Method and device for manufacture of non-contaminated MOX fuel rods

一种燃料棒、无污染的技术,应用在制造反应堆、核工程解决方案、核能发电等方向,能够解决不满足、污染、阻塞等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

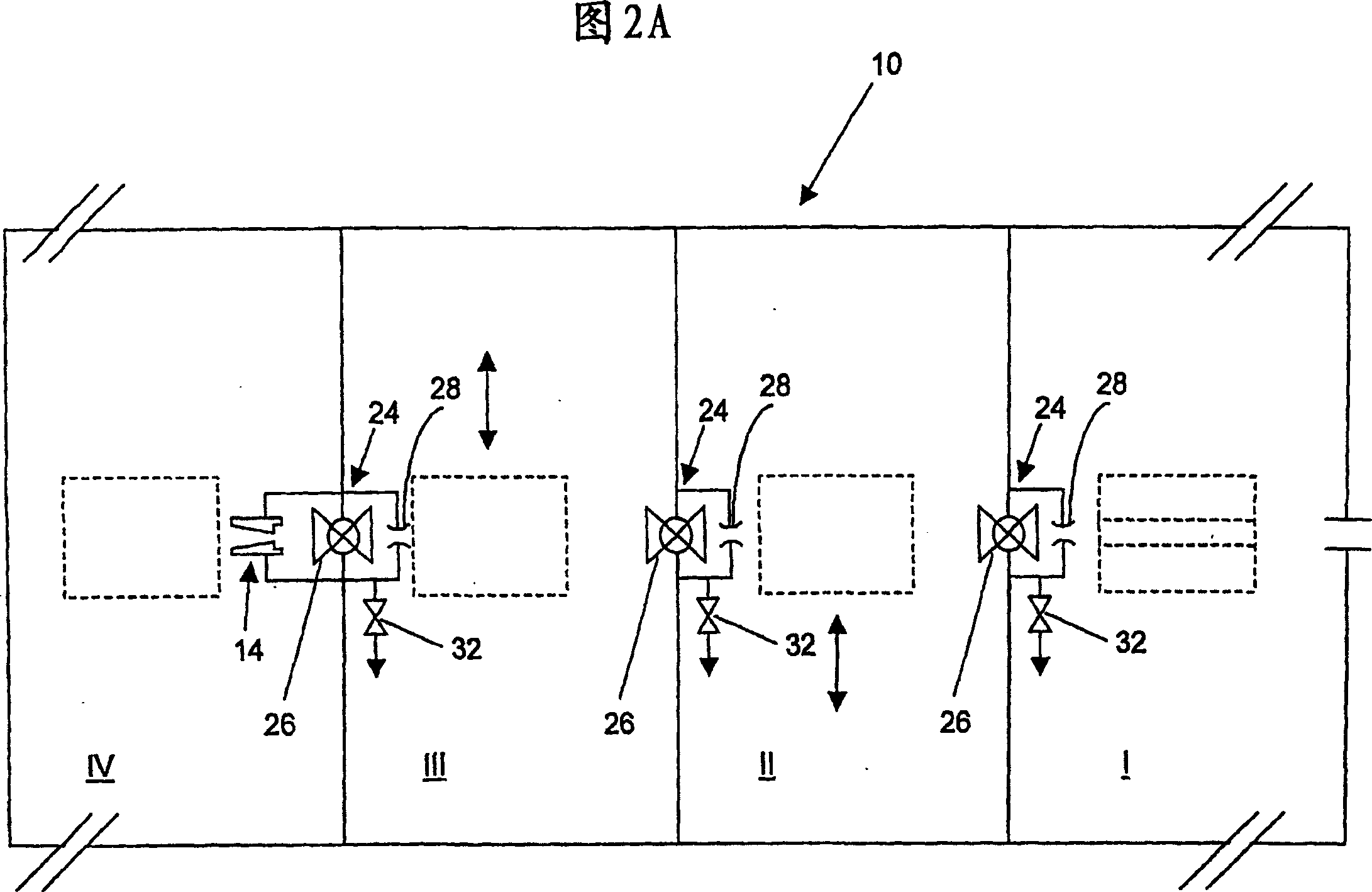

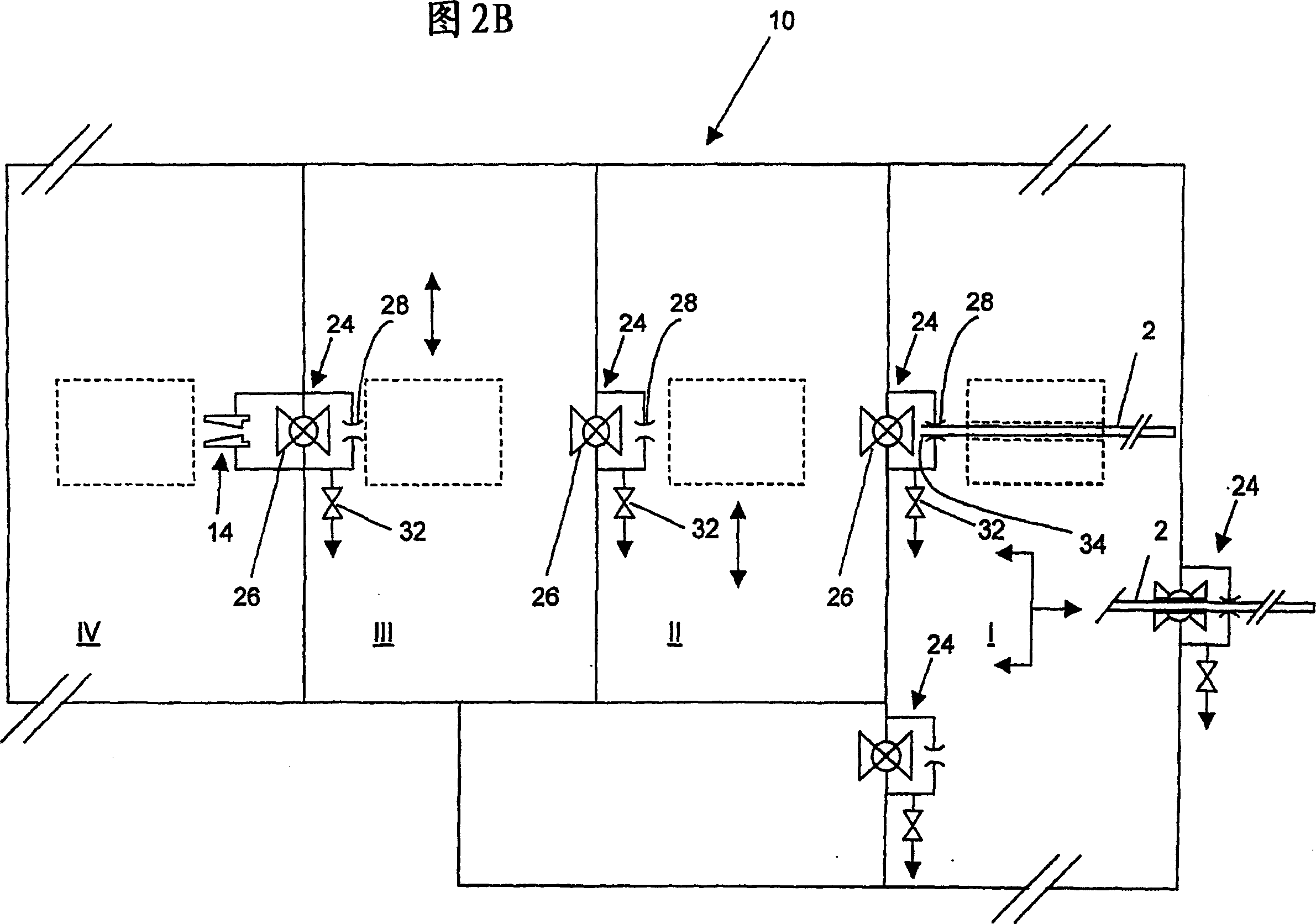

[0211] The division of various bins and the distribution of operations performed in them are possible. Table 1 gives several possible examples.

[0212] Table 1-Possible example embodiments

Compartment

#

I

II

III

IV

V

Comment

1

Cladding tube input

Decontamination inspection

Fuel rod output

(Air or helium)

Spring loading

Installation of the second plug

(The welding of the plug, if

Cork pine)

(Helium)

Cladding tube cleaning

(Helium)

Loading of pellets

(Helium)

Single fuel rod equipment

2

Input / output of cladding tube

(Variant: cladding tube to

Transmission of another box)

(Air or N 2 )

Contamination inspection

May clean

(Air or N 2 )

Spring loading

Installation of the second plug

(The welding of the plug, such as

Fruit plug pine)

(Air or N 2 )

Cladding tube cleaning

(Air or N 2 )

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com