Tube connection device

A technology for connecting devices and pipelines, which is applied in the direction of sealing surface connection, pipe/pipe joint/pipe fitting, passing element, etc., which can solve the problems of hidden safety hazards, difficult welding operations, and narrow environment for pipeline connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

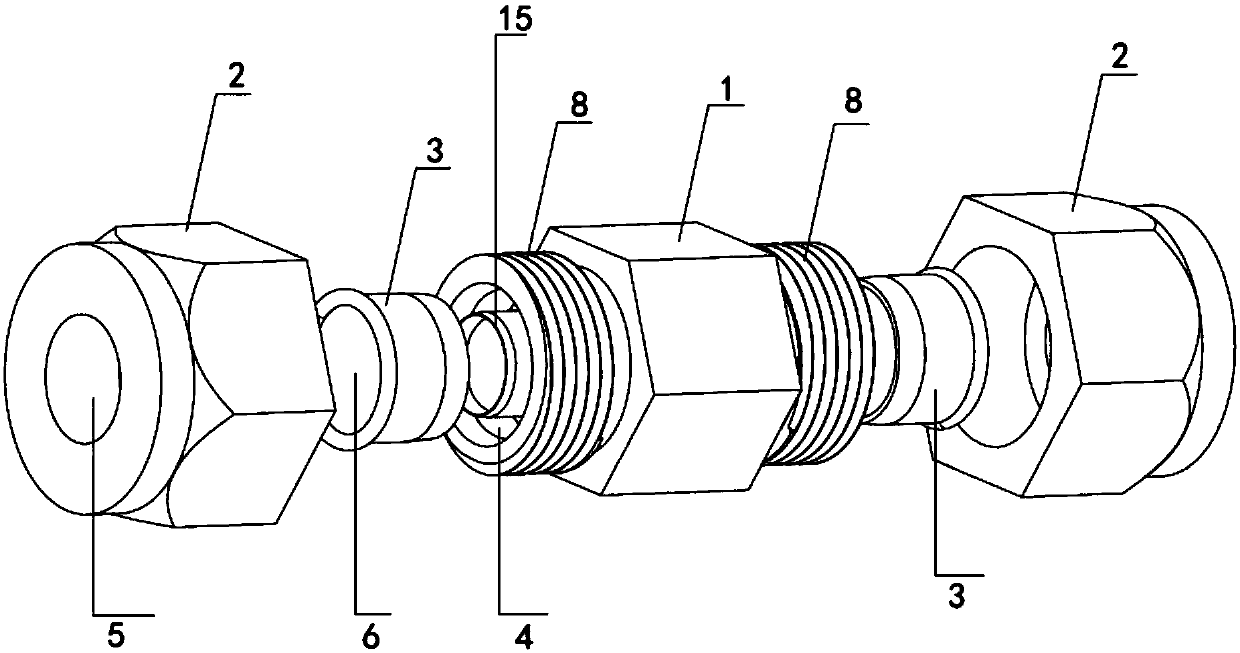

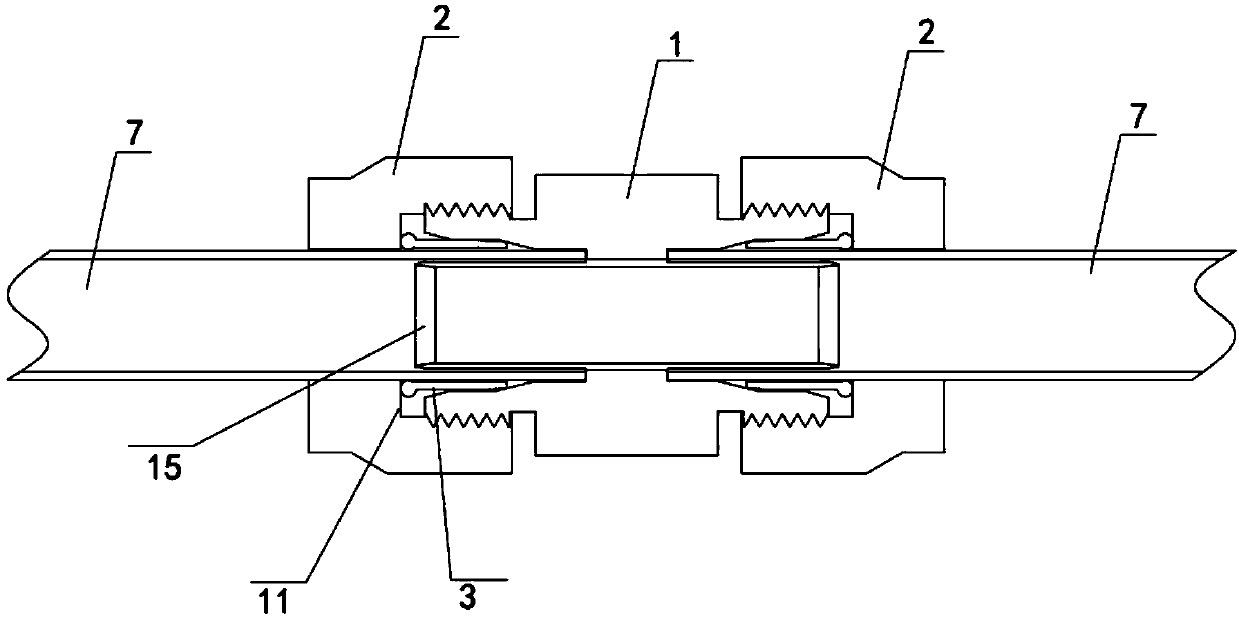

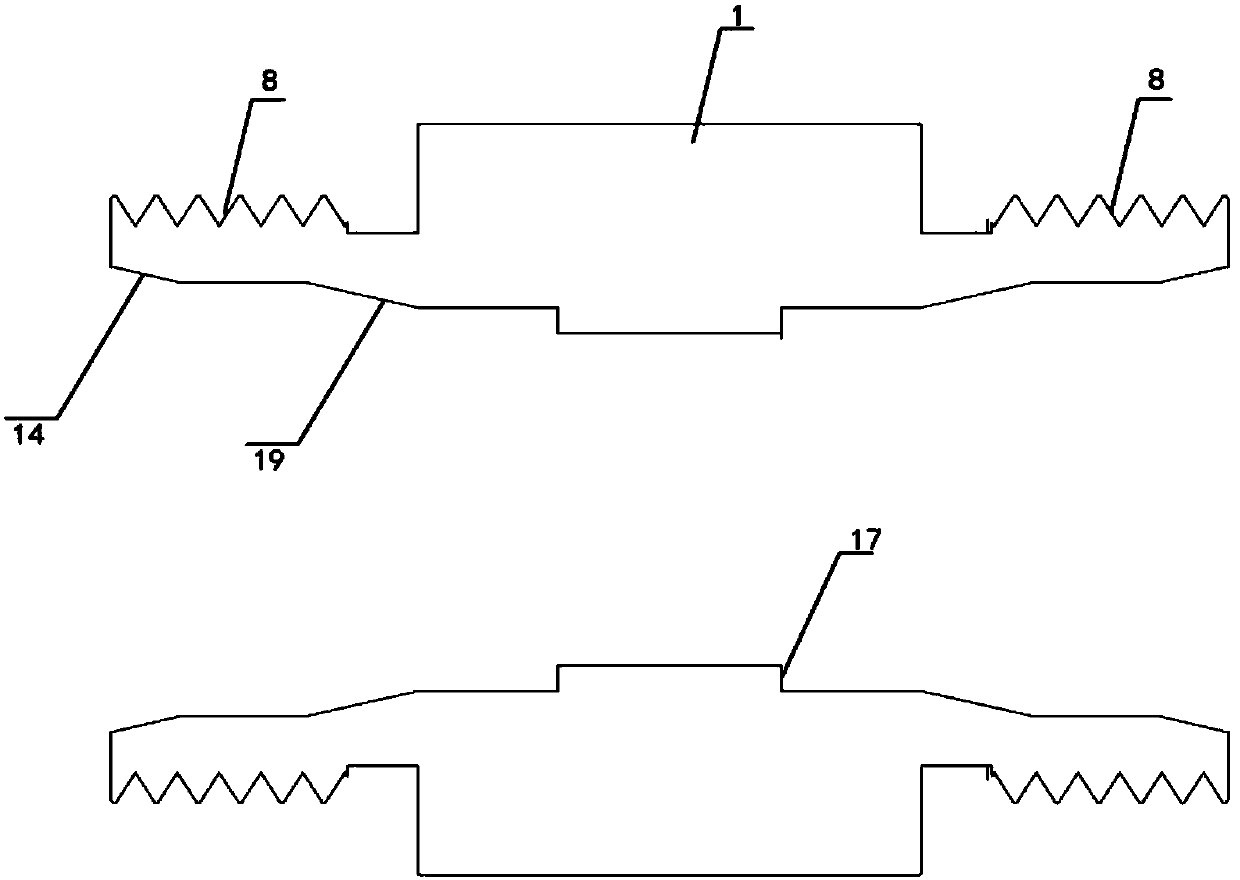

[0030] Figure 1 to Figure 6 A pipe connection according to two embodiments of the invention is shown schematically.

[0031] Such as Figure 1 to Figure 5 As shown, the pipeline connection device includes a ring body 1, a cap 2 and an outer bushing 3, the ring body 1, the cap 2 and the outer bushing 3 are all ring structures, the ring body 1 is provided with a first opening 4, and the cap 2 is provided with a second opening 5, and the outer bushing 3 is provided with a third opening 6. The axes of the first opening 4, the second opening 5 and the third opening 6 correspond to each other, and the outer bushing 3 is arranged on the ring body 1. In the first opening 4, the cap 2 is sleeved on the outside of the ring body 1, and the pipeline 7 to be connected can be inserted into the ring body 1 through the second opening 5, the third opening 6 and the first o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com