Self-resetting steel structure beam-column aseismatic joint based on shape memory alloy ring spring set

A memory alloy and steel structure technology, applied in the direction of earthquake resistance, building components, building structures, etc., can solve the problems of difficult pre-tightening force, material residue, inapplicability, etc., and achieve the effect of simplified structure, convenient installation, and avoiding residual deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

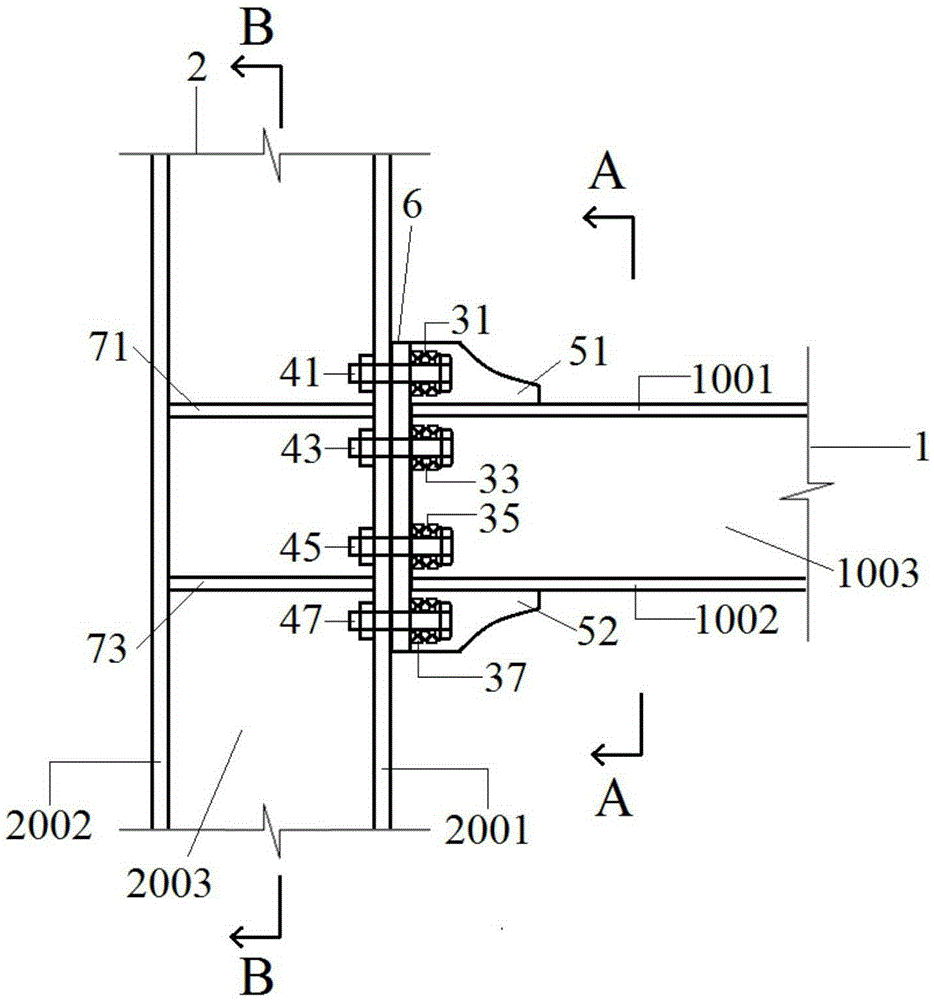

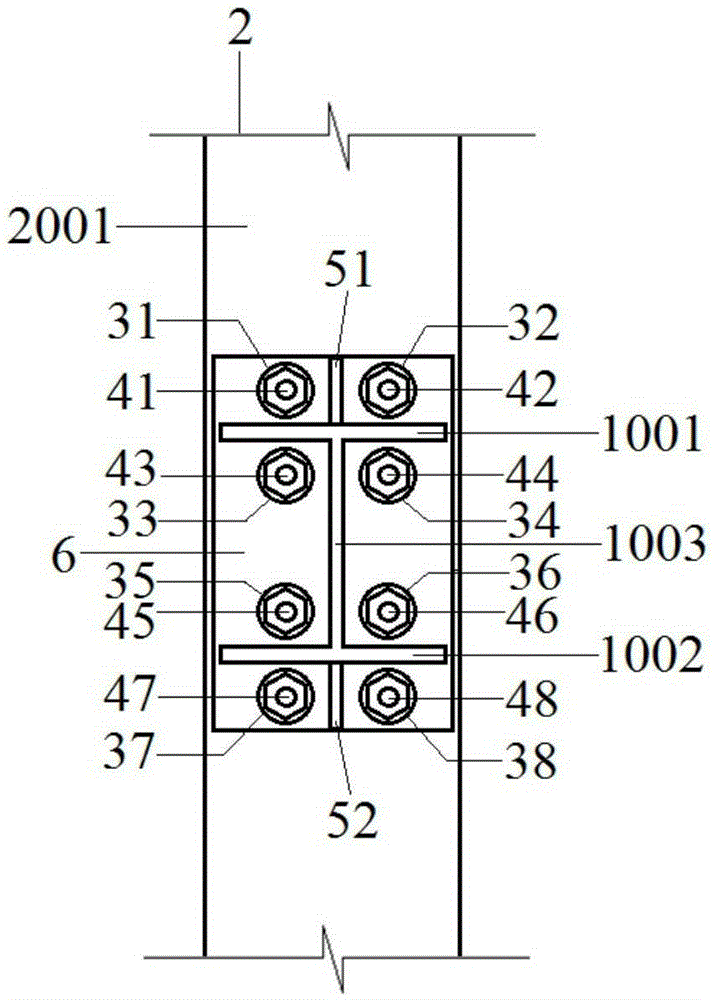

[0038]A self-resetting steel structure beam-column anti-seismic node based on a shape memory alloy ring spring group includes an I-shaped steel beam-column and a node domain used to connect the I-shaped steel beam-column. Such as figure 1 as