A preparation method and application of ultra-high-purity cobalt plate with controllable structure

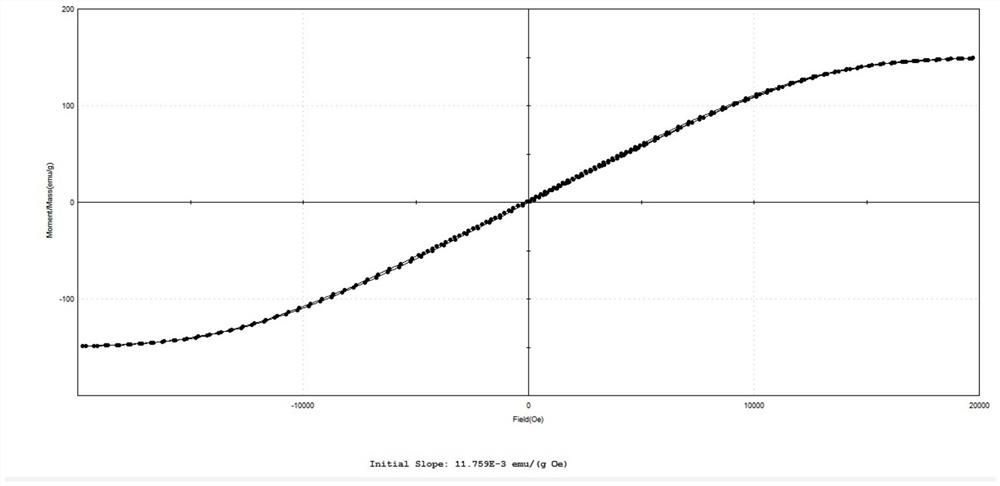

A pure cobalt plate, ultra-high technology, applied in the field of preparation of ultra-high-purity cobalt plate, can solve the problems of uneven grain size distribution, low β-Co phase content, substandard magnetic permeability, etc., and achieve billet substructure. The effect of uniform defect distribution, refinement and homogenization of billet structure and uniform internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040]This embodiment provides a method for preparing a tissue-controllable ultra-high-purity cobalt target, including the following steps:

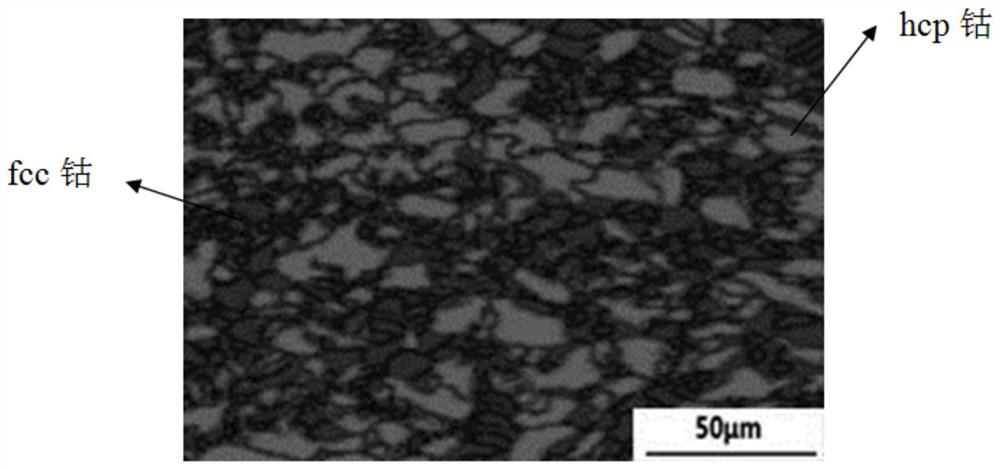

[0041] The cobalt powder (purity is 99.997%) is subjected to vacuum vertical melting after cold isostatic pressing under 200MPa pressure. The vertical melting temperature is 1320°C and the vacuum degree is 10 -4 Pa; put the vertical molten cobalt ingot in a high vacuum of 10 -4 Melting in a Pa electron beam melting furnace, the melting temperature is 1580°C, after cooling, the ingot is again placed in a high vacuum -4 Melting in a Pa electron beam melting furnace at a melting temperature of 1580°C (each melting time is 0.5 hours); the obtained high-density ingot is covered with stainless steel in an argon chamber; the wrapped ingot is heated to 950°C and kept warm For 1.5 hours, make the axial direction of the billet parallel to the direction of the forging force, and carry out two forging deformations, in which the deformation of the f...

Embodiment 2

[0058] This embodiment provides a method for preparing a tissue-controllable ultra-high-purity cobalt target, including the following steps:

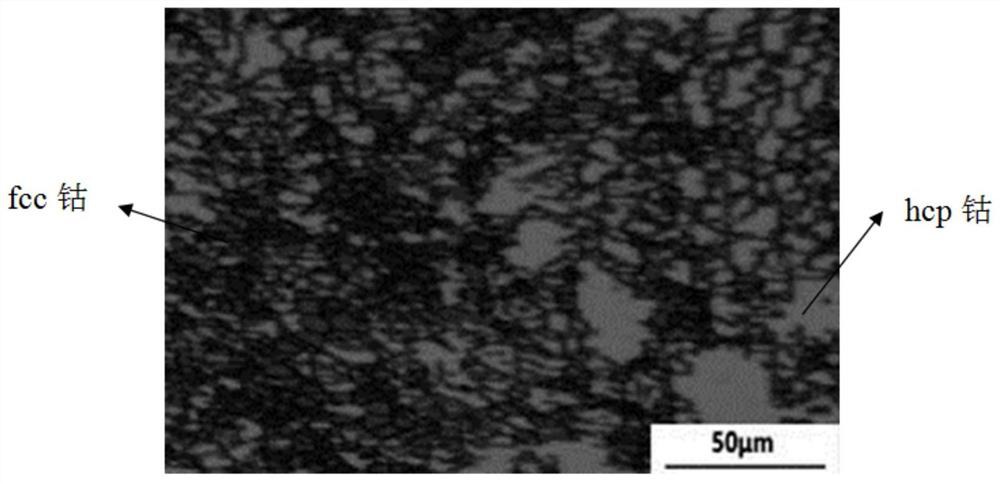

[0059] The cobalt powder (purity is 99.997%) is subjected to vacuum vertical melting after cold isostatic pressing under 200MPa pressure. The vertical melting temperature is 1320°C and the vacuum degree is 10 -4 Pa; put the vertical molten cobalt ingot in a high vacuum of 10 -4 Melting in a Pa electron beam melting furnace, the melting temperature is 1580°C, after cooling, the ingot is again placed in a high vacuum -4 Melting in a Pa electron beam melting furnace at a melting temperature of 1580°C (each melting time is 0.5 hours); the obtained high-density ingot is covered with stainless steel in an argon chamber; the wrapped ingot is heated to 950°C and kept warm For 1.5 hours, make the axial direction of the billet parallel to the direction of the forging force, and carry out two forging deformations, in which the deformation of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com