MOX fuel rod end plug marking method

A fuel rod and end plug technology, which is applied in the field of MOX fuel rod end plug marking, to achieve the effects of improving material circulation efficiency, facilitating production information recording and material tracking, and enhancing practicability and applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Step 1: Clean the end plugs. Completely immerse the end plug in alcohol with a purity greater than 99% for more than 2 minutes to remove surface contamination of the end plug. Take out the jig wiped with alcohol, and place it in a clean and ventilated place for about 10 minutes, so that the alcohol on the surface of the end plug can fully evaporate.

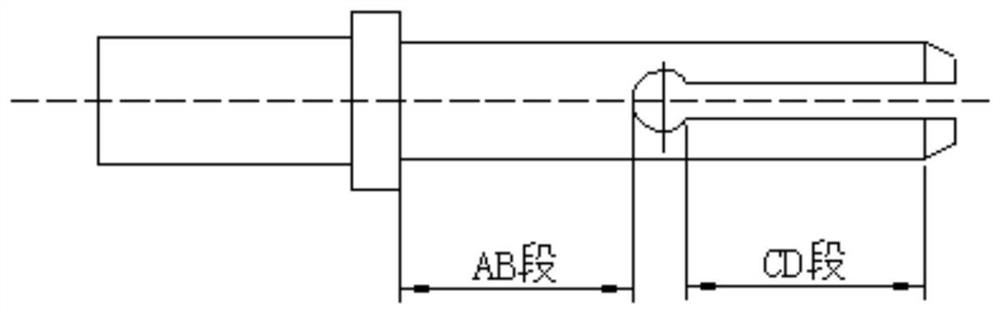

[0035] Step 2: Mark the digital code. Fix the end plug to the laser marker, exposing the outer surface CD segment of the tuning fork groove. Set the corresponding digital code in the marking control software: 001.

[0036] Set the laser power, frequency, marking speed, digital code position coordinates and other process parameters related to the marking process, and start marking. After the digital code marking on one side is completed, adjust the position of the end plug, and mark the digital code on the other side according to the same steps and process parameters.

[0037] Step 3: Mark the barcode. Fix the end plug...

Embodiment 2

[0039] Step 1: Clean the end plugs. Completely immerse the end plug in alcohol with a purity greater than 99% for more than 2 minutes to remove surface contamination of the end plug. Take out the jig wiped with alcohol, and place it in a clean and ventilated place for about 10 minutes, so that the alcohol on the surface of the end plug can fully evaporate.

[0040] Step 2: Mark the barcode. Fix the end plug to the clamping mechanism of the laser marking machine, exposing the AB section of the cylindrical surface of the non-pressed section of the end plug. Set the value represented by the barcode in the marking control software: 00002. Set the laser power, frequency, marking speed, barcode code position coordinates and other process parameters related to the marking process, and start marking.

[0041] Step three:

[0042] Mark the digital code. Fix the end plug to the laser marker, exposing the outer surface CD segment of the tuning fork groove. Set the corresponding dig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com