Electromagnetic control device, in particular for adjusting camshafts of an internal combustion engine

A technology of adjusting device and camshaft, which is applied in the direction of electromagnet with armature, electromagnet, valve device, etc., can solve the problems of damage to the strength of the plunger, time-consuming, etc., and achieve the effects of simplified installation, cost-effectiveness, and simple manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

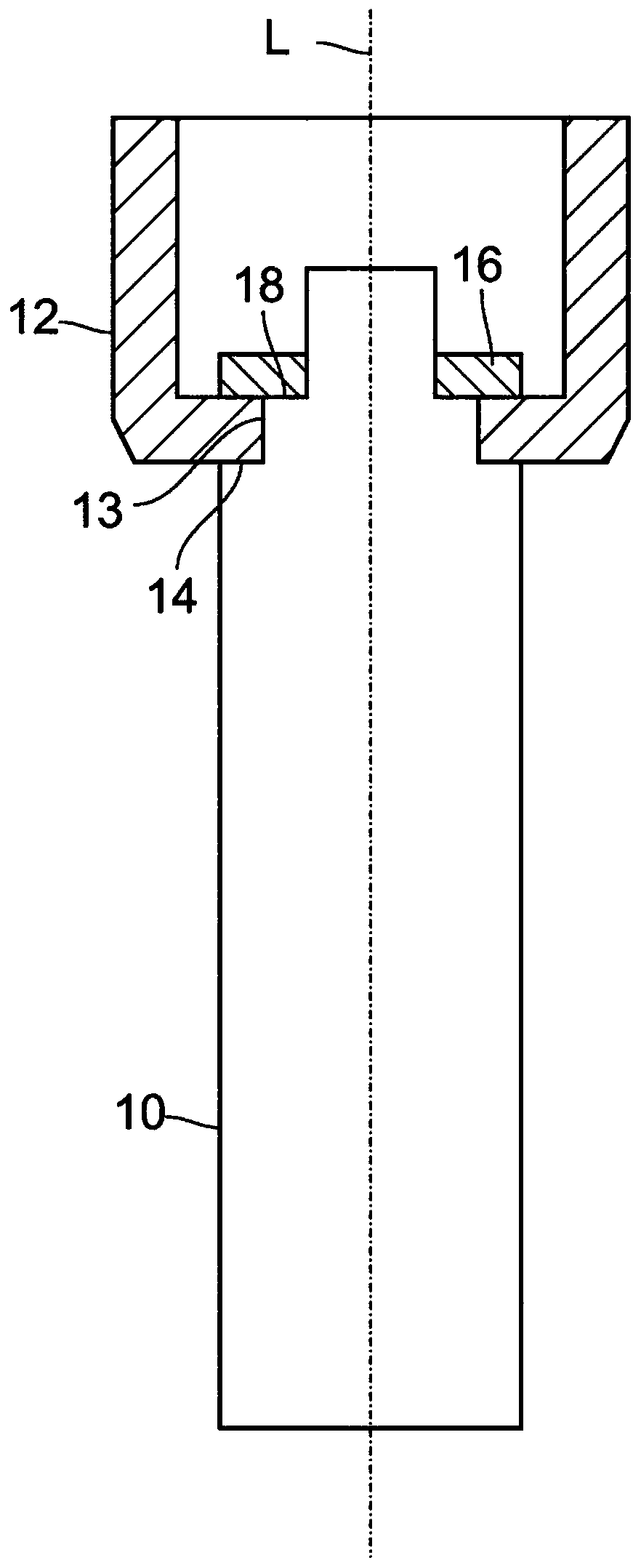

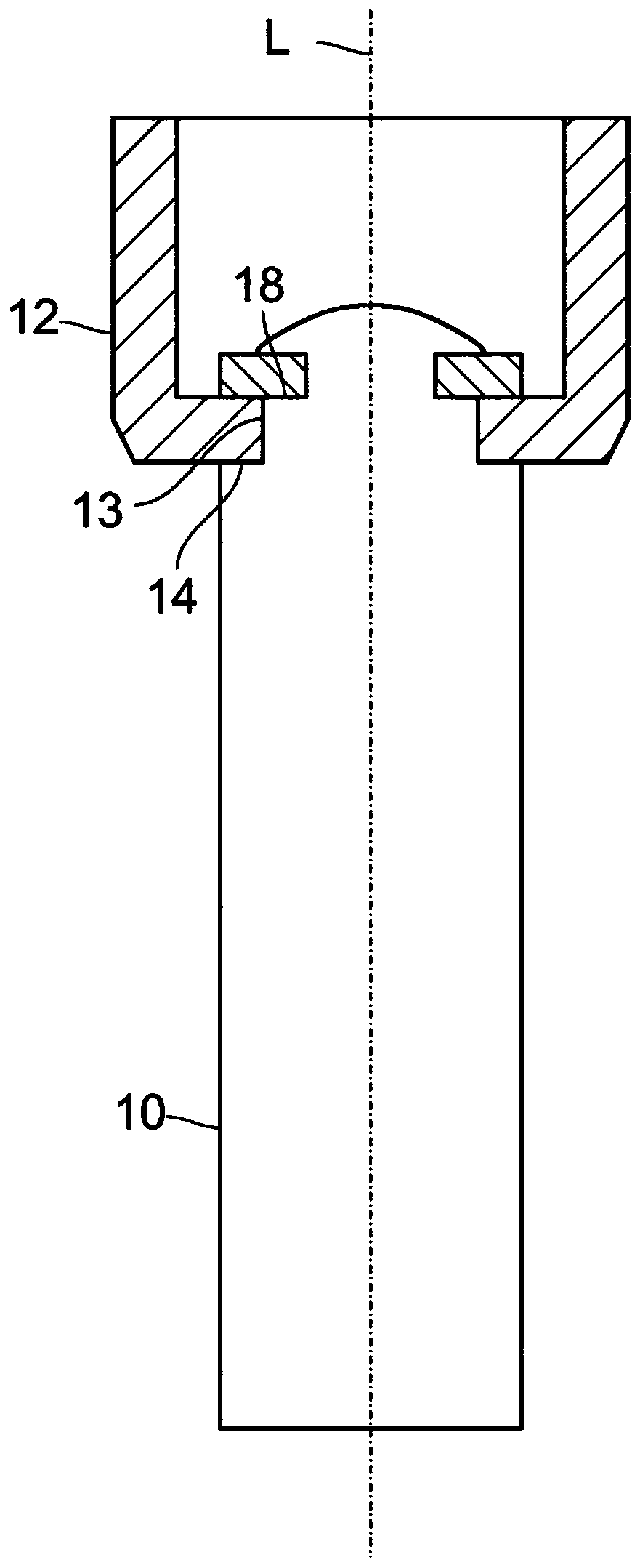

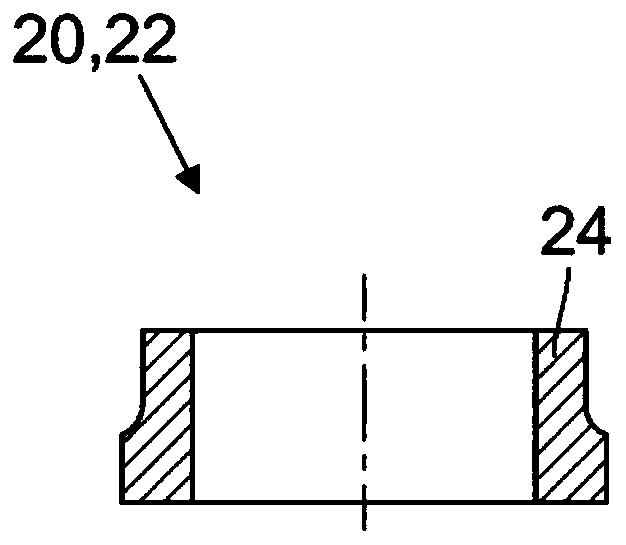

[0032] Figure 1a )with Figure 1b ) schematically shows the connection mode of the plunger 10 and the armature 12 in the prior art. refer to Figure 1a )with Figure 1b ), the plunger 10 is guided to move through the opening 13 of the armature 12 from below along the longitudinal axis L of the plunger 10 until the lower shoulder 14 of the plunger 10 fits on the armature 12 . Subsequently, the retaining washer 16 is introduced into the armature 12 from above and slid onto the plunger 10 until the retaining washer 16 rests on the upper shoulder 18 of the plunger 10 . The retaining washer 16 is dimensioned such that it protrudes radially beyond the opening 13 of the armature 12 . Subsequently, a punching tool (not shown) is introduced into the armature 12 from above, whereupon the plunger 10 is deformed so that the retaining washer 16 is fastened on the plunger 10 with a positive fit. The plunger 10 assumes a mushroom-like shape due to deformation. The position of the plunge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com