Method for welding CVD diamond thick film and hard alloy

A diamond thick film and hard alloy technology, which is applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of high welding cost, large equipment investment, and high solder requirements, achieve good surface wettability, and solve the problem of high investment. , the effect of excellent bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

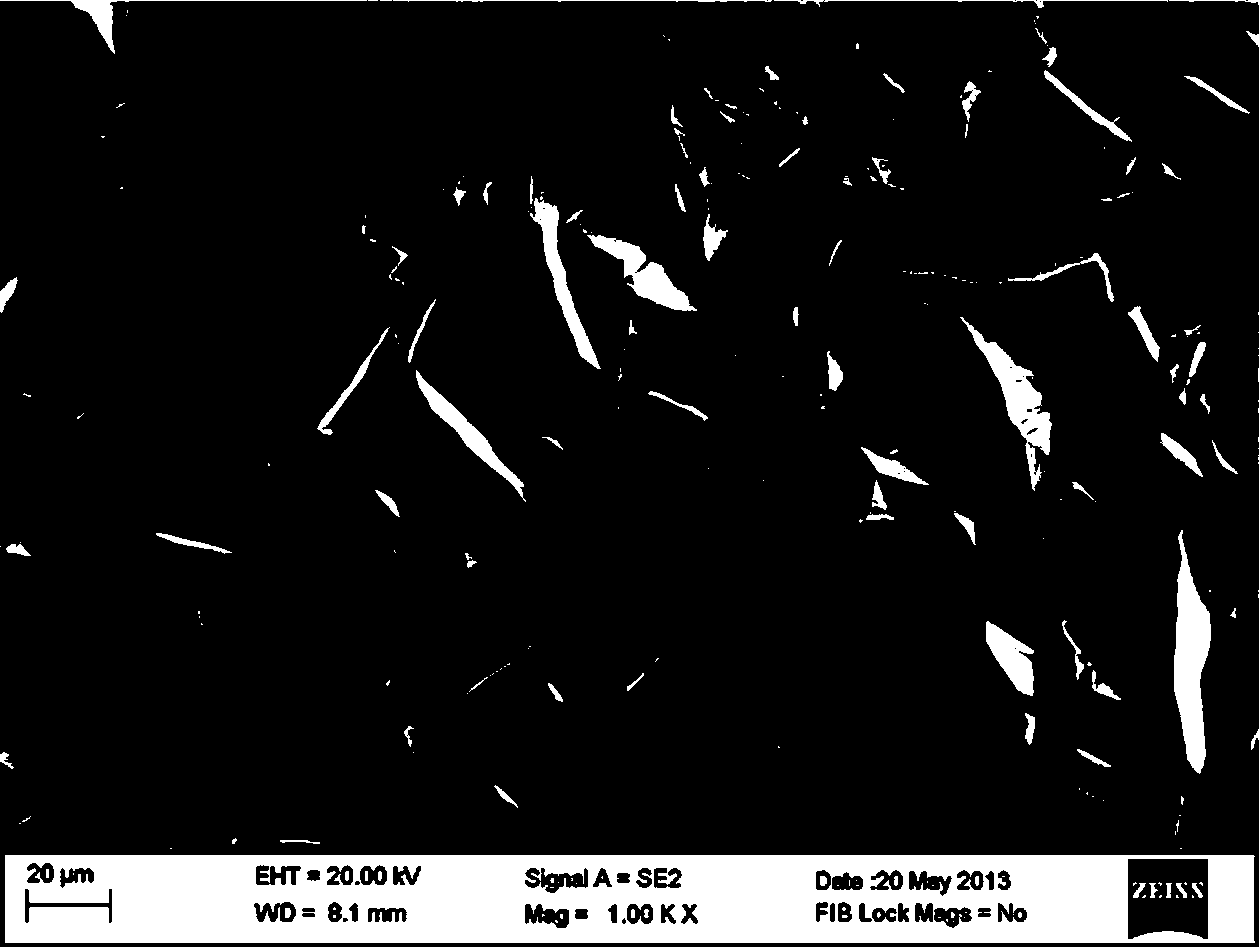

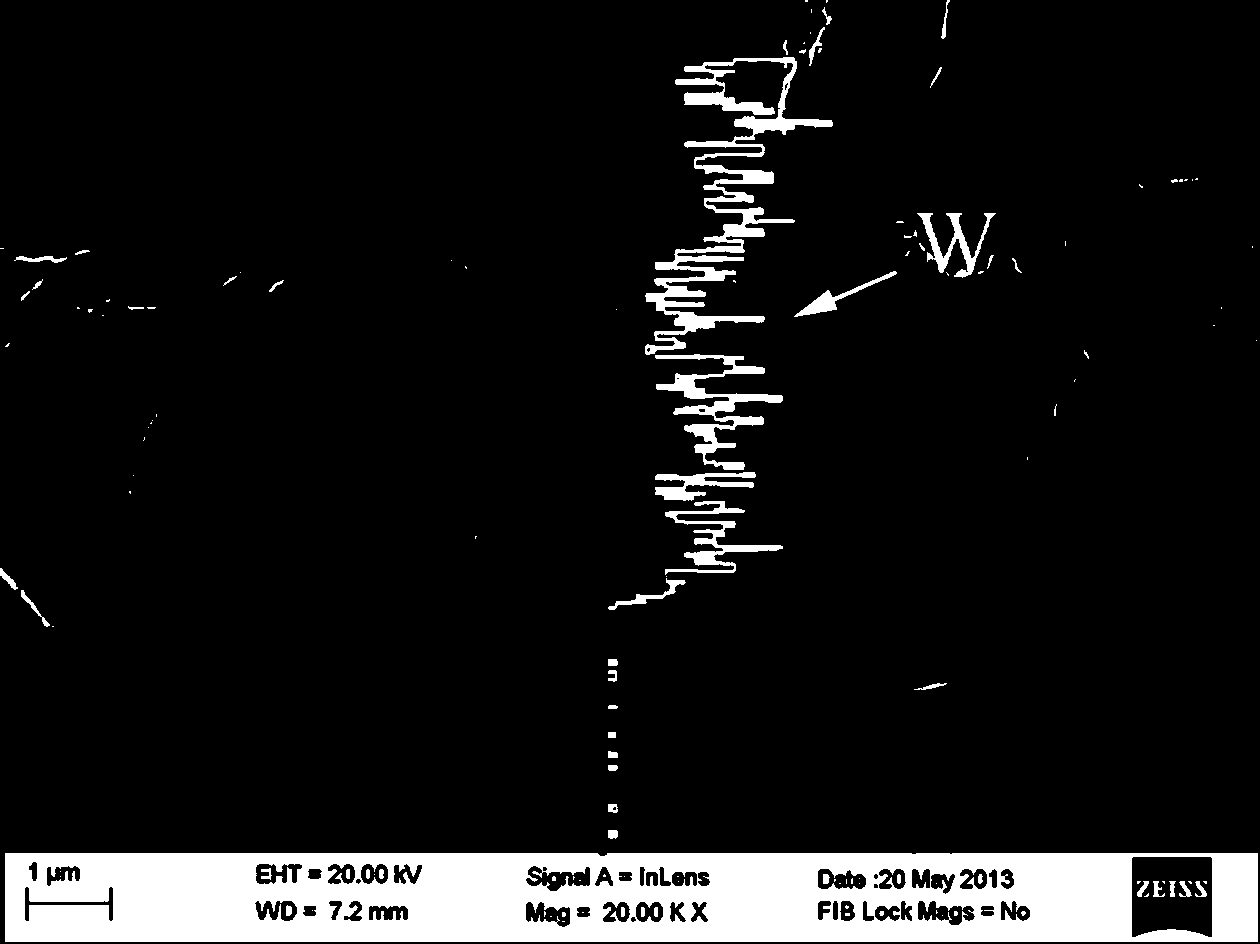

[0024] A welding method of CVD diamond thick film and cemented carbide, first using double glow plasma metallization equipment to metallize the growth surface of CVD diamond thick film, and then using the same double glow plasma metallization equipment to metallize The final CVD diamond thick film growth surface is brazed with the cemented carbide substrate;

[0025] Among them, the metallization process of CVD diamond thick film growth surface is:

[0026] The CVD diamond thick film was prepared by microwave plasma CVD method, hot wire CVD method or DC arc plasma CVD method, and the CVD diamond thick film was ultrasonically cleaned with deionized water and alcohol for 5 minutes, and dried with hot air; The CVD diamond thick film growth side is placed on the substrate table in the vacuum furnace of the double-glow plasma metallization equipment, and the metal W with a purity of 99.9% that can form strong carbides with carbon is selected as the target material. The distance be...

Embodiment 2

[0036] A welding method of CVD diamond thick film and cemented carbide, first using double glow plasma metallization equipment to metallize the growth surface of CVD diamond thick film, and then using the same double glow plasma metallization equipment to metallize The final CVD diamond thick film growth surface is brazed with the cemented carbide substrate;

