Aluminum system deoxidizing and carburizing alloy for converters, and manufacturing method thereof

A carbon alloy and alloy technology, applied in the field of metallurgy, can solve the problems of temperature loss, difficulty in ensuring alloy homogenization, and failure of converter "straight-up" process, so as to meet the needs of straight-up temperature, shorten processing time, and ensure the effect of homogenization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Preparation and use of deoxidized alloy:

[0024] (1) The composition of the deoxidized carburizing alloy is aluminum, carbon and iron. Based on the total weight of the deoxidized carburizing alloy, the weight percentages of each component are: aluminum 45%, carbon 20%, iron 35%. Alloy particle size is 30~50mm;

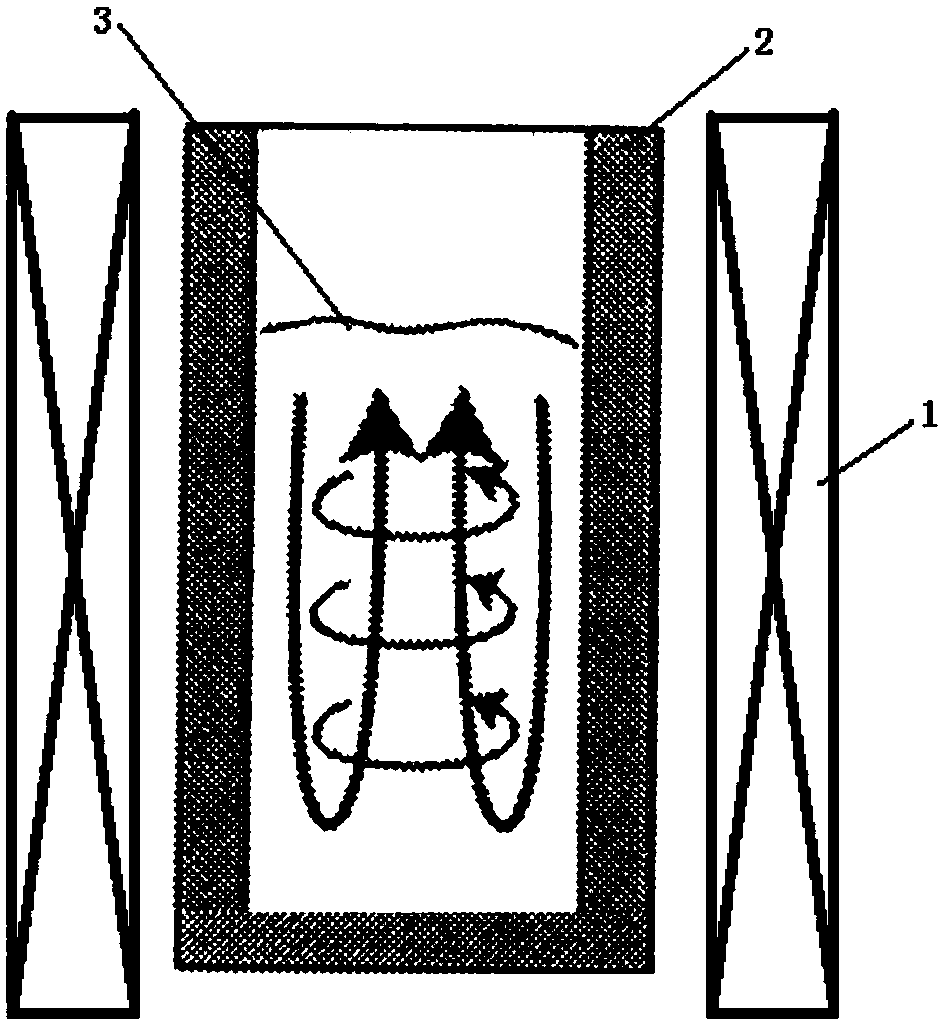

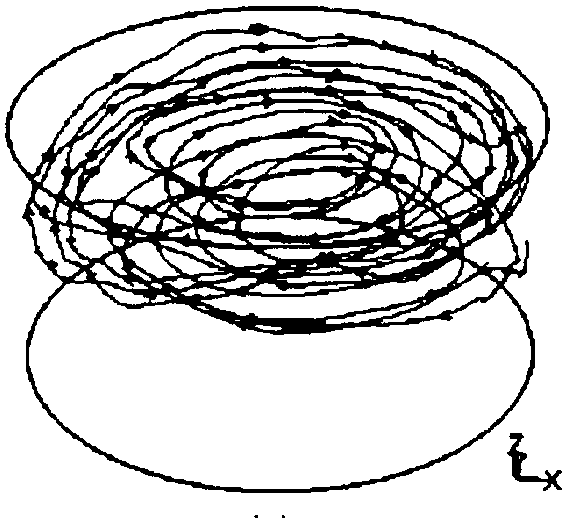

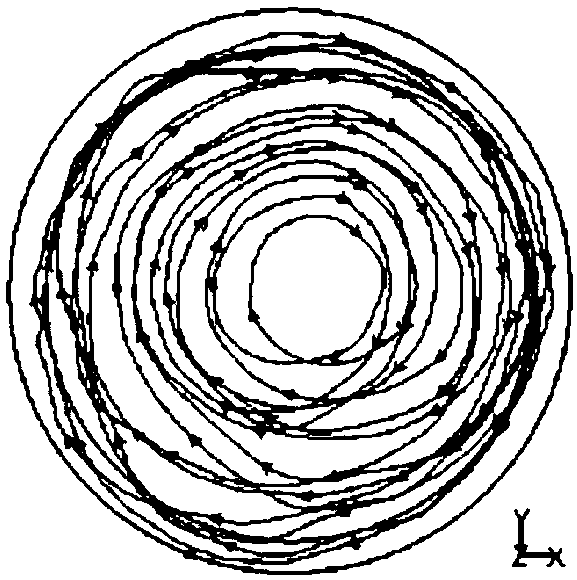

[0025] (2) Aluminum ingots, recarburizers, and industrial pure iron are used as raw materials for the production of deoxidized and carburized alloys, with a particle size of 5-12mm. First melt the aluminum ingot in the molten pool, and then add the recarburizer and industrial pure iron according to the content ratio of the finished product, that is, the ratio of aluminum: carbon: iron = 45:20:35, and apply spiral electromagnetic stirring at the same time, and the spiral electromagnetic stirring current 180A, frequency 2.8Hz, stop the spiral electromagnetic stirring after the alloy is completely solidified;

[0026] (3) Use a jaw crusher to crush the deoxidiz...

Embodiment 2

[0037] Preparation and use of deoxidized alloy:

[0038] (1) The composition of the deoxidized carburizing alloy is aluminum, carbon and iron. Based on the total weight of the deoxidized carburizing alloy, the weight percentages of each component are: aluminum 48%, carbon 21%, iron 31%. Alloy particle size is 30~50mm;

[0039] (2) Aluminum ingots, recarburizer powder, and industrial pure iron are used as raw materials for the production of deoxidized and recarburized alloys, with a particle size of 5-12mm. First melt the aluminum ingot in the molten pool, and then add carburant and industrial pure iron according to the ratio of finished product content, that is, aluminum: carbon: iron = 48:21:31, and apply spiral electromagnetic stirring at the same time, and spiral electromagnetic stirring current 190A, frequency 2.7Hz, stop the spiral electromagnetic stirring after the alloy is completely solidified;

[0040] (3) Use a jaw crusher to crush the deoxidized carburized alloy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com