A kind of znalmgin high temperature lead-free solder

A lead-free solder, high temperature technology, used in welding/cutting media/materials, welding media, metal processing equipment, etc., can solve the problem that it is difficult to process into strips or filaments, the melting point of the alloy is not significantly reduced, and the melting point of the alloy is reduced. and other problems, to achieve the effects of high microhardness and tensile strength, good wettability and suitable melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

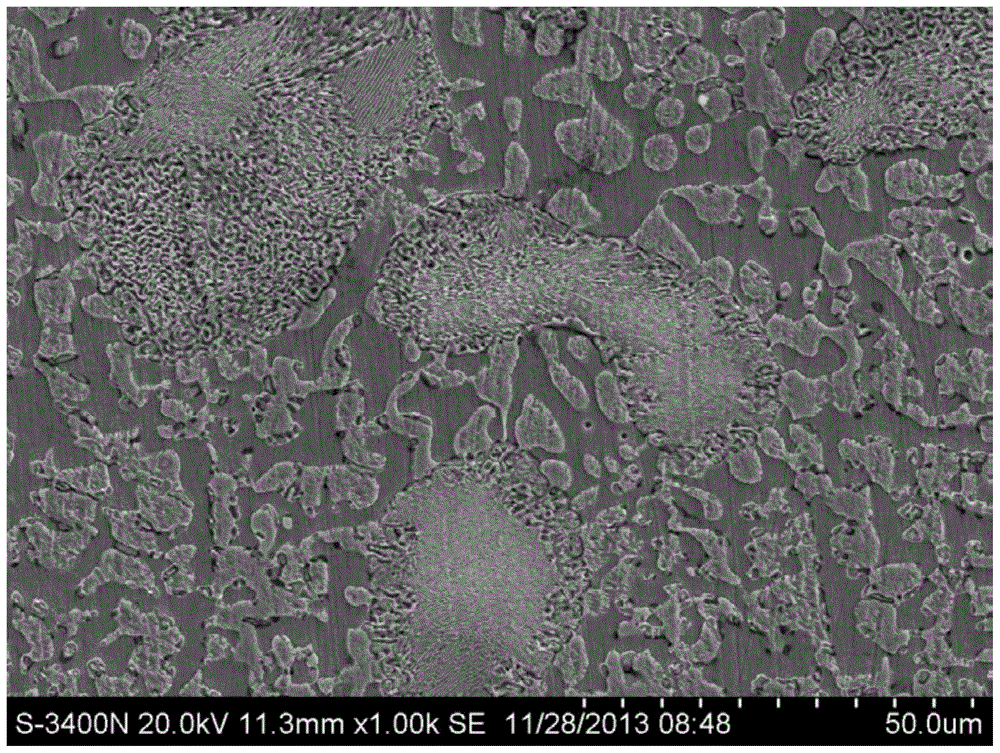

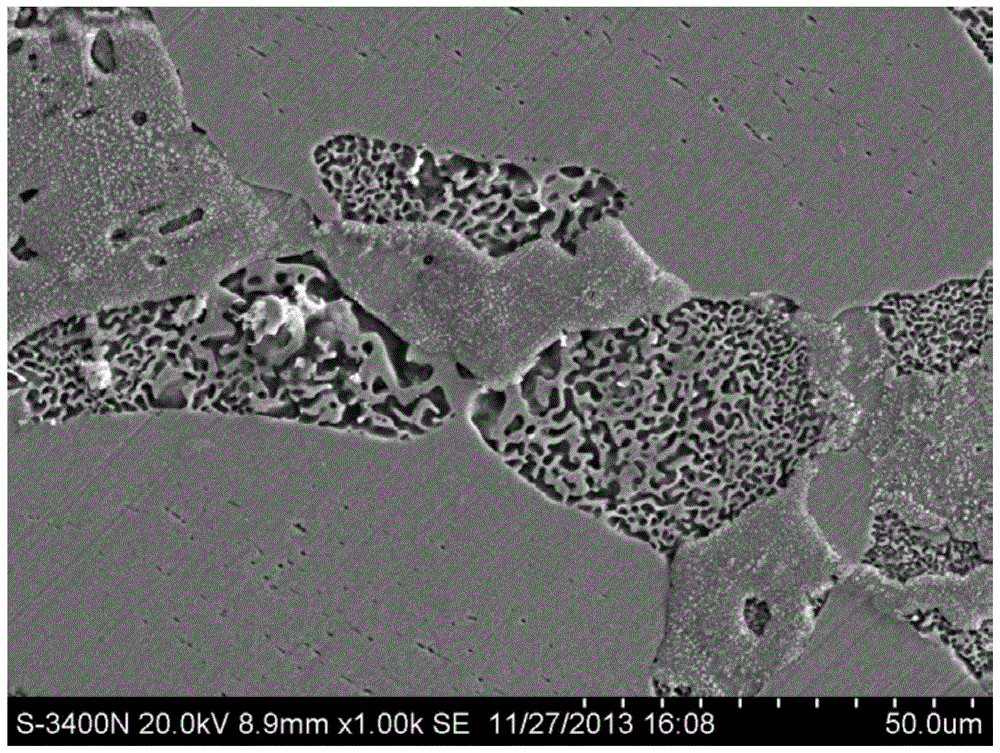

Image

Examples

Embodiment 1

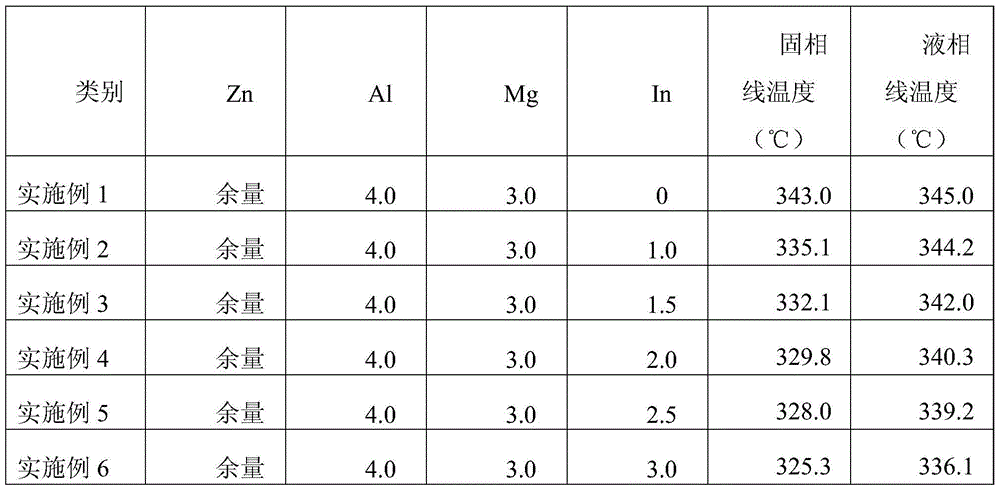

[0013] Embodiment 1: In this embodiment, a high-temperature solder for primary packaging of electronic products is composed of the following components in mass percentage: Al4.0, Mg3.0, and the balance is Zn.

Embodiment 2

[0014] Embodiment 2: In this embodiment, a high-temperature solder for primary packaging of electronic products is composed of the following components in mass percentage: Al4.0, Mg3.0, In1.0, and the balance is Zn.

Embodiment 3

[0015] Embodiment 3: In this embodiment, a high-temperature solder for primary packaging of electronic products is composed of the following components in mass percentage: Al4.0, Mg3.0, In1.5, and the balance is Zn.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com