Narrow-edge copper plate for slab mold with continuous variable taper at corner

A narrow-sided copper plate and mold technology, which is applied in the field of machinery or equipment for continuous metal casting, can solve the problems of enhancing the crack resistance of the primary shell and the inconsistent length shrinkage rate, and achieves an increase in the application range of steel grades, low deformation resistance, The effect of preventing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

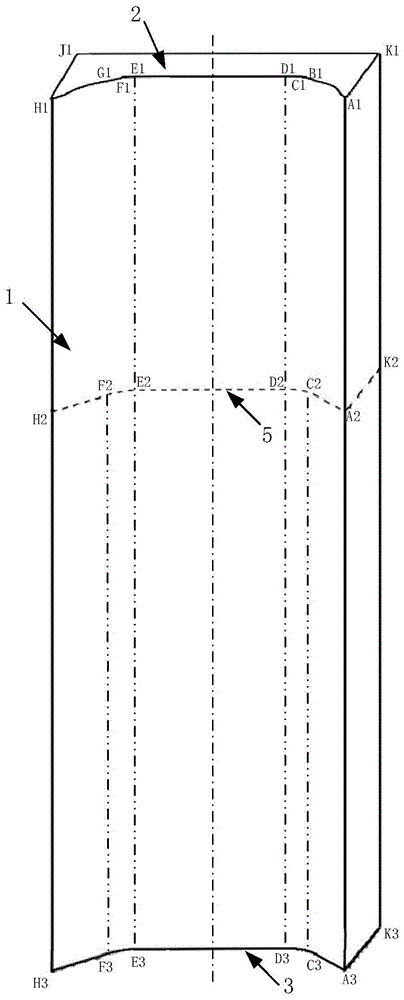

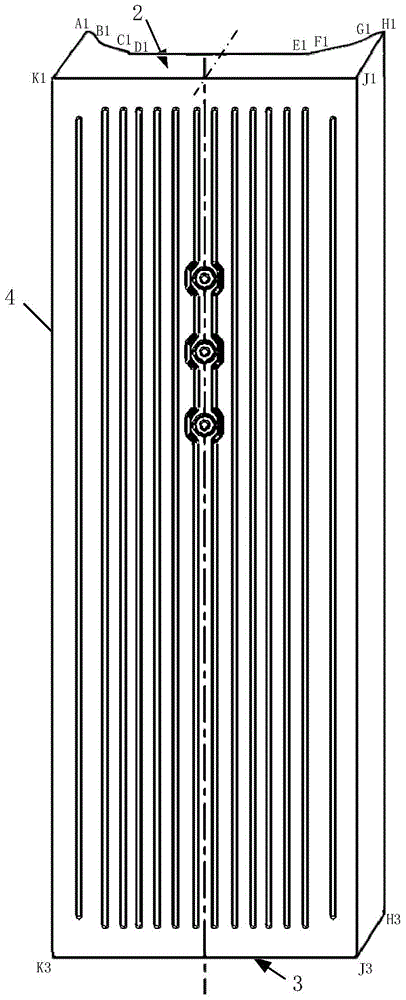

[0088] The main parameters of a specific embodiment of the slab crystallizer narrow-side copper plate with continuously changing taper at the corner of the present invention are as follows:

[0089] The upper opening width K1J1 of the trapezoidal narrow side copper plate is 313.6mm, and the lower opening width K3J3 is 311.0mm; the thickness of the middle part of the copper plate is L1K1=L3K3=39mm.

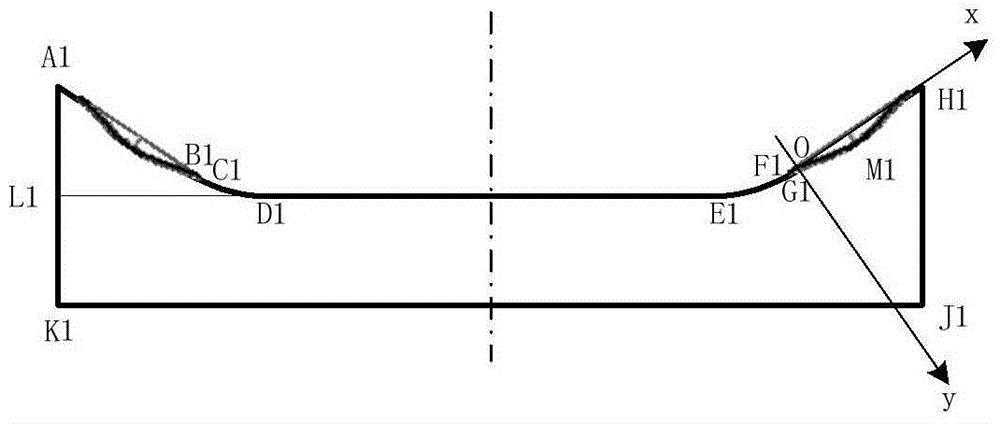

[0090] The upper contour curve A1B1C1D1E1F1G1H1 of the narrow-side copper plate is connected by the upper straight line D1E1, the funnel curves A1B1 and G1H1 with symmetrical center lines, the upper oblique lines B1C1 and F1G1 with symmetrical center lines, and the upper arc lines C1D1 and E1F1 with symmetrical center lines Composition; the length of the catchy straight line D1E1 is 175.43mm, the arc length of the catchy arcs C1D1 and E1F1 is 17.64mm, the arc radius R=30mm; the length of the catchy oblique lines B1C1 and F1G1 is 3.03mm, the catchy oblique lines The included angles ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com