Tube-in-tube type MA transmutation rod for fast neutron reactor

A fast neutron reactor and sleeve-type technology, applied in the field of sleeve-type MA transmutation rods, can solve the problem of single structure design of transmutation rods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

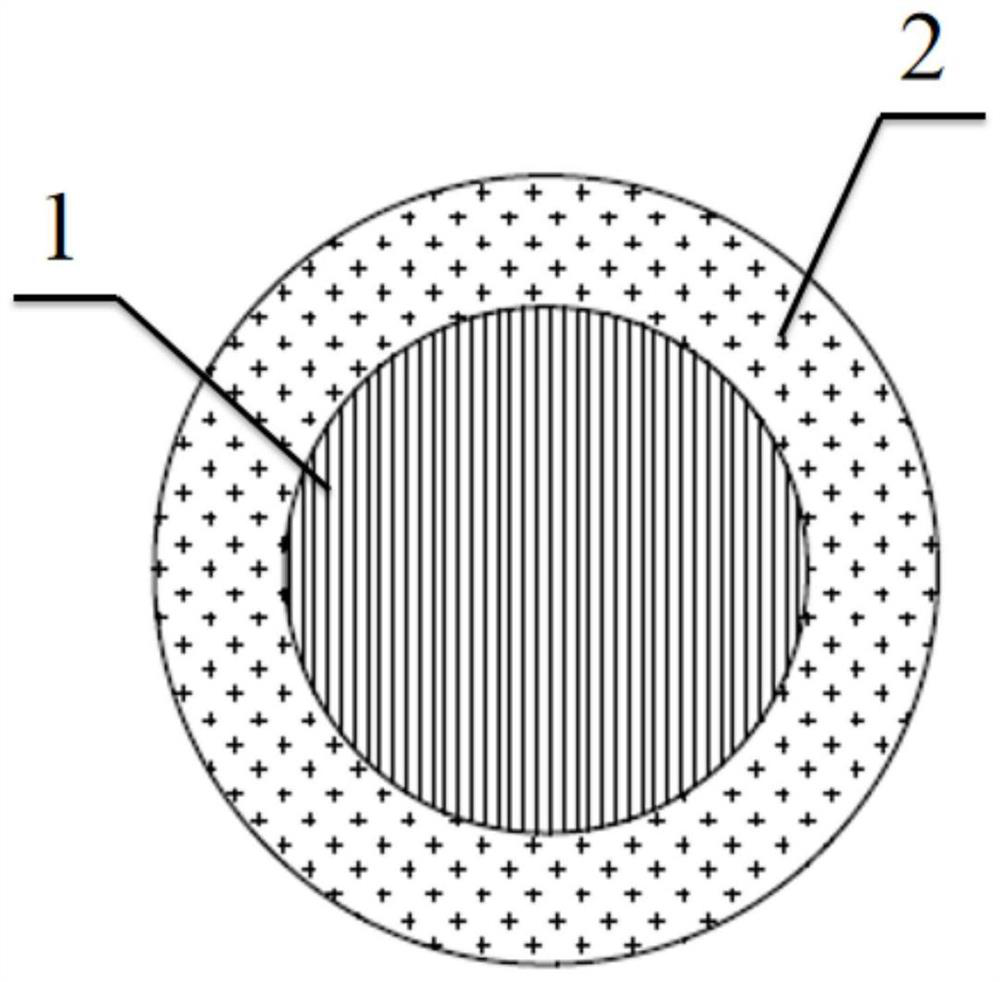

[0053] Such as figure 1 A casing-type MA transmutation rod for a fast neutron reactor is shown, the center layer of which is the MA nuclide tube 1, the thickness of the MA nuclide tube 1 is 4 mm, and the outer layer is a single-layer structure 6 LiD nuclide tube 2, 6 The thickness of the LiD nuclide tube 2 is 1mm, and the density of each transmutation rod is 10.41g / cm 3 , the radius is 5mm, and the mass of MA nuclide tube 1 in each MA transmutation rod is 313.50g; the nuclide composition of MA nuclide tube 1 includes 237 Np, 241 Am, 243 Am, 244 Cm, where 237 The mass proportion of Np is 56.2%, 241 The mass proportion of Am is 26.4%, 243 The mass proportion of Am is 12%, 244 The mass proportion of Cm is 5.4%.

