Patents

Literature

344 results about "Hydrolytic Process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrolytic process. A reaction of both organic and inorganic chemistry wherein water effects a double decomposition with another compound, hydrogen going to one compound and hydroxyl to another.

Enzyme compositions for the improved enzymatic hydrolysis of cellulose and methods of using same

InactiveUS20090209009A1Extended reaction timeReduce probabilityBiofuelsChemical recyclingFiberEnzymatic hydrolysis

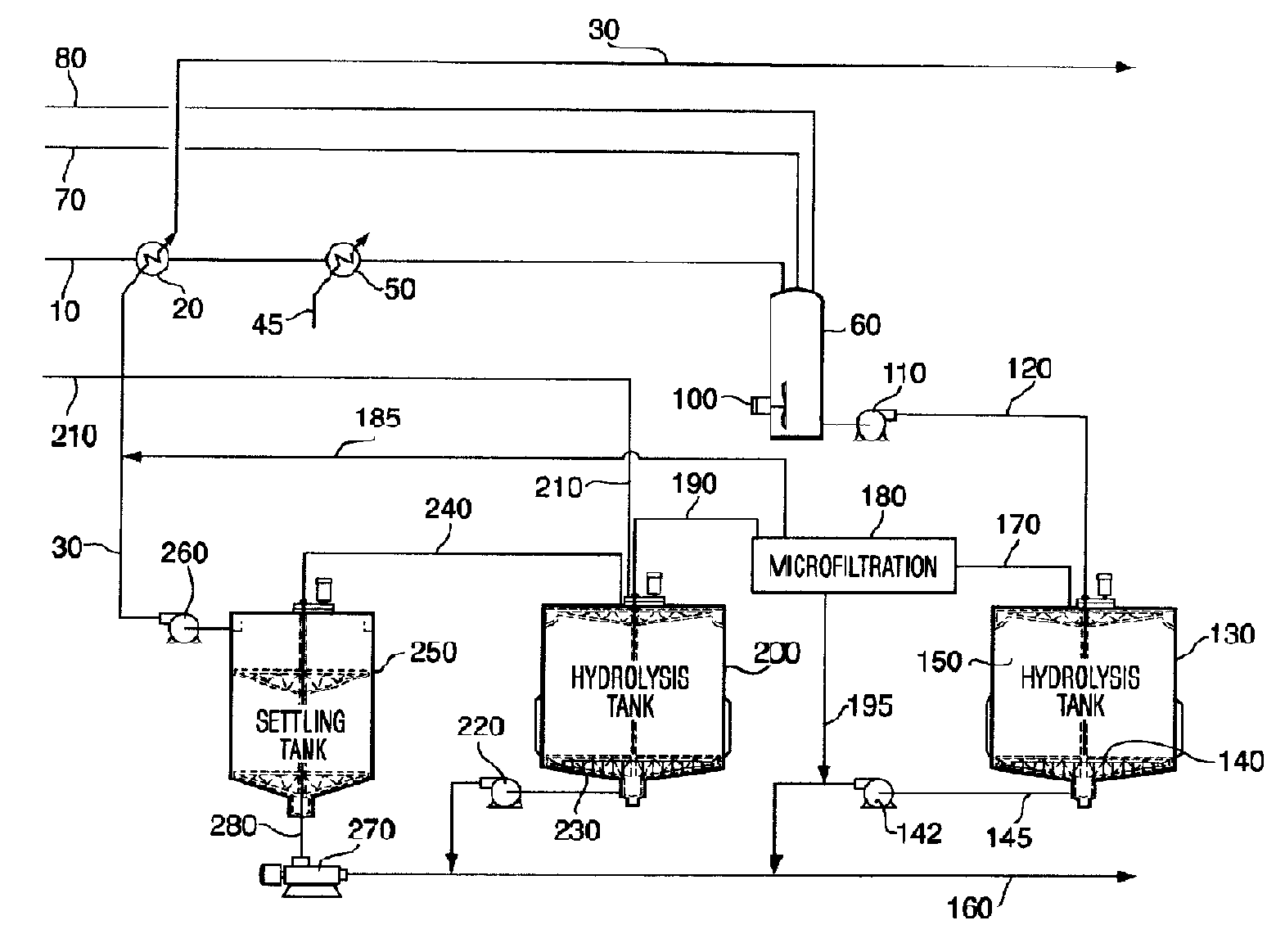

