Ceramic plastic patch type underground drip irrigation tape assembly line

A technology of underground drip irrigation and ceramic plastics, which is applied in the direction of assembly machines, transportation and packaging, and metal processing equipment, etc., can solve the problems of time-consuming and labor-intensive assembly of underground drip irrigation belts, and achieve the effects of saving manpower and material resources, strong applicability, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

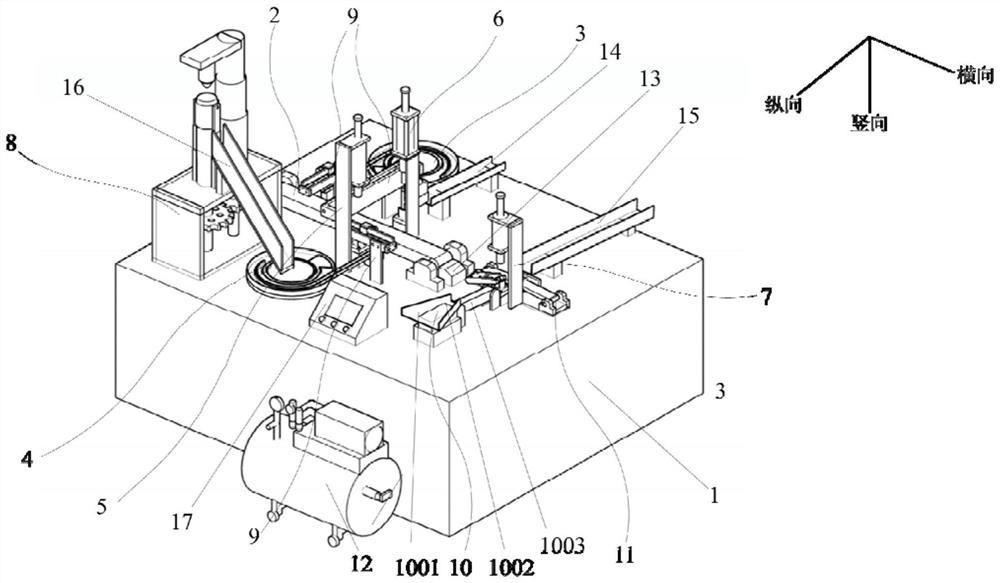

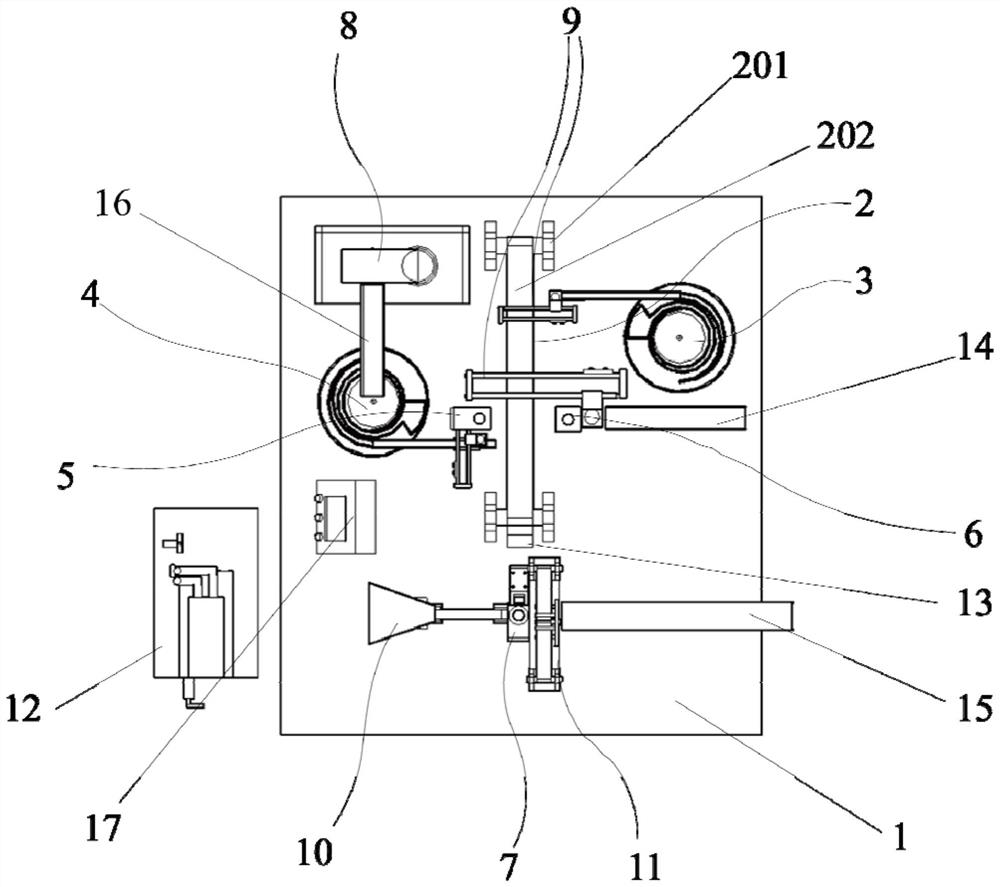

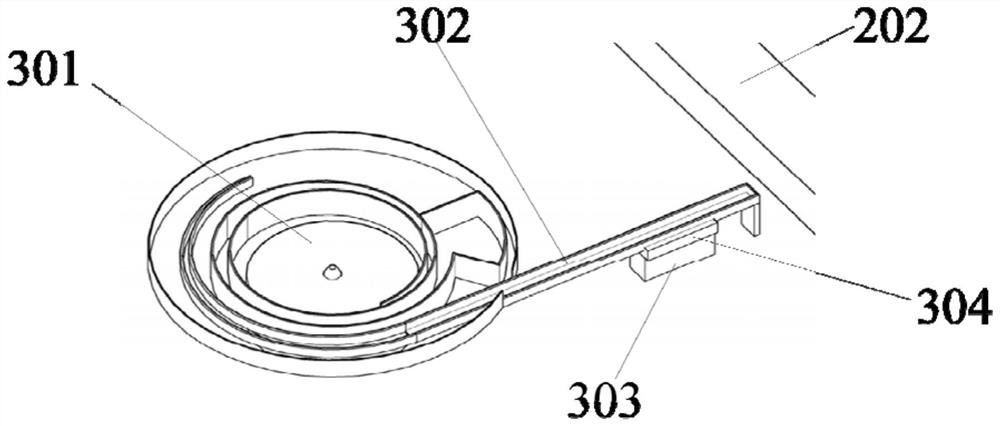

[0049] Present embodiment provides a kind of assembly line of ceramic plastic patch type underground drip irrigation belt, as Figure 1 to Figure 8As shown, it includes a workbench 1, on which a conveying mechanism 2 is arranged, and the conveying mechanism 2 is arranged along the horizontal direction; the workbench 1 around the conveying mechanism 2 is provided with a ceramic water seepage sheet feeding mechanism 3, a plastic patch feeding mechanism 4. Emitter assembly mechanism 5. Emitter air tightness inspection mechanism 6. Emitter-drip irrigation pipe assembly mechanism 7;

[0050] A plastic patch manufacturing mechanism 8 is arranged above the ceramic water seepage sheet feeding mechanism 3; the workbench 1 around the ceramic water seepage sheet feeding mechanism 3, the plastic patch feeding mechanism 4 and the emitter air tightness inspection mechanism 6 are all provided with parts Grab and send the manipulator 9; the drip irrigation pipe feeding mechanism 10 and the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com