Ship segment construction precision control method based on digital twin

A segmented construction and precision control technology, which is applied to ship construction, ship parts, ships, etc., can solve the problems of long segmental construction period, uncontrollable, and many processes, so as to reduce the workload of construction correction, shorten the construction period, Guaranteeing the effect of build quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

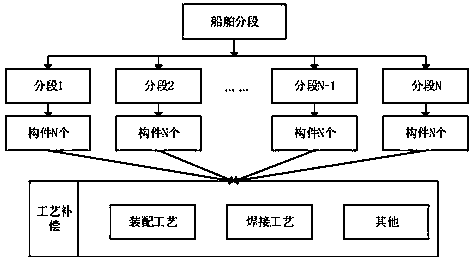

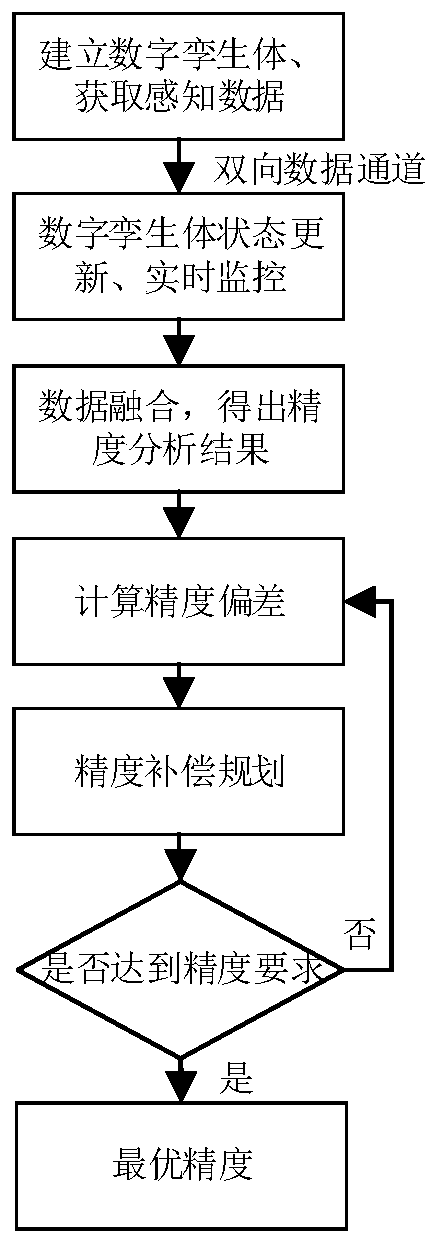

[0025] The steps of the embodiment of this method are as figure 1 shown, including the following steps:

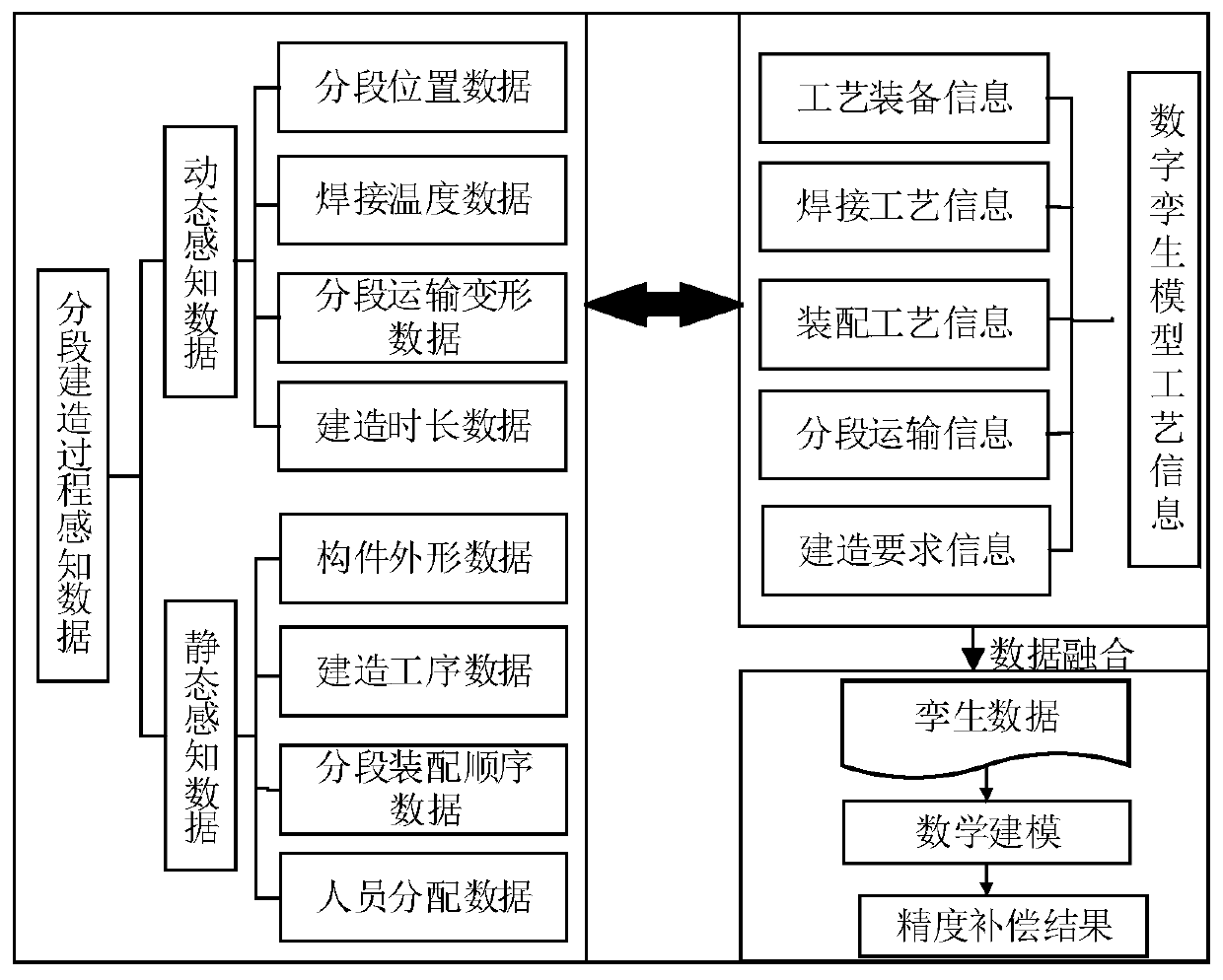

[0026] (1) Construct the digital twin of the physical entity in the information space of the ship's segmented construction process, by arranging sensory data acquisition devices at key parts of the frame. The deployed collection device collects the perception data of the construction process, and divides the collected perception data into dynamic perception data and static perception data. Among them: dynamic sensing data includes: segmental position data, welding temperature data, segmental transportation deformation data, construction duration data; static sensing data includes: component shape data, construction process data, segmental assembly sequence data, personnel allocation data.

[0027] (2) Create a two-way data channel between physical space and information space, using the Modbus data transmission protocol. The information space updates the construction stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com