Stretchable multi-mode sensor based on nanofiber core spun yarn and preparation method thereof

A nanofiber and composite nanofiber technology, applied in fiber processing, ultrasonic/acoustic fiber processing, yarn, etc., can solve the problems of inability to apply flexible wearable sensors and small flexible detectable range, and achieve large deformation space and reversibility , The production process is simple and easy to operate, and the effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

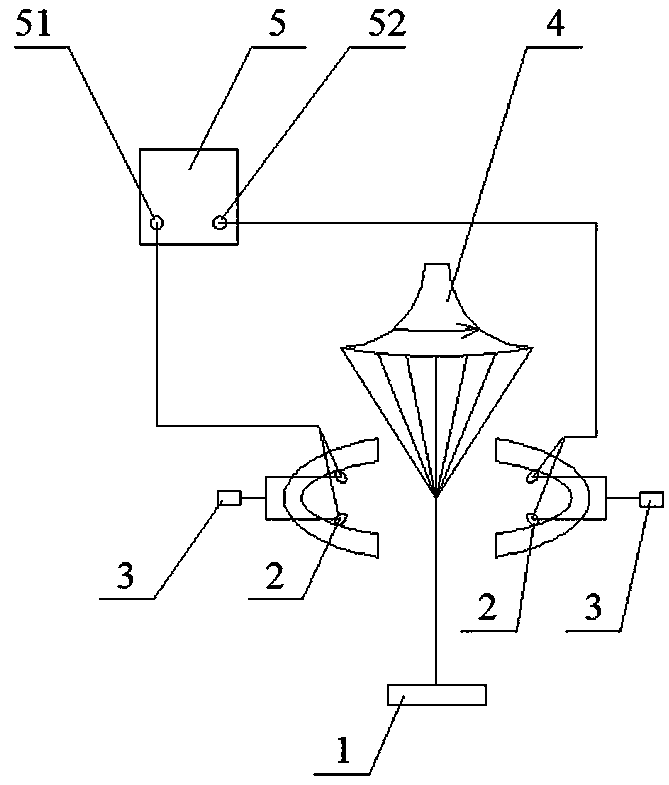

Method used

Image

Examples

Embodiment 1

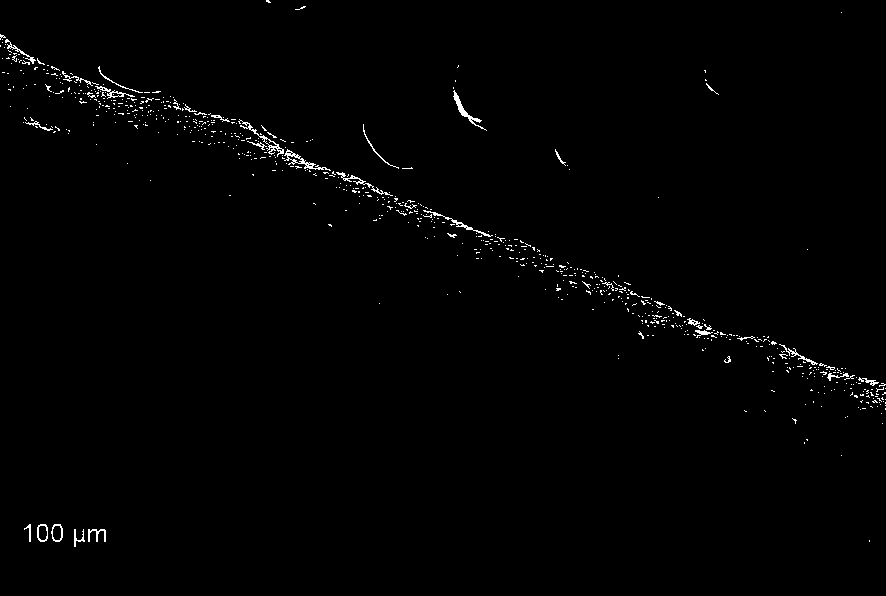

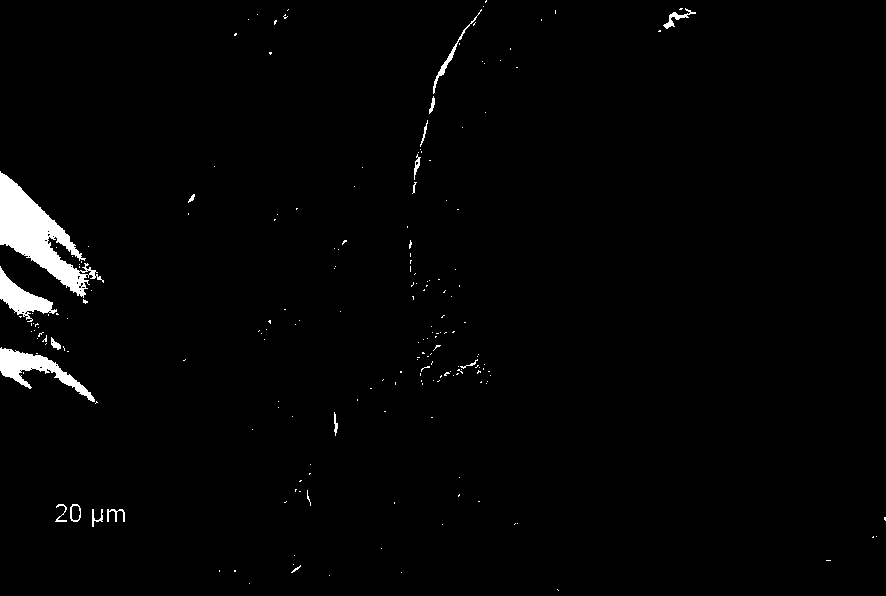

[0035] A preparation method of a flexible and stretchable multi-mode sensor based on nanofiber core-spun yarn, including the following steps: (1) Put the elastic core yarn into the lower electrode of a low-temperature plasma processor for central processing, oxygen is the working gas, and the system The pressure was kept at 30 Pa, the discharge power was 60W, and the treatment time was 45 min to obtain plasma-modified elastic core yarn;

[0036] (2) Add the carbon nanotube powder into the dimethylformamide solvent, and perform strong ultrasonic treatment under the condition of normal temperature and sealing to obtain a uniformly dispersed carbon nanotube (CNT) solution; then add high-elastic polyurethane particles, and heat Magnetic stirring 8h obtains uniform carbon nanotube / polymer conductive solution; The molecular weight of described highly elastic polyurethane particle is 200000; The mass concentration of described carbon nanotube / polymer conductive solution is 9%, carbon ...

Embodiment 2

