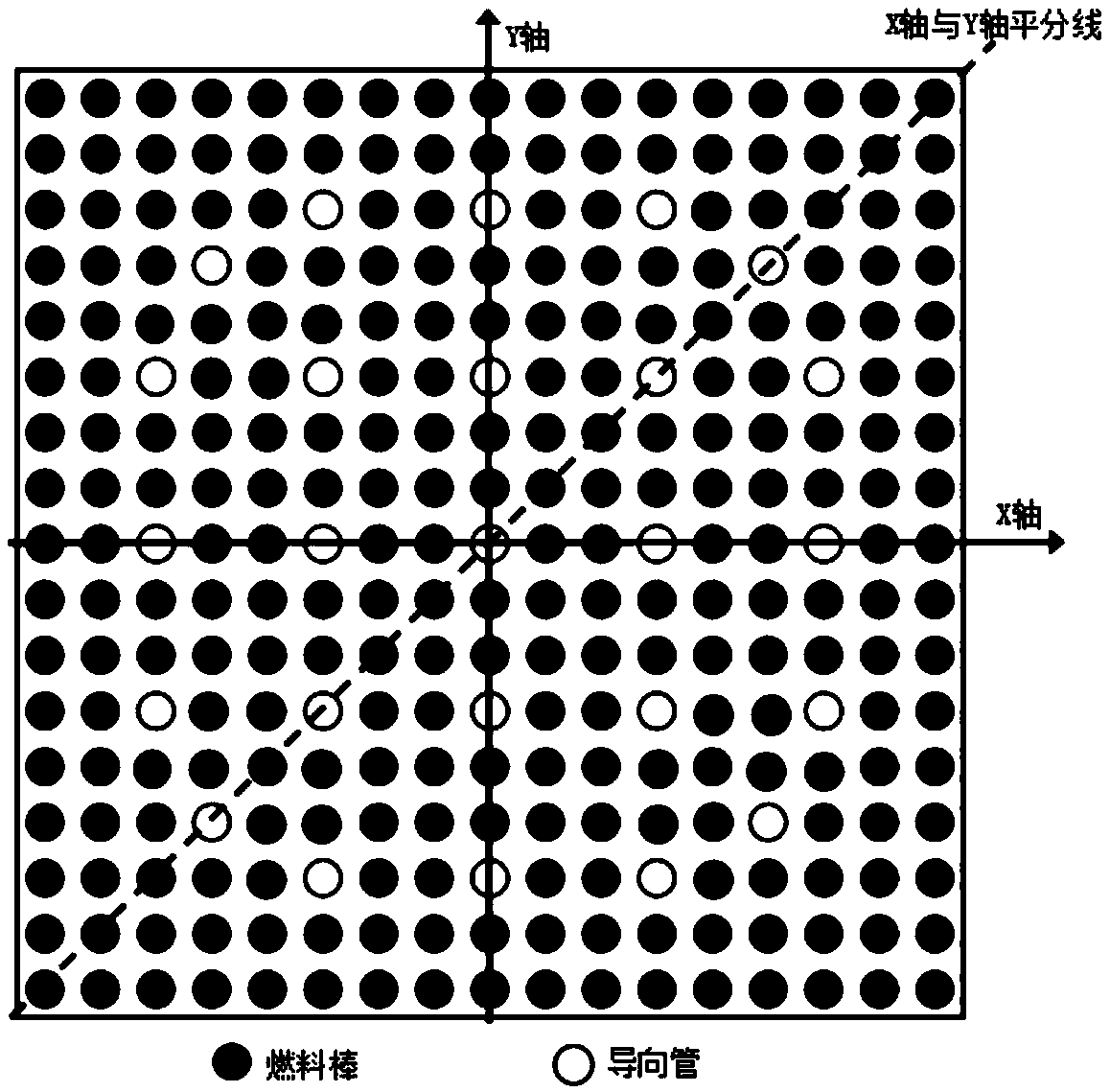

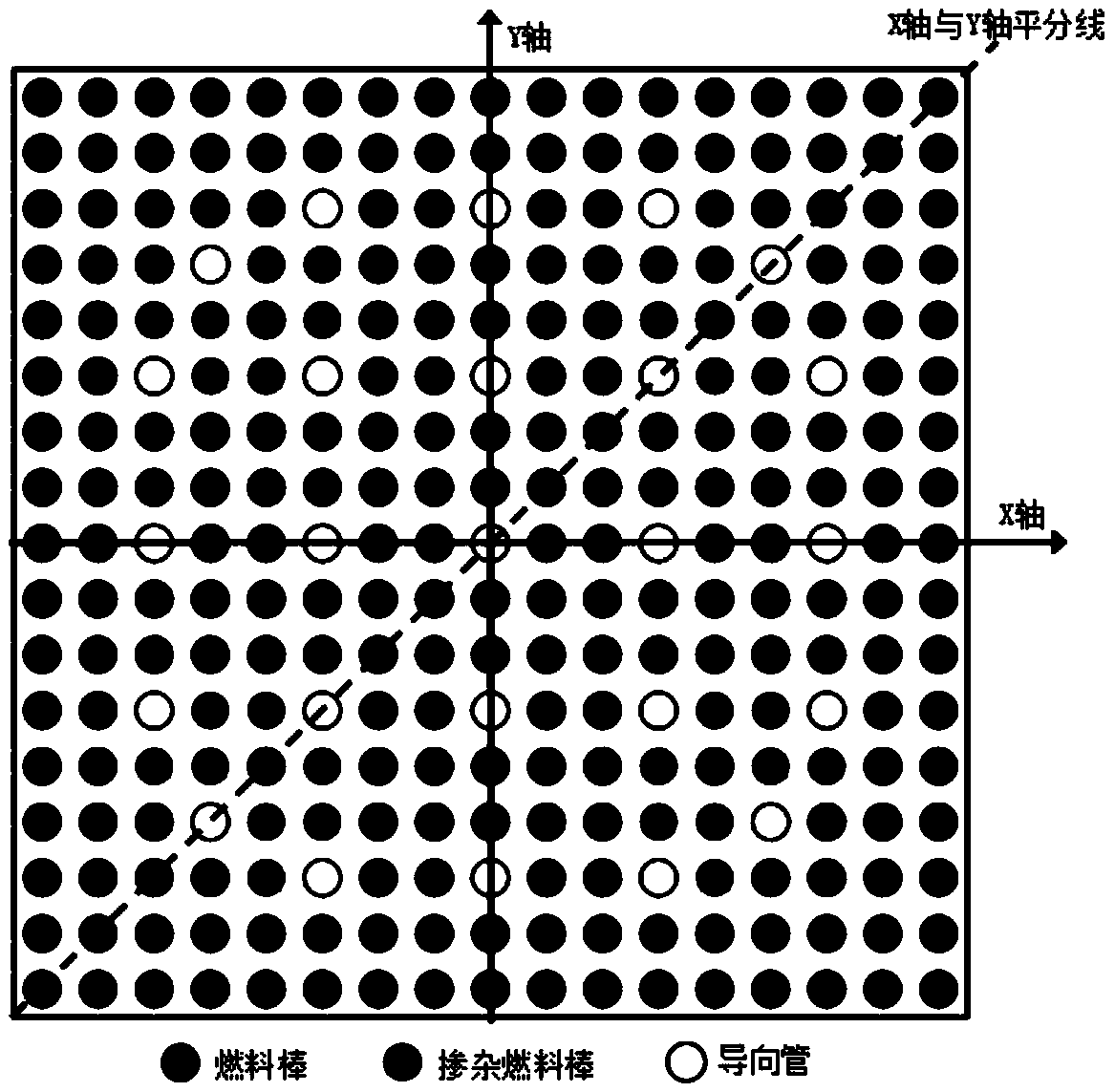

MOX fuel component for evolving and flattening power and method of flattening power

ActiveCN107093467AIncrease powerPower reachedNuclear energy generationRecycling and recovery technologiesNuclear engineeringReaction rate

The invention relates to an MOX fuel component for evolving and flattening power and a method of flattening power. The component comprises doped fuel rods, fuel rods and guide tubes, wherein the doped fuel rods are fuel rods doped with long-life sub-actinide nuclides; the doped fuel rods, the fuel rods and the guide tubes form an array, and each doped fuel rod is adjacent to one of the guide tubes. In the MOX fuel component, the fuel rods adjacent to the guide tubes are installed as the doped fuel rods, and the long-life sub-actinide nuclides in the doped fuel rods are evolved in the neutron field, thereby reducing the costs and difficulty of final treatment of spent fuel. At the same time, the fission reaction rate of the doped fuel rods is reduced to lower the original high power around the guide tubes in the MOX fuel component, thereby achieving the effects of flattening the power of the MOX fuel component and enhancing the safety of a reactor core.

