B-pillar lower hinge reinforcing plate assembly

A hinge reinforcement plate and reinforcement plate technology, which is applied in the direction of hinge plates, wing leaf parts, vehicle parts, etc., can solve the problems of unfavorable deformation, reduced strength of welding parts, and small deformation space of B-pillar in Z direction, etc., so as to facilitate stamping Effects of formability, cross-sectional size reduction, and manufacturing cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

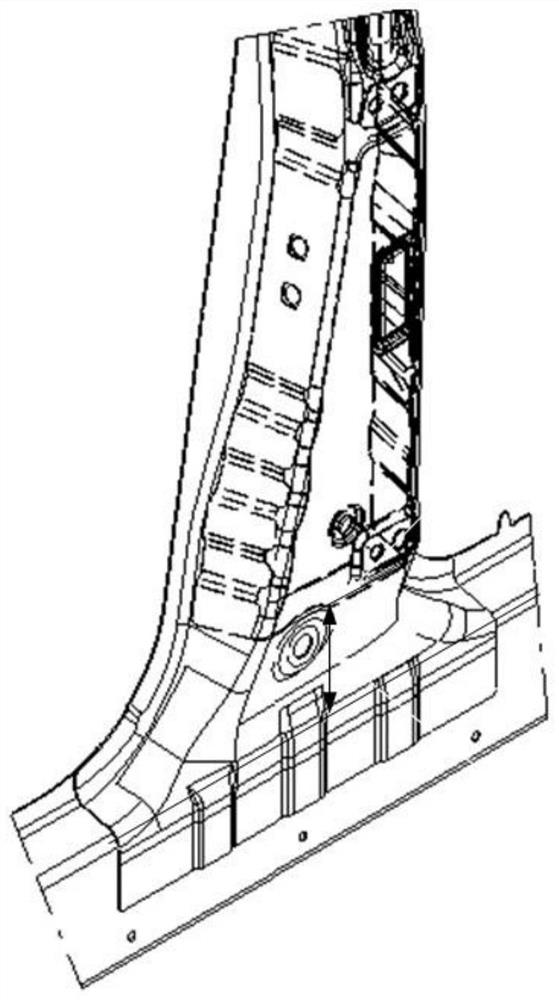

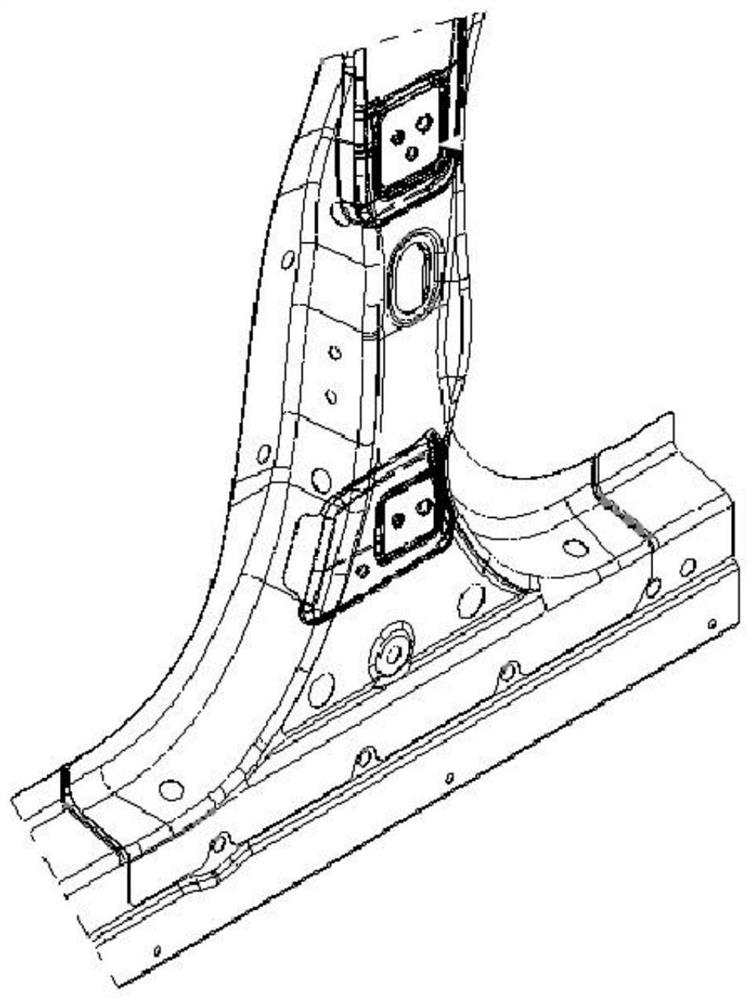

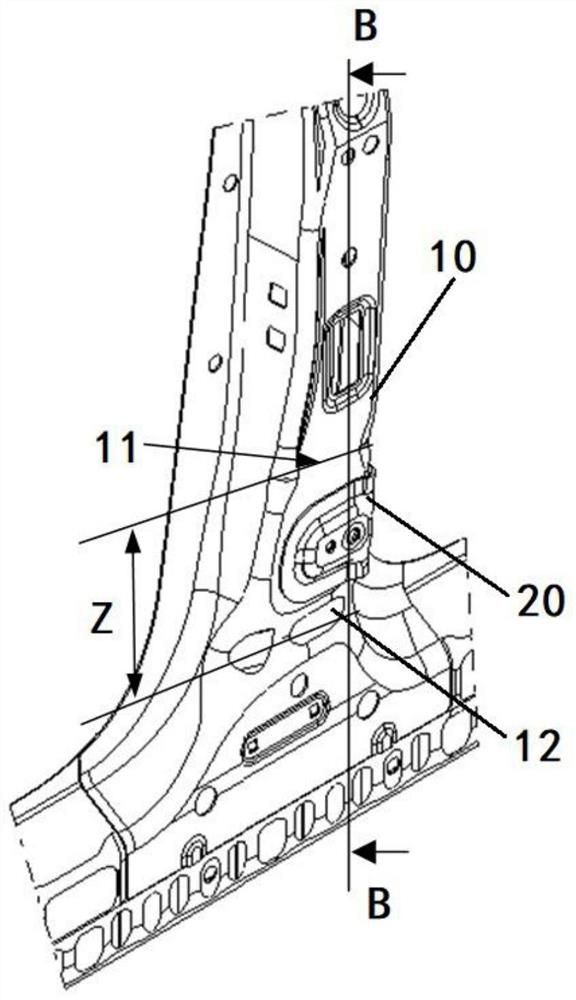

[0024] People have higher and higher requirements for automobile safety. With the development of automobile materials, the proportion of thermoformed steel plates in automobiles is increasing. In order to improve the collision safety, most of the B-pillar reinforcement plates of newly developed models are made of heat Formed steel plate, when the side of the vehicle is hit, deforms the B-pillar according to the tendency to protect the occupants and reduce the acceleration during the collision. The area above the upper hinge of the B-pillar corresponds to the chest and head of the human body. There should be no deformations that would cause fatal damage to the human body, such as failure, bending, or excessive intrusion into the cockpit space. The area of the lower hinge of the B-pillar corresponds to the buttocks and seat of the human body. The skeleton of the chair is bent and deformed at this part, which absorbs part of the kinetic energy of the collision and reduces the pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com