Hot-rolled steel sheet having good cold workability and excellent hardness after working

A technology of cold workability and hot-rolled steel plates, which is applied in the field of hot-rolled steel plates, can solve problems such as the inability to achieve cost reduction, and achieve the effects of reduced deformation resistance and extended life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

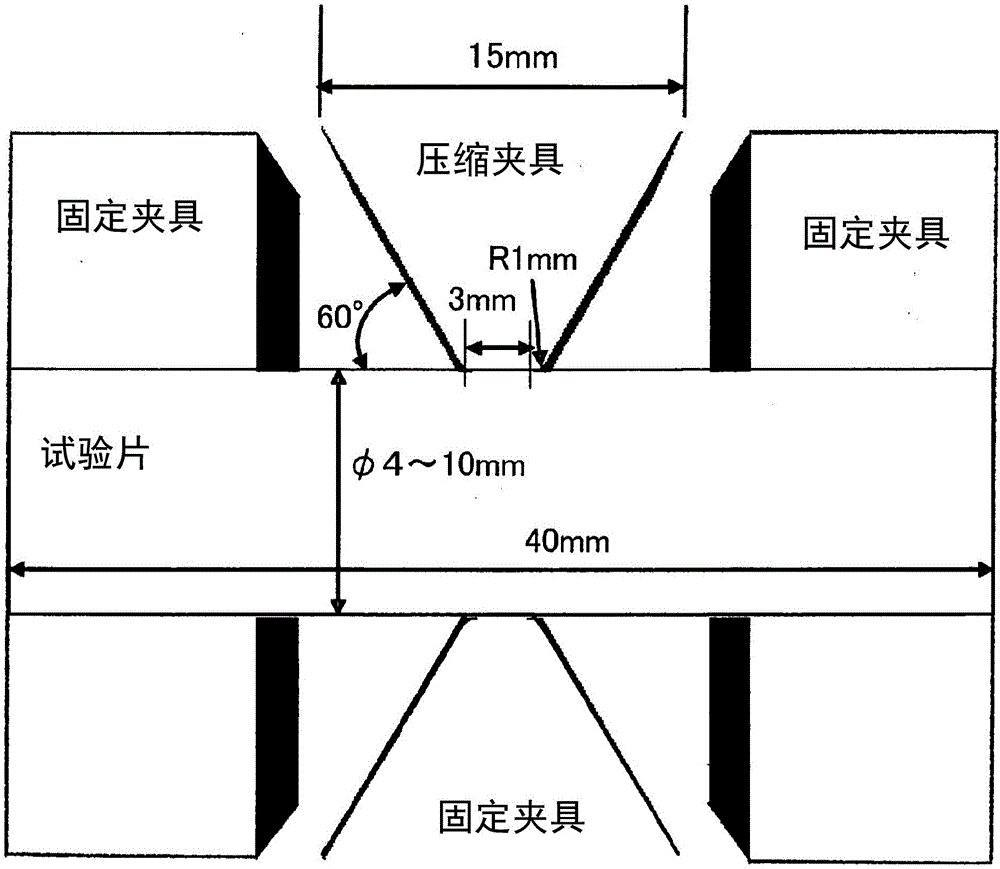

Image

Examples

preparation example Construction

[0118] [Preparation of molten steel]

[0119] Regarding the content of N in molten steel, it can be determined by adding raw materials containing N compounds to molten steel when smelting with a converter, and / or controlling the atmosphere of the converter to N 2 atmosphere to adjust.

[0120] [heating]

[0121] Heating before hot rolling is performed at 1100 to 1300°C. In this heating, in order to solid-dissolve as much N as possible without generating N compounds, high-temperature heating conditions are required. A preferable lower limit of the heating temperature is 1100°C, and a more preferable lower limit is 1150°C. On the other hand, temperatures exceeding 1300°C present operational difficulties.

[0122] [hot rolled]

[0123] Hot rolling is performed so that the finishing temperature becomes 880° C. or higher. If the finish rolling temperature is too low, ferrite transformation will occur at high temperature, the precipitated carbides in ferrite (collectively refe...

