Quick locking mechanism

A locking mechanism and fast technology, applied in the direction of locking fasteners, connecting components, mechanical equipment, etc., can solve problems such as thread damage, affecting locking function, and low locking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

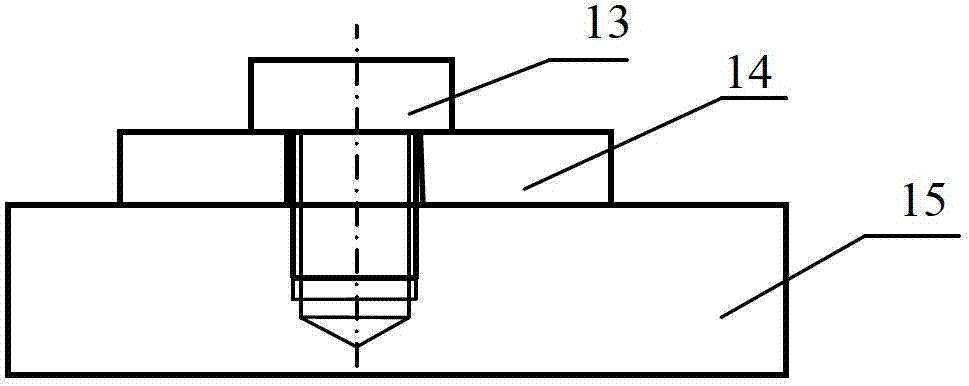

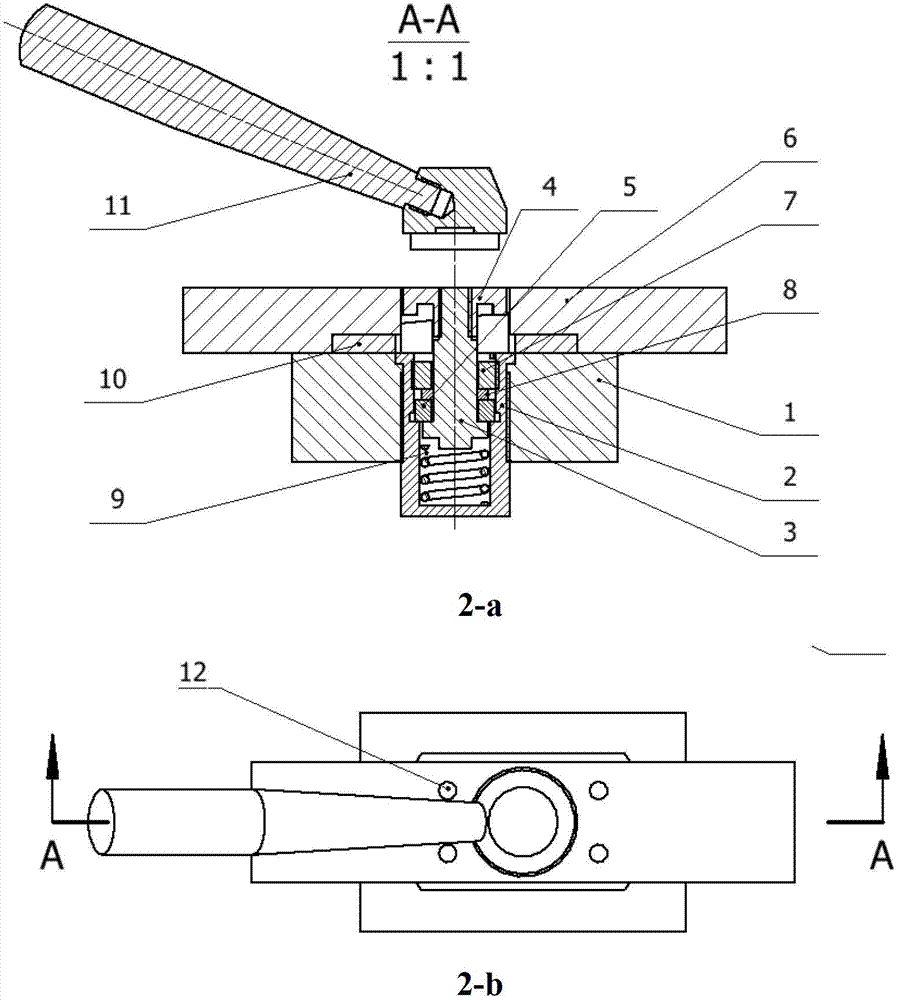

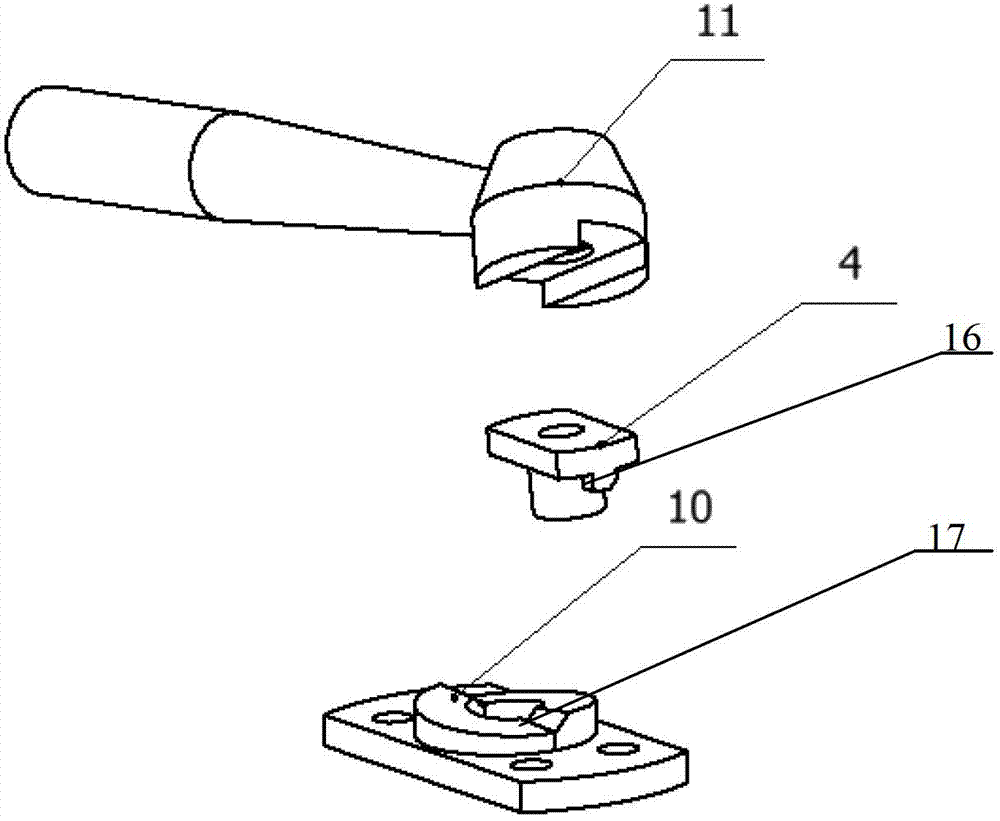

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0012] This structure is mainly composed of a locking sleeve 2, a locking shaft 3, a locking nut 4, and an oblique pressure block 10;

[0013] During the locking process of the lock nut 4 with the locking shaft 3 through the thread, it contacts with the oblique pressure block 10 with an inclined surface. The axial displacement during the locking process is the superposition of the spiral displacement and the rising displacement of the inclined surface. With anti-loose spring washer 8.

[0014] The oblique pressing block 10 is fixed on the workpiece B6 through the screw 12, and the locking sleeve 2 is fixed in the threaded hole of the workpiece A1 through the thread on its outer cylindrical surface;

[0015] A compression spring 9 is installed at the bottom of the center hole of the lock sleeve 2, and is supported on the lower end surface of the lock shaft 3. The cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com