Plastic building templates and buckle connecting pieces

A connecting piece and buckle technology, which is applied in the connecting pieces of formwork/formwork/work frame, formwork/formwork components, construction, etc., can solve the problem of inconvenient connection and assembly of formwork, insufficient pressure resistance, and gaps in formwork connection parts. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

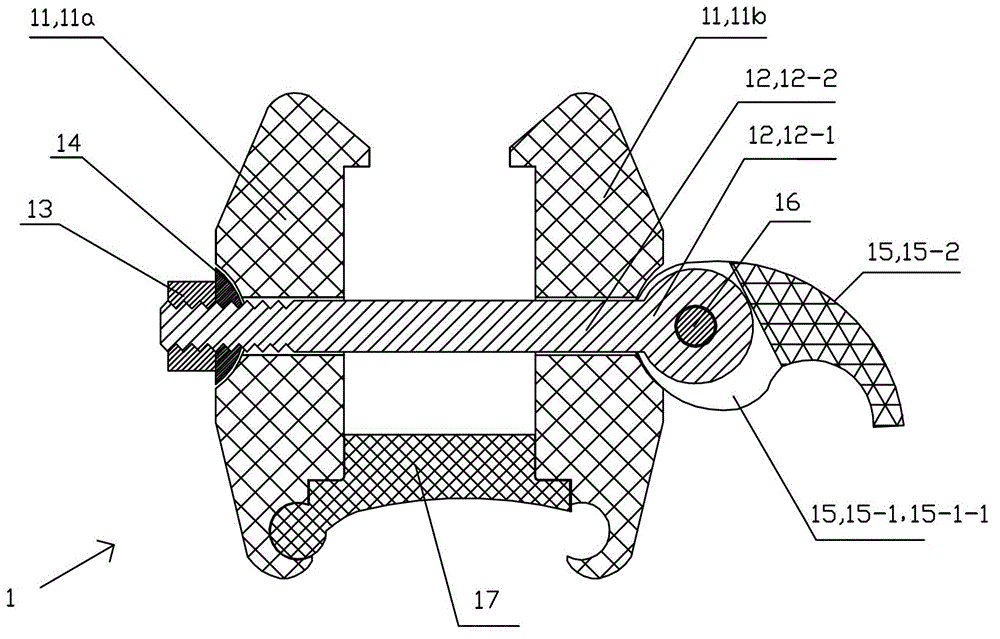

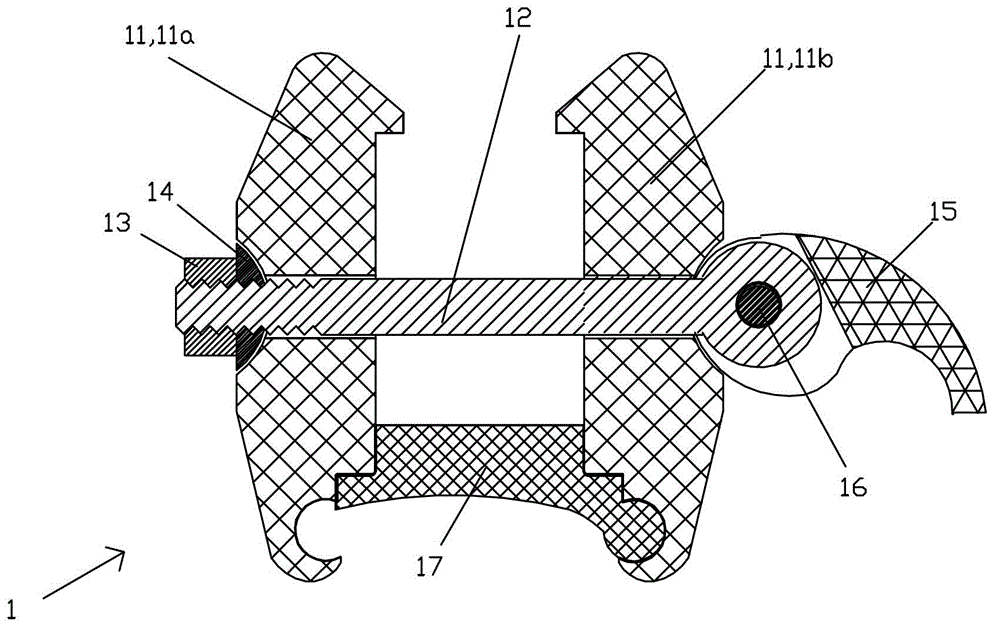

[0114] (Example 1, snap connector)

[0115] See Figure 2 to Figure 6 , the snap connector 1 of this embodiment includes a clamping plate 11 , an eye bolt 12 , a nut 13 , a washer 14 , an eccentric handle 15 , a pin 16 and a support plate 17 . Wherein there are two clamping plates 11, which are divided into a left clamping plate 11a and a right clamping plate 11b according to their left and right positions. The two clamping plates 11 have the same or substantially the same shape and are relatively arranged. In the following description, when referring to the clamping plate 11, the direction “inward” is the direction “right” for the left clamping plate 11a, and the direction “left” for the right clamping plate 11b; The direction "outward" is the direction "left" for the left clamping plate 11a, and the direction "right" for the right clamping plate 11b. Eccentric handle 15, support plate 17 and two clamping plates 11 are all injection-molded plastic integral parts, an...