Embodiment

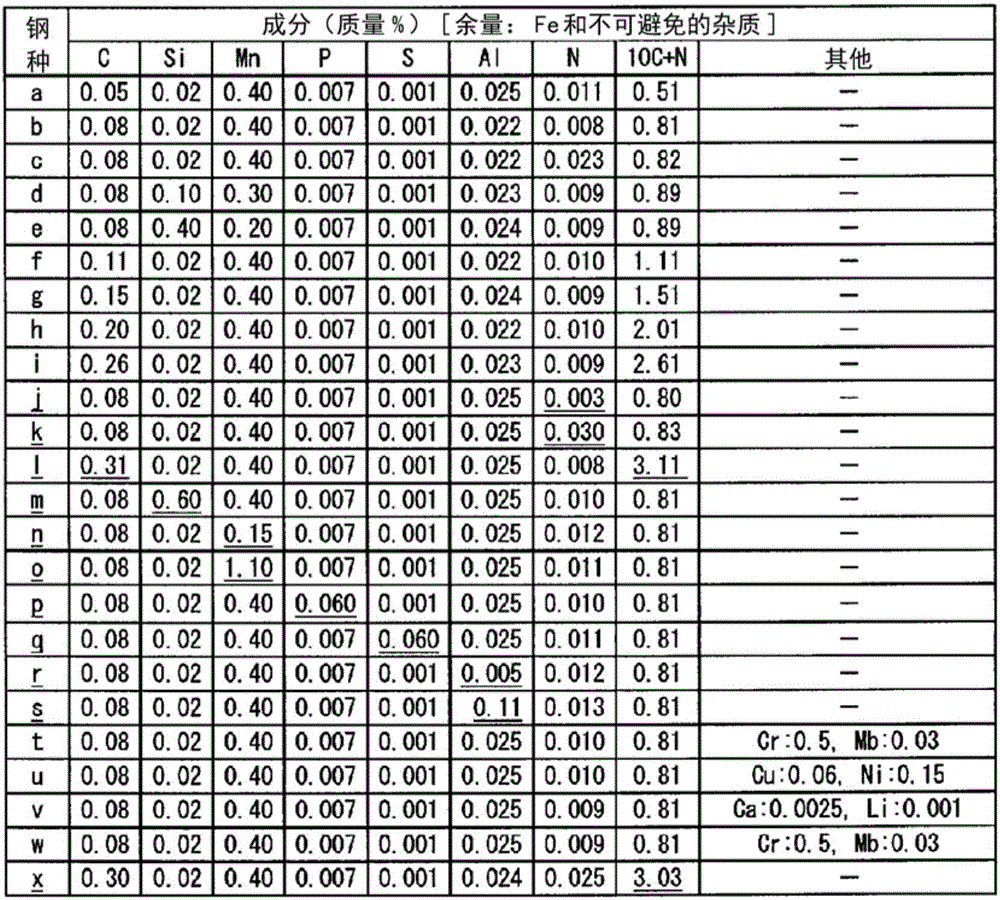

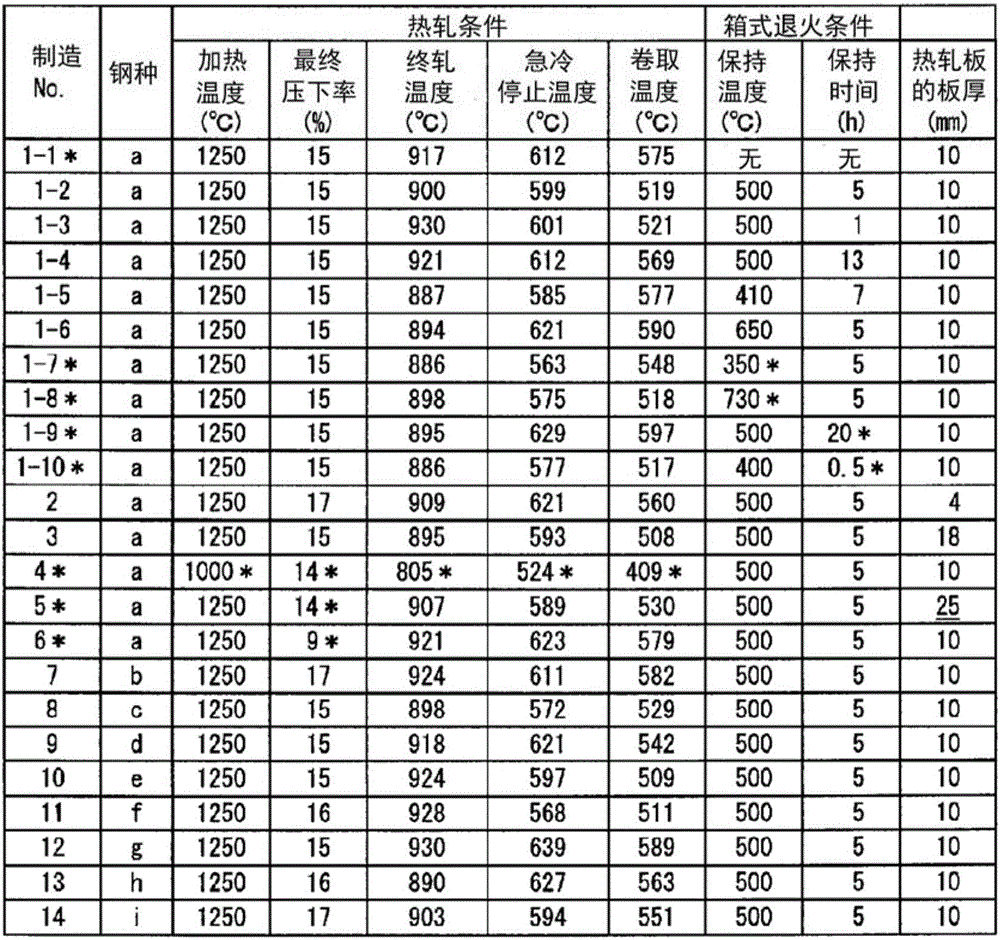

[0140] The steel with the composition shown in the following Table 1 was smelted by the vacuum melting method, cast into a steel ingot with a thickness of 120 mm, hot rolled under the conditions shown in the following Tables 2 and 3, and then subjected to box annealing to produce a hot-rolled steel sheet . It should be noted that in any test, the cooling rate until the quenching stop after the finish rolling was 20°C / s or more, and the cooling condition after the quenching stop was slow cooling for 5 to 20s at a cooling rate of 10°C / s or less, After box annealing, cool to 600°C at a cooling rate below 10°C / h, cool to 600-400°C at a cooling rate below 15°C / h, and water-cool at a cooling rate below 400°C.

[0141] For the hot-rolled steel sheet obtained in this way, the amount of solid solution N, the area ratio of each phase of the structure in the steel sheet, and the average grain size of bainitic ferrite were obtained by each measurement method described in the above [Detail...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com