Arc surface calibratkon cam mechanism and its processing method

A technology of indexing cams and arc surfaces, which is applied in the direction of mechanical equipment, belts/chains/gears, transmission parts, etc., to achieve the effects of reduced wear, small wear, and improved lubrication and stress state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof:

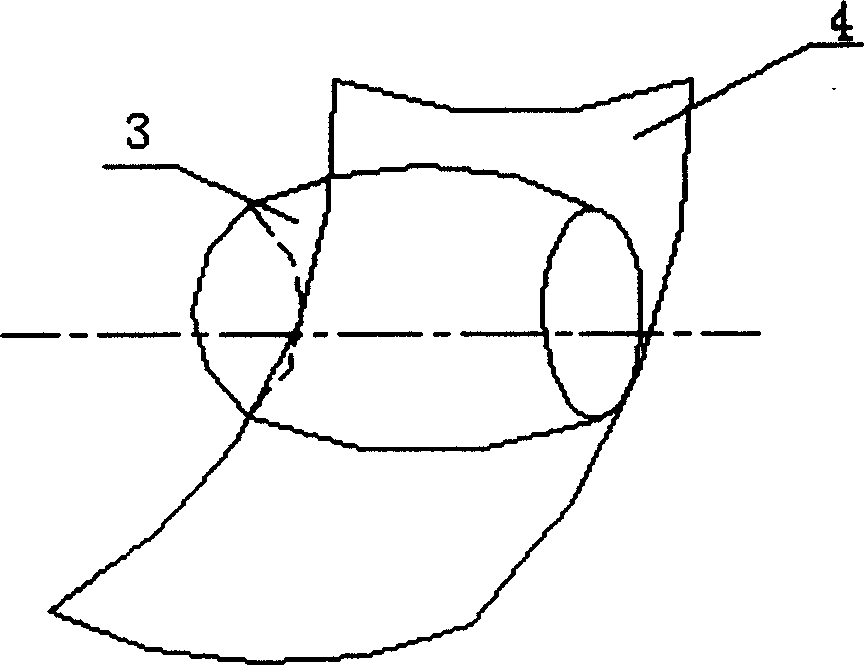

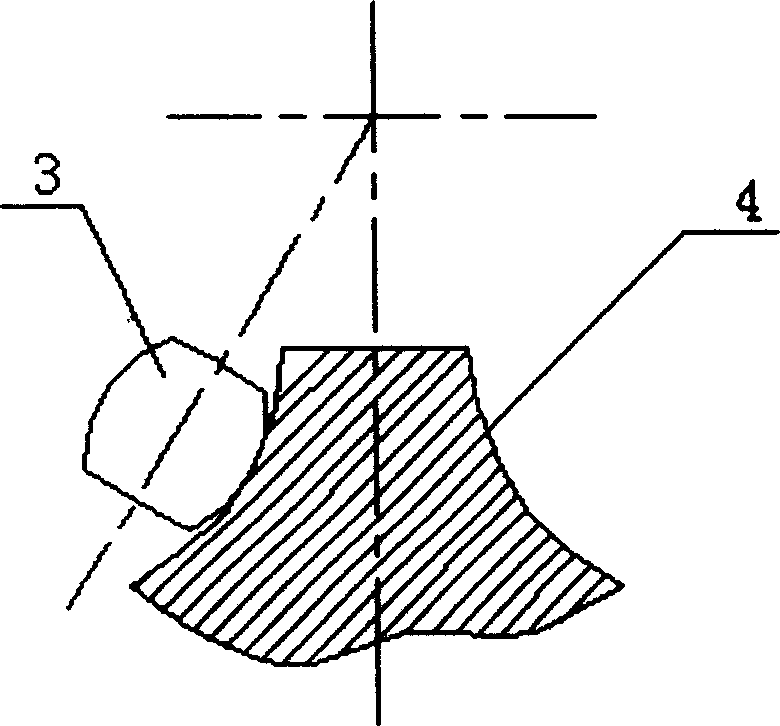

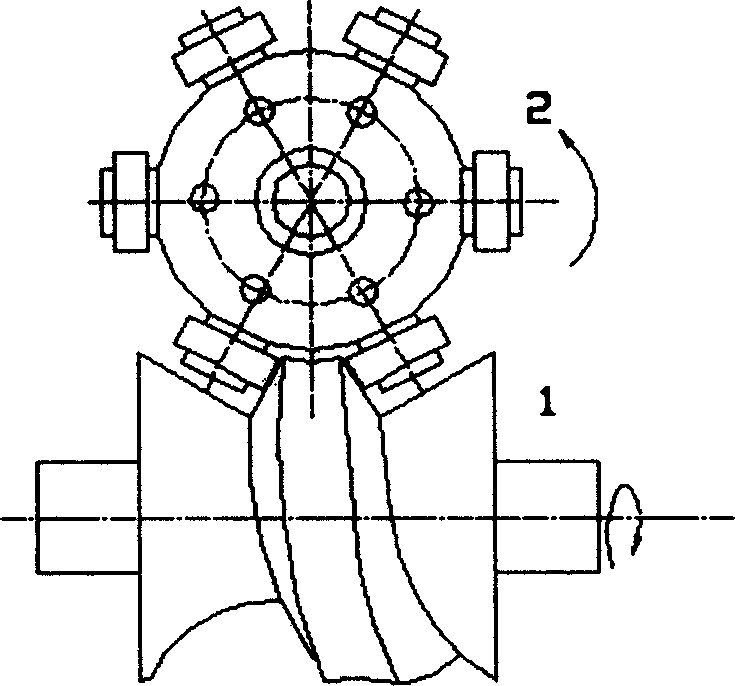

[0047] An arc indexing cam mechanism designed by the present invention includes a cam and a roller 2 engaged with it, and the cam profile 4 includes a positioning section, a transition section and an indexing section, and is characterized in that the cam profile 4 The transition section and the indexing section are concave surfaces, and the matching roller 2 is a drum-shaped roller 3 whose curvature radius is smaller than that of the concave surface of the convex profile surface 4 (see figure 1 , 2 , 3 and 4).

[0048] This design of the present invention is based on the result of in-depth research on the theoretical engagement contact line of traditional or conventional arcuate indexing cam mechanisms: the cam 1 and roller 2 theoretical engagement contact lines of traditional or conventional arcuate indexing cam mechanisms are a space curve (see e.g. ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com