Light water reactor fuel assembly, manufacturing method thereof, light water reactor core and MOX fuel assembly production method

A technology for reactors and aggregates, which is applied in the directions of reactor fuel elements, reactors, nuclear reactors, etc., and can solve the problem of inability to reduce the harmfulness of secondary actinides.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

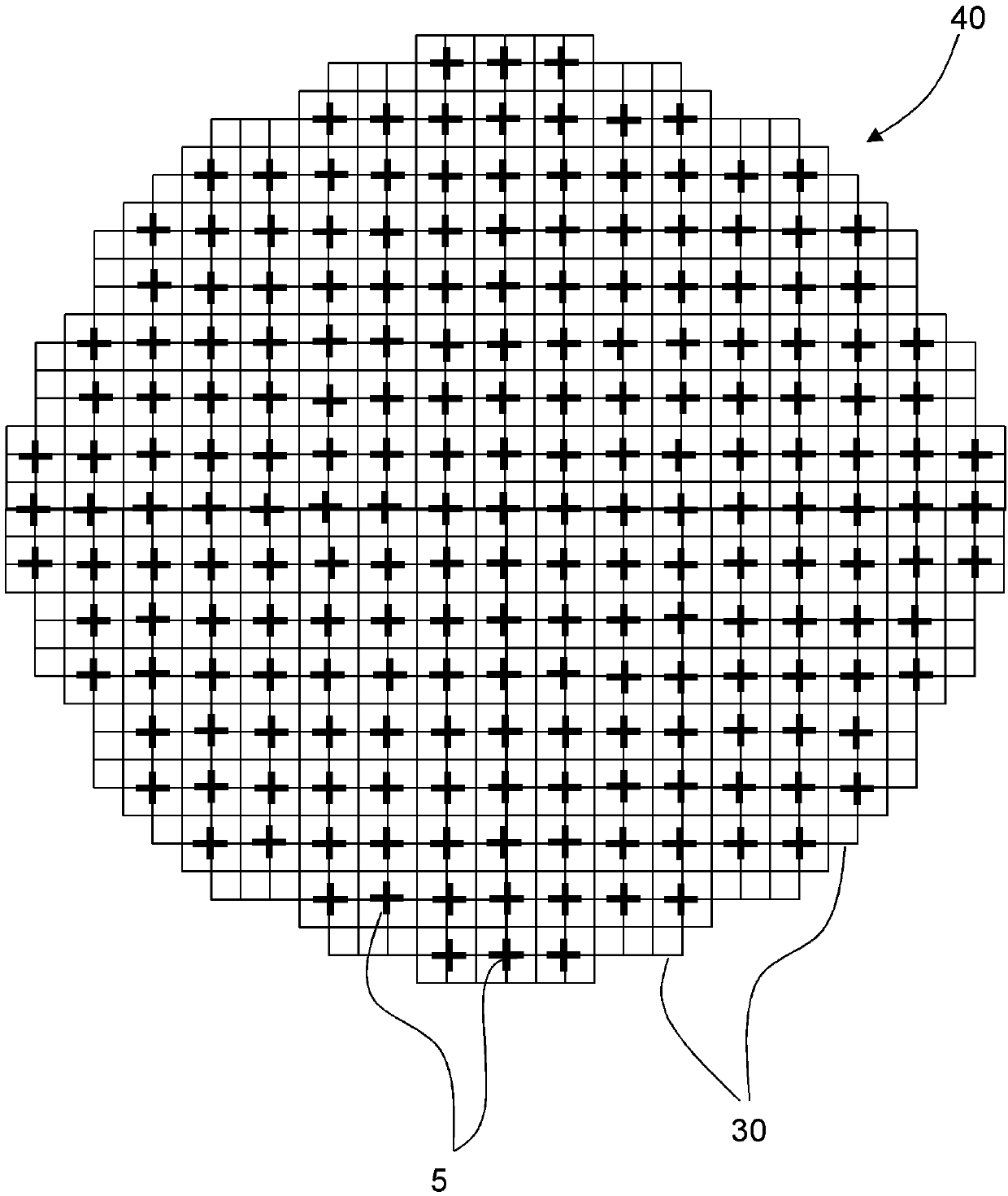

[0060] figure 1 It is a plan view showing the structure of the light water reactor core of the first embodiment. The light water reactor core 40 has a plurality of light water reactor fuel assemblies 30 and a plurality of control rods 5 . Hereinafter, the case of BWR is taken as an example for description.

[0061] The light water reactor fuel assemblies 30 are arranged side by side in a grid pattern, and form a substantially circular light water reactor core 40 as a whole. In addition, except for the aggregates 30 for light water reactor fuel which are partially arranged around the light water reactor core 40, four of each form a set of square grids, and in the center of each square grid, control rods 5 Can be configured in a pluggable manner. In addition, as will be described later, the number of fuel assemblies 30 for a light water reactor is set based on basic specifications such as the output of the core. For example, taking the Advanced Boiling Water Reactor (ABWR) a...

no. 2 Embodiment approach

[0107] This second embodiment is an embodiment based on the first embodiment.

[0108] Figure 12 It is a graph showing the dependence characteristic of the ratio of the mass of uranium 235 to the mass of heavy metal at the initial stage of the operation cycle of the fuel assembly for a light water reactor on the initial uranium enrichment degree. As the result of the combustion calculation is Figure 12 As shown, as the initial enrichment of uranium increases, the ratio of the mass of uranium 235 at the end of the operation cycle to the mass of the initial heavy metal also increases. For example, when the initial enrichment degree of uranium is 3.8% of the comparative example, it is about 0.006, that is, about 0.6 wt% (weight percent) as described above. In addition, when the initial enrichment degree of uranium is 10%, it is about 0.05, that is, 5 wt%, and when the initial enrichment degree of uranium is 20%, it is about 0.15, that is, 15 wt%.

[0109] Figure 13 It is a...

no. 3 Embodiment approach

[0119] Figure 14 It is a comparison table of the specifications of the light water reactor fuel assembly based on the third embodiment and the normal type uranium fuel assembly based on the comparative example. This embodiment is a modification of the first embodiment. In the first embodiment, the average uranium enrichment degree of the fuel assemblies for light water reactors is higher than that of ordinary type uranium fuel assemblies, but in the fuel assemblies 30 for light water reactors in the third embodiment , Compared with ordinary uranium fuel assemblies, the uranium enrichment degree is increased, and the concentration of combustible poisons is also increased. exist Figure 14 In the example shown in , the uranium enrichment is 4.8% and the combustible poison concentration is 5.5%. In this way, according to the degree of uranium enrichment, the concentration of combustible poisons also increases.

[0120] Figure 15 It is a graph showing the comparison of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com