[0037] Among them, the metallization process of CVD diamond thick film growth surface is:

[0038] The CVD diamond thick film was prepared by microwave plasma CVD method, hot wire CVD method or DC arc plasma CVD method, and the CVD diamond thick film was ultrasonically cleaned with deionized water and alcohol for 5 minutes, and dried with hot air; The CVD diamond thick film growth side is placed on the substrate table in the vacuum furnace of the double-glow plasma metallization equipment, and Ti, which can form strong carbides with carbon elements, is selected as the target material. The target material and the CVD diam...

Embodiment 3

[0044] A welding method of CVD diamond thick film and cemented carbide, first using double glow plasma metallization equipment to metallize the growth surface of CVD diamond thick film, and then using the same double glow plasma metallization equipment to metallize The final CVD diamond thick film growth surface is brazed with the cemented carbide substrate;

[0045] Among them, the metallization process of CVD diamond thick film growth surface is:

[0046] The CVD diamond thick film was prepared by microwave plasma CVD method, hot wire CVD method or DC arc plasma CVD method, and the CVD diamond thick film was ultrasonically cleaned with deionized water and alcohol for 4 minutes, and dried with hot air; The CVD diamond thick film growth side is placed on the substrate table in the vacuum furnace of the double-glow plasma metallization equipment, and Zr, which can form strong carbides with carbon elements, is selected as the target material. The target material and the CVD diam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com