Conveying container for fast reactor MOX fuel component

A technology for transporting containers and fuel assemblies, which is used in portable protective containers, nuclear engineering, etc., can solve the problems of no buffering performance, limited accident mitigation ability, and unfavorable protection of fuel assemblies, and achieves good thermal insulation performance and good buffering. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

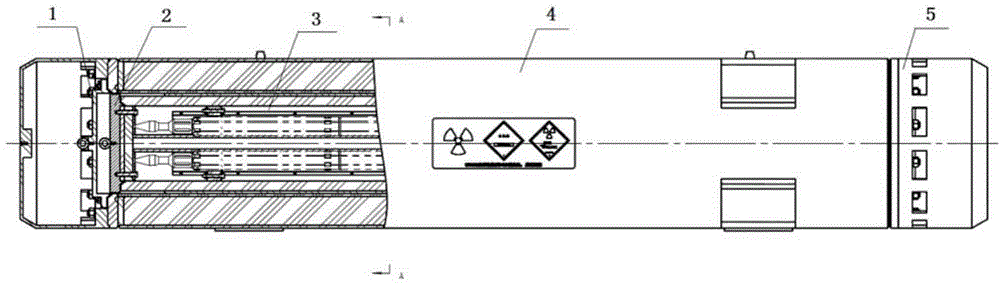

[0040] The fast reactor MOX fuel assembly transport container is used for the transportation of MOX fuel assemblies of China Experimental Fast Reactor, and is transported from the MOX fuel assembly manufacturer to the new fuel bank of China Experimental Fast Reactor. Its structure is verified by calculation analysis and test, which can meet the requirements of laws and regulations for the safe transportation of radioactive substances. Under normal transportation conditions and accident transportation conditions, it has good shielding, inclusiveness, critical safety, heat insulation and buffering properties. .

[0041] Such as figure 1As shown, the fast reactor MOX fuel assembly transport container is composed of a cylinder assembly 4, a middle penetration member 3, a first layer of compression end caps 2, a second layer of compression end caps 1, and buffers 5 at both ends. Each shipping container contains 4 boxes of MOX fuel assemblies.

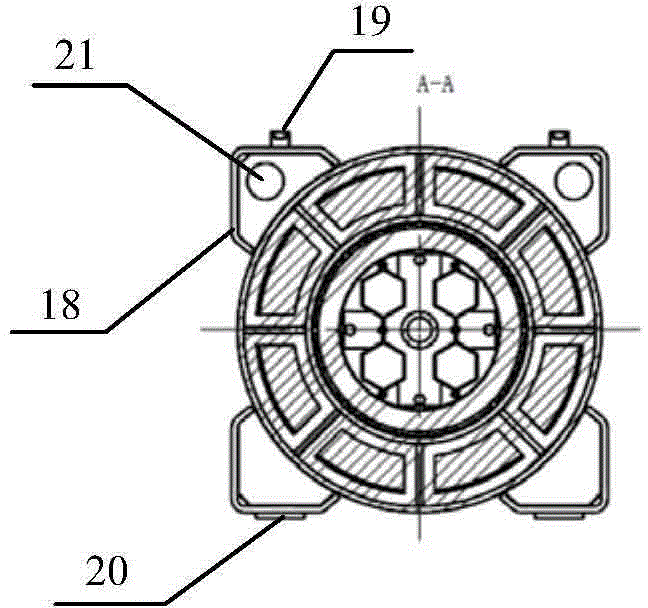

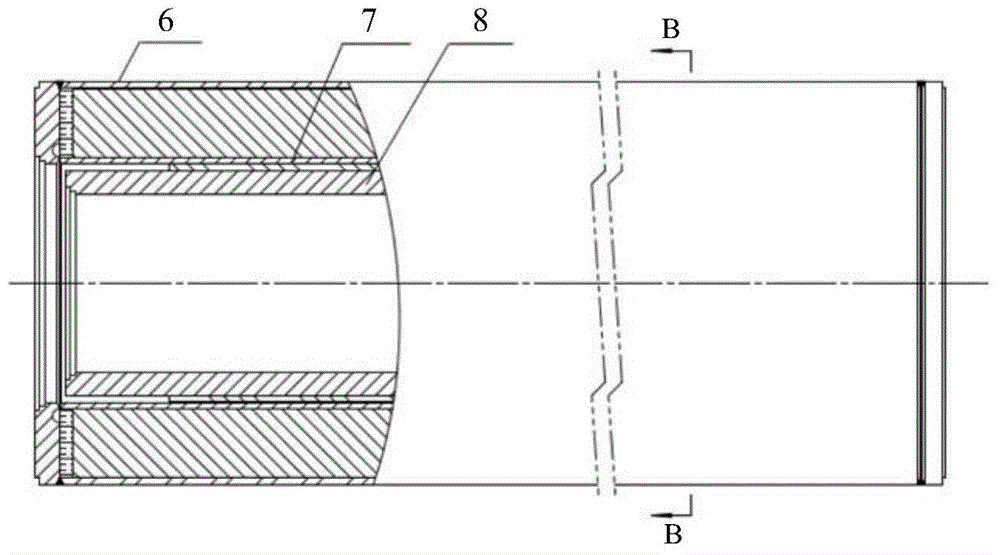

[0042] The structure of the barrel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com