Owner:SUN YAT SEN UNIV

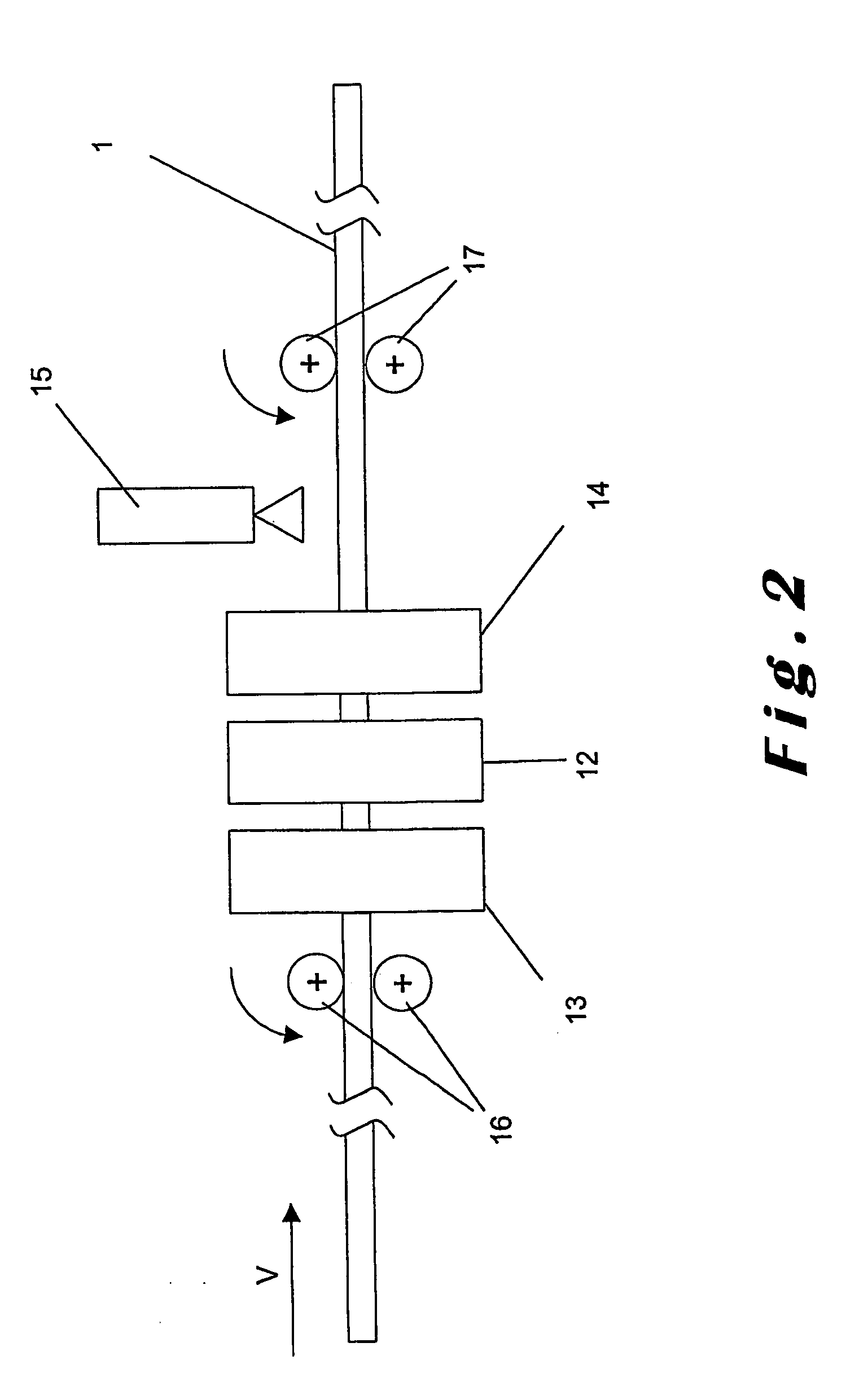

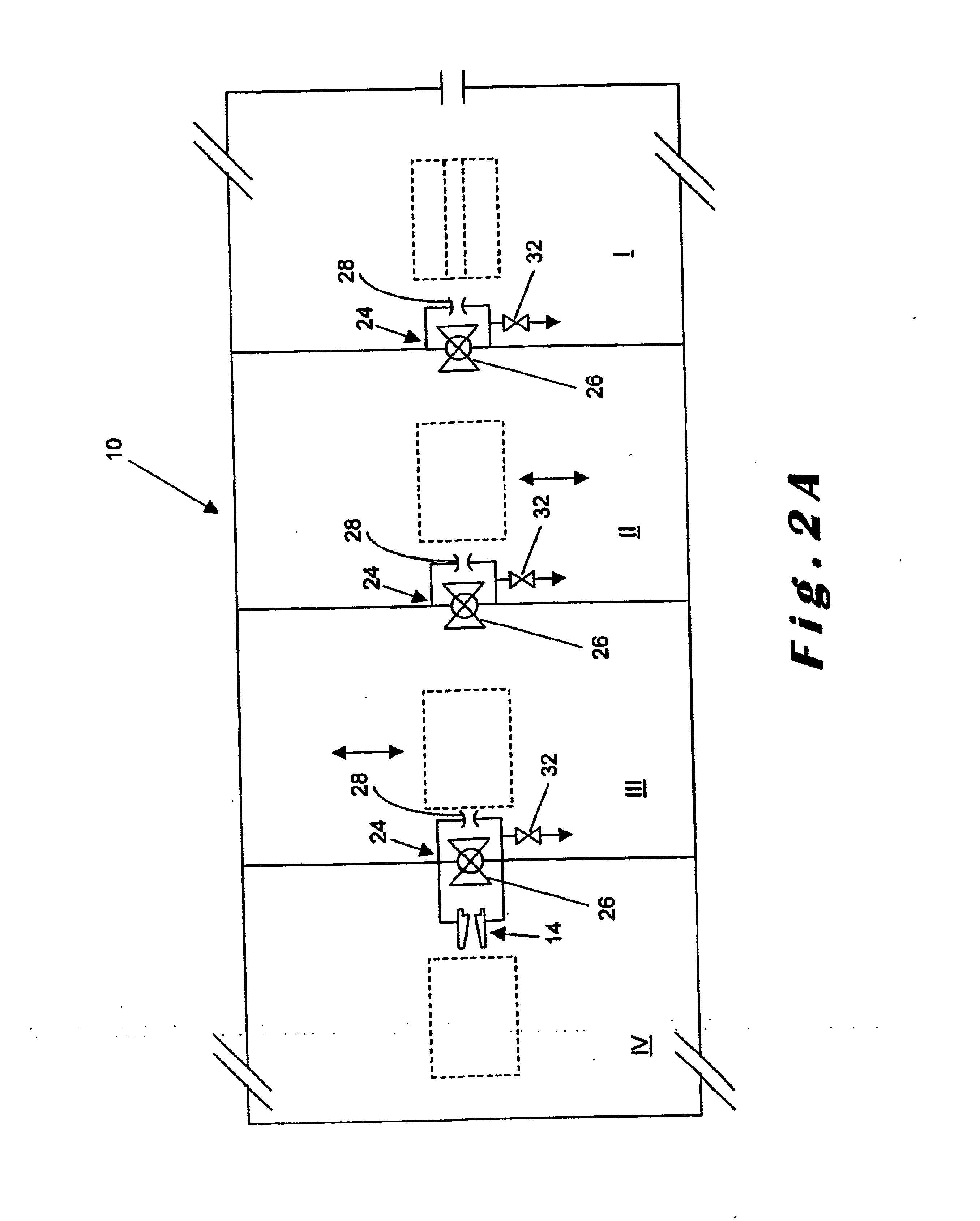

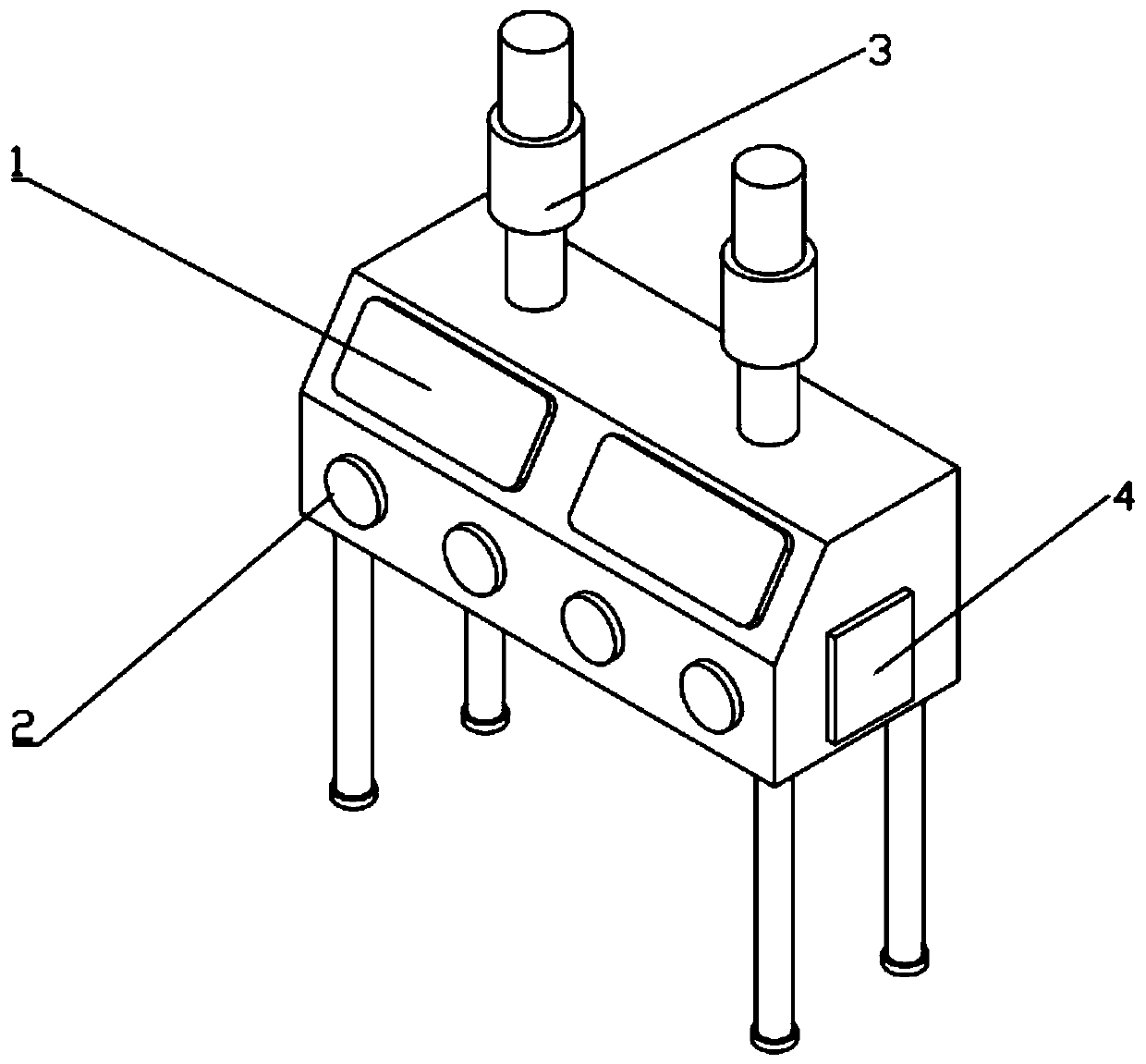

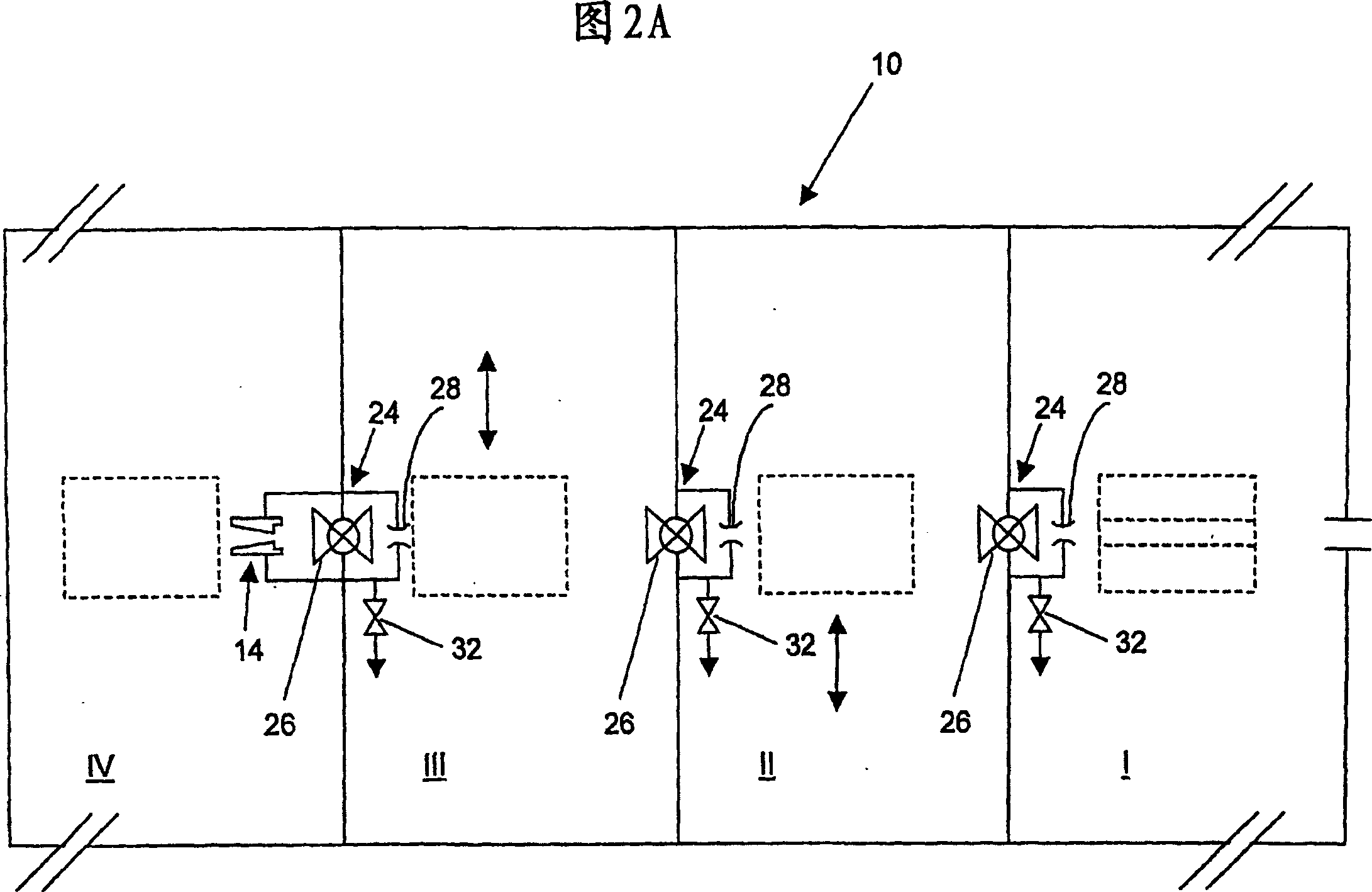

Method and device for manufacturing non-contaminated mox fuel rods

ActiveUS20070079496A1Increase contentNuclear energy generationMetal rolling stand detailsBiomedical engineeringMOX fuel