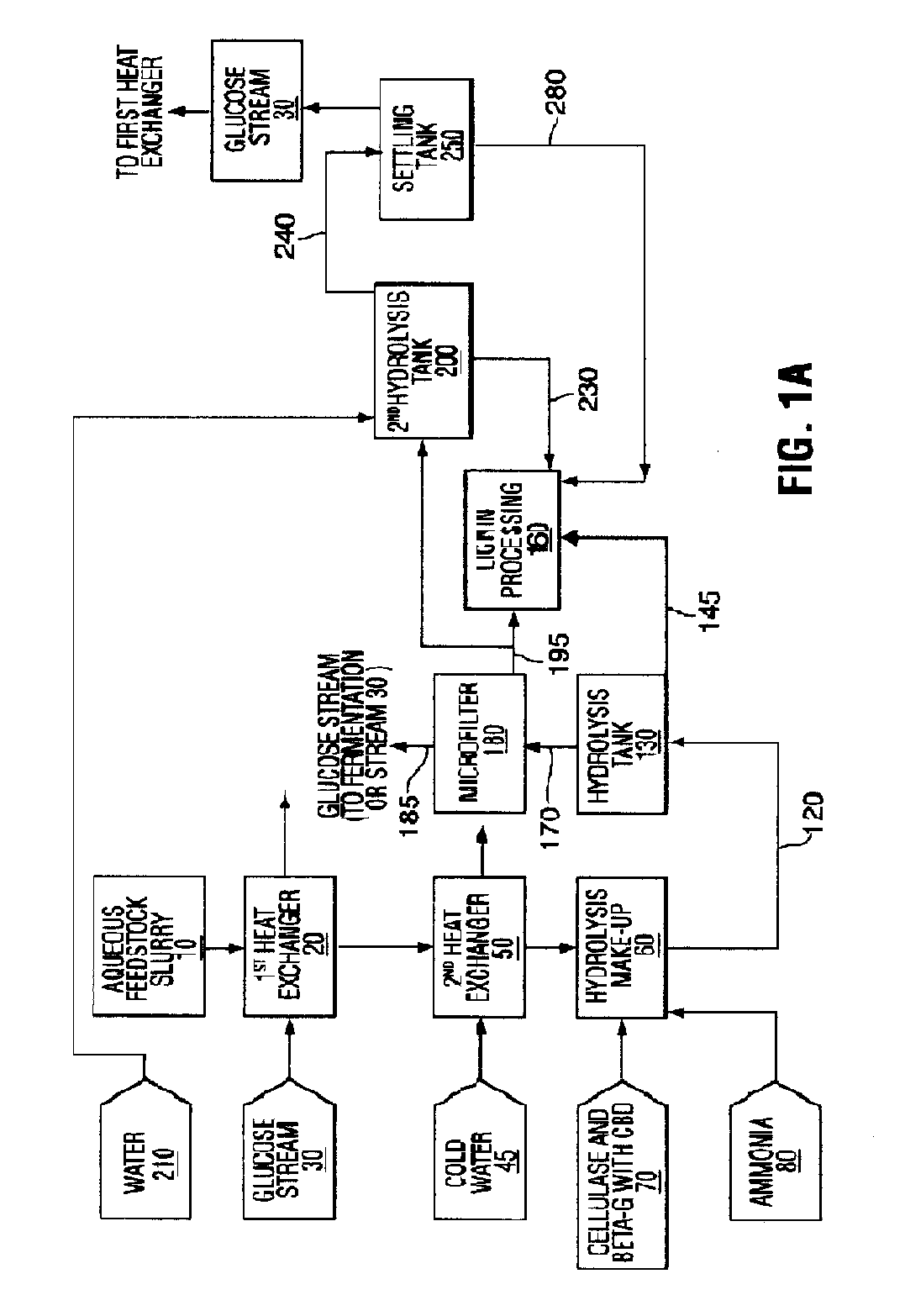

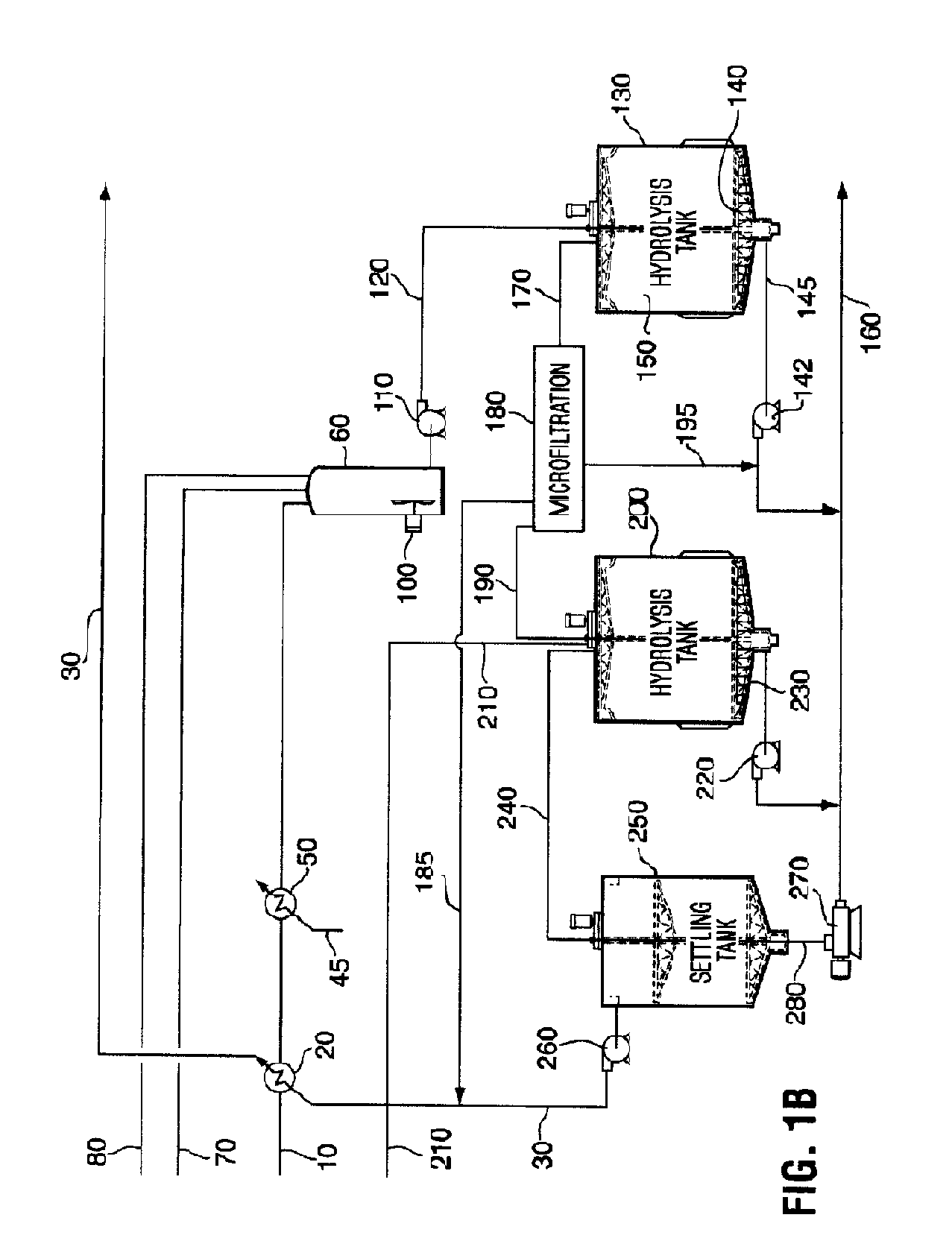

A process for the enzymatic hydrolysis of cellulose to produce a hydrolysis product comprising glucose from a pretreated lignocellulosic feedstock and enzymes for use in the process are provided. The process comprises hydrolyzing an aqueous slurry of a pretreated lignocellulosic feedstock with cellulase enzymes, one or more than one β-glucosidase enzyme and a binding agent for binding the β-glucosidase enzyme to fiber solids present in the aqueous slurry. During the hydrolysis, both the cellulase enzyme and β-glucosidase enzyme bind to the fiber solids. The hydrolysis is performed in a solids-retaining hydrolysis reactor so that unhydrolyzed fiber solids and bound enzyme are retained in the reactor longer than the aqueous phase of the slurry.

Owner:IOGEN ENERGY CORP

Apparatus for the evaporation of aqueous organic liquids and the production of powder pre-forms in flame hydrolysis processes

InactiveUS20050205215A1Drying using combination processesEvaporator liquid feederOrganic liquidsEvaporation

