Radiation protection method for MOX pellet preparation process

A preparation process and radiation protection technology, applied in the field of radiation protection of MOX pellet preparation process, can solve the problems of high-tech radiation protection, operator hazards, inability to achieve the radiation protection capability of MOX fuel pellets, etc., and achieve the effect of ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0024] The radiation protection method of the MOX pellet preparation process of the present invention is as follows:

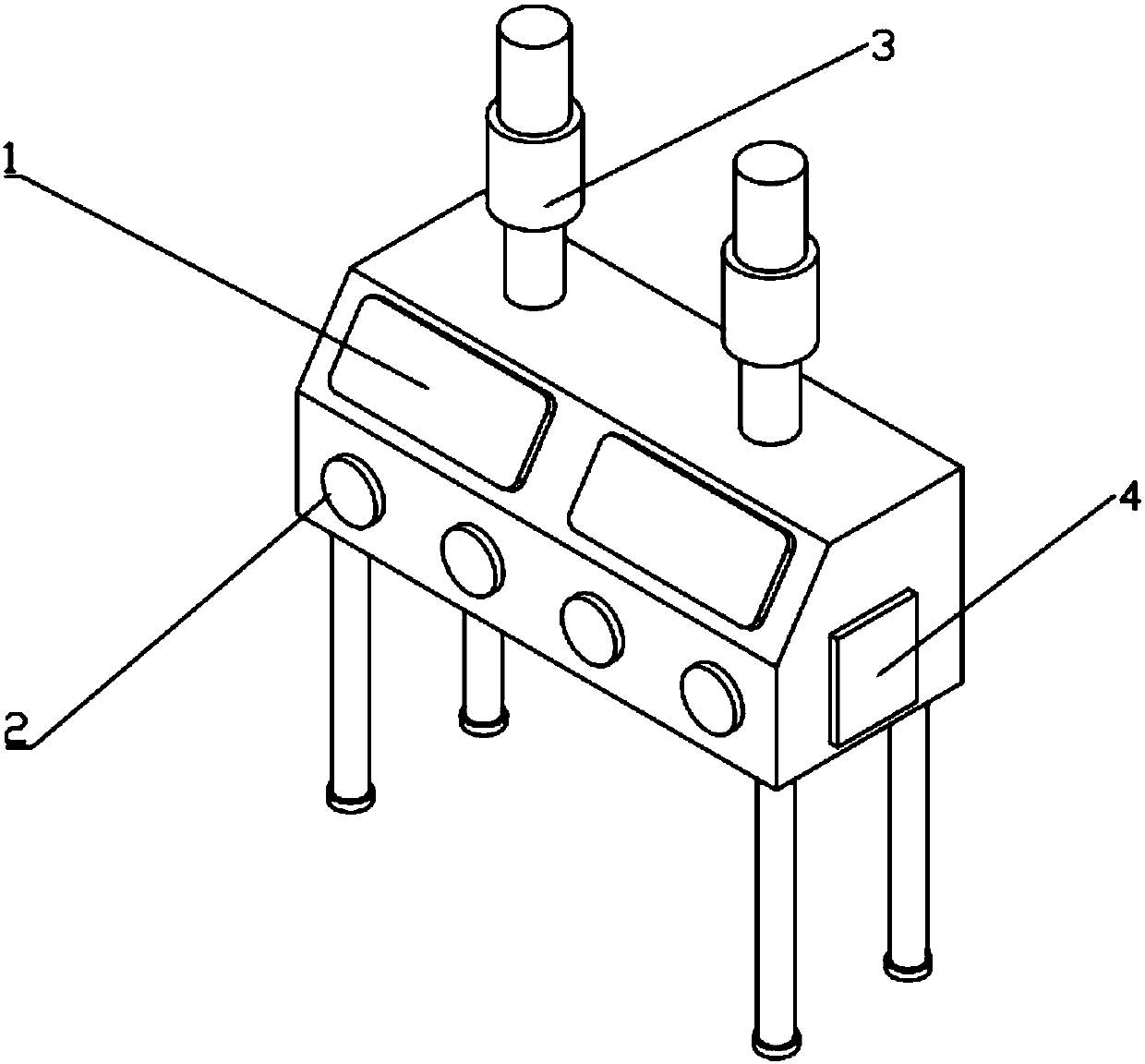

[0025] The key equipment of the production line is enclosed by a glove box, which is the most basic and main way of radiation protection. Such as figure 1 As shown, the glove box structure mainly includes an inner shell and an outer shielding material. The frame of the inner shell is integrally processed, 304 stainless steel material, the thickness is small, about 5-10mm, integrally formed or welded. The integrated structure avoids the need to add a sealing structure at the connection due to the block design, reducing the risk of leakage. The inner shell is only used as an α-radiation shield and provides the mechanical strength of the entire glove box. Its ability to shield other radiation is weak. At this time, a certain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com