Cavity type prevention device for tunnel bottom deformation of ballastless track, and construction method

A technology of ballastless track and construction method, which is applied in the direction of tunnels, shaft equipment, earthwork drilling and mining, etc. It can solve the problems that the smoothness of the line cannot be guaranteed, and achieve the effects of saving renovation and maintenance costs, ensuring safety, and reasonable tunnel design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

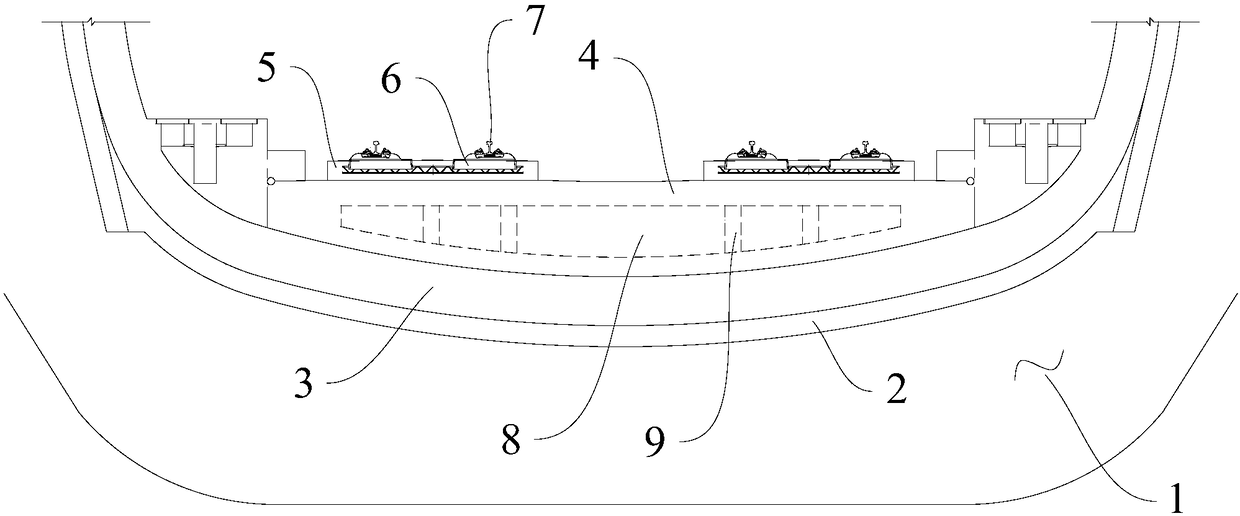

[0031] Such as figure 1 As shown, the bottom part of the ballastless track tunnel mainly includes the tunnel bottom surrounding rock 1, on which the primary support 2, the secondary lining 3, and the inverted arch filling layer 4 are successively arranged above the tunnel bottom surrounding rock 1. A track bed slab 5 is laid on the arch filling layer 4 , a sleeper 6 is arranged on the track bed slab 5 , and a ballastless track 7 is installed on the sleeper 6 .

[0032] A cavity-type preventive device for ballastless track tunnel bottom deformation, including a cavity 8 provided in an inverted arch filling layer 4, and several columns 9 are provided inside the cavity 8, The column 9 is a concrete structure, and the column 9 and the cavity 8 are integrally poured into a molding structure

[0033] Several hollow chambers 8 are evenly arranged along the longitudinal direction of the tunnel, and each hollow chamber 8 is arranged symmetrically with respect to the longitudinal axis ...

Embodiment 2

[0036] Such as figure 1 As shown, a construction method for a cavity-type preventive device for ballastless track tunnel bottom deformation, including any one of the above-mentioned cavity-type preventive device for ballastless track tunnel bottom deformation, its construction method is :

[0037] Step 1: Binding the reinforcement cage of the inverted arch filling layer 4;

[0038] Step 2: arranging several inner formworks in the inverted arch filling layer 4 along the longitudinal direction of the tunnel, so that all the inner formworks form the required cavities 8 of several closed areas;

[0039] Step 3: Pouring the inverted arch filling layer 4 to form the inverted arch filling layer 4 with a cavity 8 .

[0040] Wherein, in the closed area in the step 2, a columnar-shaped reinforcement cage is also bound inside, and a columnar-shaped formwork is arranged outside the columnar-shaped reinforcement cage to form the column 9, the column 9, the cavity 8 and the upper column. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com