MOX fuel cladding tube reutilization method

A cladding tube and fuel technology, which is used in fuel elements, nuclear power generation, climate sustainability, etc., to achieve the effect of improving utilization, high reliability and good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

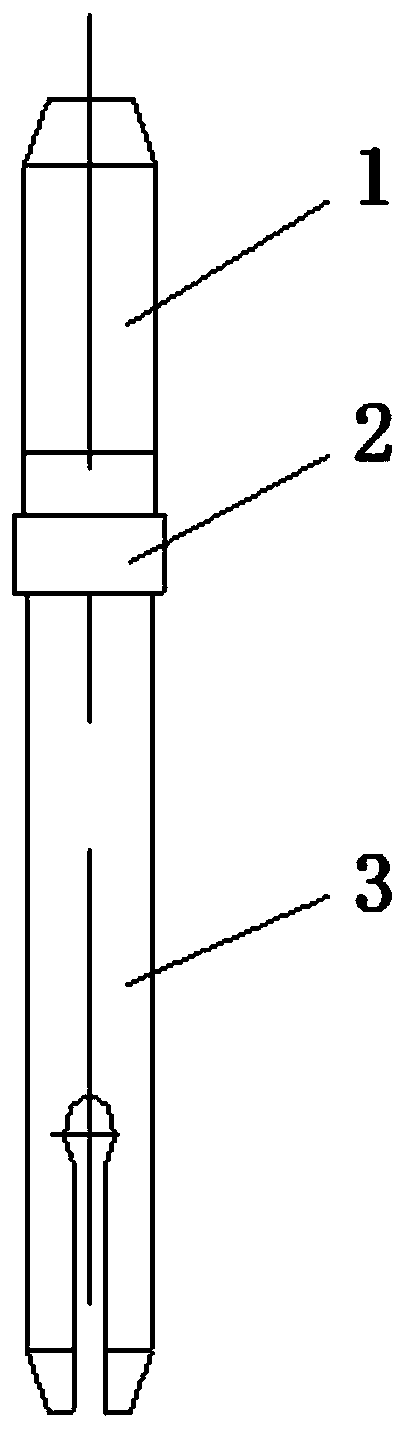

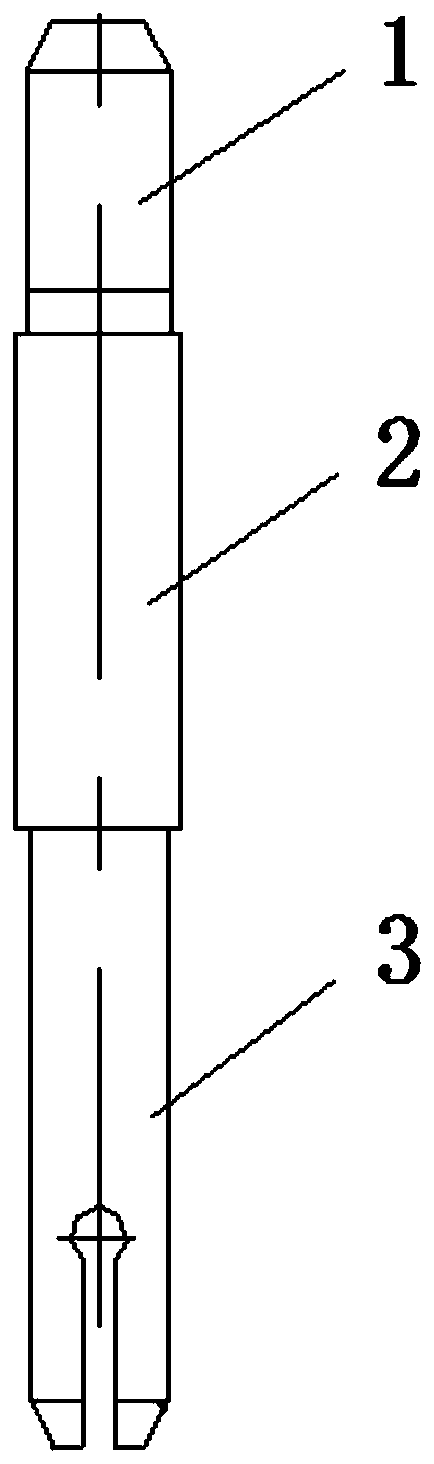

[0041] A method for reusing MOX fuel cladding tubes, the raw materials are MOX fuel stainless steel cladding tubes and stainless steel lower end plug assembly weldments that have failed to weld, comprising the following steps:

[0042] Step 1: Use a steel ruler to measure the original length a of the weldment of the cladding tube and the lower end plug that failed to weld, and then measure a length from the end of the lower end plug on the weldment that failed to weld the lower end plug and the cladding tube. The scope covers the welding seam and the lower end plug press-in section, and then mark it with a marker pen;

[0043] Step 2: Cut off the lower end plug from the mark by turning, and deburr the cladding tube with a triangular pyramid;

[0044] Step 3: measure the length b of the cladding tube after cutting, and calculate the length c of the end plug to be compensated, where c=a-b;

[0045] Step 4: Reprocess the lower end plug, wherein the dimensions of the lower end pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com