Hot impact extrusion process and device for large annular barrel type forged piece

A forming process and ring cylinder technology, applied in the direction of metal extrusion, manufacturing tools, indenters/punch rods, etc., can solve the problems of easy forging cracks on the end and surface, waste of punching core material, uneven deformation, etc. Achieve the effect of solving uneven deformation and cracking, improving uneven end face and uniform deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Such as Figure 1 to Figure 12 As shown, a hot stamping extrusion molding process for large-scale ring-type forgings, the process steps are:

[0041] 1. A hot stamping and extrusion molding process for large-scale ring-type forgings, characterized in that the process steps are:

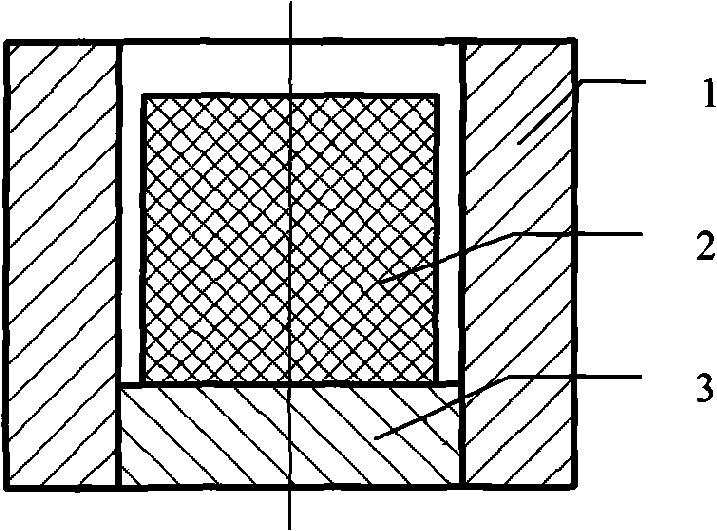

[0042] ① Place the squeeze pad 3 on the press platform;

[0043] ② Put the heated billet 2 on the extrusion pad 3;

[0044] ③ Set the extrusion cylinder 1 on the extrusion pad 3;

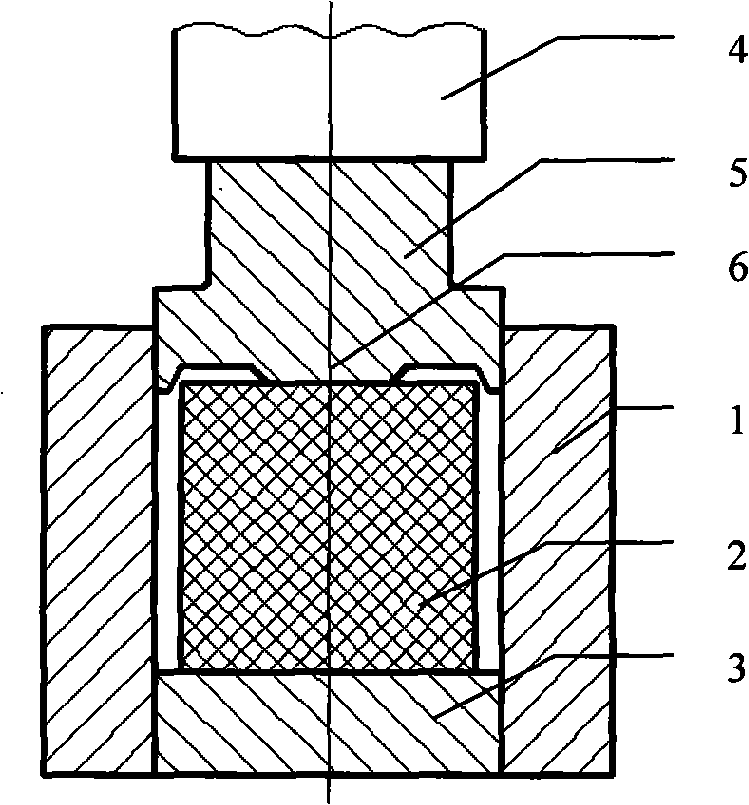

[0045] ④ Place the forming punch 5 on the blank 2 in the extrusion cylinder 1, and press the forming punch 5 with the anvil 4 of the press machine, so that the blank 2 fills the mold cavity;

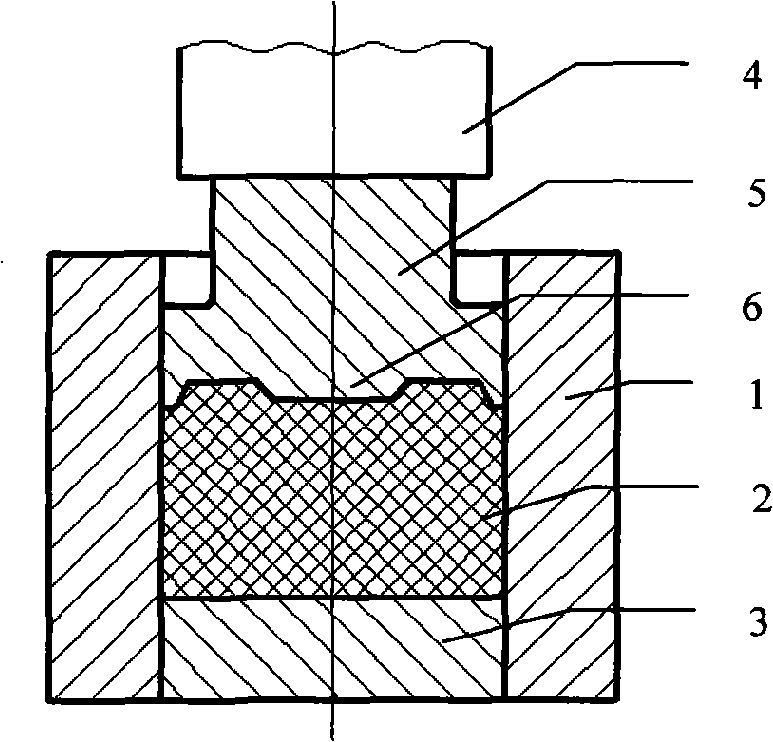

[0046] ⑤Take out the profiling punch 5, and add pulverized coal lubricant in the blank pit pressed by the profiling punch 5;

[0047] ⑥ Put the solid punch 7 against the blank pit pressed by the positive pressure punch 5, place it vertically, use the press anvil 4 to press the solid punch 7, and squeeze the blank 2 to the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com