Preparation method and application of a cobalt-tantalum-zirconium alloy target

A zirconium alloy and target technology, which is used in the preparation of cobalt-tantalum-zirconium alloy targets, can solve the problems of substandard magnetic permeability, uneven texture, coarse grains, etc., and reduce the anisotropy field and coercivity. , the effect of increasing nucleation points and uniform internal organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

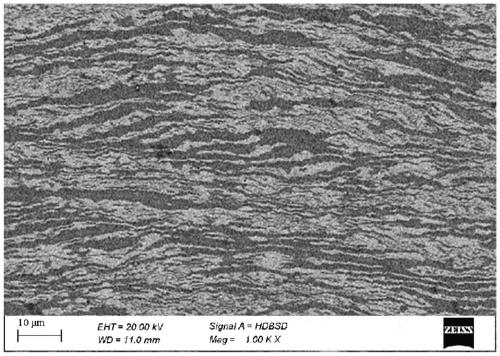

[0042] This embodiment provides a method for preparing a cobalt-tantalum-zirconium alloy target, which includes the following steps:

[0043] Cobalt powder (purity is 99.995%), zirconium powder (purity is 99.99%), tantalum powder (purity is 99.99%), hafnium powder (purity is 99.99%), boron powder (purity is 99.99%) under 200MPa pressure cold Vacuum vertical melting treatment is carried out after isostatic pressing, the vertical melting temperature is 1350°C, and the vacuum degree is 10 -4 Pa, to obtain the Co-6.0Ta-3.0Zr-1.5Hf-0.01B alloy billet; the vertical melting cobalt billet is 10 -4 Melting in a Pa electron beam melting furnace, the melting temperature is 1600°C, after cooling, the ingot is again placed in a high vacuum -4 Melting in a Pa electron beam melting furnace at a melting temperature of 1600°C (each melting time is 0.5 hours); the obtained high-density billet is covered with stainless steel in an argon chamber; the wrapped billet is heated to 1000°C and kept w...

Embodiment 2

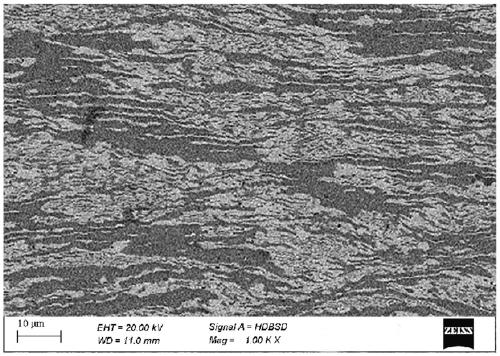

[0059] This embodiment provides a method for preparing a cobalt-tantalum-zirconium alloy target, which includes the following steps:

[0060] Cobalt powder (purity is 99.995%), zirconium powder (purity is 99.99%), tantalum powder (purity is 99.99%), hafnium powder (purity is 99.99%), boron powder (purity is 99.99%) under 200MPa pressure cold Vacuum vertical melting treatment is carried out after isostatic pressing, the vertical melting temperature is 1200 ℃, and the vacuum degree is 10 -4 Pa, to obtain the Co-9.0Ta-5.0Zr-2.0Hf-0.01B alloy billet; the vertical melting cobalt billet is 10 -4 Melting in a Pa electron beam melting furnace, the melting temperature is 1550°C, after cooling, the ingot is again placed in a high vacuum -4 Melting in a Pa electron beam melting furnace at a melting temperature of 1550°C (each melting time is 0.5 hours); the obtained high-density billet is covered with stainless steel in an argon chamber; the wrapped billet is heated to 1000°C and kept w...

Embodiment 3

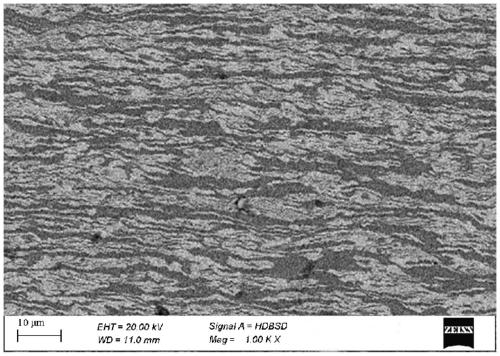

[0065] This embodiment provides a method for preparing a cobalt-tantalum-zirconium alloy target, which includes the following steps:

[0066] Cobalt powder (purity is 99.995%), zirconium powder (purity is 99.99%), tantalum powder (purity is 99.99%), hafnium powder (purity is 99.99%), boron powder (purity is 99.99%) under 200MPa pressure cold Vacuum vertical melting treatment is carried out after isostatic pressing, the vertical melting temperature is 1380°C, and the vacuum degree is 10 -4 Pa, to obtain the Co-3.0Ta-2.0Zr-1.0Hf-0.01B alloy billet; the vertical melting cobalt billet is 10 -4 Melting in a Pa electron beam melting furnace, the melting temperature is 1700°C, after cooling, the ingot is again placed in a high vacuum -4 Melting in a Pa electron beam melting furnace at a melting temperature of 1700°C (each melting time is 0.5 hours); the obtained high-density billet is covered with stainless steel in an argon chamber; the wrapped billet is heated to 1000°C and kept w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen content | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com