Owner:BELGONUCLEAIRE SA

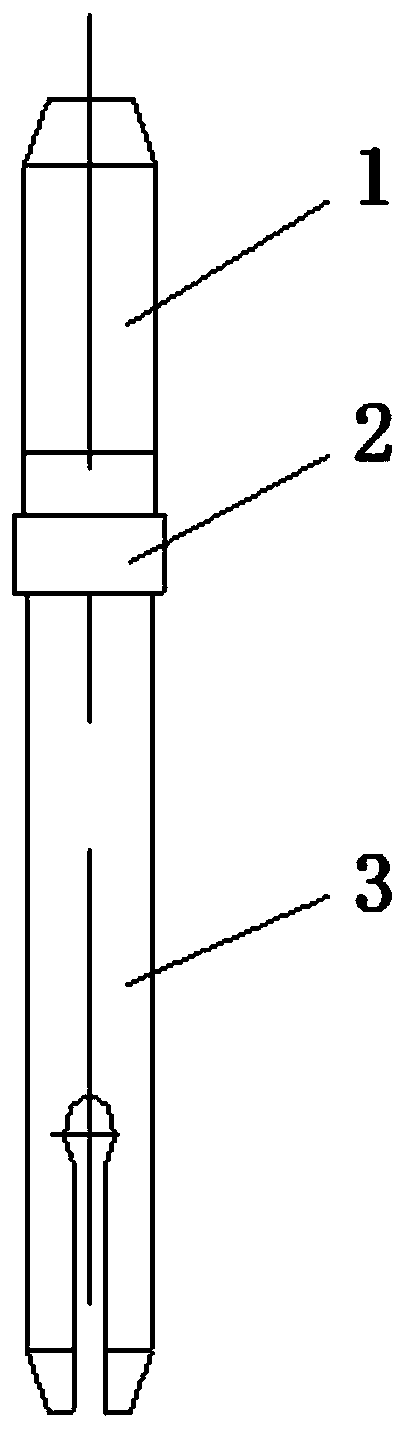

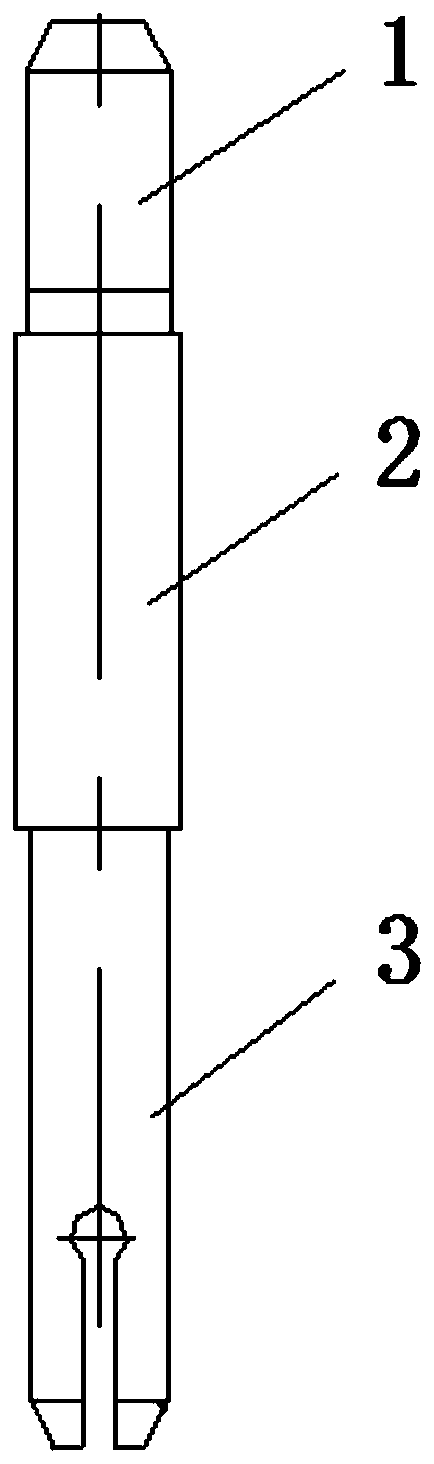

MOX fuel cladding tube reutilization method

ActiveCN111430055AIncrease profitMeet needsFuel elementsNuclear energy generationMOX fuelAtomic physics

The invention relates to the technical field of nuclear fuel element preparation, and particularly discloses an MOX fuel cladding tube reutilization method which comprises the following steps: cuttingoff a lower end plug on an assembly weldment, reprocessing the lower end plug, and ensuring that the total length of the assembly weldment is not changed after the reprocessed lower end plug and thecut cladding tube are assembled and welded. The MOX fuel cladding tube after the lower end plug fails to be welded is cut, and the end plug is lengthened to ensure that the total length of the fuel rod is unchanged, so that the utilization rate of the cladding tube is increased.

Owner:THE 404 COMPANY LIMITED CHINA NAT NUCLEAR

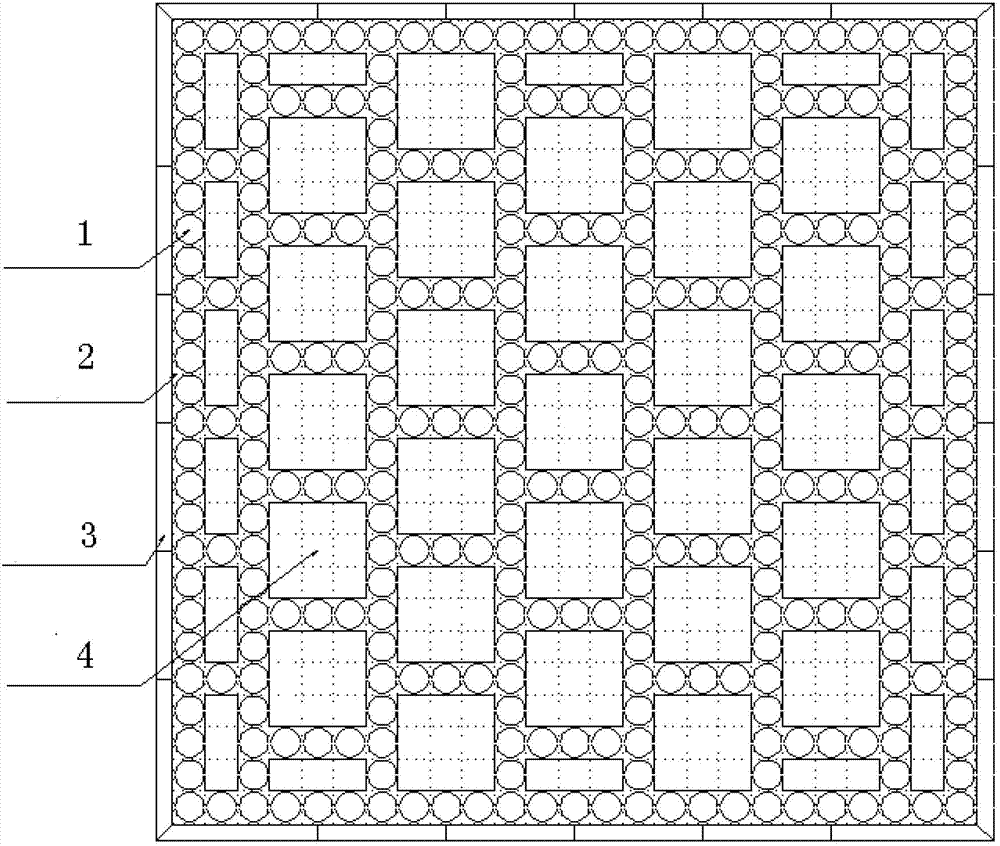

MOX (Mixed Oxide) fuel assembly structure suitable for supercritical water reactor

InactiveCN102768863AImprove securityMinor changesNuclear energy generationFuel element assembliesMixed oxideNuclear power

The invention discloses an MOX (Mixed Oxide) fuel assembly structure suitable for a supercritical water reactor, belonging to the field of nuclear power generation. A plurality of water boxes are formed into a square shell, a plurality of water rods are arranged in the shell formed by the water boxes, an MOX fuel rod with the diameter of R is arranged in a gap between every two adjacent water rods, the water rods include large water rods and small water rods, the cross section of each large water rod is of a square with the length of 3R and the width of 3R, the cross section of each small water rod is of a rectangle with the length of 3R and the width of R, gaps between every two adjacent water rods and between each water rod and each water box are both R and filled by the MOX fuel rods which are tidily arranged, and gaps between the MOX fuel rods and the water rods or between the MOX fuel rods and the inner walls of the water boxes form a fuel agent cooling channel. By using the MOX assembly structure is adopted in the supercritical water reactor, the same effects with the traditional structure in which only a UO2 assembly design is used can be achieved, and the condition of uneven power distribution factors of an assembly can be improved. The MOX fuel assembly structure has the characteristics of simple structure and little improvement on the traditional supercritical water reactor assembly and can be used for improving the safety of the reactor.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

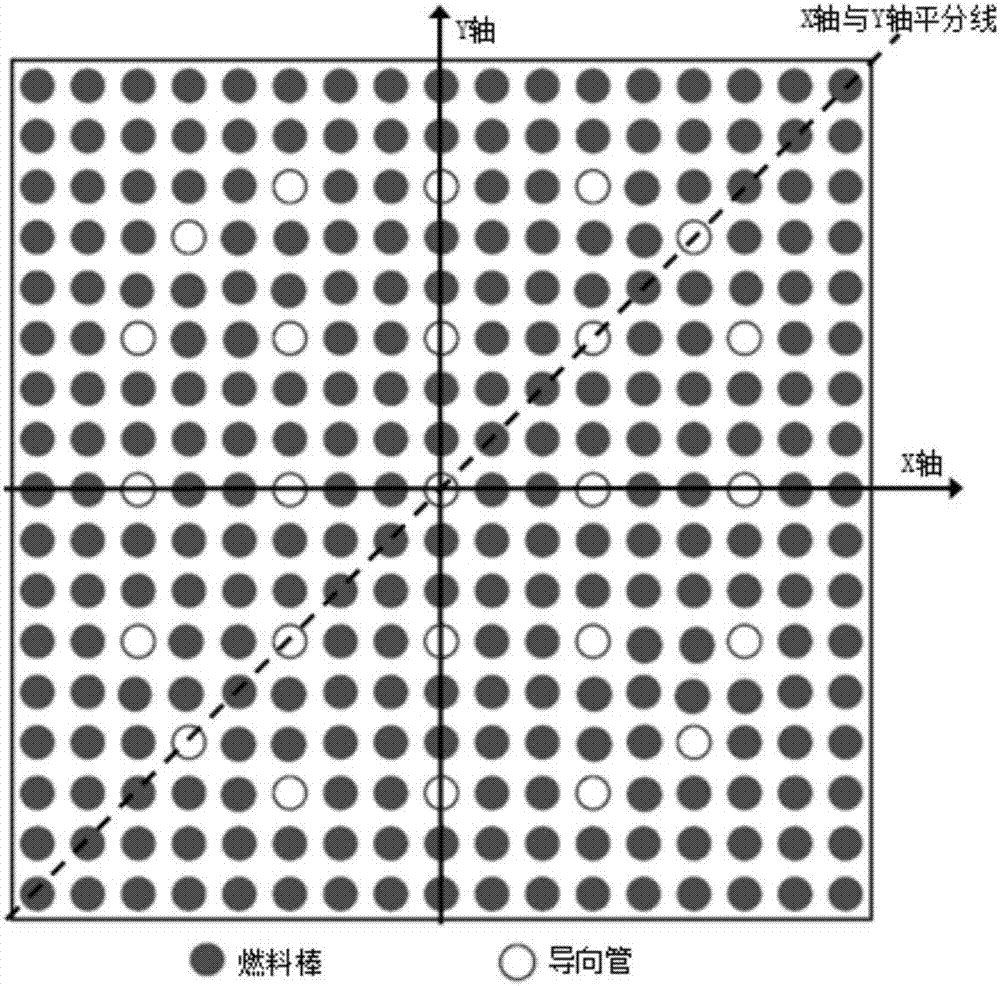

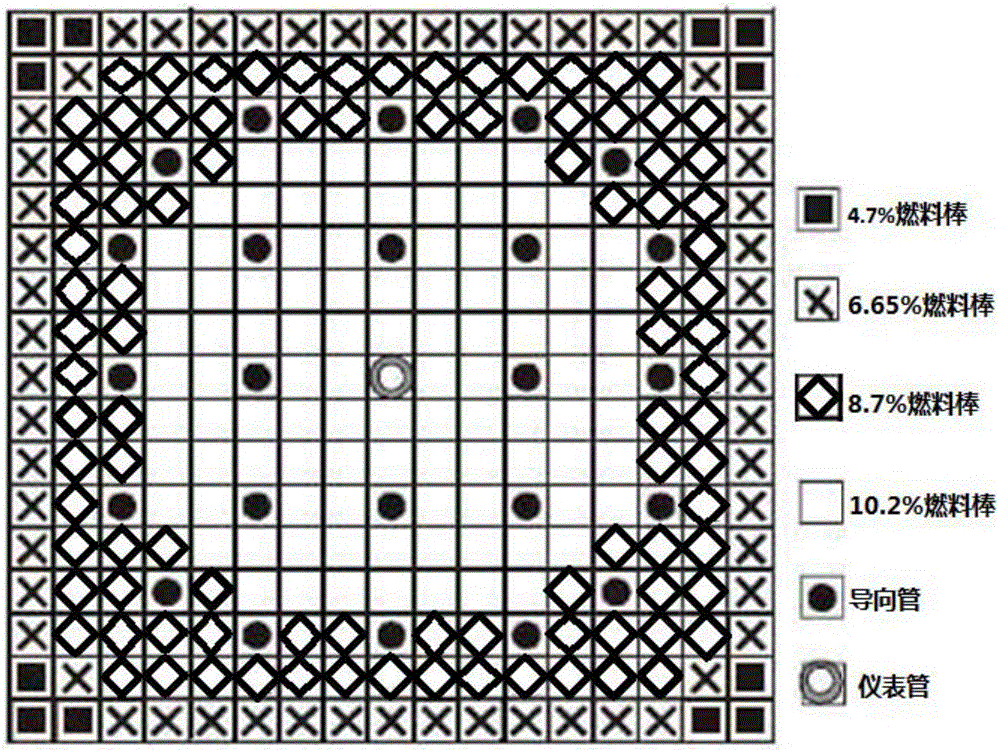

Method for loading MOX fuel assembly arranged at multiple sub-regions in radial direction