Embodiment 2

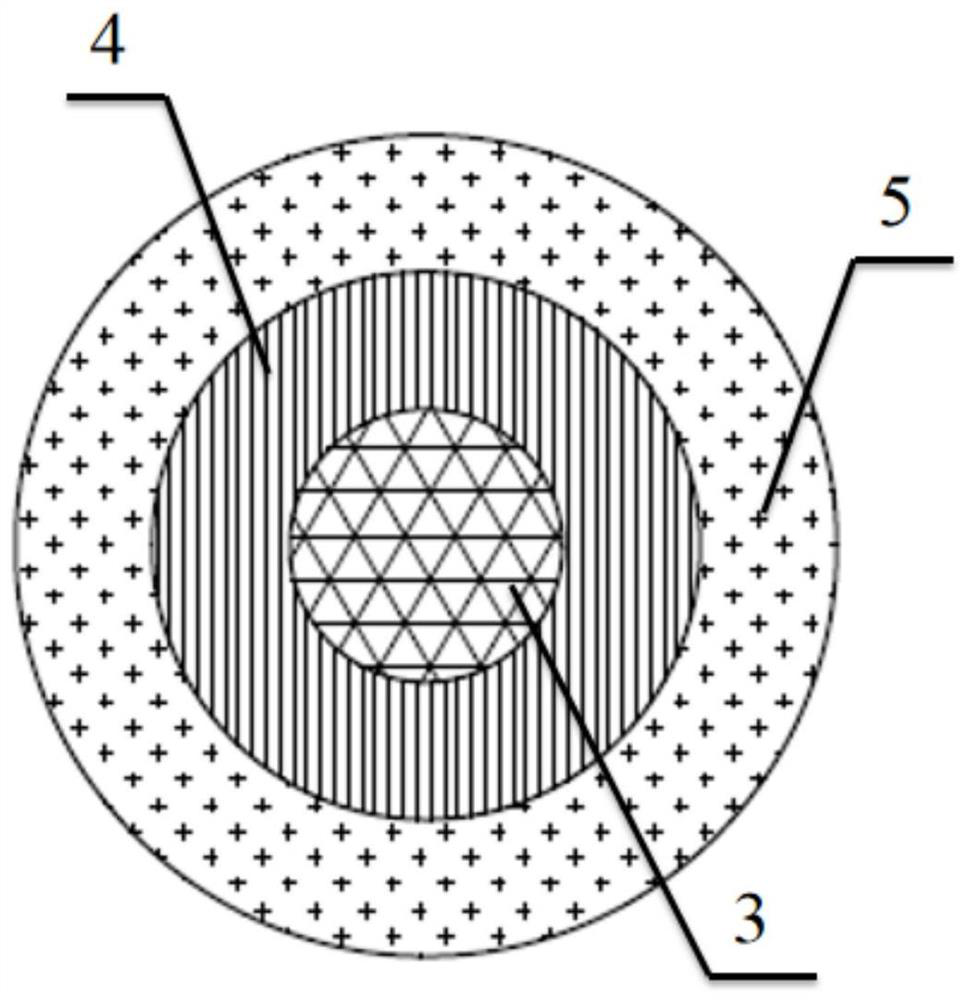

[0055] Such as figure 2 A sleeved MA transmutation rod for a fast neutron reactor is shown, the central layer of which is the MOX nuclide tube 3, the thickness of the MOX nuclide tube 3 is 1.5mm, and the outer layer includes the first outer layer and the surrounding setting In the second outer layer outside the first outer layer, the first outer layer is the MA nuclide tube 4, the thickness of the MA nuclide tube 4 is 3mm, and the second outer layer is 6 LiD nuclide tube 5, 6 The thickness of the LiD nuclide tube 5 is 0.5mm, and the density of each transmutation rod is 10.41g / cm 3 , the radius is 5mm, and the mass of the MA nuclide tube 4 in each transmutation rod is 352.68g; the nuclide composition of the MA nuclide tube 4 includes 237 Np, 241 Am, 243 Am, 244 Cm, where 237 The mass proportion of Np is 56.2%, 241 The mass ratio of Am is 26.4%, 243 The mass proportion of Am is 12%, 244 The mass proportion of Cm is 5.4%; the constituent nuclides of the MOX nuclide tube...