Embodiment 2

[0130] (Example 2, plastic building formwork: single positive cantilever formwork)

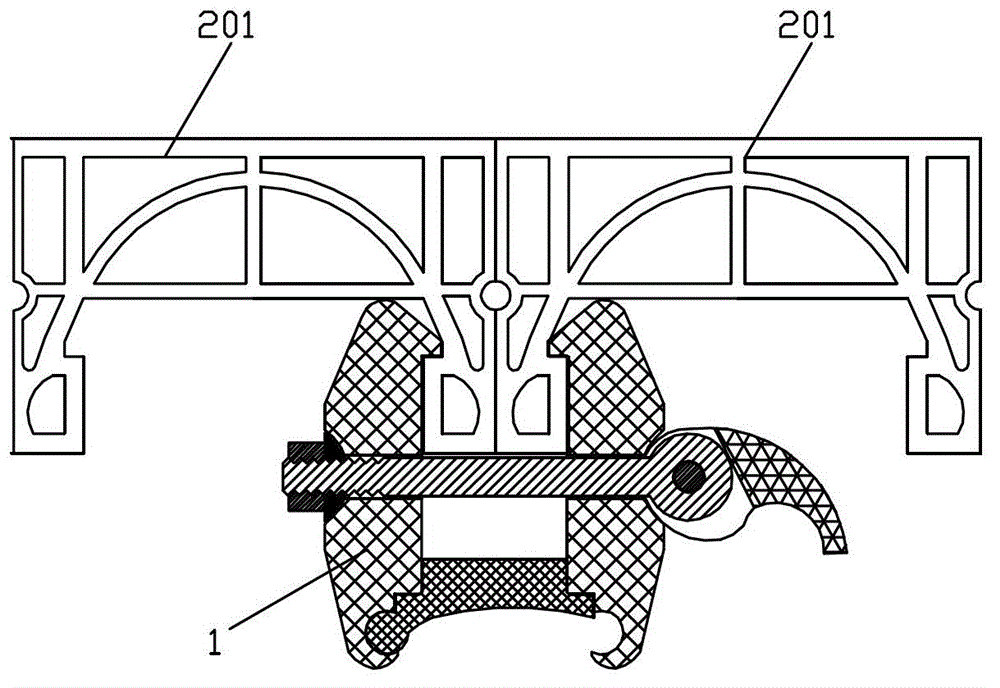

[0131] See Figure 7 , the plastic building formwork of this embodiment is a single positive cantilever formwork 201. The single cantilever formwork 201 is one of the series formworks of the cantilever structural formwork 2 . The single front cantilever formwork 201 is an extruded integral part, which is a frame-shaped plastic member obtained by melting polyvinyl chloride plastic pellets and extruding through corresponding molds. The single positive cantilever formwork 201 (that is, the first single arch unit) includes a front side horizontal plate 21-1, a middle horizontal plate 21-2, a left vertical plate 22-1, and a right vertical plate 22- 2. The longitudinal ribs 24, the arched ribs 25, the first slanting plate 26-1 and the second slanting plate 26-2, also include a left supporting foot 23-1 and a right supporting foot 23-2. The left supporting foot 23-1 and the right supporting foot 2...

Embodiment 3

[0147] (Example 3, plastic building formwork: double cantilever formwork)

[0148] See Figure 12-1 , the plastic construction formwork of this embodiment is a double positive cantilever formwork 202. The double front cantilever formwork 202 is one of the series formworks of the cantilever beam structural formwork 2 . The double front cantilever formwork 202 is an extruded integral part, which is a frame-shaped plastic member obtained by melting polyvinyl chloride plastic pellets and extruding through corresponding molds. In terms of shape, the double front cantilever formwork 202 is composed of one basic unit repeated once in the left and right direction; this basic unit is called the first single arch unit, and its shape is the same as the single The shape of the cantilever beam formwork 201 is the same; that is, the double cantilever beam formwork 202 is formed by connecting the right side of the first single arch unit on the left side and the left side of the first singl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com