Method forming via hole that utilizes lazer drill

A technology of laser drilling and vias, which is applied to the removal of conductive materials by chemical/electrolytic methods, the processing of insulating substrates/layers, and printed circuits. It can solve the problems of long processing time, increased processing difficulty, and via-hole Surface unevenness and other problems, to achieve the effect of shortening the processing time, ensuring uniformity, and reducing the phenomenon of electroplating defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Preferred embodiments of the present invention will be specifically described below with reference to the accompanying drawings.

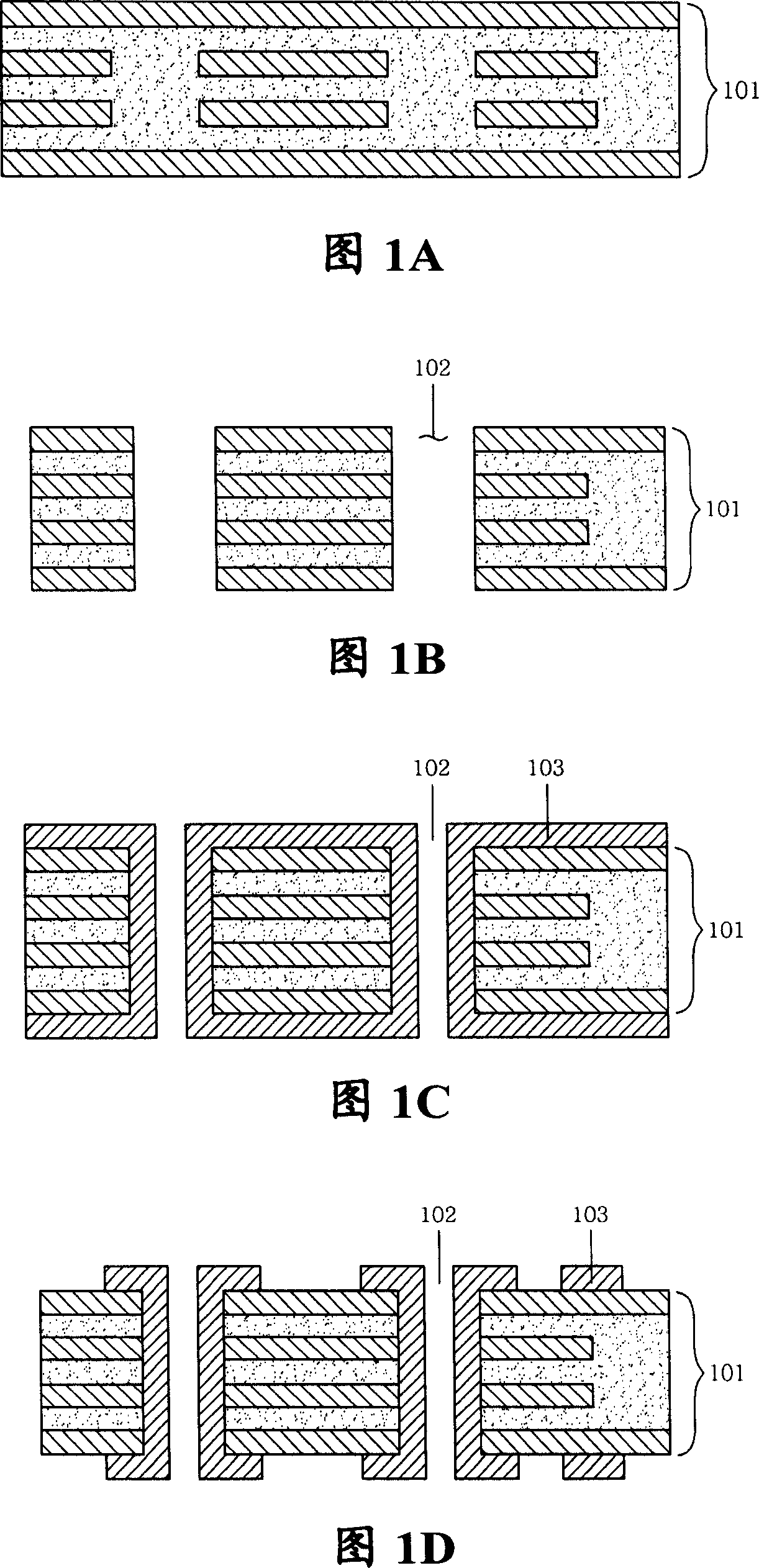

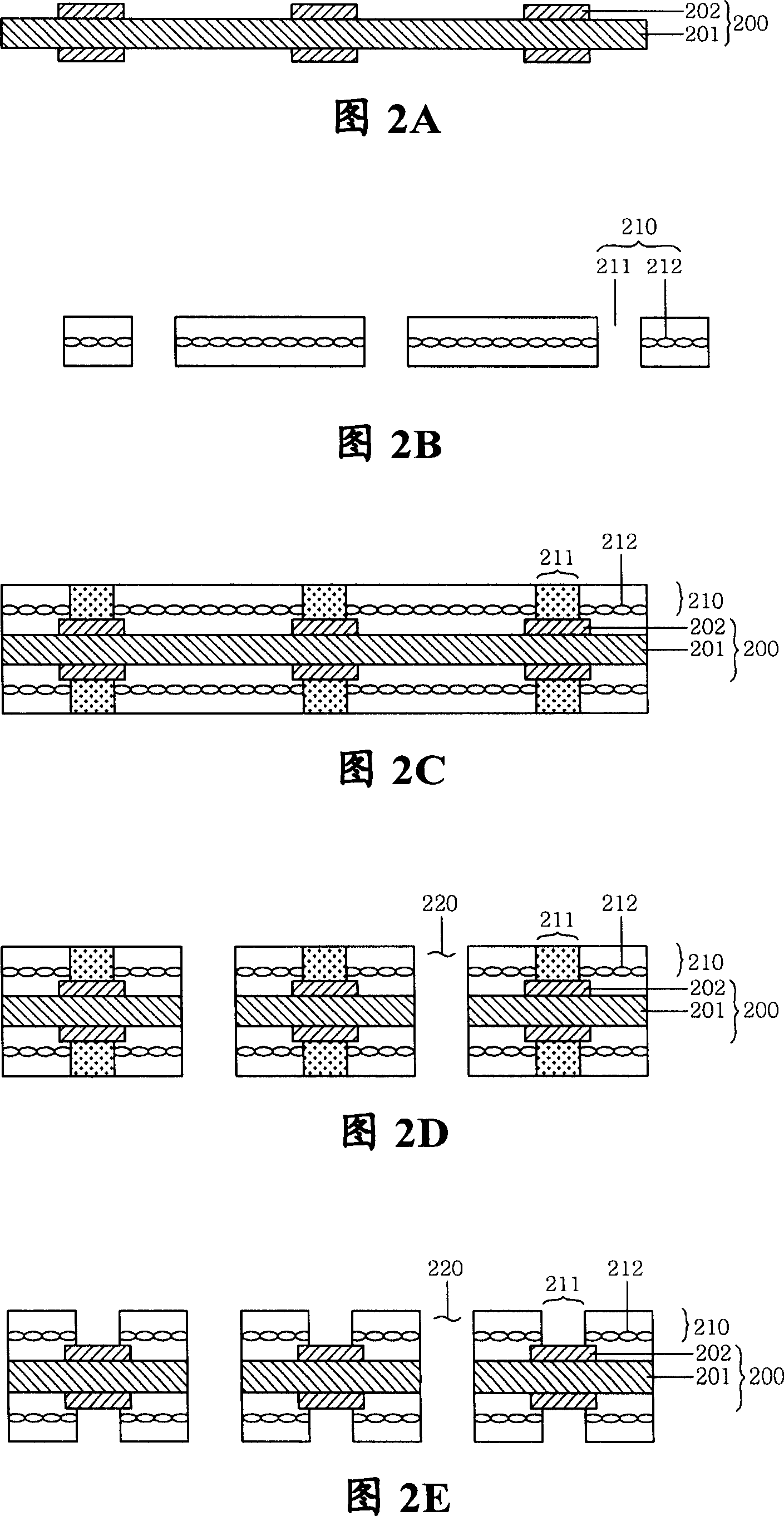

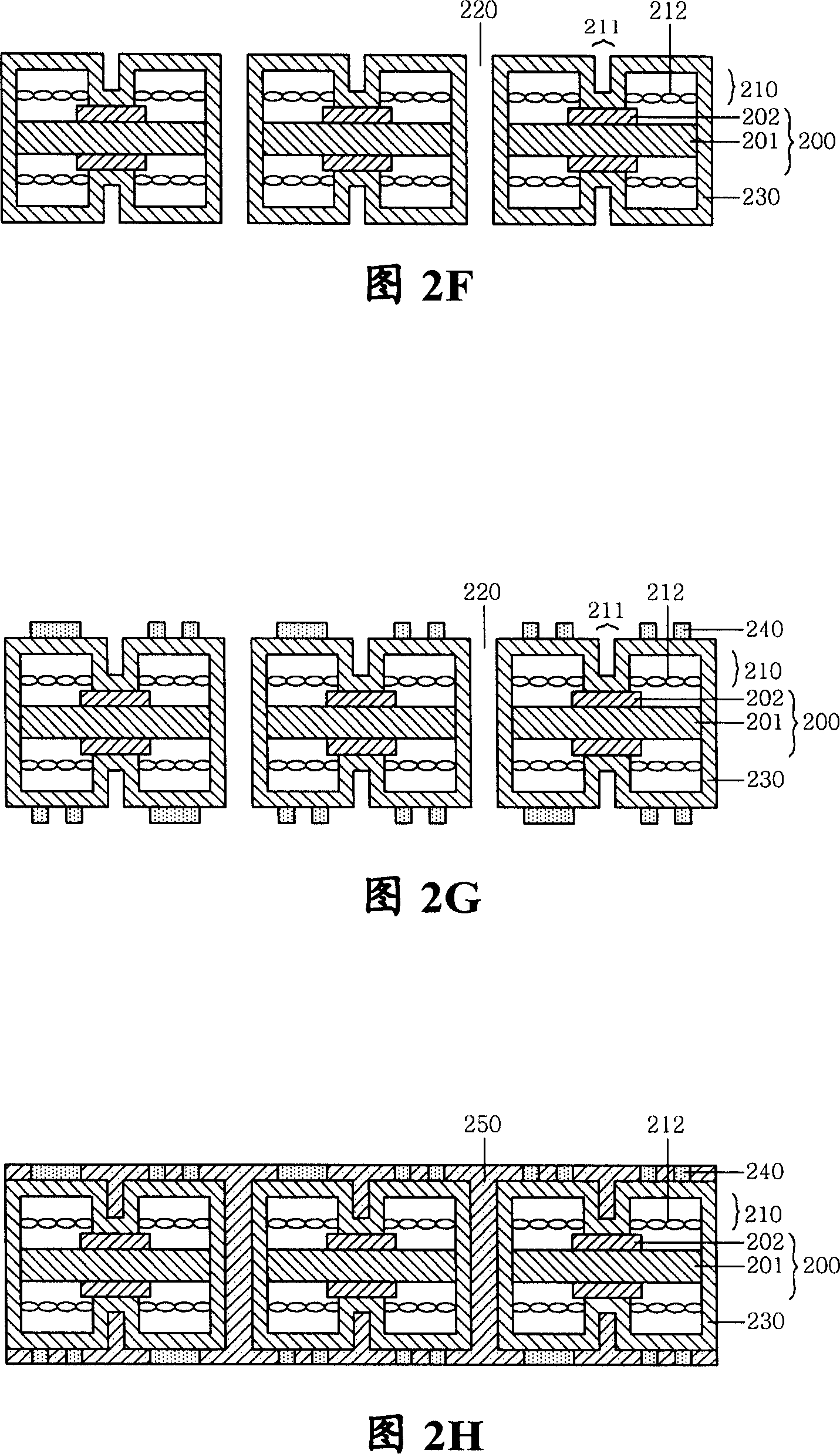

[0025] 2A to 2J are flowcharts of a via hole forming method using a laser drilling machine according to an embodiment of the present invention.

[0026] First, as shown in FIG. 2A , a first circuit board 200 in which circuits 202 are formed on both surfaces of an insulating layer 201 is prepared. In this case, any of prepreg or resin may be used for the insulating layer 201 , and common electrolytic copper foil is used for the circuit 202 .

[0027] Next, as shown in FIG. 2B , a plurality of prepregs 210 drilled with holes are prepared by mechanical drilling at positions where via holes 211 are to be formed. The above-mentioned prepreg 210 is a sheet-shaped raw material (see FIG. 3 ) in which a thermosetting resin is permeated into a base material such as glass fiber and cured to a B stage (B stage refers to a semi-cured state of the resin)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com