Linear vibrating motor

A linear vibration and motor technology, applied in the field of motors, can solve the problems of not reducing the vibration amplitude and reducing the size of the motor, and achieve the effect of ensuring normal operation, low resistance and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

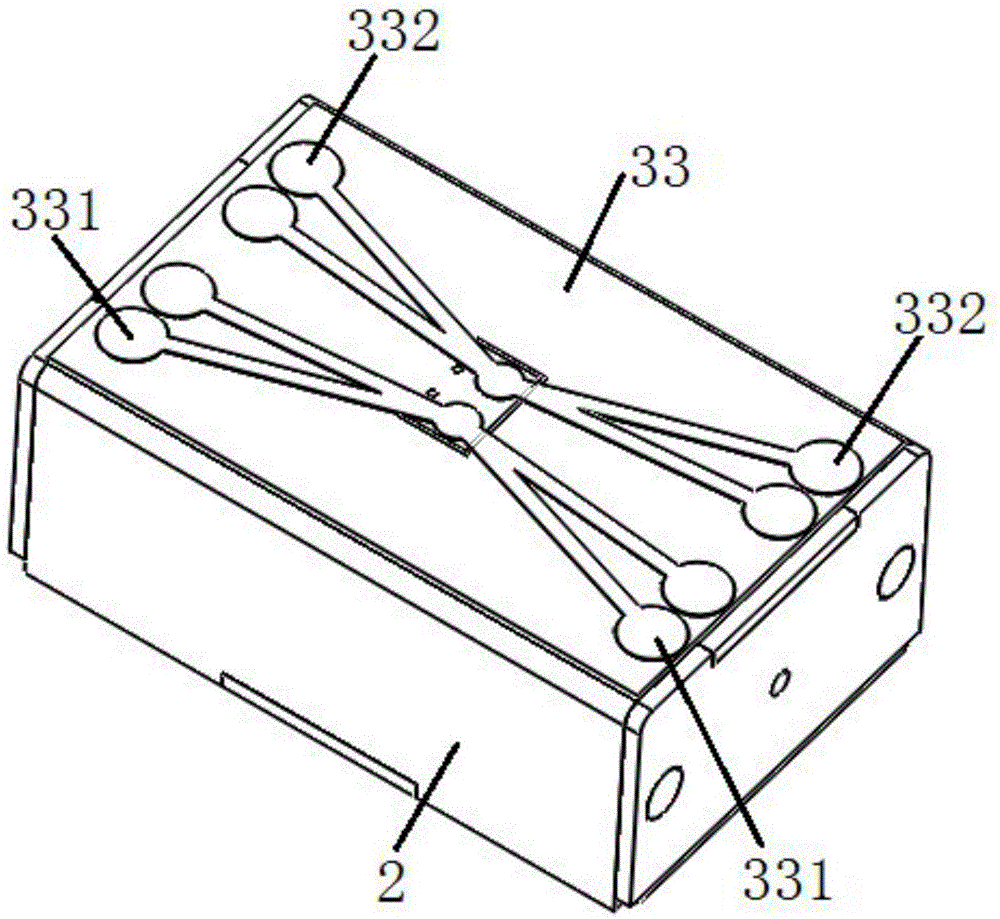

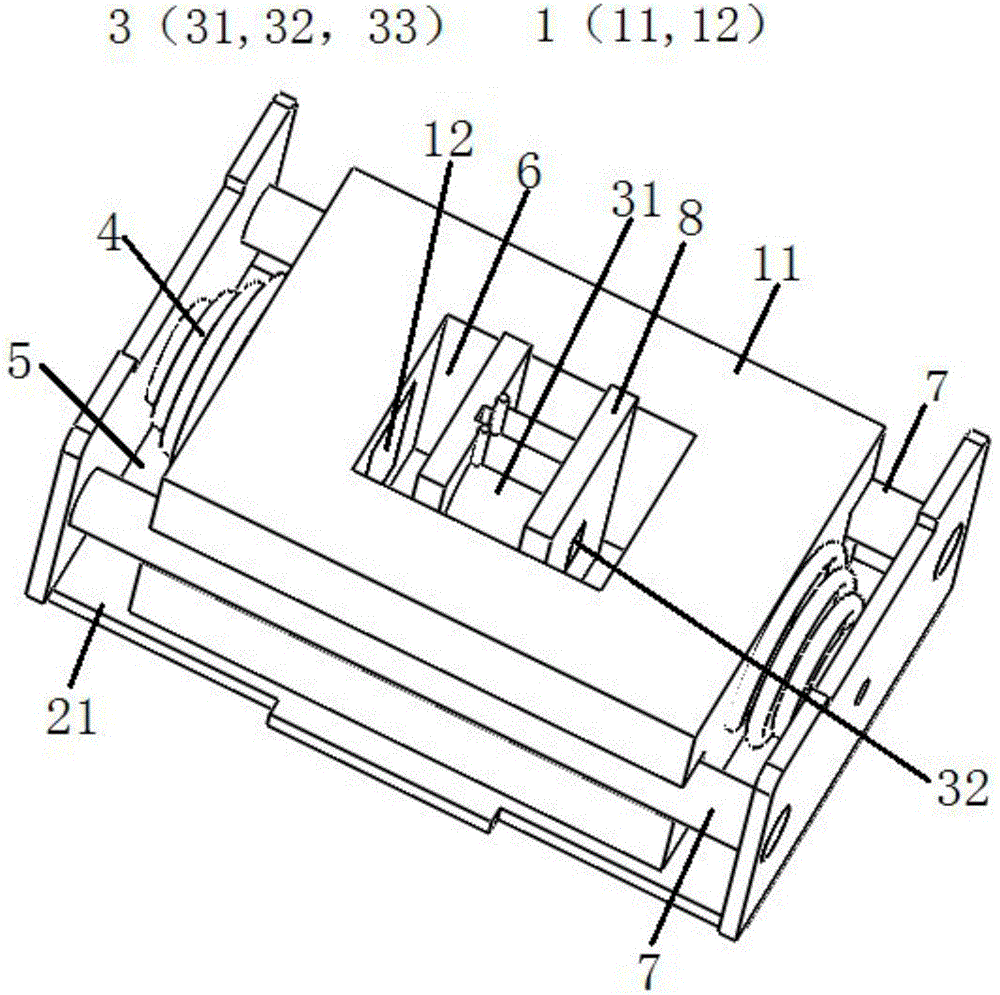

[0062] This embodiment provides a linear vibration motor, such as figure 1 with figure 2 As shown, it includes a housing 2 , a vibrating assembly 1 , a stator assembly 3 , two elastic components 4 , a guiding structure and a fixing mechanism 8 . Under the cooperation of the two elastic components 4 and the stator assembly 3 , the mass block 11 can be driven to make reciprocating linear motion along its length direction.

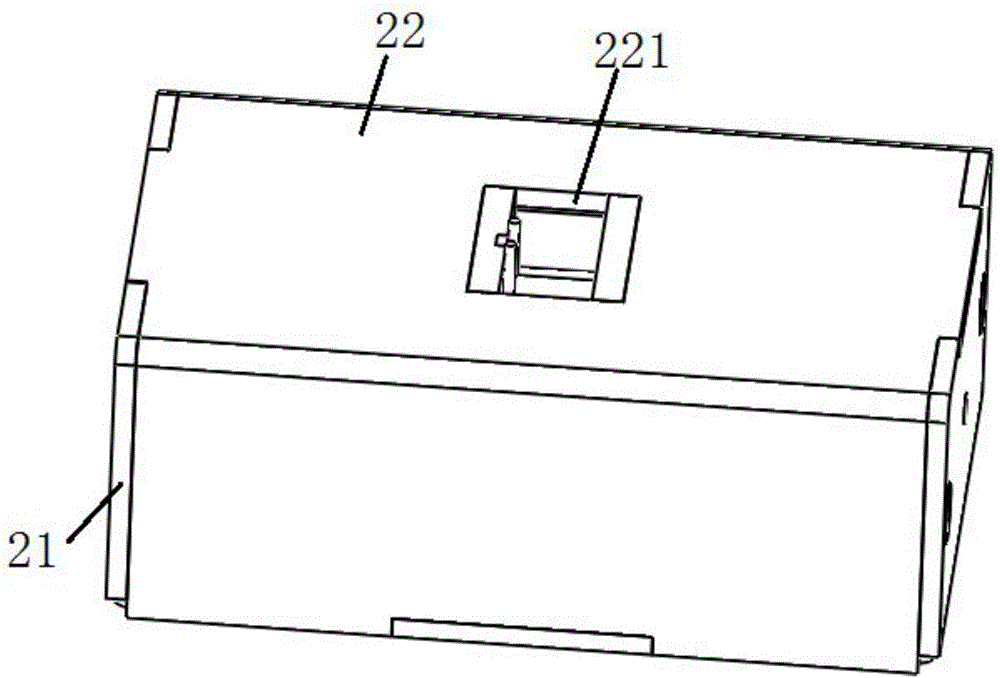

[0063] Such as image 3 with Figure 4 As shown, the housing 2 has an installation cavity, including a base 21 and an upper casing 22 mounted on the base 21, wherein the base 21 includes a bottom plate and a first vertical plate (such as Such as figure 1 The left and right side walls in the middle); the upper casing 22 includes a top plate and a second vertical plate (for example, which is fixed on the two side walls of the top plate and extends downward figure 1 The front and rear side walls in the middle), two second vertical plates are vertically ins...

Embodiment 2

[0087] This embodiment provides a linear vibration motor, such as Figure 9-Figure 12 As shown, the difference with the linear vibrating motor provided in Embodiment 1 is only:

[0088] Under the action of external force, the first part 41 and the transition section 43 of the elastic member 4 can be compressed toward the second part 42 and embedded in the second part 42; Extend and drive the mass 11 to move away from the second part 42 .

[0089] Such as Figure 10 , Figure 12 with Figure 13 As shown, the elastic member 4 is also preferably a tower spring, and the setting direction of the tower spring in Embodiment 1 is just opposite, the tower top of the tower spring is used as the first part 41, and the tower bottom is used as the second part 42, and the outer shell Two vertical limiting protrusions 212 are formed on the inner wall surface, the second part 42 of the tower spring is located between the two limiting protrusions 212 and abuts against the inner wall surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com