MOX waste core block crushing device

A crushing device and pellet technology, applied in grain processing, etc., can solve problems such as flying dust, reducing work efficiency, and affecting raw material components, and achieve the effect of reducing operating intensity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

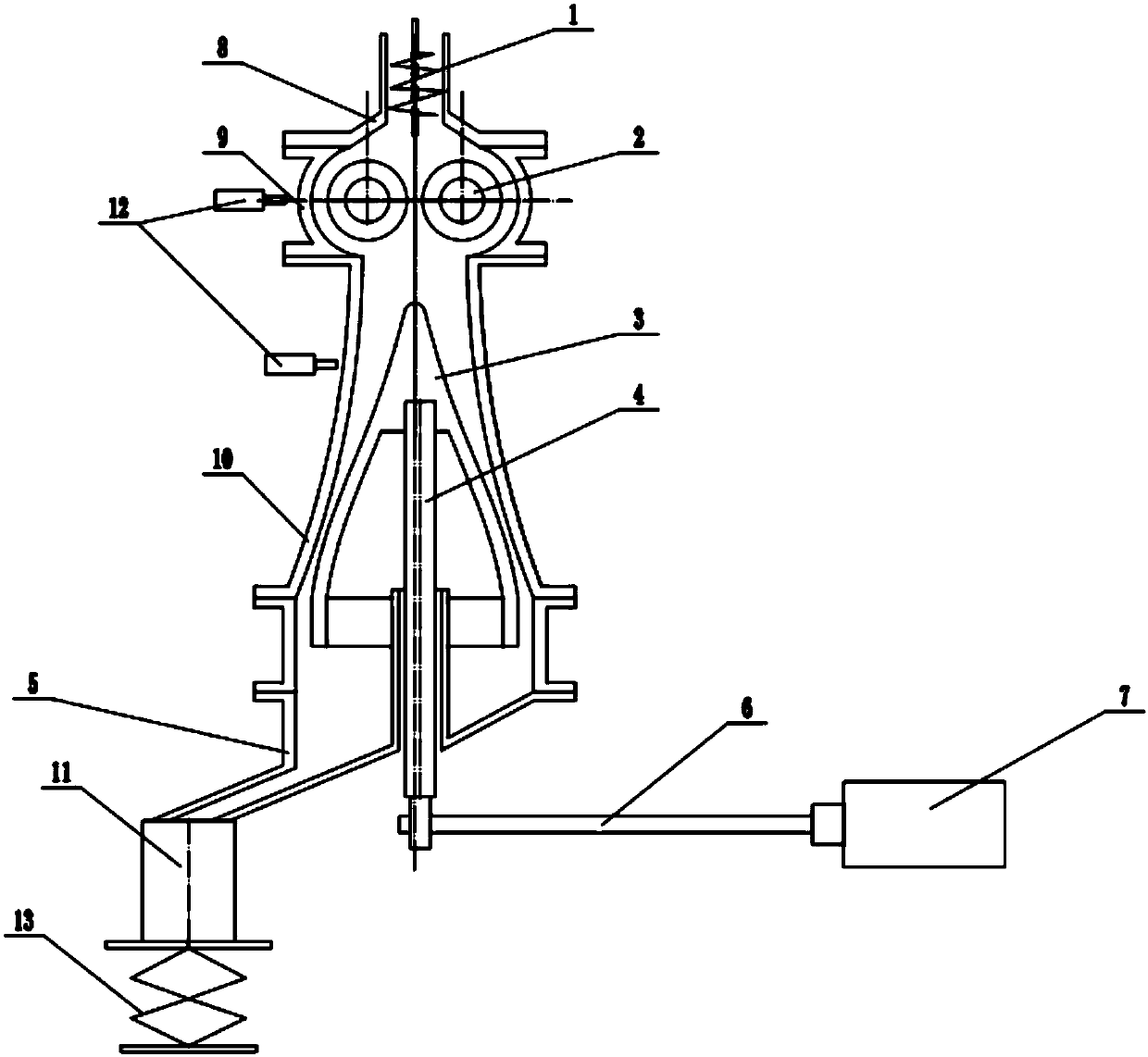

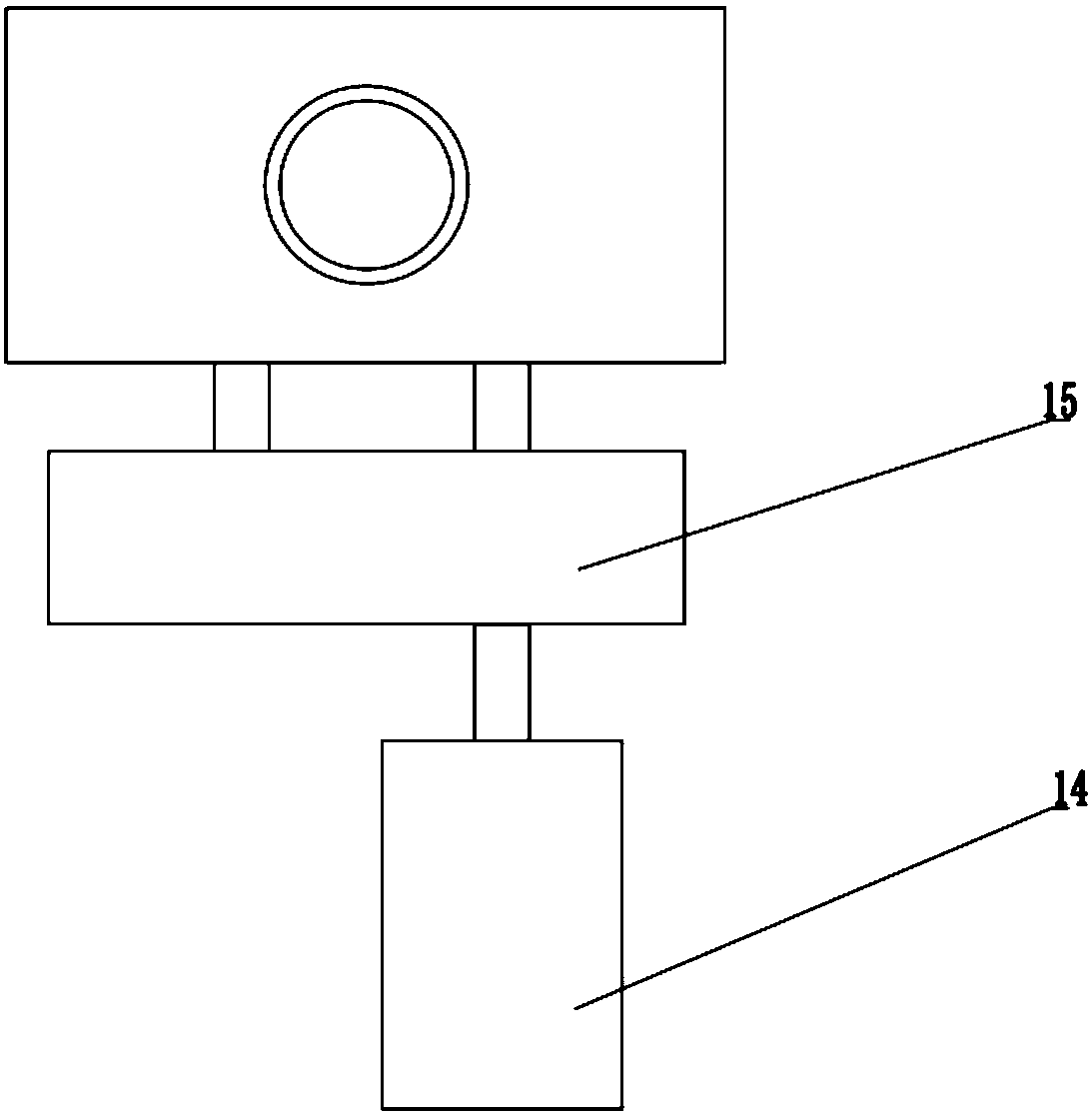

[0020] Such as figure 1 , figure 2 As shown, the MOX waste pellet crushing device of the present invention includes a screw feeding mechanism 1, a double roller 2, a moving cone 3, an eccentric shaft 4, a material receiving housing 5, a transmission shaft 6, a transmission motor A7, and a material receiving device housing 8 , double roll housing 9, static cone 10, material receiving container 11, vibrating cylinder 12, lifting platform 13, transmission motor B14 and gear set 15; screw feeding mechanism 1 is a circular tube structure, containing helical blades, arranged vertically , The angular speed of the blade rotation is low, and the waste green body relies on gravity and the action of the spiral blade discharge, slowly enters the crushing device, and is fully crushed to avoid equipment blockage caused by the presence of too many green b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com