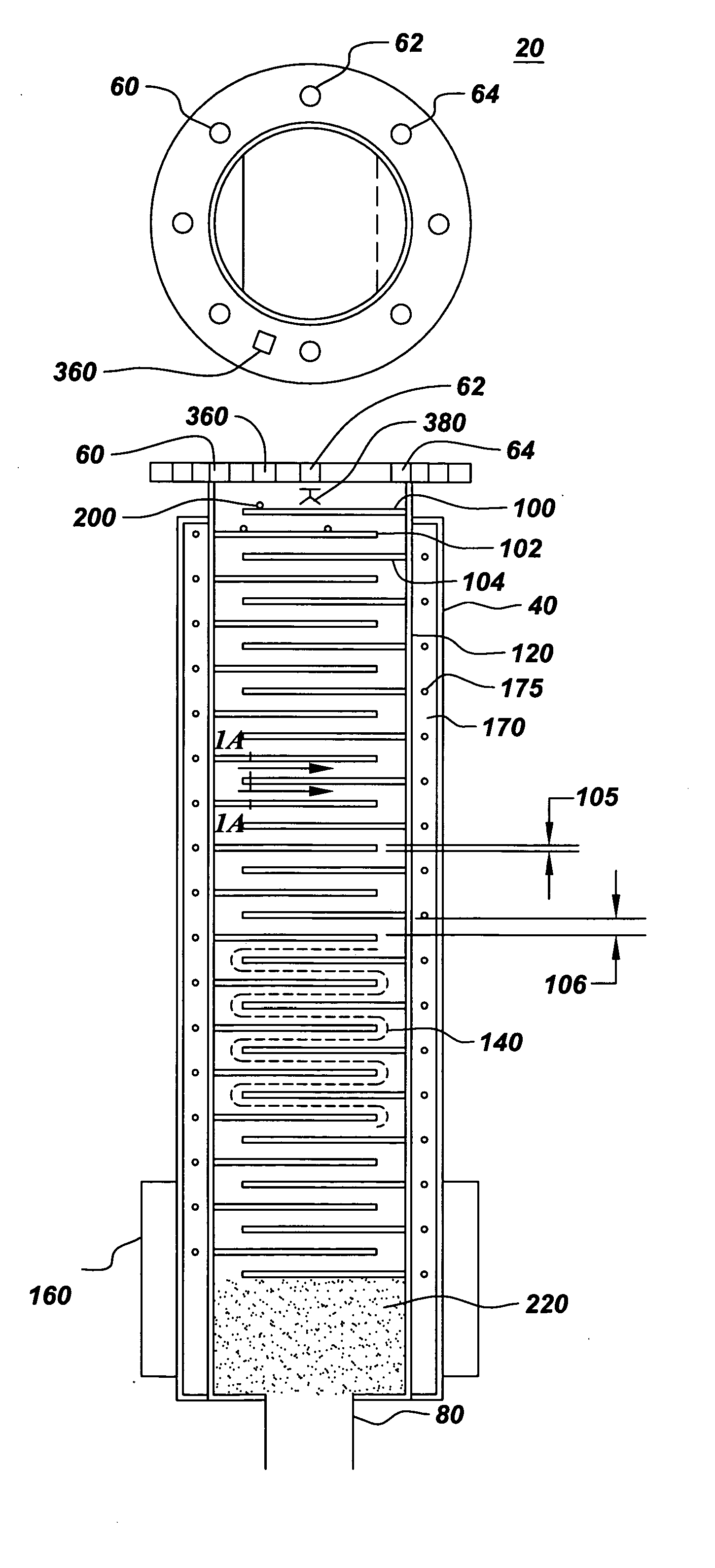

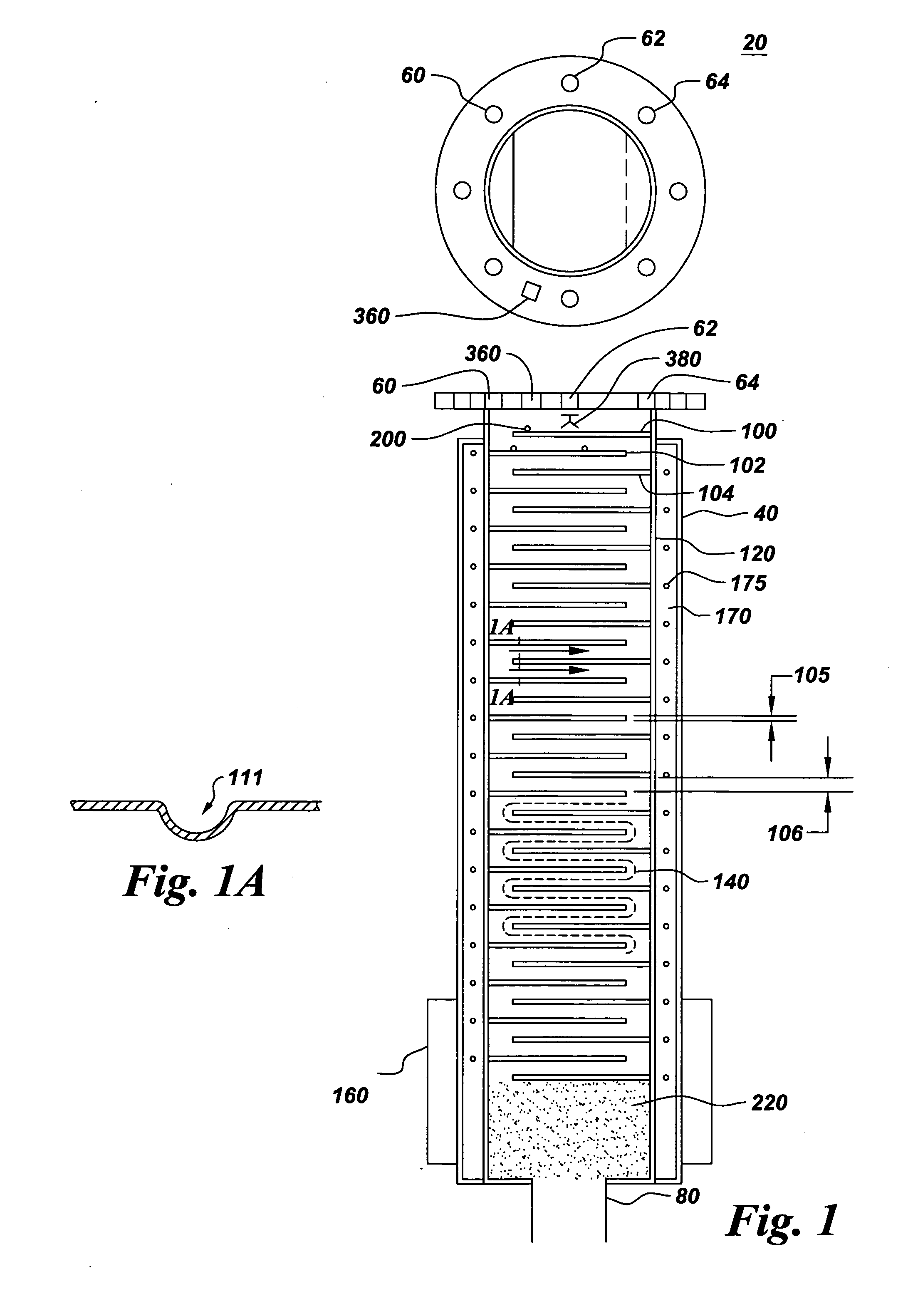

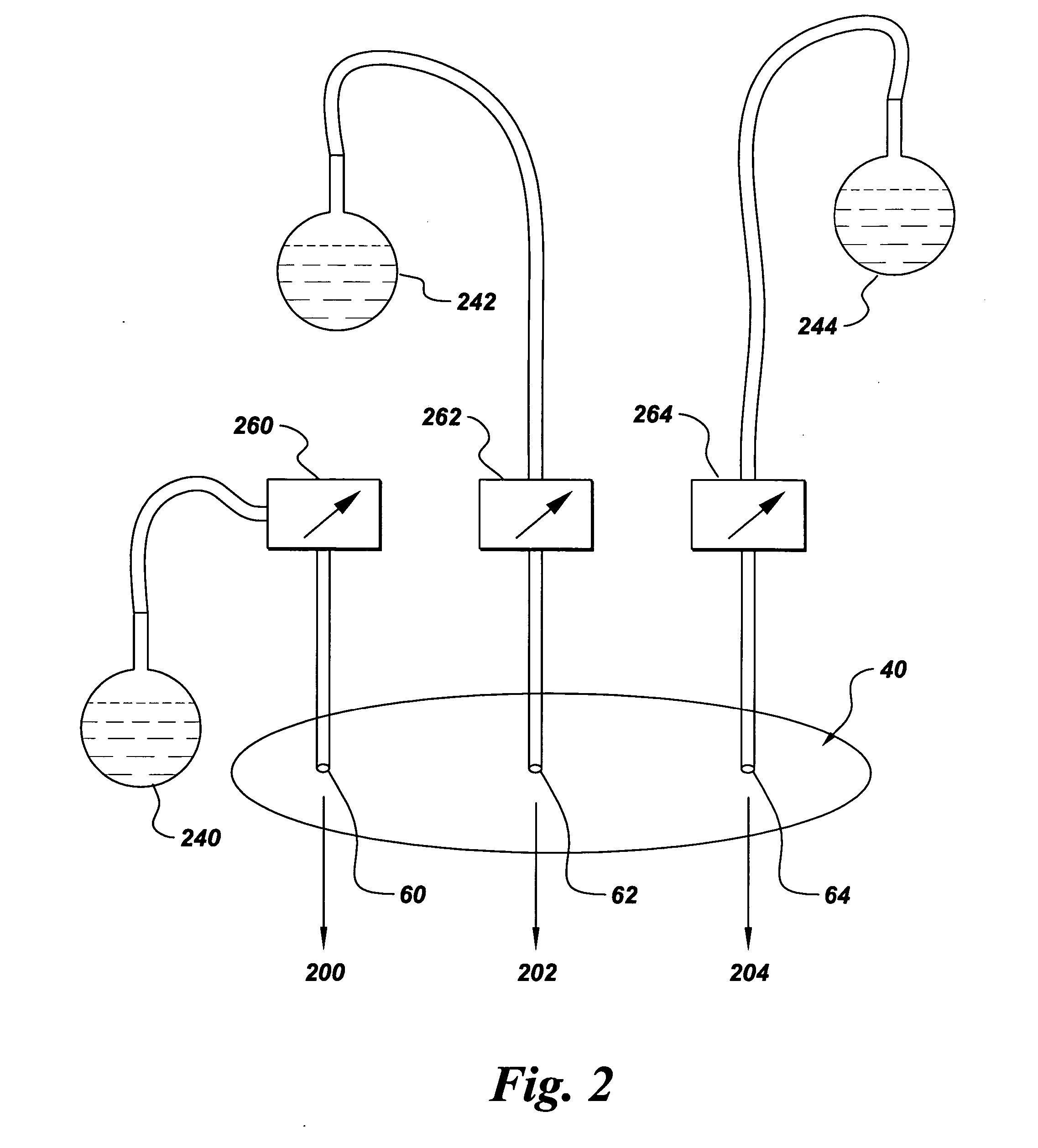

An organic liquid evaporation system is disclosed. The organic liquid evaporation system comprises a housing having at least one inlet and at least one outlet. At least a first evaporator plate radially extending from a sidewall of the housing, and at least a second evaporator plate radially extending from a sidewall of the housing define a serpentine flow path within the housing. A heating source is in thermal communication with the first evaporator plate and the second evaporator plate, wherein the heating source provides heat to the first and second evaporator plates to evaporate organic liquid introduced within the inlet to produce a vapor through the outlet. A method for preparing powder pre-forms and oxide soot using the organic liquid evaporation system is also disclosed.