InactiveCN106297905AImprove performanceReduce contentNuclear energy generationReactor fuel elementsNuclear engineeringLarge core

The invention relates to a method for loading an MOX fuel assembly arranged at multiple sub-regions in the radial direction. The MOX fuel assembly is arranged at the multiple sub-regions in the radial direction, the Pu content at each sub-region is designed and loaded, the Pu content of fuel pellets at the external sub-regions of the assembly is lower than that of fuel pellets at the internal sub-regions of the assembly, and it is guaranteed that the average Pu content of the assembly meets the designing requirement; meanwhile, fuel manufacturing difficulty caused by the type of the fuel pellets is considered to reduce a large core power peak factor, caused by an energy spectrum interference effect between the MOX fuel assembly and a UO2 fuel assembly, at the interface of the MOX fuel assembly and the UO2 fuel assembly, a brand-new MOX fuel assembly radial loading design is achieved, and the performance of the fuel assembly is improved.

Owner:CHINA NUCLEAR POWER ENG CO LTD

Recycling method for MOX pellets

ActiveCN109727696ASolve the problem of single processing methodRealize rational utilizationNuclear energy generationRadioactive decontaminationPu elementImpurity

The invention provides a recycling method for MOX pellets. The method comprises the following steps: step 1, selecting MOX fuel pellets, and analyzing and detecting appearances, sizes, uranium plutonium contents, impurity contents, O / M and density data; step 2, recycling pellets with unqualified O / M; step 3, recycling pellets with unqualified densities; step 4, recycling pellets with unqualified outer diameters; and step 5, recycling pellets with a plurality of unqualified indexes.

Owner:THE 404 COMPANY LIMITED CHINA NAT NUCLEAR

MOX fuel assembly for pressurized nuclear reactors

InactiveUS20080181350A1Satisfactory controlEfficient use ofNuclear energy generationFuel element assembliesNuclear reactor coreNuclear reactor

This invention relates to a MOX fuel assembly for PWRs that enables satisfactorily suppressing a power peaking factor without the necessity of reducing the Pu content per fuel assembly. The MOX fuel assembly has a lattice arrangement in which one or more burnable poison contained UO2 fuel rods and a plurality of MOX fuel rods are disposed in an n-rows by n-columns (n×n) lattice array. The MOX fuel rod consists of at least two kinds of MOX fuel rods including a plurality of first MOX fuel rods and a plurality of second MOX fuel rods. The first MOX fuel rod has a predetermined Pu content and a predetermined Pu weight, and the second MOX fuel rod has substantially the same Pu content as that of the first MOX fuel rod and a different Pu weight from that of the first MOX fuel rod.

Owner:NUCLEAR FUEL INDS

MOX waste core block crushing device

InactiveCN107855166AMeet recycling requirementsReduce operating intensityGrain treatmentsWaste processingDrive shaft

The invention belongs to the technical field of nuclear fuel production waste processing, and particularly relates to an MOX waste core block crushing device. The lower end of a spiral feeding mechanism is connected with the upper end of a material collection device shell. The upper end of a double-roller shell is connected with the lower end of the material collection device shell. Double rollersare located in the double-roller shell. The upper end of a fixed cone is connected with the lower end of the double-roller shell. A movable cone is arranged in the fixed cone. An eccentric shaft is inserted in the movable cone. The center axis of the movable cone does not coincide with the center axis of the eccentric shaft. The eccentric shaft is matched with a transmission shaft through a gear.The transmission shaft is connected with a transmission motor A through a coupling. The lower end of the fixed cone is connected with a material collection shell with the bottom face inclined. The eccentric shaft penetrates the material collection shell. The lower end of the material collection shell is connected with a material collection container. The material collection container is arrangedon a lifting rack. The double rollers are made to move oppositely at different rotating speeds by a transmission motor B through a gear set. By means of the MOX waste core block crushing device, unqualified MOX fuel core blocks subjected to sintering are crushed into powder particles which are of a certain particle size and certain particle size uniformity, and the MOX raw material recycling requirement is met.

Owner:THE 404 COMPANY LIMITED CHINA NAT NUCLEAR

Light water reactor fuel assembly, manufacturing method thereof, light water reactor core and MOX fuel assembly production method

Owner:KK TOSHIBA

Metallography detection method of MOX pellets

InactiveCN107543819AAvoid crackingAvoid obscurityPreparing sample for investigationMaterial analysis by optical meansEpoxyMetallography

The invention belongs to the technical field of product analysis and inspection, and particularly relates to a metallography detection method of MOX pellets. MOX fuel pellets with intact surfaces andno cracks are selected, and sodium sulfide is added into epoxy resin to configure an inlay sample agent; the MOX fuel pellets are placed in the central position of phenolic resin inlay sample sleeves,the inlay sample agent is poured in, and after standing and solidification of the inlay sample agent, inlaid samples are taken from the inlay sample sleeves; the inlaid samples are arranged in clamping plates of a grinding and polishing device and fixed, grinding is conducted on grinding and polishing plates from coarse to fine separately, and sample water is washed each time when the grinding and polishing plates are replaced; the washed samples continue to be arranged in the grinding plates and fixed, and the samples are polished on a lint, meanwhile the Al2O3 grinding and polishing liquidis poured on the grinding and polishing plates, and the samples are washed with water after the grinding and polishing; corrosion soaking is conducted on the ground and polished samples using a corrosion liquid prepared from HNO3 and HCl, and then the surfaces of the samples are washed with water after the corrosion soaking, and rinsing and dry blowing are conducted using anhydrous ethanol. According to the metallography detection method of the MOX pellets, accurate measurements of the grain sizes of the pellets and equivalent diameters of pores can be achieved.

Owner:THE 404 COMPANY LIMITED CHINA NAT NUCLEAR

The radiation protection method of mox pellet preparation process

The invention belongs to the technical field of nuclear chemical radiation protection and in particular relates to a radiation protection method for an MOX pellet preparation process. Key equipment ona production line is enclosed by using glove boxes; the whole production line is formed by sequentially connecting a plurality of glove boxes; radioactive aerosol is used as an atmosphere in each glove box; each glove box is matched with an independent mechanical pump; the front end of the mechanical pump is designed to be provided with a filter-cloth-type efficient dust filter; the mechanical pump has the effect of making the average pressure inside each glove box smaller than the normal atmosphere pressure 300kPa; the glove box with the highest radiation level is placed in the middle of theproduction line; the radiation level of the glove box closer to the outer side is lower; the pressure of the glove box with a higher radiation level is lower; the pressure difference of the adjacentglove boxes is 20kPa; a sealing door with a sealing ring is designed at a junction between every two glove boxes; and the sealing door is closed under the condition that materials are not transferred.A whole set of radiation protection, detection and dirt removal method is established, the safety production of MOX fuel pellets is realized, and the safety of production operating personnel is guaranteed.

Owner:THE 404 COMPANY LIMITED CHINA NAT NUCLEAR

Fuel assembly for light water reactor and manufacturing method thereof, light water reactor core, and method of manufacturing mox fuel assembly

Owner:KK TOSHIBA

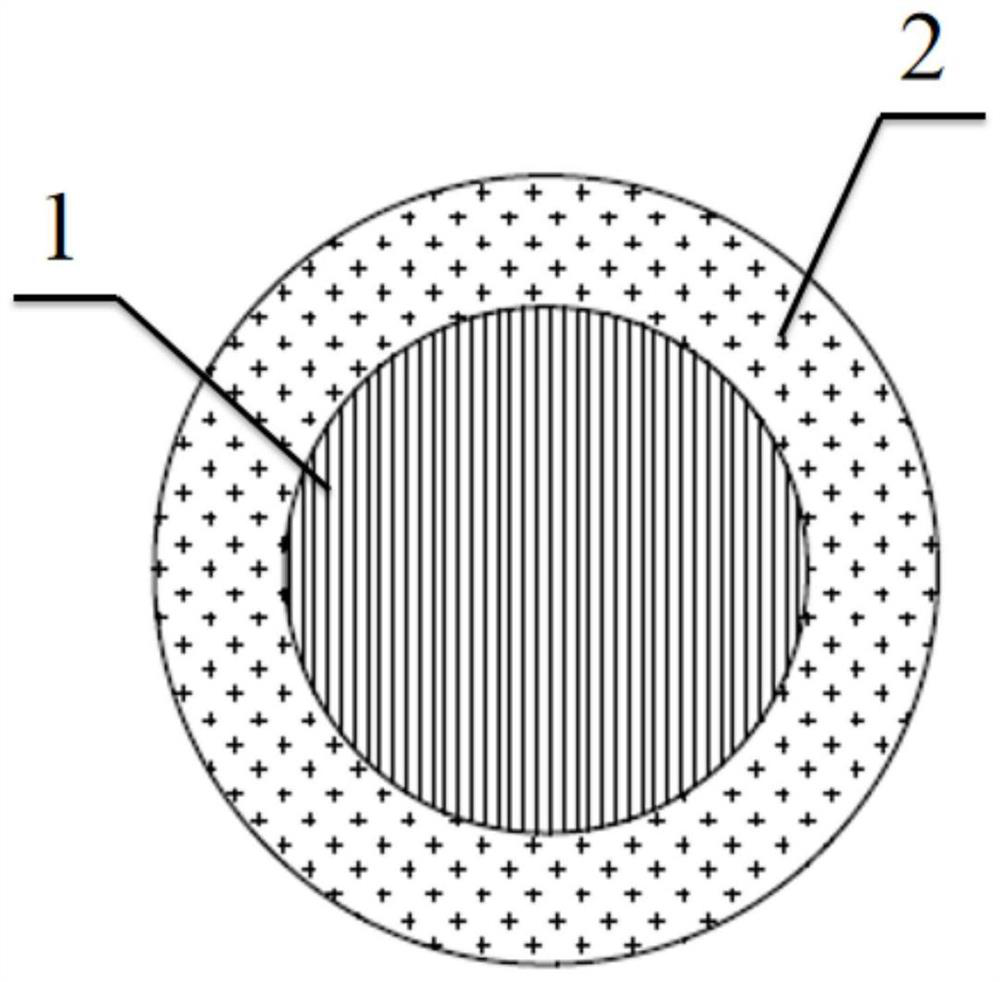

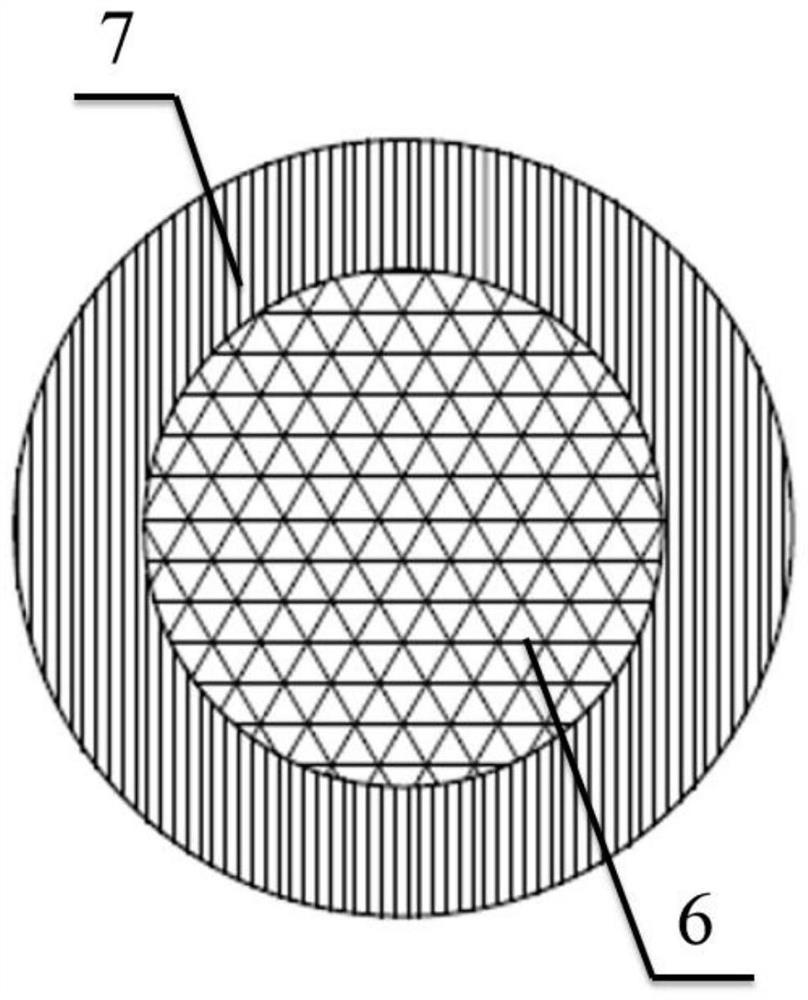

Tube-in-tube type MA transmutation rod for fast neutron reactor

ActiveCN113488204ASolve the real problemNuclear energy generationShieldingNuclear engineeringFast-neutron reactor

