Material storing and material taking integrated automatic screw driving machine

A locking screw machine, an integrated technology, applied in metal processing, metal processing equipment, manufacturing tools and other directions, can solve the problems of single product, low production efficiency of locking screws, and occupation of locking time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer and more comprehensible, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

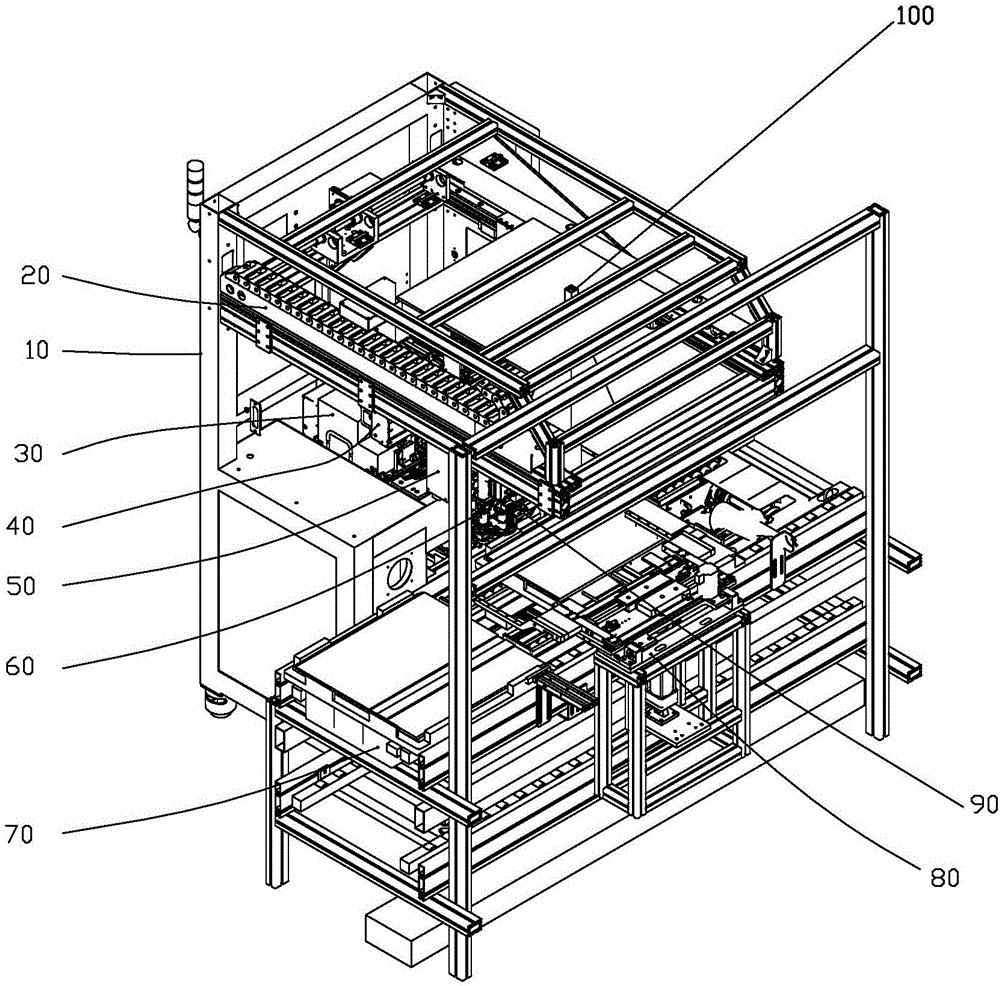

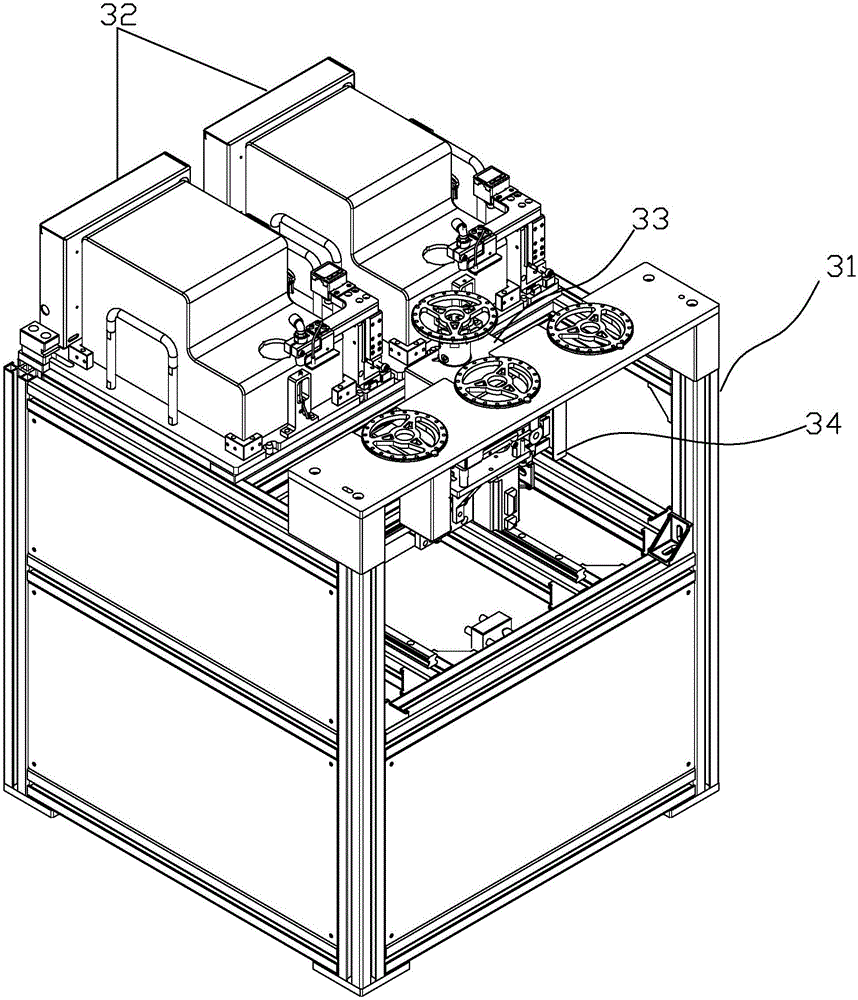

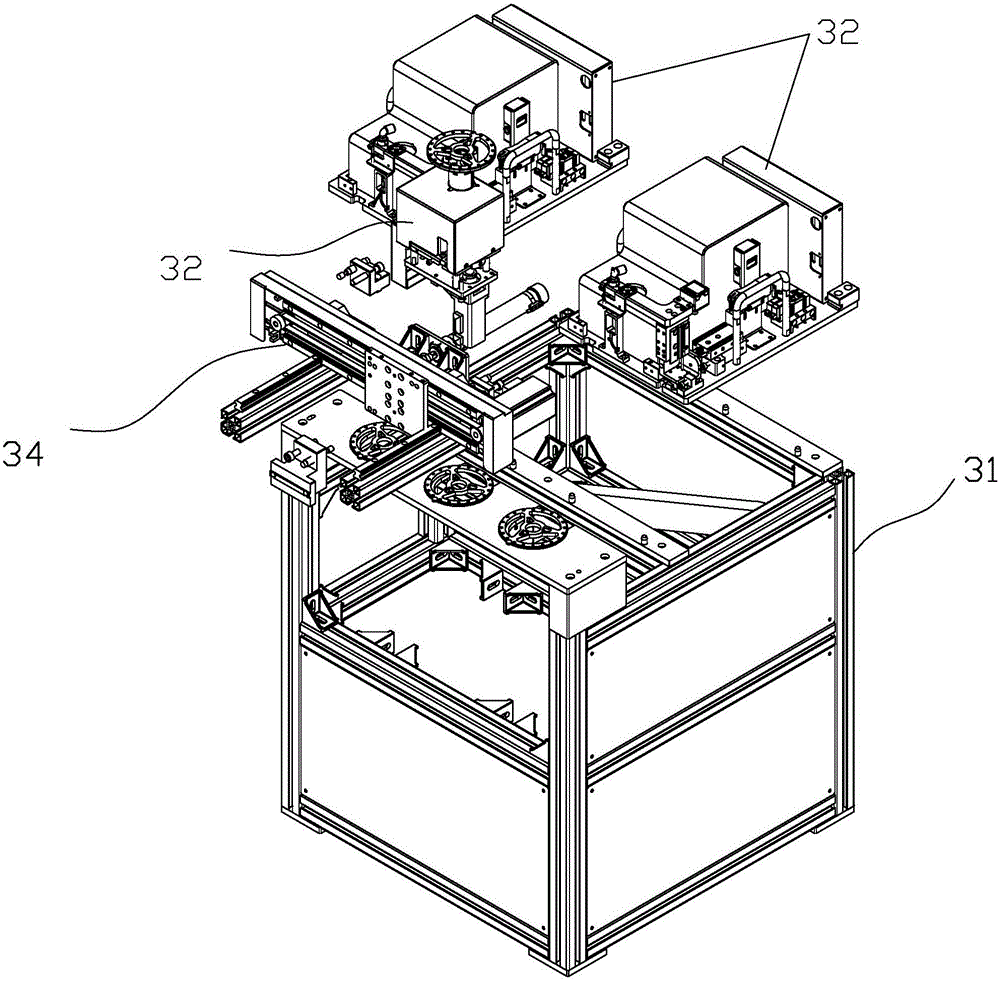

[0035] Please refer to Figure 1 to Figure 18 As shown, an integrated automatic locking screw machine for accessing materials is described below in conjunction with the embodiments, including a cabinet main body bracket 10, a cabinet attachment bracket installed on the side of the cabinet main body bracket 10; a Y-axis assembly 20, an X-axis assembly 40, and a Z-axis assembly 50. Feeding tray screw feeding system 30, left and right lifting and rotating locking device 60, CCD auxiliary positioning system 100, flipping fixture 80, product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com