A method for preparing high-purity lead acetate and nanometer lead powder using waste lead paste

A technology of waste lead paste and lead acetate, which is applied in nanotechnology, carboxylate preparation, recycling technology, etc., and can solve the problem of low purity of lead powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

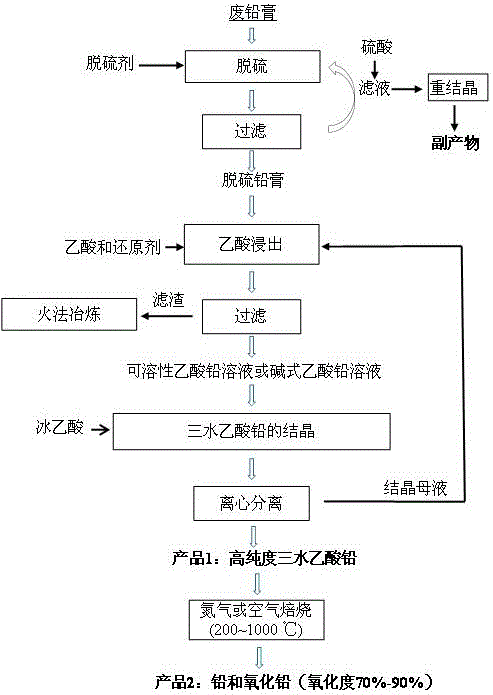

[0051] like figure 1Shown, according to the preparation method of high-purity lead acetate trihydrate of the present invention, may further comprise the steps:

[0052] (1) After the waste lead-acid battery was acid-poured, it was crushed, sorted, and screened to obtain lead paste; take 100 g of waste lead paste, add 20 g of sodium carbonate, 1 g of sodium bicarbonate and 300 g of water In the compound desulfurization agent solution (waste lead paste: sodium carbonate: sodium bicarbonate: solvent water = 1:0.2:0.01:3), stir and react at room temperature for 4 hours, filter and separate, the obtained filter residue is 92g of desulfurization lead paste, and return the filtrate to The compound desulfurizer solution is reused. The sulfur content in the desulfurized lead paste was measured, and the primary conversion rate was calculated to be 95.33%.

[0053] (2) Add 9.2 g of acetic acid solution with a mass concentration of 10% to the obtained 92 g of desulfurized lead paste (th...

Embodiment 2

[0056] Compared with Example 1, its difference is that the consumption of medicament wherein has been changed, comprises the following steps:

[0057] (1) After the waste lead-acid battery is poured acid, it is crushed and sorted, and the lead paste is obtained by screening. Get waste lead plaster 100 g, add the compound desulfurizer solution (waste lead plaster: sodium carbonate: sodium bicarbonate: solvent water=1:0.5: 5:20), stirred and reacted at room temperature for 6 hours, filtered and separated, the obtained filter residue was desulfurized lead paste, and the filtrate was returned to the composite desulfurized agent solution for reuse. The sulfur content in the desulfurized lead paste was measured, and the primary conversion rate was calculated to be 99.37%.

[0058] (2) Add 482.5 g of acetic acid solution with a mass concentration of 30% to the obtained 96.5 g of desulfurized lead paste (the mass ratio of desulfurized lead paste: acetic acid solution is 1:5) and 10 g...

Embodiment 3

[0061] Compared with Example 1, its difference is that the consumption of medicament wherein has been changed, comprises the following steps:

[0062] (1) After the waste lead-acid battery is poured acid, it is crushed and sorted, and the lead paste is obtained by screening. Get waste lead plaster 100 g, add the compound desulfurizer solution (waste lead plaster: sodium carbonate: sodium bicarbonate: solvent water=1:0.4: 2:10), stirred and reacted at room temperature for 6 hours, filtered and separated, the obtained filter residue was desulfurized lead paste, and the filtrate was returned to the composite desulfurized agent solution for reuse. The conversion rate of the obtained desulfurized lead paste was analyzed, and the primary conversion rate was 99.60% through calculation.

[0063] (2) Add 290.1 g of acetic acid solution with a mass concentration of 30% to 96.7 g of the obtained desulfurized lead paste (the mass ratio of desulfurized lead paste: acetic acid solution i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxidation state | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com