The invention discloses a tube-in-tube type MA transmutation rod for a fast neutron reactor. The tube-in-tube type MA transmutation rod comprises a central layer which is externally provided with at least one outer layer in a surrounding manner, wherein the central layer is an MA nuclide tube, and the outer layer is a 6LiD nuclide tube, or the central layer is an MOX nuclide tube, and the outer layer is the MA nuclide tube and / or the 6LiD nuclide tube. According to the tube-in-tube type MA transmutation rod for the fast neutron reactor, a thermal fast neutron conversion material 6LiD is creatively added into the structural design of the MA transmutation rod. The invention provides three schemes of the basic structure of the transmutation rod, namely (1) a 6LiD / MA tube-in-tube type transmutation rod; (2) a 6LID / MA / MOX tube-in-tube type transmutation rod; and (3) an MA / MOX tube-in-tube type transmutation rod. The thicknesses of the tube walls of 6LiD, MA and MOX fuel in each scheme are continuously optimized, so a novel transmutation rod structure for disposing MA nuclide is provided, and the transmutation rate of the transmutation rod containing MA nuclide is improved.

Owner:SOUTHWEAT UNIV OF SCI & TECH

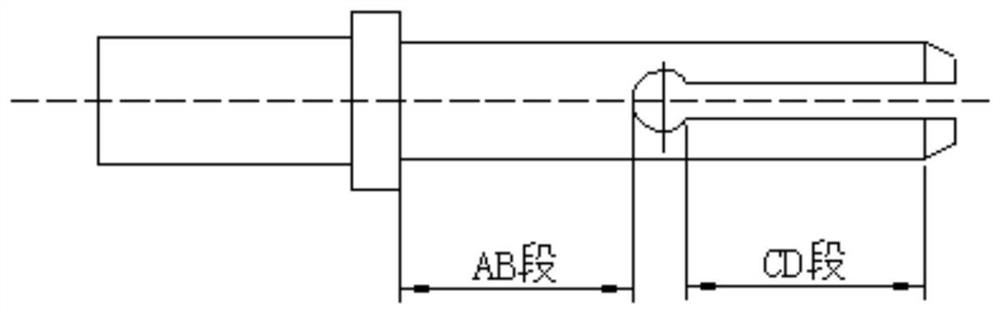

MOX fuel rod end plug marking method

PendingCN112466481AEasy to trackRealize automatic recordingFuel elementsNuclear energy generationProcess engineeringMOX fuel

The invention provides an MOX fuel rod end plug marking method, which comprises the steps: cleaning an end plug; marking a digital code; and marking bar code, and carrying out other steps. According to the invention, the digital code and the bar code are marked on the MOX fuel rod end plug at the same time, so that automatic recording of coded information in the fuel rod production process is achieved under the hot chamber shielding condition that manual intervention is inconvenient and direct, production information recording and material tracking are facilitated, the material circulation efficiency of the MOX fuel rod production line is improved, and the production efficiency is indirectly improved.

Owner:THE 404 COMPANY LIMITED CHINA NAT NUCLEAR

MOX fuel assembly for transmutation and power flattening and method of power flattening

ActiveCN107093467BPower reachedWeaken fission reaction rateNuclear energy generationRecycling and recovery technologiesReaction rateNuclear engineering

The invention relates to an MOX fuel component for evolving and flattening power and a method of flattening power. The component comprises doped fuel rods, fuel rods and guide tubes, wherein the doped fuel rods are fuel rods doped with long-life sub-actinide nuclides; the doped fuel rods, the fuel rods and the guide tubes form an array, and each doped fuel rod is adjacent to one of the guide tubes. In the MOX fuel component, the fuel rods adjacent to the guide tubes are installed as the doped fuel rods, and the long-life sub-actinide nuclides in the doped fuel rods are evolved in the neutron field, thereby reducing the costs and difficulty of final treatment of spent fuel. At the same time, the fission reaction rate of the doped fuel rods is reduced to lower the original high power around the guide tubes in the MOX fuel component, thereby achieving the effects of flattening the power of the MOX fuel component and enhancing the safety of a reactor core.

Owner:SUN YAT SEN UNIV

Method and device for manufacture of non-contaminated MOX fuel rods

InactiveCN1332396CHas a high plutonium contentNo pollution in the processNuclear energy generationReactors manufactureEngineeringMechanical engineering

Owner:BELGONUCLEAIRE SA

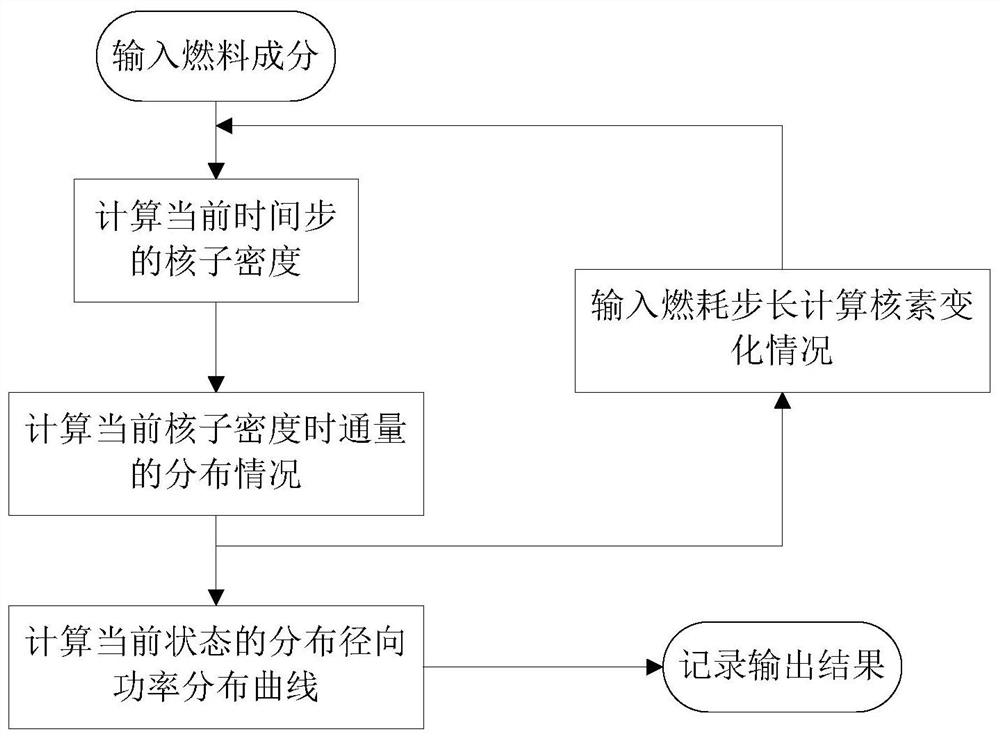

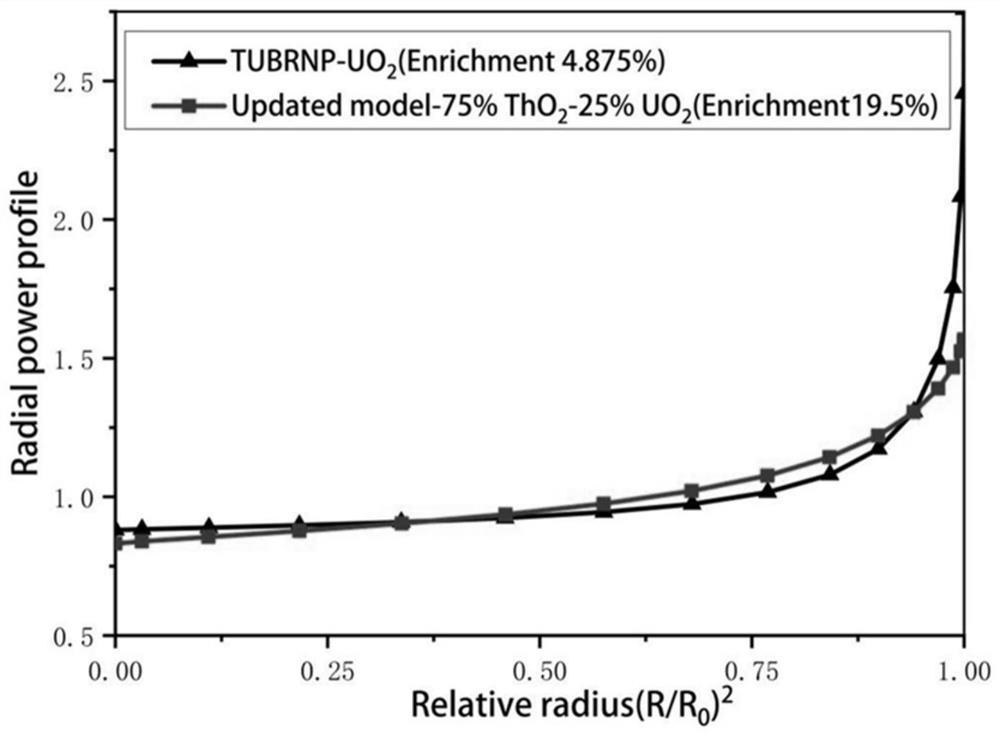

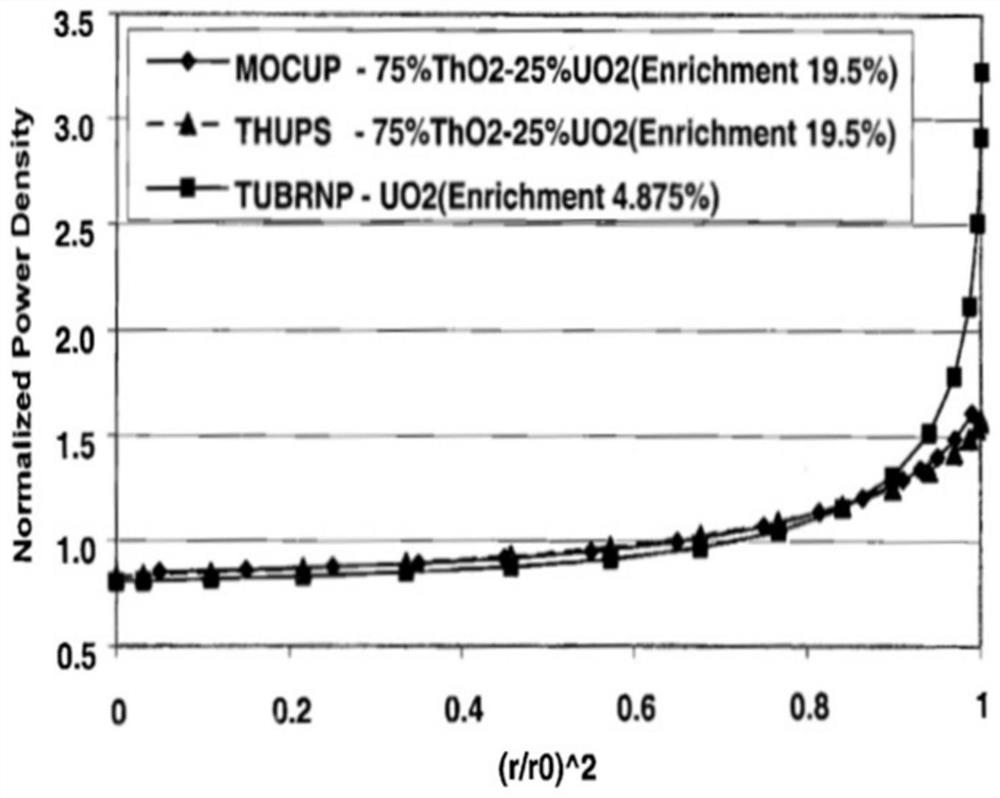

A Calculation Method for Radial Power Distribution of Thorium-Based Mixed Oxide Fuels

