Solid-liquid four-phase horizontal spiral centrifuge

A decanter centrifuge and distance technology, applied in centrifuges, centrifuges with rotating drums, etc., can solve the problems of increasing production costs and inconvenient operation, saving production and use costs, convenient operation, and improving products. The effect of quality and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

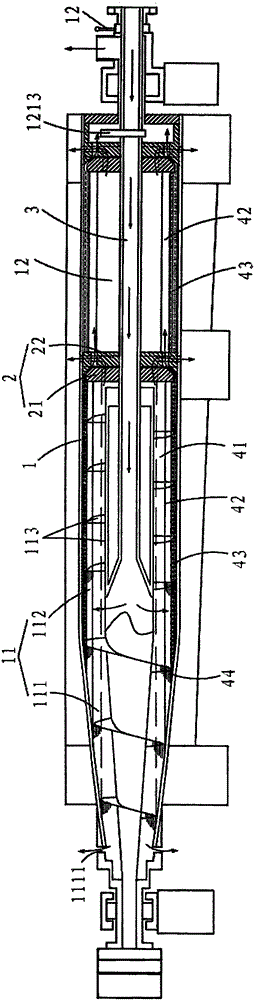

[0027] A solid-liquid four-phase decanter centrifuge includes a drum and a separation plate.

[0028] The drum 1 includes a first separation chamber 11 and a second separation chamber 12 , the first separation chamber 11 includes a conical section 111 and a straight section 112 , and the end of the conical section 111 has a slag outlet 1111 . A screw conveyor 113 is provided inside the first separation chamber 11 . The end of the second separation chamber 12 is fixedly connected to the end cover 121, and the end cover 121 is provided with liquid outlet holes 122 at different distances from the axis along the radial direction.

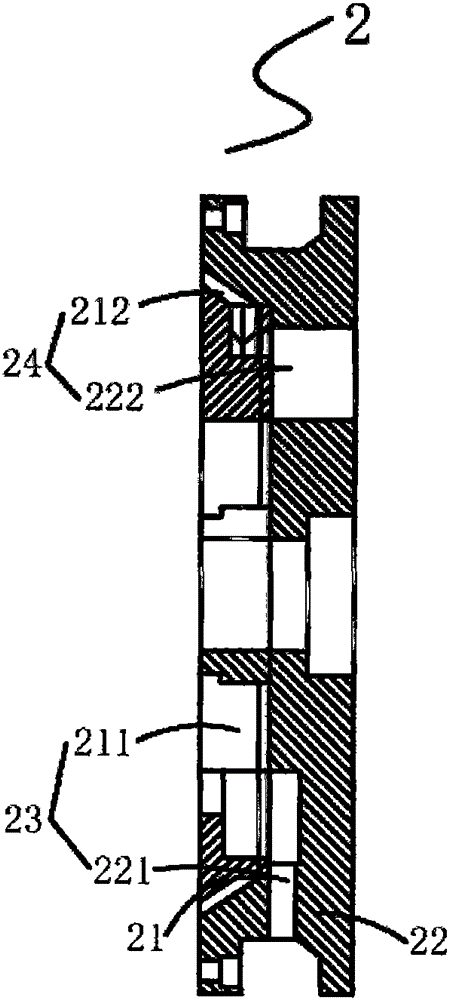

[0029] The separation plate 2 is arranged between the first separation chamber 11 and the second separation chamber 12 and sleeved on the feed pipe 3 . The separation plate 2 includes a gland 21 and a connecting plate 22 fixed on the gland 21 . The gland 21 is located in the first separation chamber 11 , and it is provided with 6 outer through holes 2...

Embodiment 2

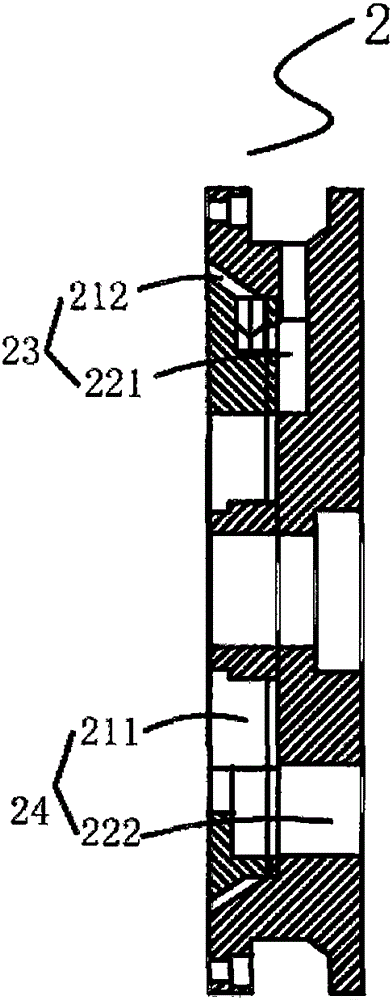

[0040] In this embodiment, the separation plate 2 is designed such that the communication hole 24 is close to the axis, and the overflow hole 23 is far away from the axis. That is to say, the gland 21 is located in the first separation chamber 11, and it is provided with 6 outer through-holes 211 near the axial center along the radial direction, and 6 inner through-holes 212 are arranged away from the axial center.

[0041] The outer through hole 221 of the connecting plate 22 is designed to be away from the axis, and the inner through hole 222 is close to the axis. The left end of the outer through hole 221 is connected with the inner through hole 212 on the gland 21 and the right end communicates with the inner wall of the drum 1, and the inner through hole 212 and the outer through hole 221 are connected to connect the first separation chamber 11 and the outer wall of the drum 1 Connected overflow hole 23. Compared with the first embodiment, the diameter of the inner through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com