[0043] A preparation method of a flexible and stretchable multi-mode sensor based on nanofiber core-spun yarn, including the following steps: (1) Put the elastic core yarn into the lower electrode of a low-temperature plasma processor for central processing, oxygen is the working gas, and the system The pressure was maintained at 60 Pa, the discharge power was 80 W, and the treatment time was 30 minutes to obtain plasma-modified elastic core yarn;

[0044] (2) Add the carbon nanotube powder into the toluene solvent, and carry out strong ultrasonic treatment under the condition of room temperature and sealing to obtain a uniformly dispersed carbon nanotube (CNT) solution; then add the Parafilm film, stir magnetically at 70 °C for 6 h to obtain a uniform The carbon nanotube / Parafilm conductive solution; The model of the Parafilm film is PM992; The mass concentration of the CNT / Parafilm solution is 11%, and the mass ratio of the carbon nanotube (CNT) and the Parafilm film is 1:5; ...

Embodiment 3

[0050] A method for preparing a flexible and stretchable multi-mode sensor based on nanofiber core-spun yarn, comprising the following steps: (1) Put the elastic core yarn into the center of the lower electrode of a low-temperature plasma processor, oxygen is the working gas, and the system pressure is Maintain 100Pa, discharge power is 120 W, and treatment time is 20 min to obtain plasma-modified elastic core yarn;

[0051] (2) Add the carbon nanotube powder into the toluene solution, and perform strong ultrasonic treatment under normal temperature and sealed conditions to obtain a uniformly dispersed carbon nanotube (CNT) solution; then add the Parafilm film and stir magnetically at 80 °C for 4 h to obtain a uniform CNT / Parafilm conductive solution. The model of the Parafilm film is PM992; the mass concentration of the CNT / Parafilm solution is 13%, and the mass ratio of carbon nanotubes (CNT) to the Parafilm film is 1:7;

[0052] (3) Evenly coat the CNT / Parafilm conductive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com