ActiveCN113314190BAccurate radial power distribution calculation resultsAccurate density changeChemical processes analysis/designComputational theoretical chemistryNuclear engineeringMOX fuel

Owner:SOUTH CHINA UNIV OF TECH

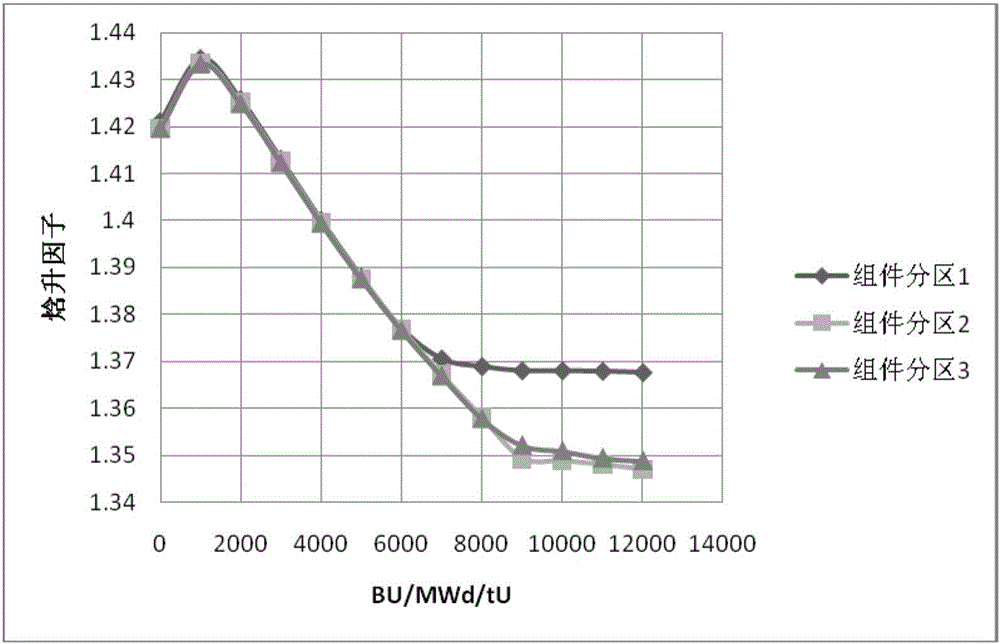

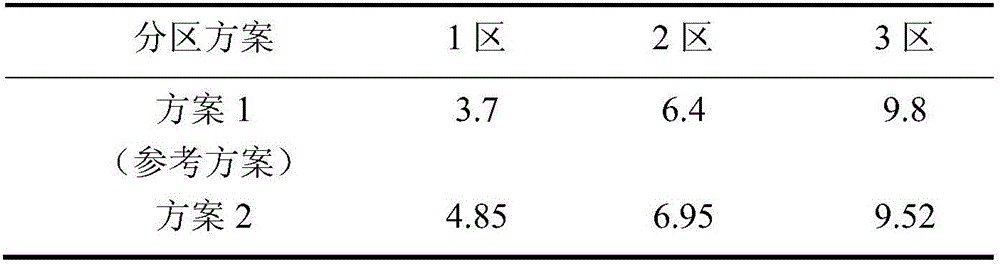

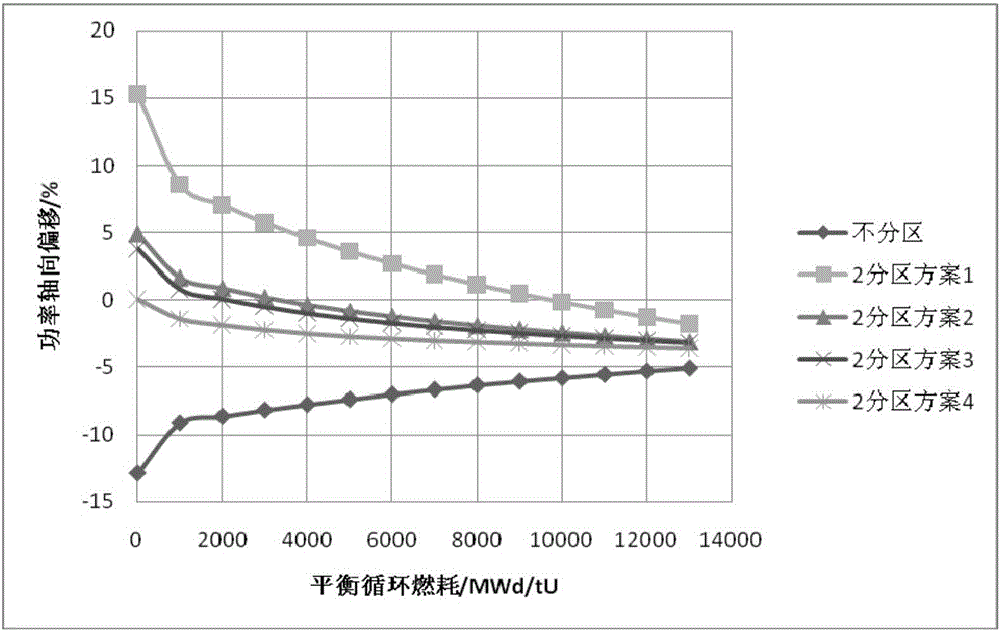

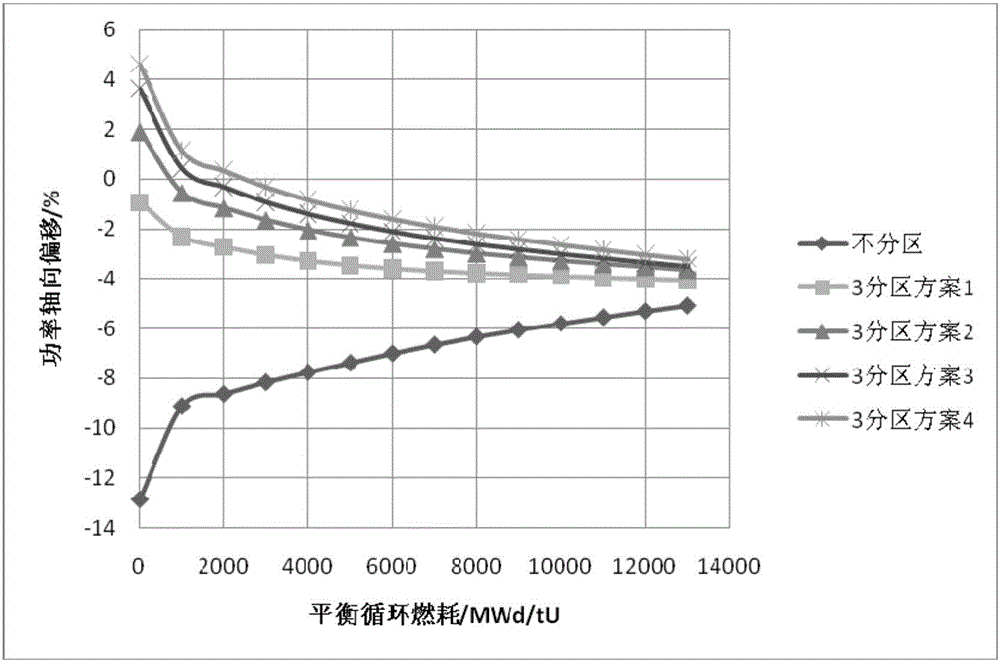

Loading method for MOX fuel assemblies axially arranged in multiple zones

InactiveCN106297906AImproved axial power distributionImprove performanceNuclear energy generationReactor fuel elementsEngineeringMOX fuel

The invention relates to a loading method for MOX fuel assemblies axially arranged in multiple zones. The MOX fuel assemblies are arranged in multiple zones in the axial direction, the Pu content in each zone is subjected to loading design, the Pu content of fuel pellets in the upper zones of the assemblies is increased, and the Pu content of fuel pellets in the lower zones of the assemblies is decreased, so that it is guaranteed that the average Pu content of the assemblies meets design requirements, and meanwhile it is avoided that positive axial power offset at the beginning of the fuel cycle life is caused when the average Pu content does not meet design requirements. On the basis that the axial power offset is relieved, the fewest types of Pu content fuel pellets are adopted to achieve axial loading design of the MOX fuel assemblies.

Owner:CHINA NUCLEAR POWER ENG CO LTD

Dry recovery process of mox fuel pellet waste

ActiveCN106782736BHigh recovery rateShort recycling processRadioactive decontaminationLiquid wasteCombustion

The invention belongs to the field of nuclear fuel. In order to solve the problem that an MOX fuel pellet waste wet recycling technology has many defects, the invention provides a dry recycling technology for MOX fuel pellet waste. The technology comprises the following steps of 1, burning MOX fuel pellet waste; 2, crushing by using a crusher; 3, screening; 4, ball milling; and 5 recycling. According to the technology provided by the invention, powdering of the MOX fuel pellet waste is achieved by crushing-ball milling technologies, so that the technology is fundamentally different from a dry recycling technology for UO2 fuel pellet waste using an oxidized crushing technology. Practical application shows that the MOX fuel pellet waste wet recycling technology provided by the invention has the advantages of high recycling rate, short recycling technical process, high in speed, simple in equipment, low in cost, and being free from generating radioactive liquid waste, and can be recycled in an MOX combustion manufacturer; the recycled power has similar sintering performance with the common MOX raw material powder, and can be mixed with common raw materials for preparing MOX fuel pellets.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