Owner:GENERAL ELECTRIC CO

Treatment Systems and Processes for Lignocellulosic Substrates that Contain Soluble Carbohydrates

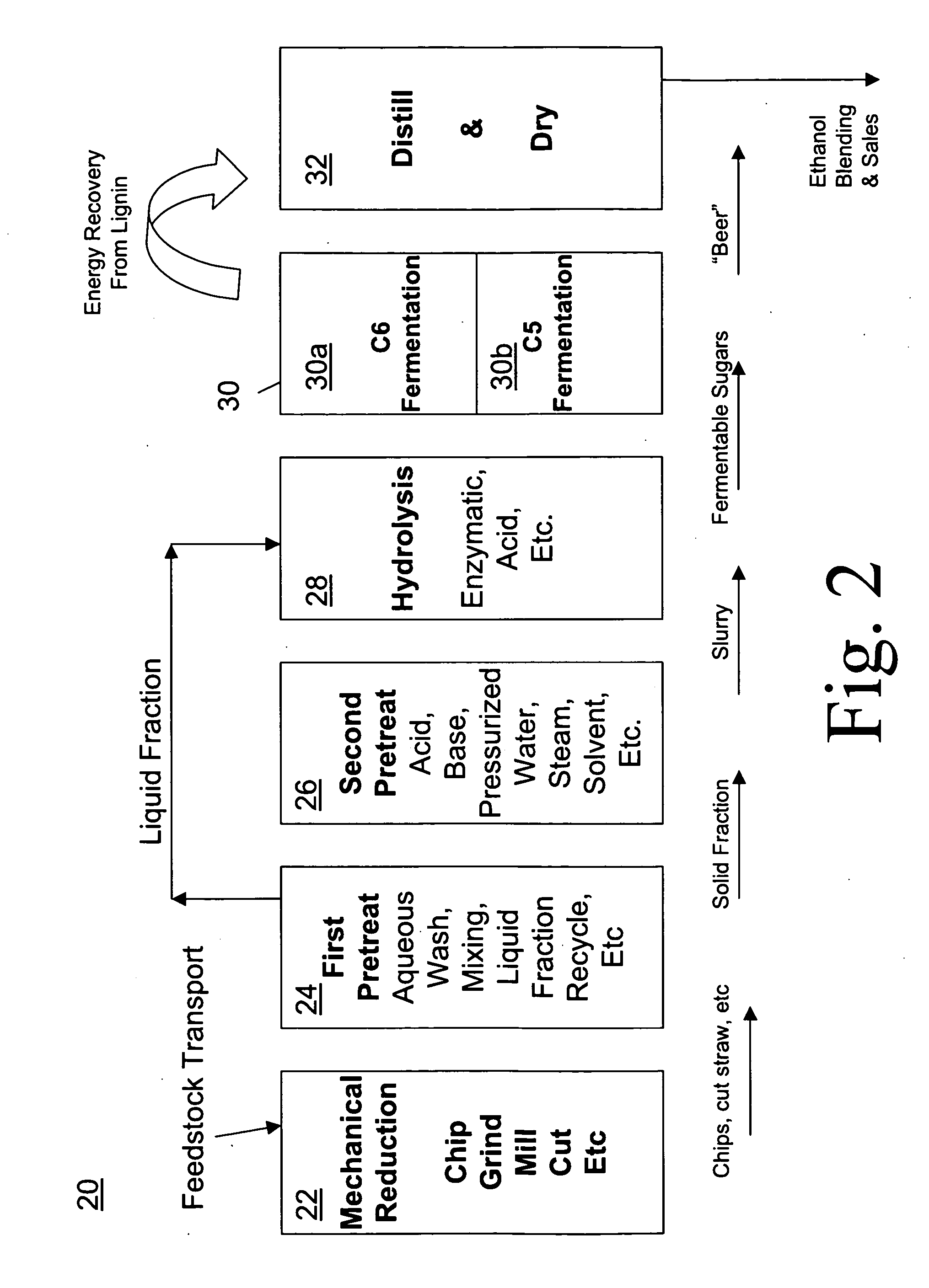

InactiveUS20090061495A1Lowering capital cost per unit of ethanol producedImprove throughputBiofuelsFermentationDistillationPolymer

A biorefining process used to convert lignocellulosic biomass into ethanol via a fermentation pathway. In a first pretreatment process step, the biomass is mixed with an aqueous wash solution to remove soluble carbohydrates from the biomass structure. Next, the solid fraction is separated from a liquid fraction. In a second pretreatment process, the solid fraction is pre-treated to make the fiber bundles and complex polysaccharides more amenable to enzymatic hydrolysis. Following the second pretreatment process, the pre-treated biomass is subjected to one or more enzymes in a hydrolysis process. The liquid fraction isolated from the first pretreatment process is diverted past the second pretreatment process and is recombined with the solid fraction in the hydrolysis process. The enzyme cocktail in the hydrolysis process breaks down the alpha- and hemicellulose polymers into fermentable sugars. Finally, a fermentation process produces a “beer” that is further processed in a distillation and dehydration process.

