Center pillar assembly of sedan

A column and assembly technology, applied in the direction of upper structure sub-assembly, vehicle parts, upper structure, etc., can solve the problems of limited cavity, inability to effectively absorb energy, breaking and deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

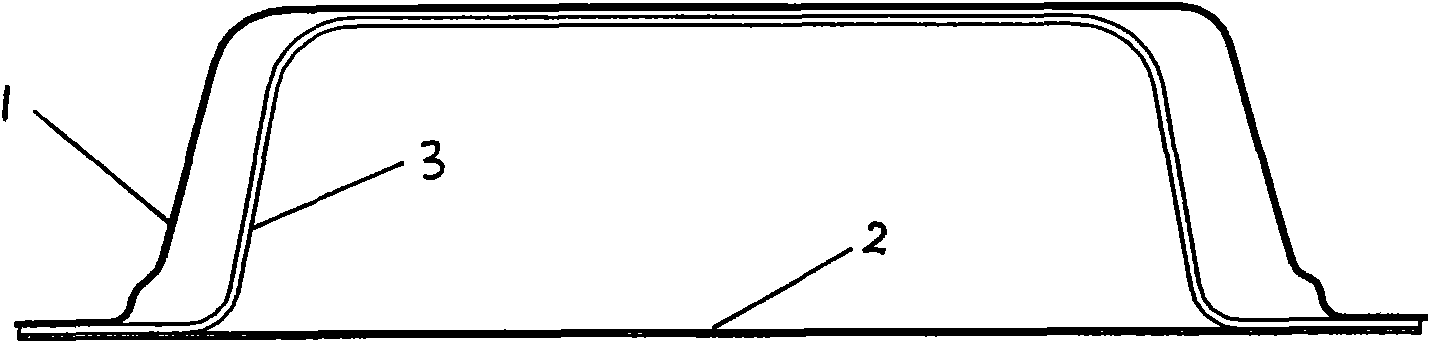

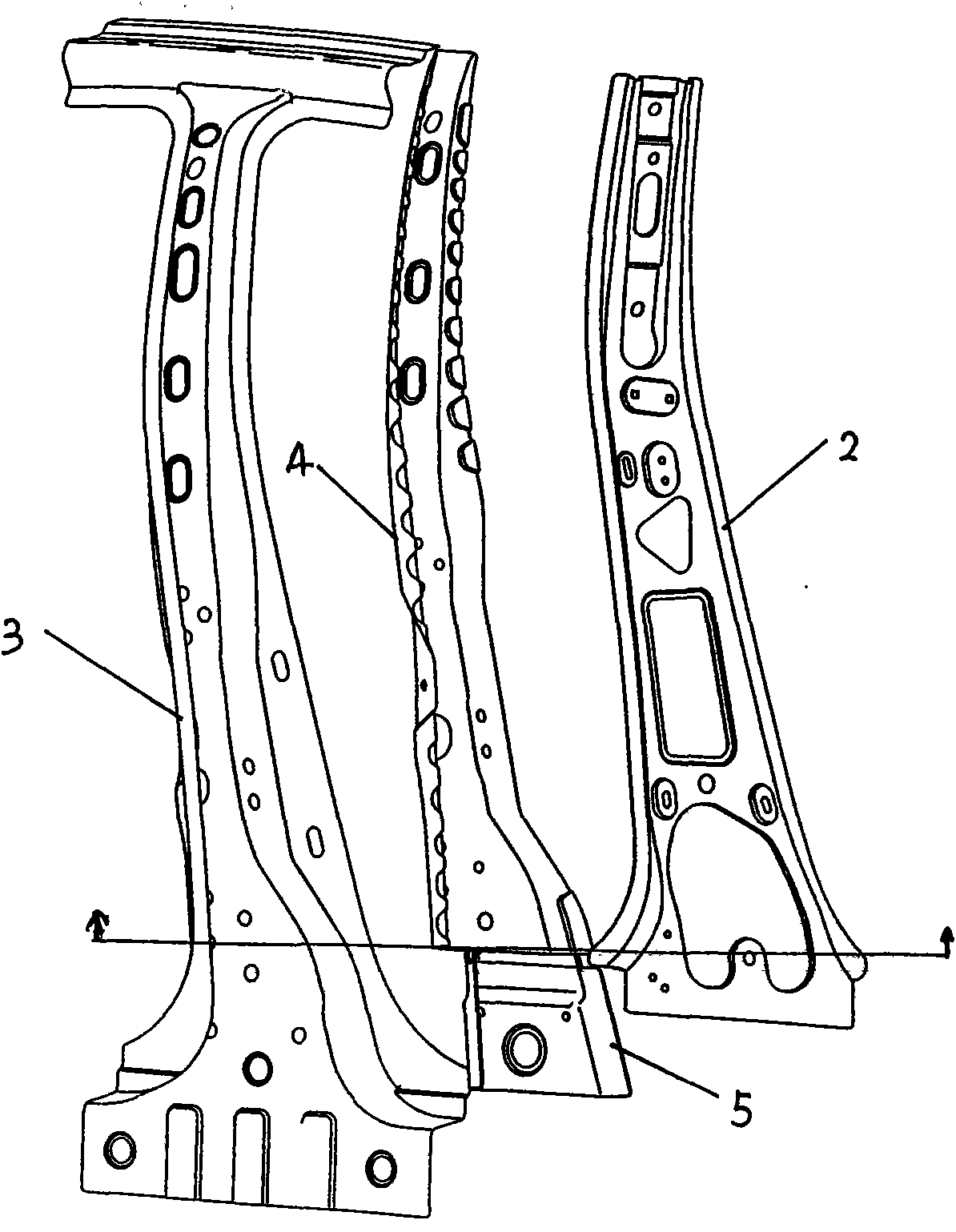

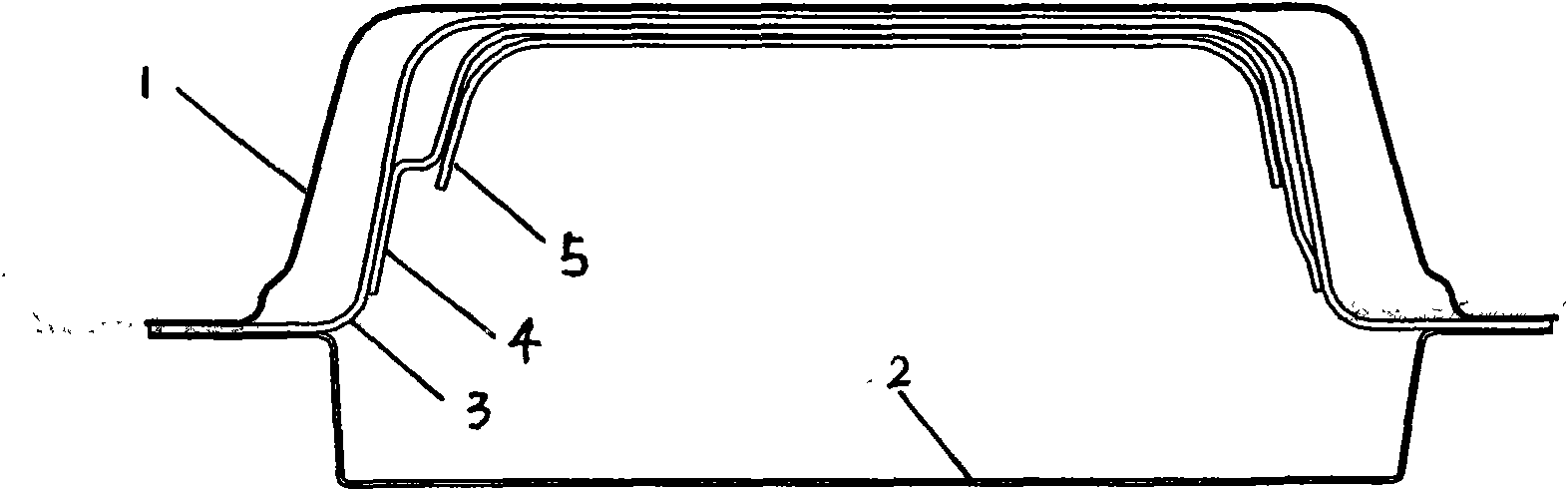

[0011] see figure 2 and image 3 , The center pillar assembly of the car includes a side wall outer skin 1, a center pillar inner skin 2, a center pillar reinforcement 3, a center pillar hinge installation reinforcement 4 and a center pillar lower reinforcement 5. The cross-sections of the side outer skin 1 and the central pillar reinforcement 3 are U-shaped structures in the same direction, and the side outer skin 1 covers the center pillar reinforcement 3 . The cross-section of the center pillar inner skin 2 is also U-shaped, and its direction is opposite to that of the center pillar reinforcement. It is butt-welded with the side wall outer skin 1 and the center pillar reinforcement 3, forming a nearly square shape between them. center pillar cavity. The inner side of the center pillar reinforcement 3 is welded with a hinge installation reinforcement 4 , and the cross section of the hinge installation reinforcement 4 is U-shaped in the same direction as the center pillar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com