shown, figure 1 It is a side view of the self-resetting steel structure beam-column anti-seismic node based on the shape memory alloy ring spring group according to the embodiment of the present invention.

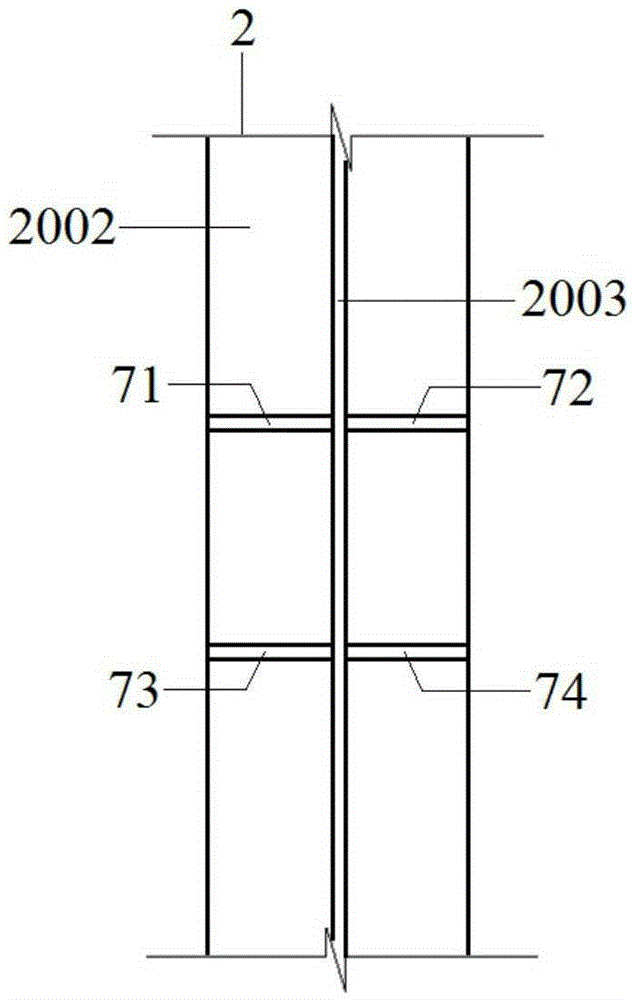

[0039] The I-shaped steel beam and column include the I-shaped steel beam 1 and the I-shaped steel column 2. The beam end of the I-shaped steel beam 1 is closely attached to the front flange 2001 of the I-shaped steel column through the end plate 6, so that it is perpendicular to the I-shaped steel column 2 place. I-shaped steel beam 1 is divided into I-shaped steel beam upper flange 1001, I-shaped steel beam lower flange 1002 and I-shaped steel beam web 1003 according to the internal space position, wherein: said I-shaped steel beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com