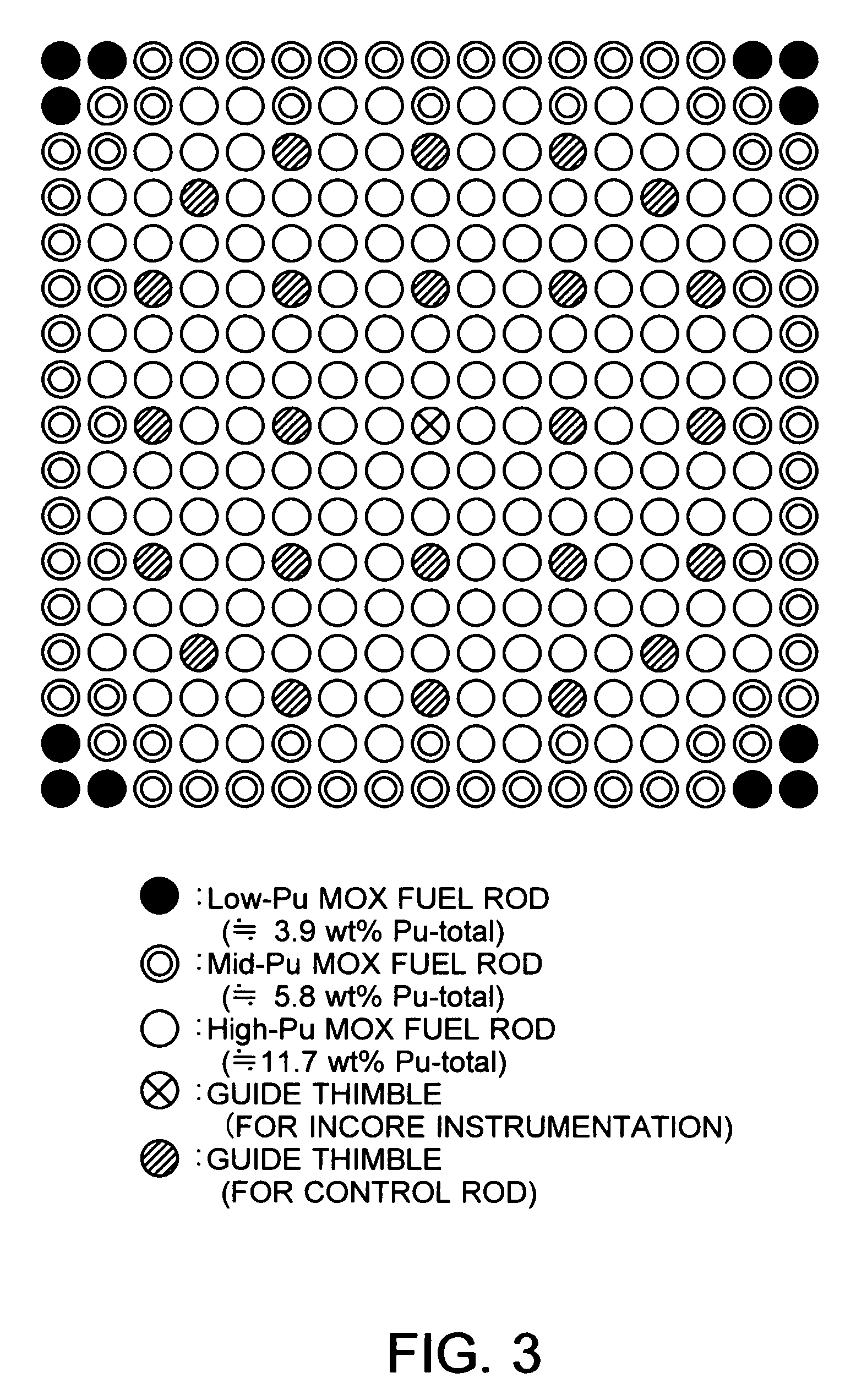

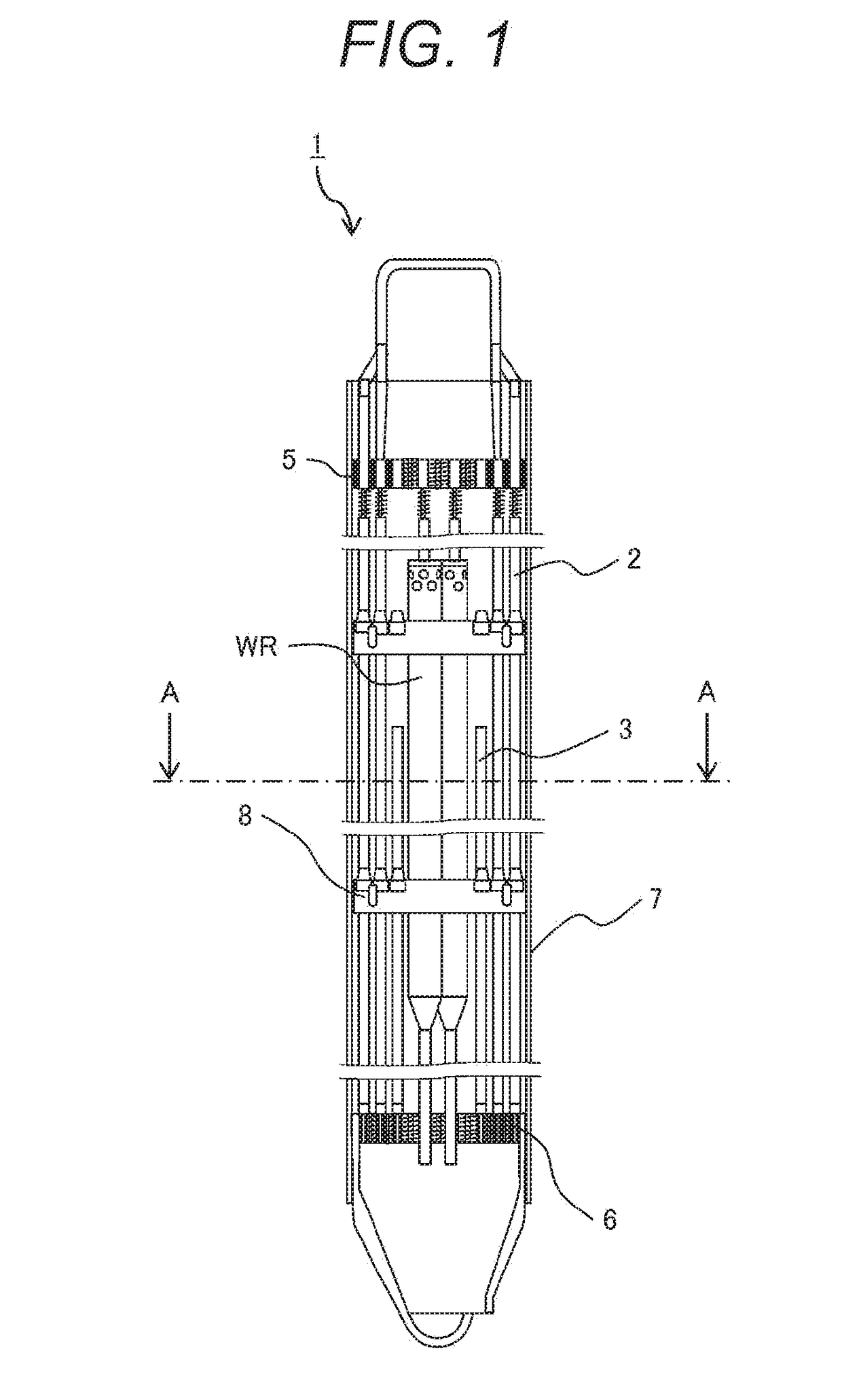

Fuel Assembly and Reactor Loaded with the Same

ActiveUS20190051421A1Flattening excess reactivityIncreasing average fissile plutonium enrichment of a MOX fuelNuclear energy generationNuclear engineering problemsNuclear engineeringUranium

A fuel assembly capable of linearizing change of an infinite multiplication factor of a fuel and flattening excess reactivity while increasing average fissile plutonium enrichment of a MOX fuel, and a reactor loaded with the fuel assembly can be provided. A fuel assembly includes first fuel rods containing Pu and not containing burnable poison, a second fuel rod containing uranium and burnable poison and not containing Pu, a water rod, and a channel box accommodating the first and second fuel rods and the water rod in a bundle. The second fuel rod is disposed on an outermost periphery and / or adjacent to the water rod, of a fuel rod array in a horizontal section, N2<N1 (N2 is a positive integer including zero) is satisfied where the number of the second fuel rods arranged on the outermost periphery is N1 and the number of the second fuel rods arranged adjacent to the water rod is N2, and W2<N2+W0<W1 (W2 is a positive integer including zero) is satisfied where the number of the second fuel rods arranged without being vertically and / or horizontally adjacent to each other in the horizontal section is W0, the number of the second fuel rods arranged vertically and / or horizontally adjacent to only one second fuel rod in the horizontal section is W1, and the number of the second fuel rods arranged vertically and / or horizontally adjacent to two second fuel rods in the horizontal section is W2, of the second fuel rods arranged on the outermost periphery.

