Method for realizing TiAl-based alloy connection by adopting Al foil as intermediate layer

A technology of base alloy and intermediate layer, applied in welding equipment, metal processing equipment, non-electric welding equipment, etc., can solve the problems of low high temperature strength of TiAl alloy joints, deterioration of joint corrosion and oxidation resistance, etc., to achieve stable welding quality, The effect of reducing energy consumption and reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

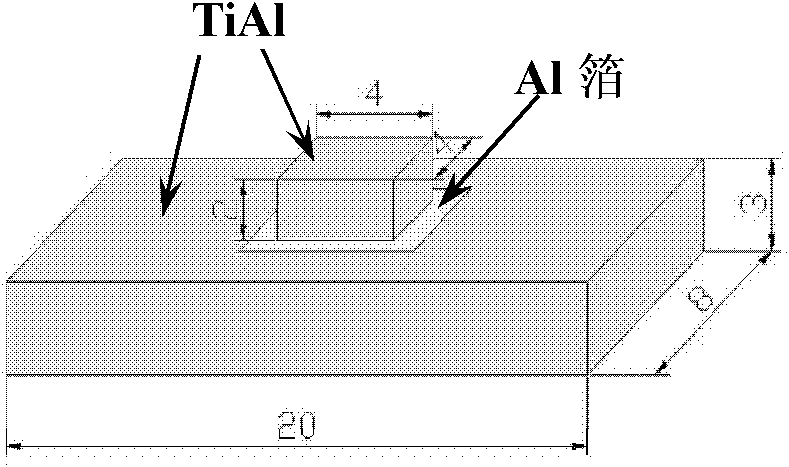

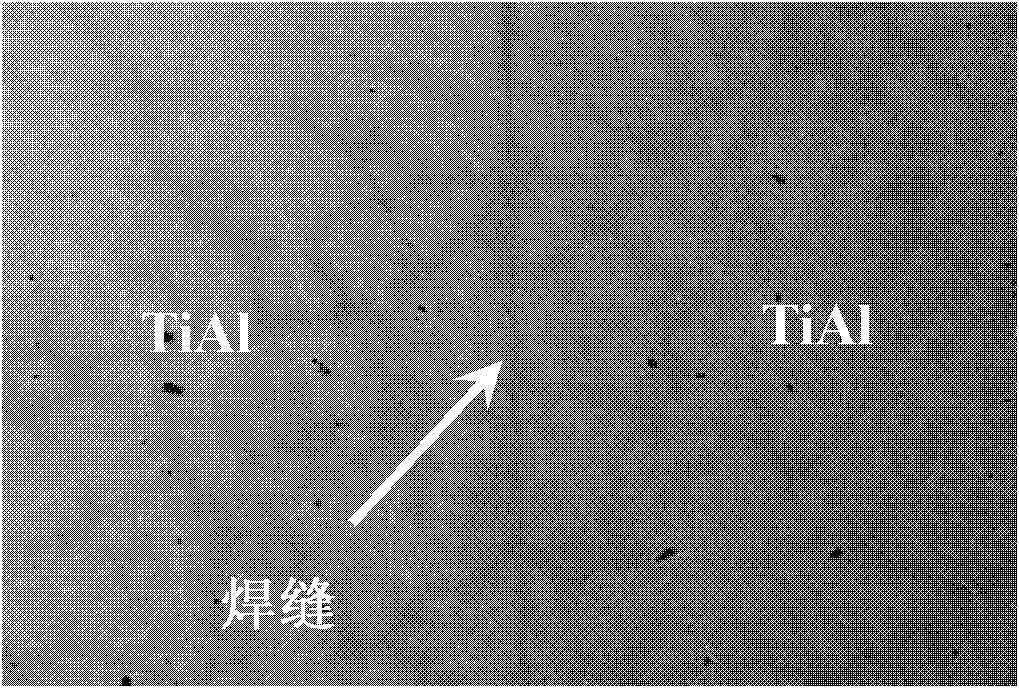

[0013] Specific Embodiment 1: In this embodiment, a method of using Al foil as an intermediate layer to realize the connection of TiAl-based alloys is carried out in the following steps: 1. The TiAl-based alloys are processed into the required size by wire cutting to obtain TiAl to be welded 2. Polish the connection surface of the TiAl-based alloy to be welded with sandpaper, and then put the connection surface into acetone and ultrasonically clean it for 5-10 minutes; 3. Then place the Al foil with a thickness of 15-25 μm on the Apply a pressure of 0.01 to 0.1 MPa between the joint surfaces of the welded TiAl-based alloy, place it in a vacuum heating furnace for welding, and when the vacuum degree in the vacuum heating furnace reaches 1×10 -3 ~2×10 -2 After Pa, start heating with electricity at a heating rate of 30-50°C / min, heat it to 1100-1200°C and keep it at this temperature for 4-8 hours, and then cool it to room temperature at a cooling rate of 5-10°C / min to complete Ti...

specific Embodiment approach 2

[0015] Embodiment 2: This embodiment differs from Embodiment 1 in that: in step 2, put the connection surface into acetone and ultrasonically clean it for 8 minutes. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0016] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that in Step 3, an Al foil with a thickness of 18-23 μm is placed between the connecting surfaces of the TiAl-based alloy to be welded. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com