Owner:BEATTY CHRIS +2

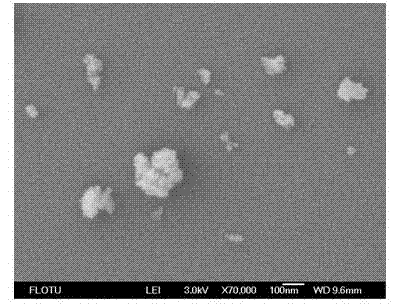

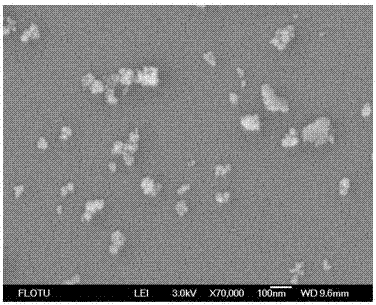

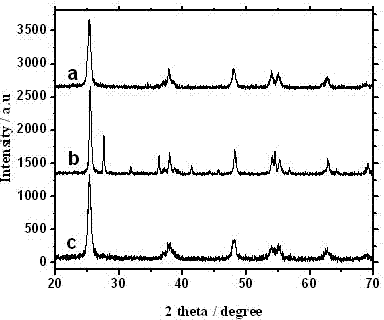

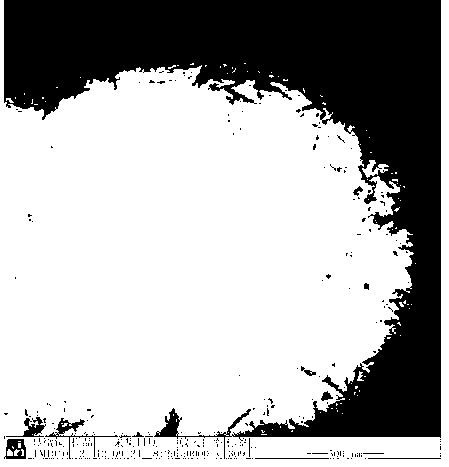

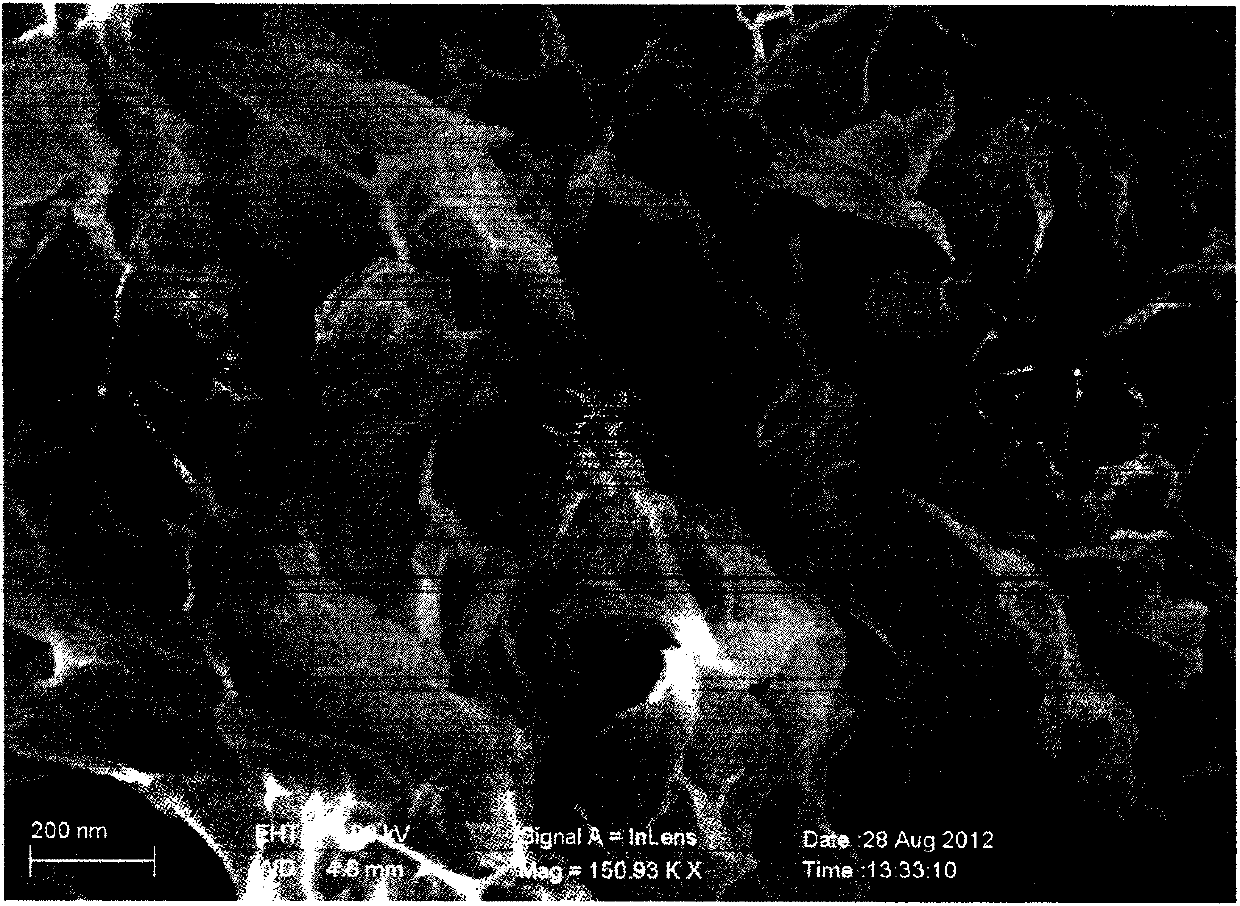

High-magnetic heavy-metal ion adsorbent carrying conductive high molecules and preparation method thereof

