Deep three-soft coal seam asymmetric tunnel supporting structure

A technology for three-soft coal seam and roadway support, applied in mining equipment, earthwork drilling, installation of anchor rods, etc. The effect of slowing down plastic deformation and restraining large nonlinear deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

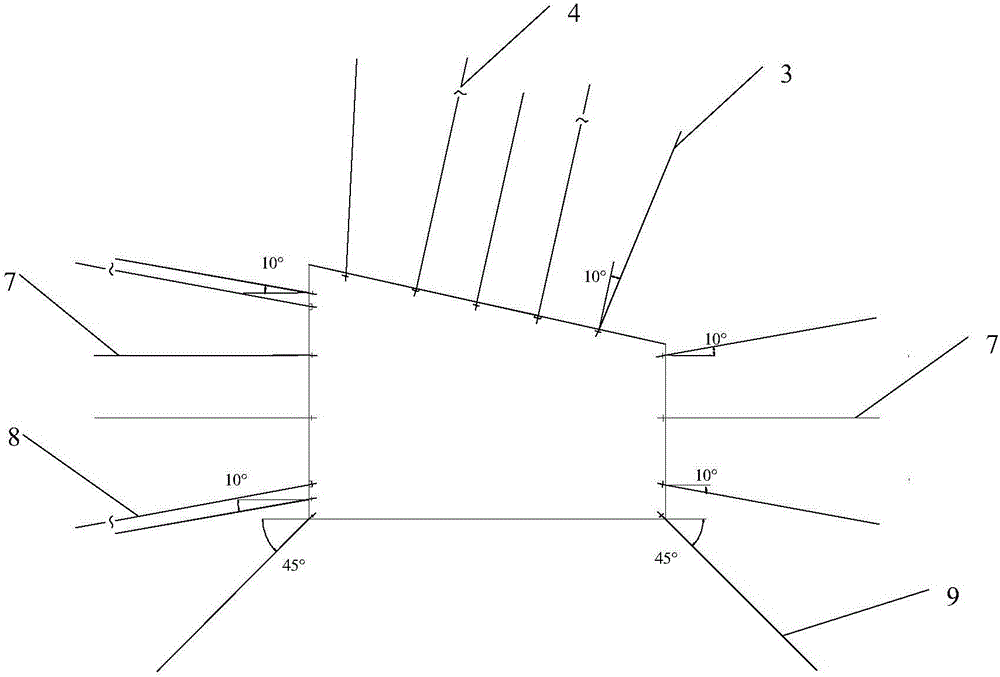

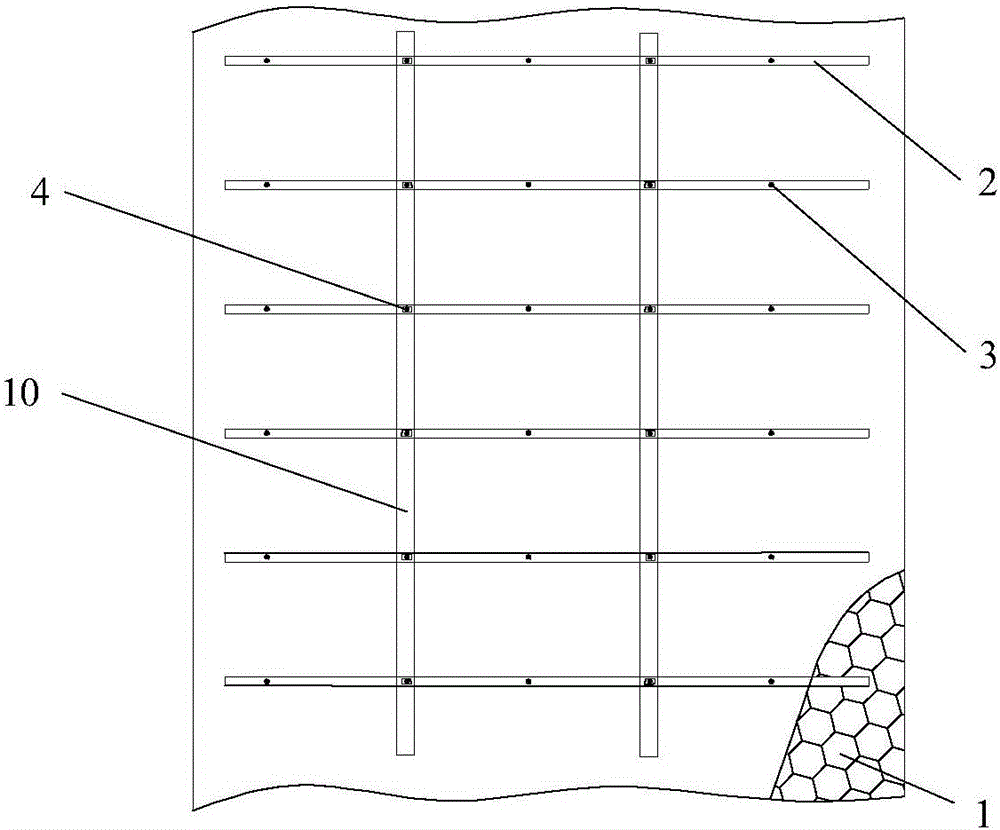

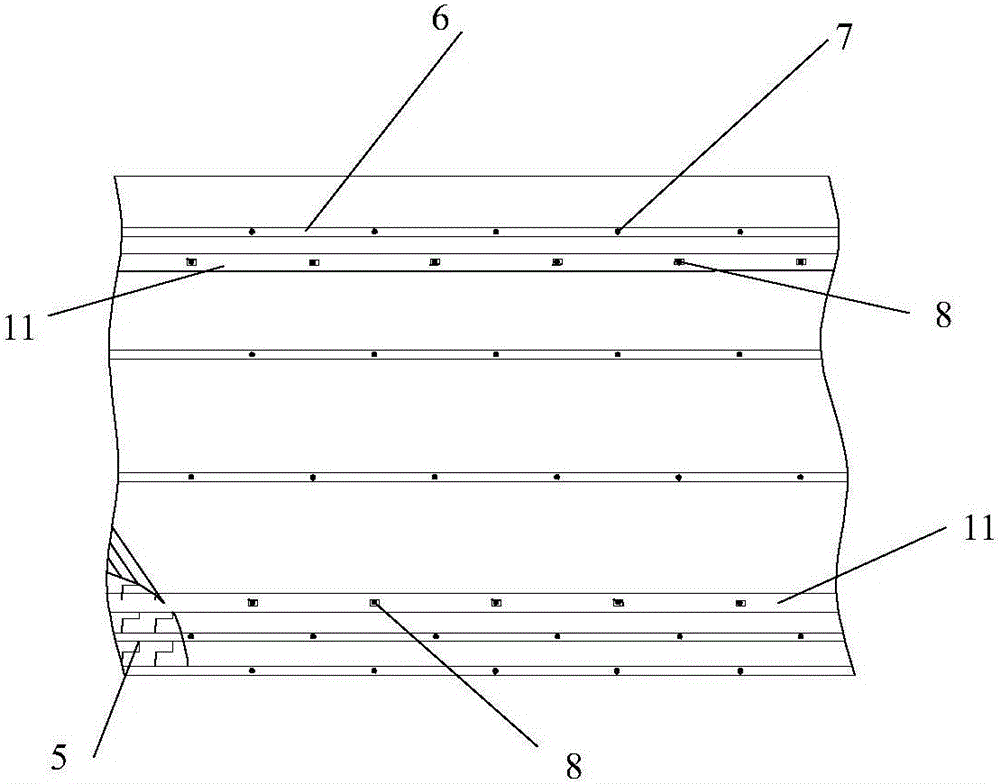

Method used

Image

Examples

Embodiment

[0033] Taking the deep three-soft coal seam roadway of a coal mine in the Huainan mining area as an example, the roadway support structure of the present invention is used to systematically study the roadway surrounding rock control effect.

[0034] 1. Basic situation of roadway

[0035]Occurrence conditions of the three soft coal seams in the deep part of the mine: the roof and floor are composed of mudstone and clay rock, and partly composed of fine sandstone and siltstone, and there is a mudstone interlayer of about 1.2m in the middle of the coal seam. The roof mudstone is 1m thick and has low strength, and the siltstone is 7m thick and is medium-hard rock. The roof mudstone is 3.5m thick and the claystone is 1.8m thick, both of which are typical soft rocks. The roof and floor are all soft rock, and the coal seam is a typical three-soft coal seam.

[0036] The buried depth of the three-soft coal seam roadway is -650m, the vertical self-weight stress of the roadway is abou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com