Embodiment 3

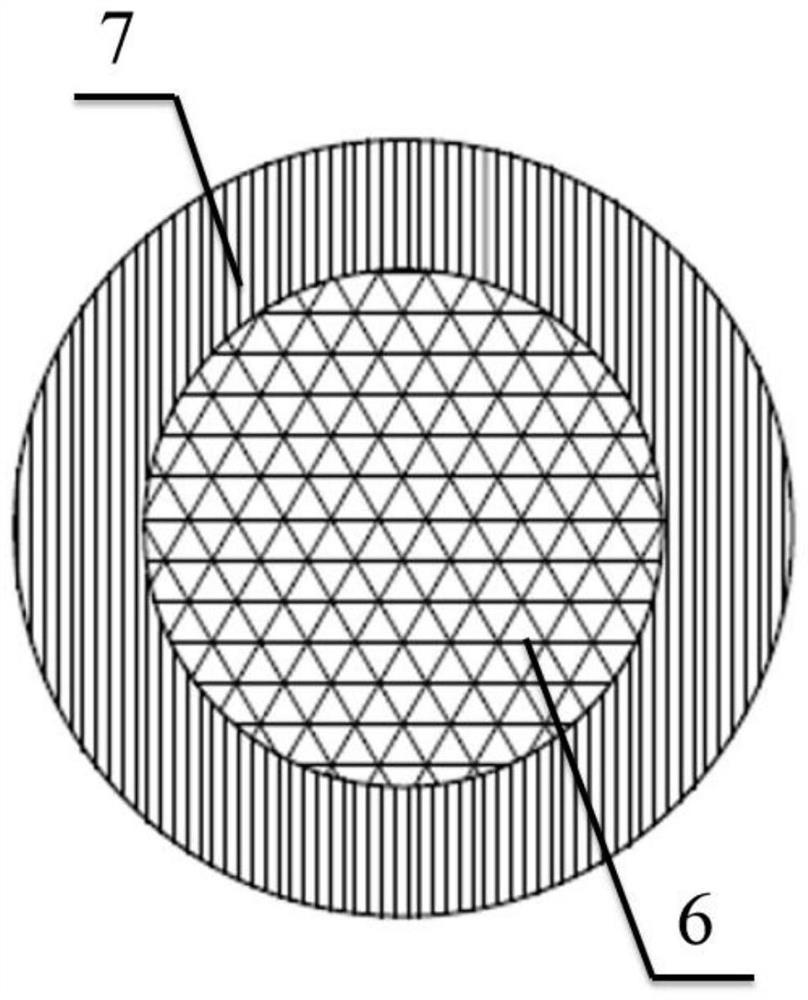

[0057] Such as image 3 A casing-type MA transmutation rod for a fast neutron reactor is shown, the central layer of which is the MOX nuclide tube 6, the thickness of the MOX nuclide tube 6 is 4mm, the outer layer is the MA nuclide tube 7, and the MA core The thickness of the plain tube 7 is 1mm, and the density of each transmutation rod is 10.41g / cm 3 , the radius is 5mm, and the mass of the MA nuclide tube 7 in each transmutation rod is 176.34g; the nuclide composition of the MA nuclide tube 7 includes 237 Np, 241 Am, 243 Am, 244 Cm, where 237 The mass proportion of Np is 56.2%, 241 The mass proportion of Am is 26.4%, 243 The mass proportion of Am is 12%, 244 The mass proportion of Cm is 5.4%; the constituent nuclides of the MOX nuclide tube include 238 U 235 U 238 Pu, 239 Pu, 240 Pu, 241 Pu and 242 Pu, of which, 238 U 235 The ratio of U is 0.003:1, 238 Pu, 239 Pu, 240 Pu, 241 Pu and 242 The ratio of Pu is 0.009:0.615:0.220:0.29750.119:0.041.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com