Owner:HITACHI LTD

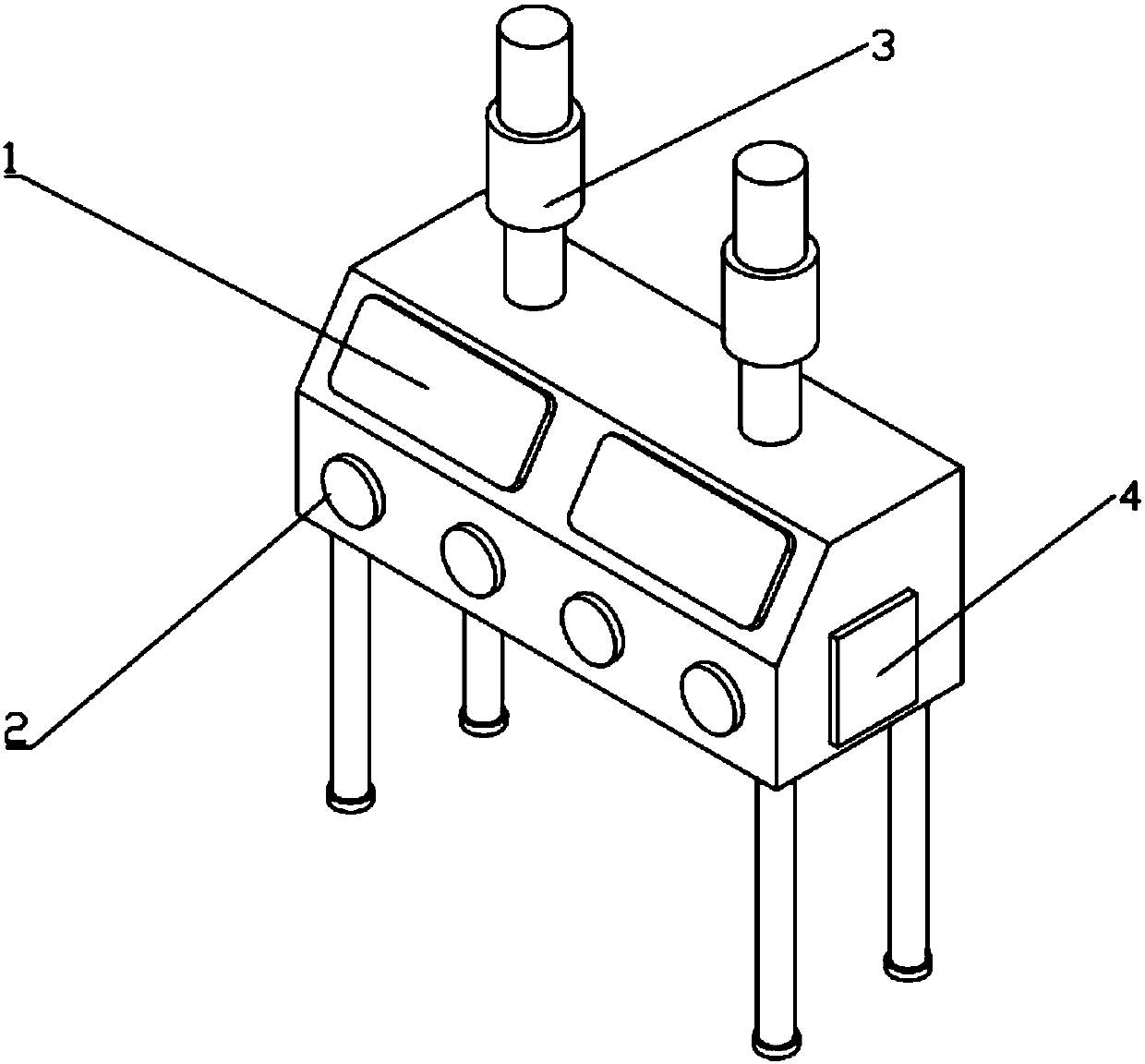

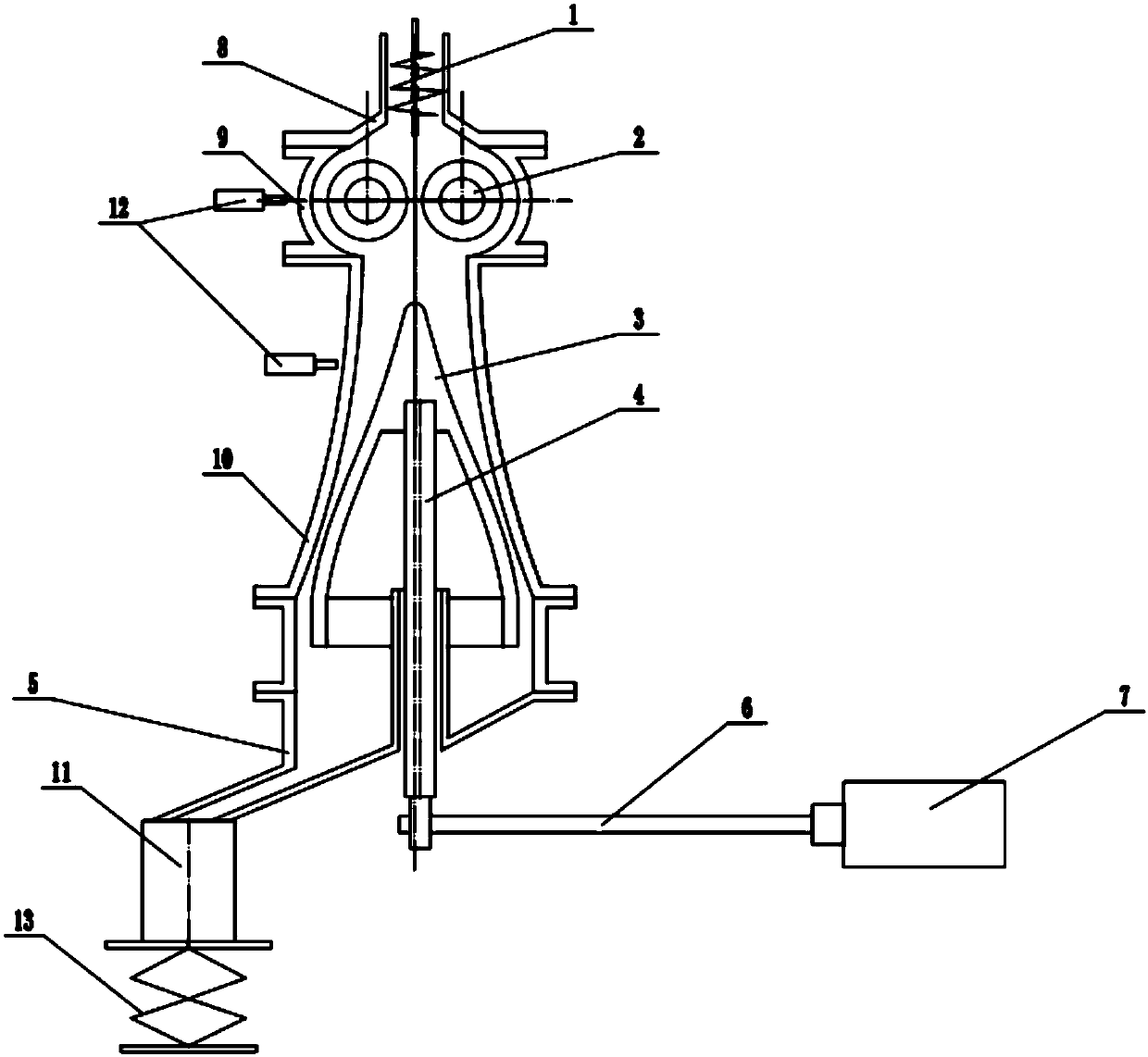

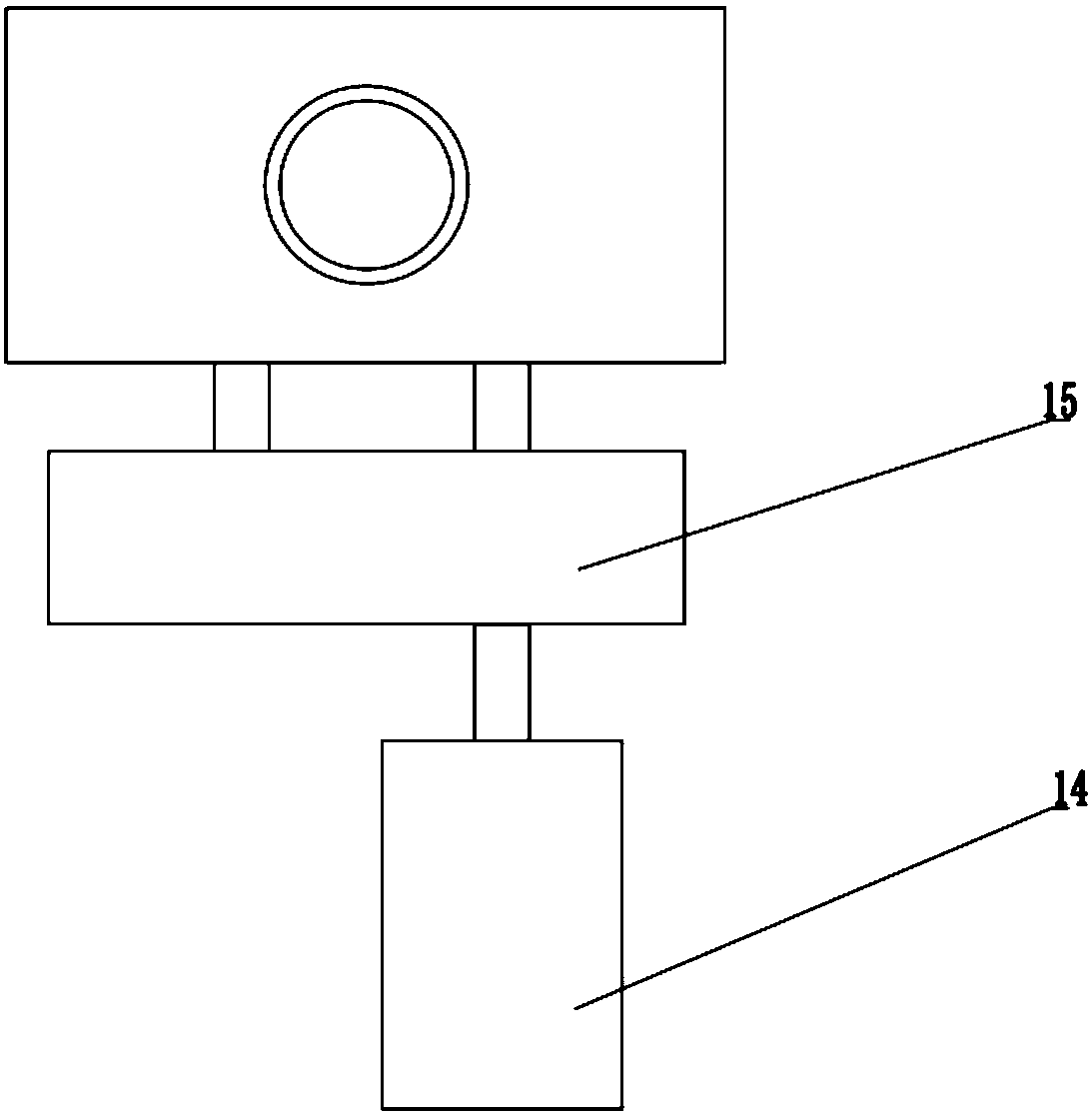

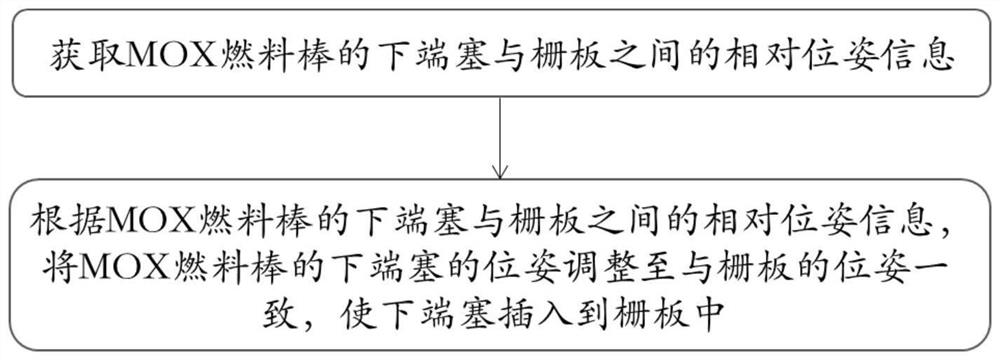

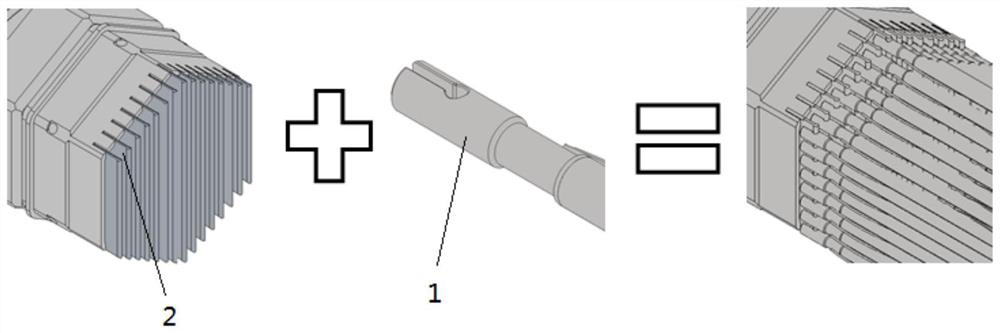

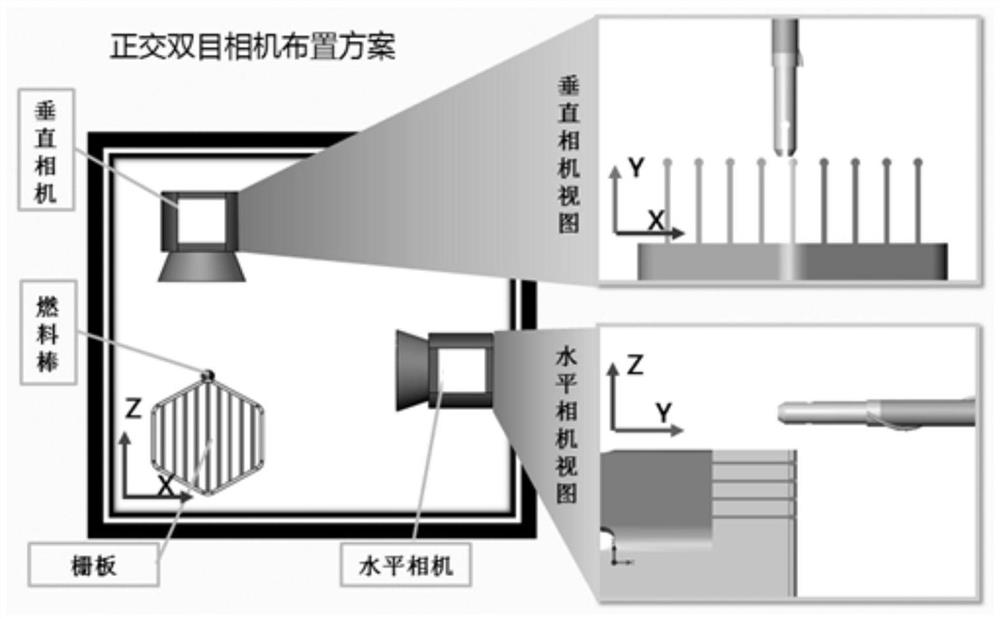

Method and device for assembling MOX fuel rod bundle

PendingCN114708993ARealize automatic assemblyImprove securityReactor fuel elementsEngineeringStructural engineering

The invention discloses an MOX fuel rod bundle assembling method and device. The method comprises the steps that S1, relative pose information between lower end plugs of MOX fuel rods and a grid plate is obtained; and S2, according to the relative pose information between the lower end plug of the MOX fuel rod and the grid plate, the pose of the lower end plug of the MOX fuel rod is adjusted to be consistent with the pose of the grid plate, so that the lower end plug is inserted into the grid plate. The invention further discloses a device for assembling the MOX fuel rod bundle. According to the MOX fuel rod assembling machine, automatic assembling of MOX fuel rods can be achieved, and the assembling safety and assembling efficiency of the MOX fuel rods are improved.

Owner:CHINA NUCLEAR POWER ENG CO LTD

Returning recycling method for MOX fuel pellet with unqualified density

ActiveCN109949960AMeet the requirements of development materialsNo flying phenomenonRadioactive decontaminationMetallurgyImpurity

Owner:THE 404 COMPANY LIMITED CHINA NAT NUCLEAR

Wet hydrogen sintering method of MOX fuel pellet

The invention relates to the technical field of nuclear-grade powder pellet sintering and particularly discloses a wet hydrogen sintering method of a MOX fuel pellet. The wet hydrogen sintering methodof the MOX fuel pellet comprises the following steps that firstly, feeding green bodies into a furnace; secondly, conducting gas replacement for flushing; thirdly, conducting wet hydrogen sintering;and fourthly opening the furnace. According to the wet hydrogen sintering method of the MOX fuel pellet, by controlling sintering temperature, the temperature keeping time, the sintering atmosphere and other key parameters in the sintering process, the specific sintering stages are optimized, the technical problems that the density of the pellet is uneven, the density is low, the O / M ratio is on the high side, and grains are under size are solved, and the wet hydrogen sintering method provides the corresponding technical support for volume production.

Owner:THE 404 COMPANY LIMITED CHINA NAT NUCLEAR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com