Loading method for MOX fuel assemblies axially arranged in multiple zones

A fuel assembly and multi-partition technology, applied in the direction of reactor fuel elements, nuclear reaction control, nuclear power generation, etc., can solve the problem of core axial power offset downwards, achieve the effect of improving performance and axial power distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

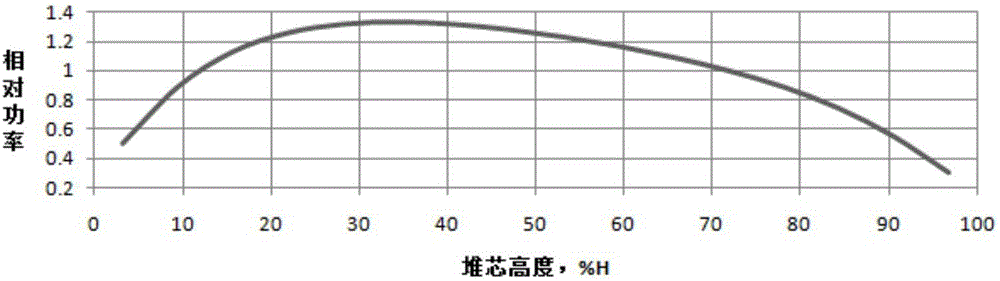

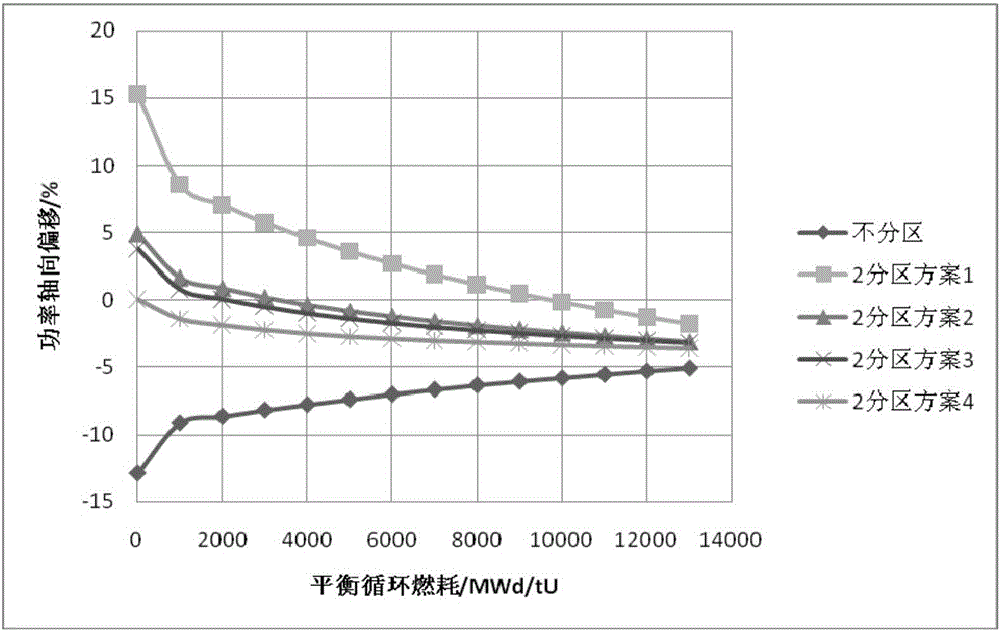

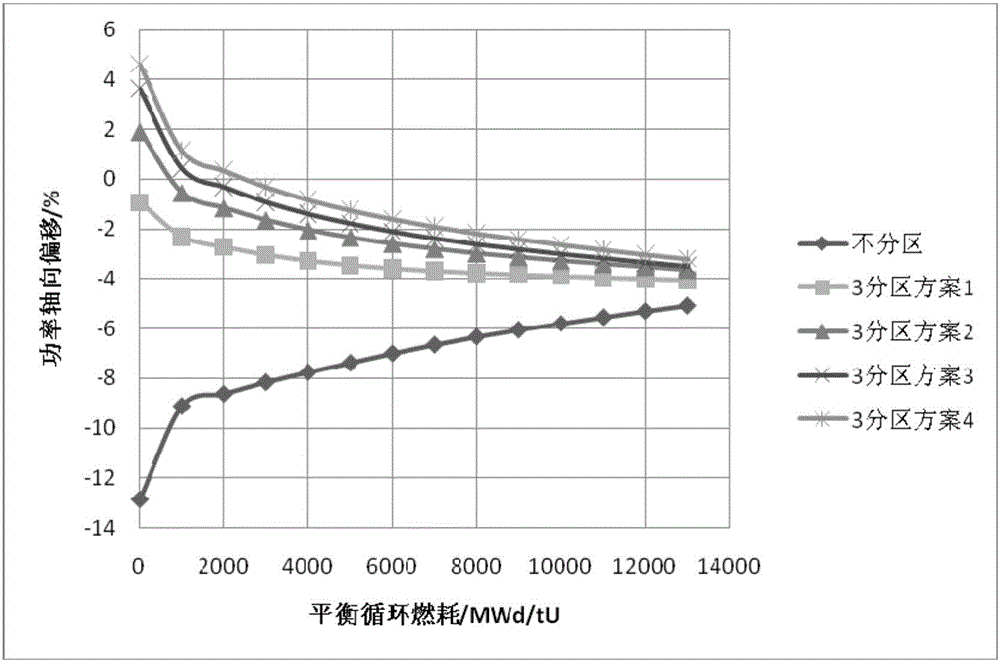

[0016] The MOX fuel assembly loading method provided by the present invention divides the MOX fuel assembly axially into multiple partitions, and the content of Pu in each partition is different. The principle of zoning is to arrange the axial power distribution diagram of the core at the beginning of life according to the axial non-zoning arrangement of components, as shown in figure 1 As shown, from the axial power distribution, it can be seen that the downward power shift is very serious, so it is necessary to increase the content of fuel pellets Pu in the upper part of the assembly and reduce the content of fuel pellets Pu in the lower part of the assembly to increase the upper part of the core. To reduce the power axial offset, but at the same time, it is necessary to avoid the resulting positive axial power offset at the beginning of the fuel cy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com