Alfa and Beta type titanium alloy sheet with excellent cold rolling properties and cold handling properties, and production method therefor

一种处理性、冷轧性的技术,应用在α+β型钛合金板及其制造领域,能够解决减小冷轧变形阻力等问题,达到变形阻力小、高板厚减少率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0127] Next, examples of the present invention will be described, but the conditions in the examples are examples of conditions adopted for confirming the practicability and effects of the present invention, and the present invention is not limited to this example of conditions. In the present invention, various conditions can be adopted as long as the object of the present invention is achieved without departing from the gist of the present invention.

[0128]

[0129] A titanium material having the composition shown in Table 1 was melted by a vacuum arc melting method, hot forged to form a slab, heated to 940°C, and then passed through a slab thickness reduction rate of 97%. Hot-rolled to form a 3 mm hot-rolled sheet. The finishing temperature of hot rolling was 790°C.

[0130] The hot-rolled sheet was pickled to remove scale, and a tensile test piece was prepared to investigate the tensile properties, and X-ray diffraction (using RINT2500 manufactured by Rigaku Co., Ltd....

Embodiment 2

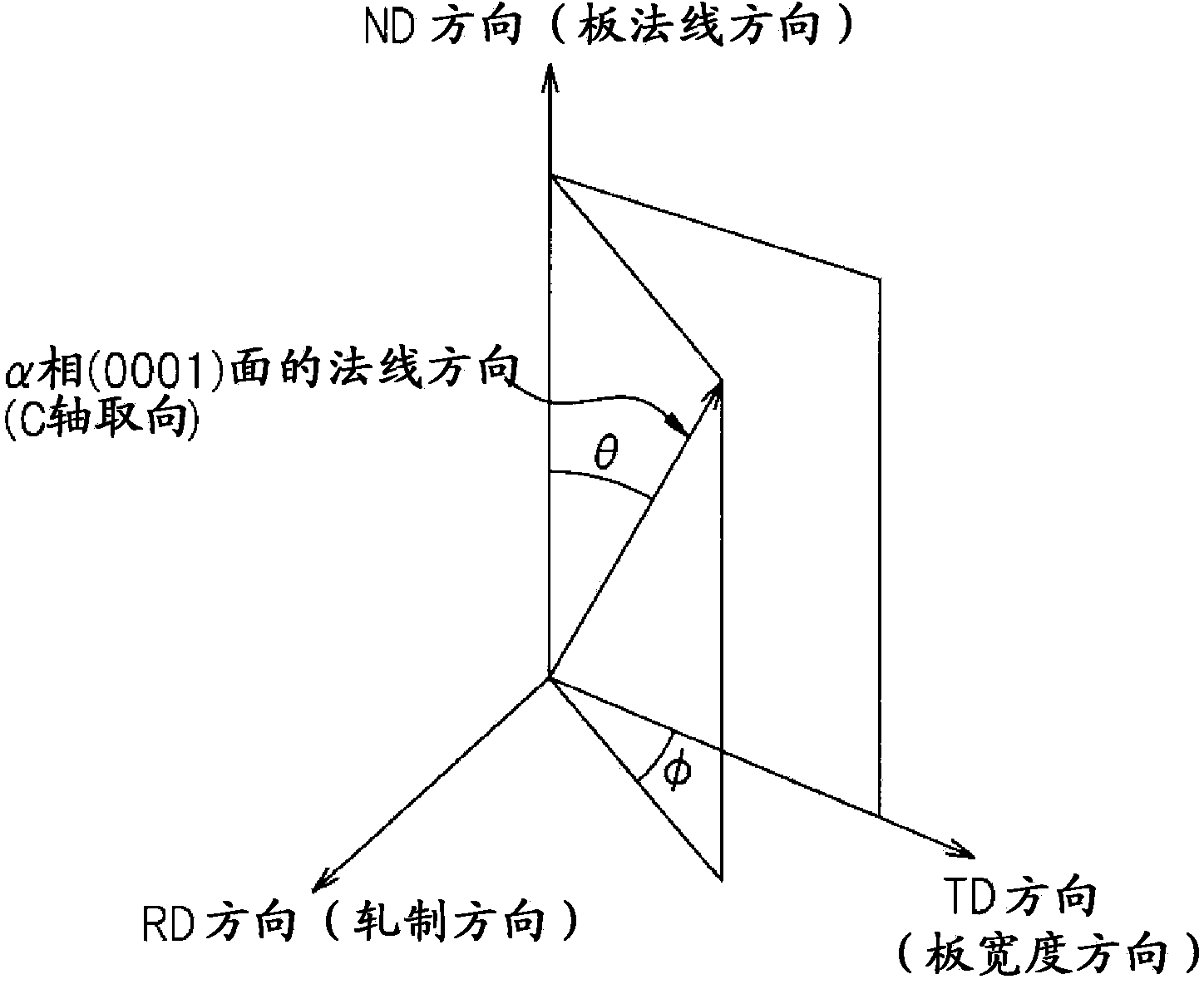

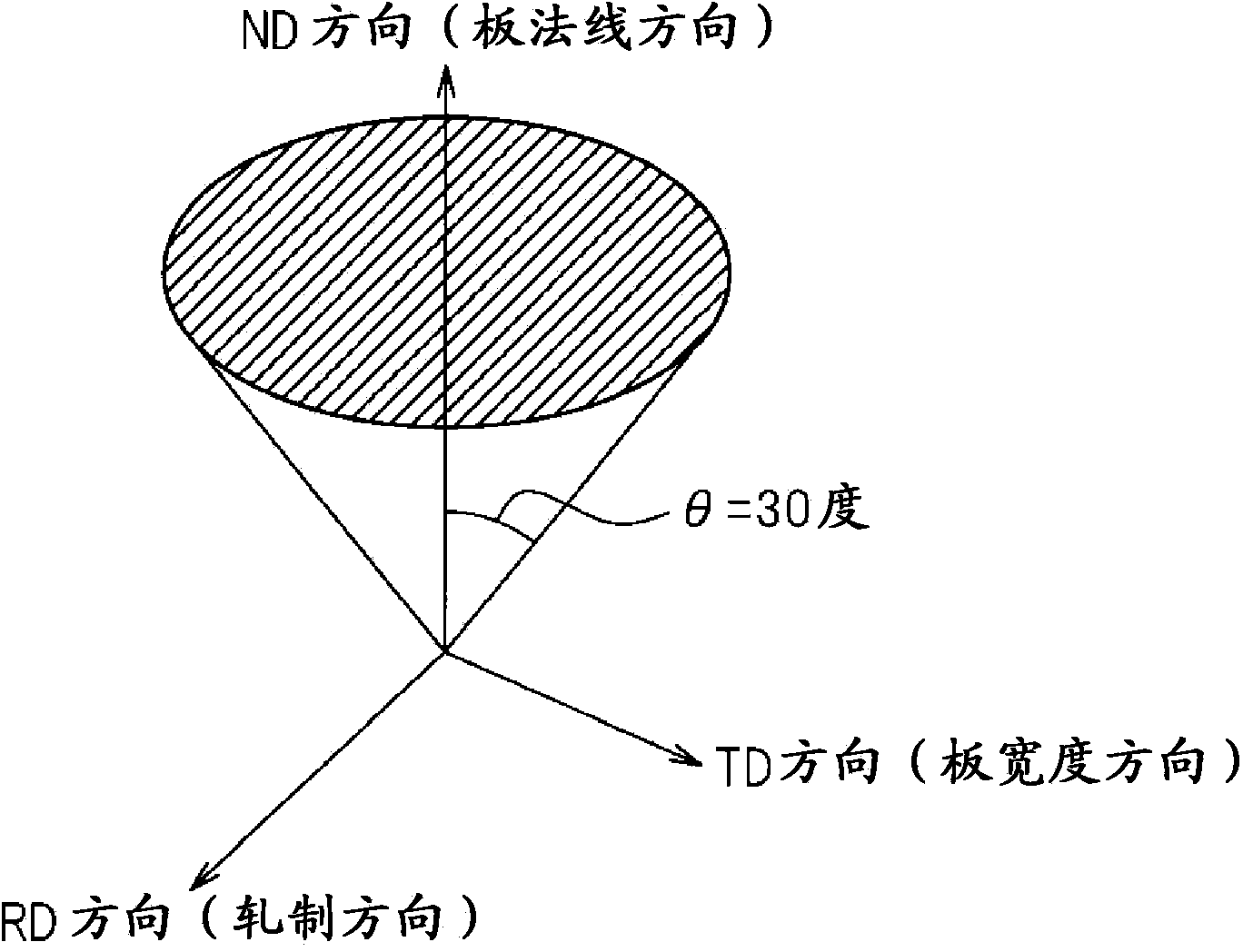

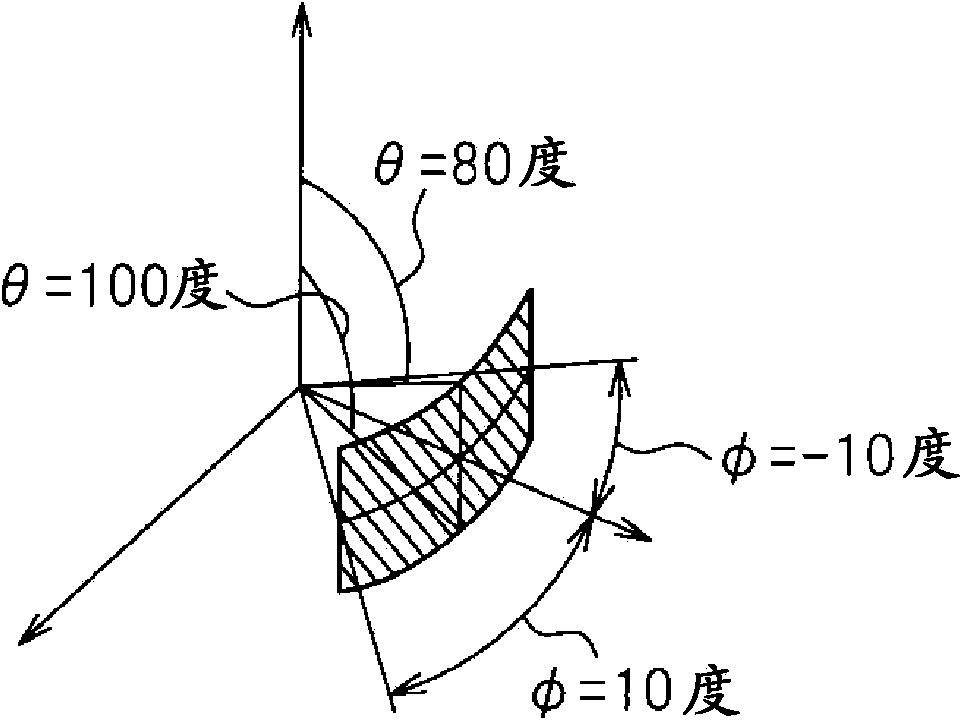

[0146] The billets of test numbers 4, 8, and 14 in Table 1 were hot-rolled under the various conditions shown in Tables 2 to 4, then pickled to remove scale, and then the tensile properties were investigated, and X-ray diffraction (Using RINT2500 manufactured by Rigaku Co., Ltd., Cu-Kα, the voltage is 40kV, the current is 300mA), and the (0002) pole diagram of titanium is tilted from the plate width direction to the normal direction within the orientation angle of 0 to 10° and Take the normal direction of the plate as the central axis and rotate the X-ray relative intensity peak within the orientation angle of ±10° from the width direction of the plate as XTD, and set the orientation inclined from the normal direction of the plate to the width direction of the plate to 0 to 30° When the X-ray relative intensity peaks within the angle and within the orientation angle rotated around the normal of the plate as the central axis are XND, their ratio: XTD / XND is used as the X-ray ani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com