Preparation method of amino resin retanning agent, retanning agent and application of retanning agent

A technology of amino resin and retanning agent, applied in application, animal husbandry, small raw hide/large raw hide/leather skin/fur chemical treatment, etc., to achieve good product quality, good product quality and simple reaction products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

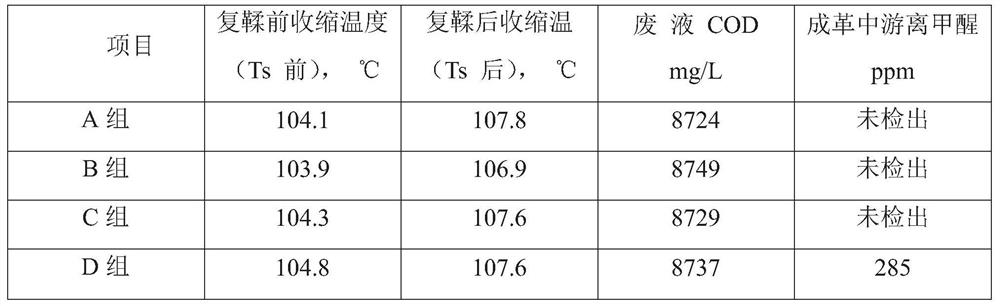

Examples

preparation example Construction

[0029] The invention provides a preparation method of amino resin retanning agent, which uses amino-terminated polyoxyethylene ether to modify dialdehyde monomers, and finally etherifies and blocks free aldehyde groups. Compared with the existing preparation method, avoiding the use of sulfonating reagents in the preparation process, such as sodium bisulfite and other sodium salts, and using amino-terminated polyoxyethylene ether to modify the dialdehyde monomer, so that retanning The agent product has good water solubility and stability, so that it does not appear crystallization caused by sodium salt during storage and use.

[0030] Herein, a range indicated by "one value to another value" is a general representation which avoids enumerating all values in the range in the specification. Therefore, the description of a specific numerical range covers any numerical value in the numerical range and the smaller numerical range bounded by any numerical value in the numerical ra...

Embodiment 1

[0039] (1) Stir and mix 25.81Kg glyoxal and 20Kg pure water at room temperature, adjust the pH value to 8.5, add 6.45Kg polyetheramine D-230, stir evenly, then raise the temperature to 85°C, and continue the reaction for 1.5 hours to obtain Dialdehyde modified products;

[0040] (2) First mix 7.10Kg melamine and 27.74Kg pure water at room temperature, adjust the pH value to 8.5, then add the dialdehyde modified product prepared in step (1) in three equal parts, each interval 10 minutes, react at a temperature of 80°C for 1.0 hour, then raise the temperature to 90°C, and continue the reaction for 20 minutes to obtain a non-ionic amino resin prepolymer;

[0041](3) Add 12.90Kg of ethanol to the nonionic amino resin prepolymer obtained in step (2), adjust the pH value to 5, then react at 60°C for 2 hours, finally adjust the pH value to neutrality, and the product is this The amino resin retanning agent product of embodiment.

Embodiment 2

[0043] (1) Stir and mix 42.28Kg glutaraldehyde and 20.06Kg pure water at room temperature, adjust the pH value to 8.5, add 4.07Kg polyetheramine D-230, stir evenly, then raise the temperature to 80°C, and continue the reaction for 1.0 hour, Obtain dialdehyde modified product;

[0044] (2) First mix 6.50Kg melamine and 21.00Kg pure water at room temperature, adjust the pH value to 8.5, then add the dialdehyde modified product prepared in step (1) in three equal parts, each interval 10 minutes, react at a temperature of 75°C for 1.0 hour, then raise the temperature to 85°C, and continue to react for 10 minutes to obtain a non-ionic amino resin prepolymer;

[0045] (3) Add 11.49Kg diethylene glycol to the nonionic amino resin prepolymer obtained in step (2), adjust the pH value to 4, then react at 60°C for 2 hours, and finally adjust the pH value to neutrality, the product Be the amino resin retanning agent product of the present embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com