Method and device for assembling MOX fuel rod bundle

A technology of fuel rod bundles and fuel rods, which is applied in the direction of reactor fuel elements, reactors, nuclear engineering, etc., can solve problems such as difficult to meet the automatic assembly of MOX fuel rods, improve safety and assembly efficiency, avoid safety risks, and improve safety The effect of sexuality and intelligence level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

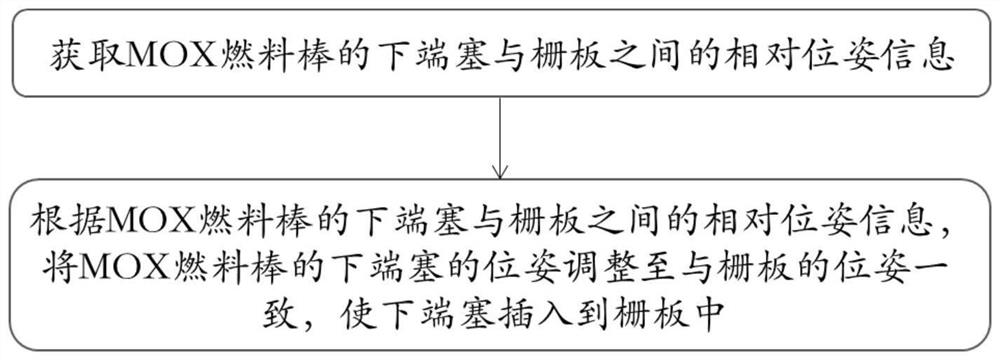

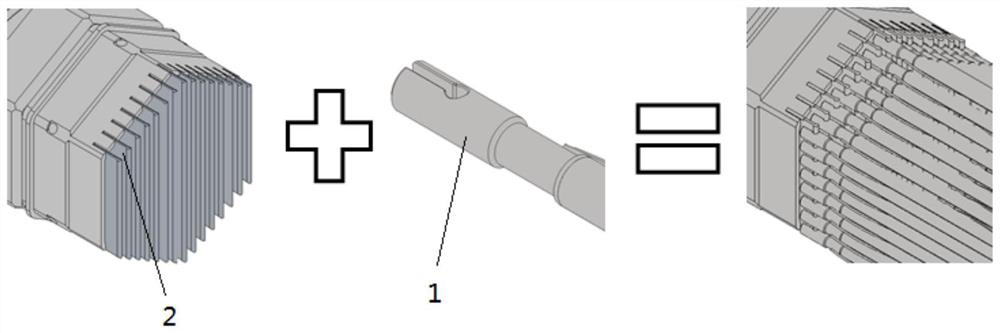

[0075] like figure 1 , figure 2 As shown, a method of MOX fuel bundle assembly, comprising:

[0076] S1, obtain the relative pose information between the lower end plug 1 of the MOX fuel rod and the grid plate 2;

[0077] S2, according to the relative posture information between the lower end plug 1 of the MOX fuel rod and the grid plate 2, adjust the posture and posture of the lower end plug 1 of the MOX fuel rod to be consistent with the posture and posture of the grid plate 2, so that the lower end plug 1 is inserted into the grid plate 2. in grid 2.

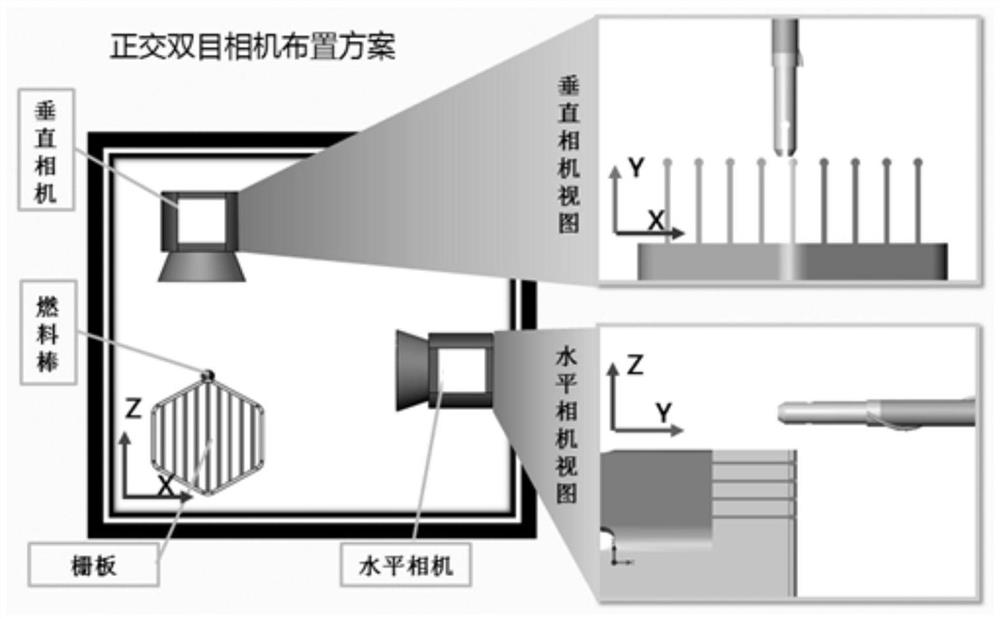

[0078] Specifically, in step S1, the relative pose information between the lower end plug of the MOX fuel rod and the grid plate is obtained, including:

[0079] Collect the image of the relative position of the lower end plug of the MOX fuel rod and the grid plate;

[0080] Perform image recognition processing on the collected relative position images to obtain the relative pose information between the lower end plug of...

Embodiment 2

[0132] This embodiment discloses a device for assembling MOX fuel bundles, including a data acquisition module, a data processing module, and an industrial robot, wherein:

[0133] An industrial robot, used to control the movement of the MOX fuel rod, so that the lower end plug of the MOX fuel rod is close to the grid plate fixed on the assembly station;

[0134] The data acquisition module is used to acquire the relative position image of the lower end plug of the MOX fuel rod and the grid plate;

[0135] The data processing module is electrically connected with the data acquisition module and the industrial robot respectively, and is used for receiving the relative position image transmitted by the data acquisition module and performing image recognition processing on it to obtain the relative pose between the lower end plug of the MOX fuel rod and the grid plate information, and transmit the relative pose information between the lower end plug of the MOX fuel rod and the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com