Metal connecting plate of a chain link of an energy chain

A technology of metal connecting plate and energy guide chain, applied in the field of energy guide chain, can solve the problems of high manufacturing cost and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

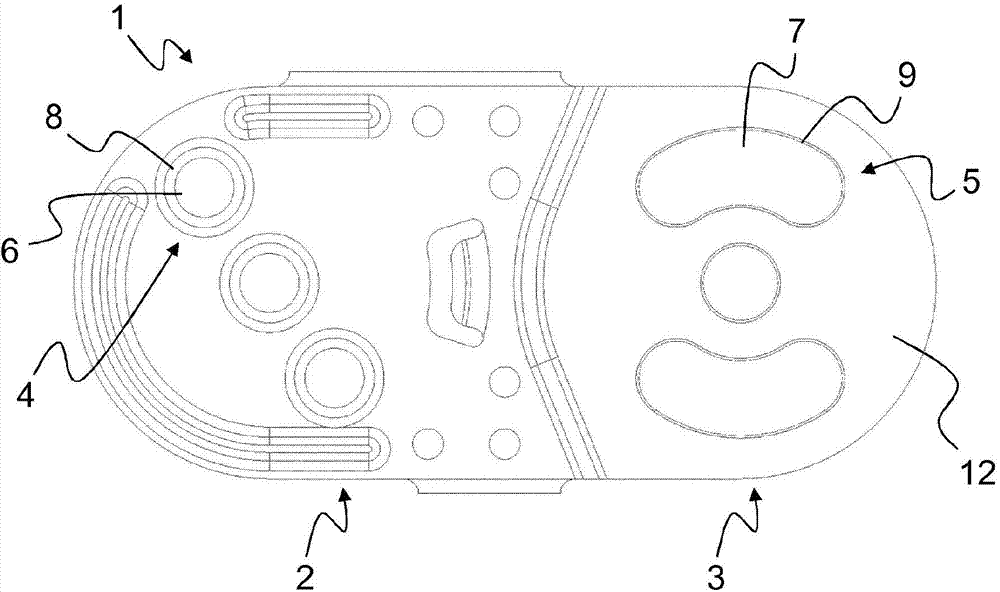

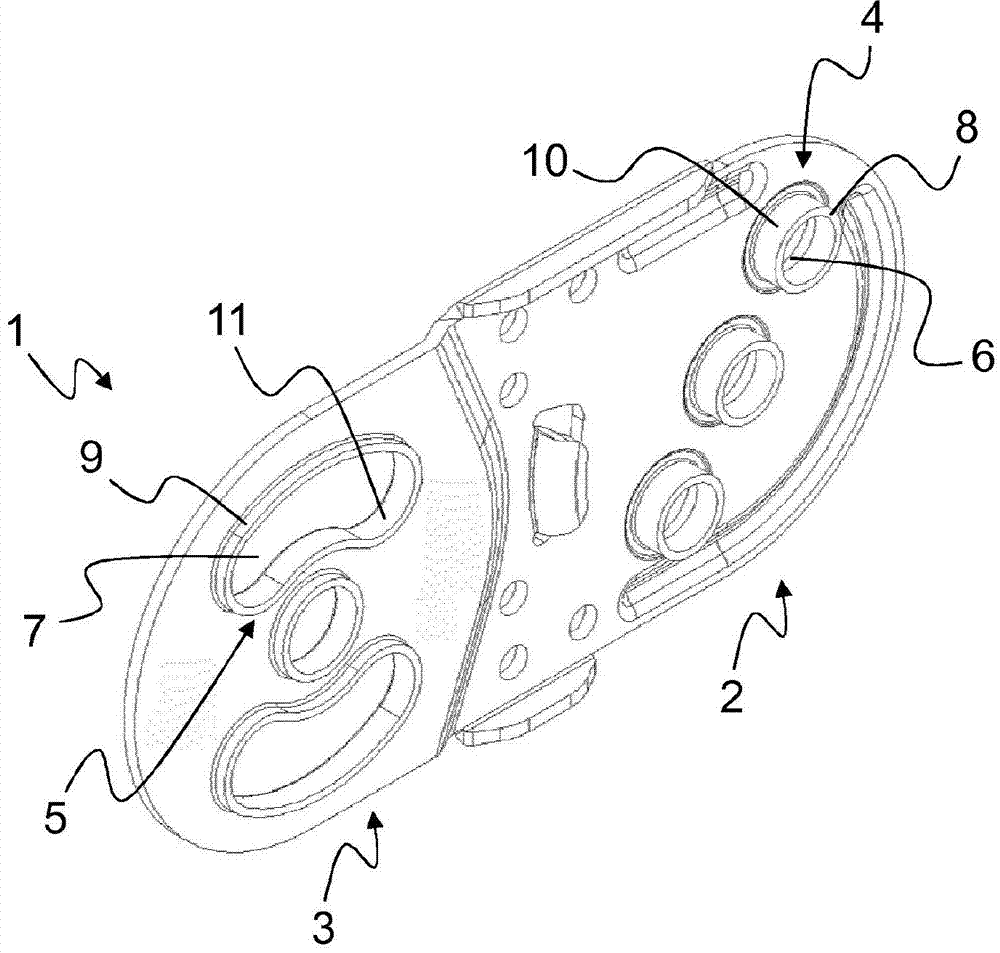

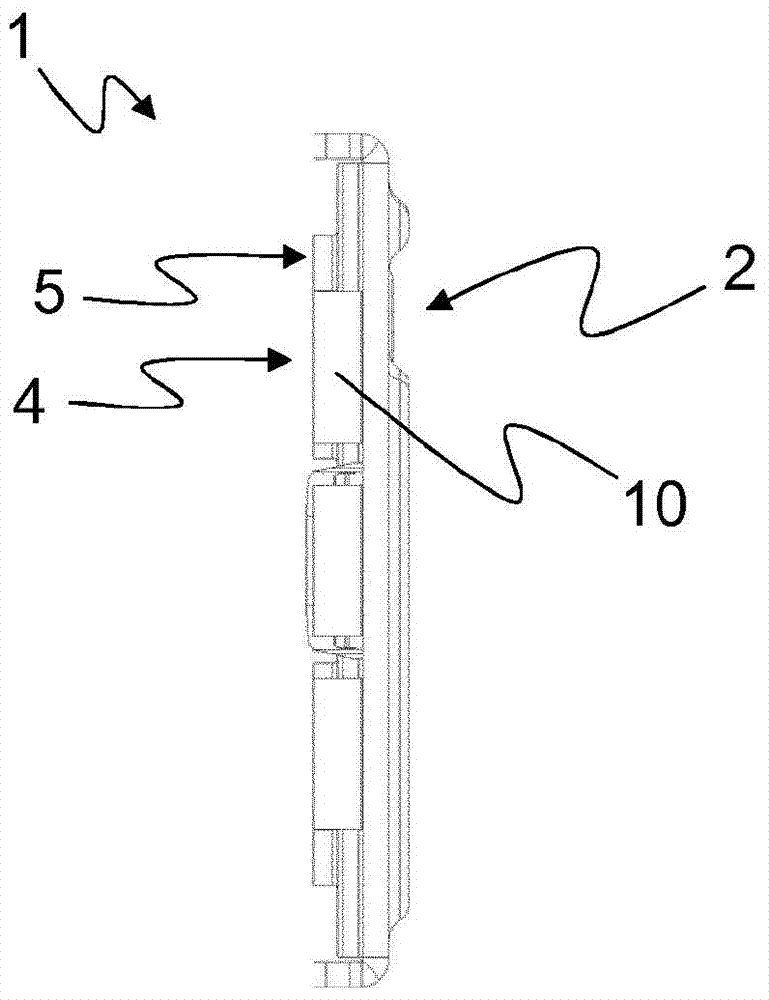

[0049] figure 1 A plan view of an embodiment variant of a metal web 1 is shown, wherein the first end 2 is shown on the left in the illustration and the second end 3 is shown on the right in the illustration. In this embodiment variant of the metal web 1 , two first elements 4 are provided at the first end 2 , which can be introduced into the second end of another structurally identical metal web 1 . part 3 in the kidney-shaped second element 5 . For greater clarity, only one of the elements is provided with a reference sign in each case. The first element 4 has a first bore 6 with a first flange 8 . It should be noted here that the flange 8 of the first hole 6 extends (substantially) perpendicularly to the metal web 1 . On the second end 3 there is a second kidney-shaped element 5 which has a second bore 7 with a second collar 9 . The second element 5 is intended to receive the first element 4 , thereby enabling rotation between two interconnected metal webs 1 inside the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com