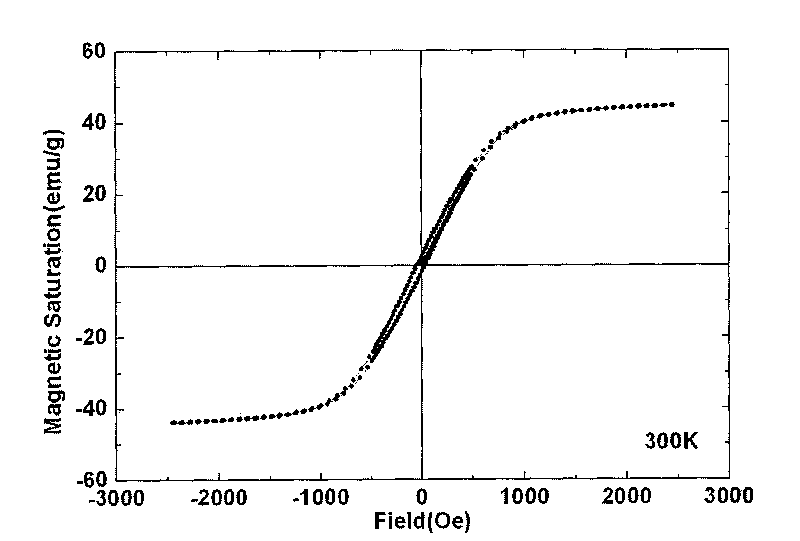

ActiveCN101708463AStable in natureHigh magnetic responsivenessOther chemical processesWater contaminantsMicrospherePolypyrrole

The invention discloses a high-magnetic heavy-metal ion adsorbent carrying conductive high molecules and a preparation method thereof. The adsorbent comprises high-magnetic microspheres carrying conductive high molecules, each of which comprises a Fe3O4 polycrystal sphere cluster, an amorphous SiO2 protective layer and a polypyrrole adsorption outer layer from inside to outside. The preparation method of the adsorbent is realized in a way that: carrying out a solvent thermal reduction reaction on soluble ferrites to obtain the Fe3O4 magnetic sphere cluster; carrying out the basic hydrolysis by using tetraethoxysilane to obtain the Fe3O4-SiO2 nuclear shell sphere cluster; and finally, carrying out the free radical polymerization reaction on the pyrrole monomers to obtain the Fe3O4-SiO2-polypyrrole functional particles. The heavy-metal ion adsorbent has the characteristics of stable property, high adsorption rate and reproducibility, has favorable adsorption and recovery properties on dichromic ions, and has the advantages of simple preparation process, low material price and no environmental pollution. Compared with the normal chemical absorbent, the product of the invention is convenient to use and achieves the effects of waste water treatment, pollution abatement and environment protection.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

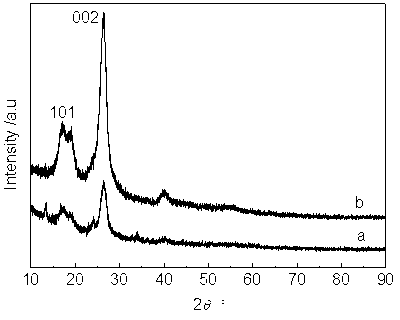

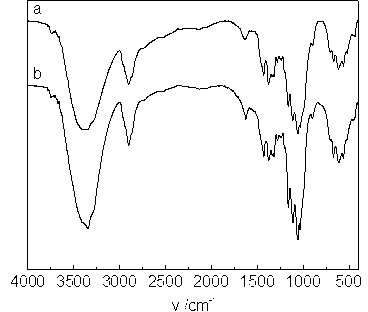

A direct method to prepare molecularly imprinted tio2/wo3 composite photocatalyst with visible light response

InactiveCN102284284AHigh mechanical strengthHigh visible light activityWater/sewage treatment by irradiationWater contaminantsFunctional monomerLight response

The invention discloses a method for preparing a molecularly imprinted TiO2 / WO3 composite photocatalyst with visible light response through a direct method. The method is as follows: a titanium alkoxide is used as a sol and functional monomer precursor, an organic pollutant is used as a template molecule, absolute alcohol is used as a solvent, glacial acetic acid is used as an inhibitor, a sol-gel method is adopted, and the materials are prepared according to a certain ratio, wherein the molar ratio of the template molecule to Ti is 1:20-1:10, and the titanium alkoxide, absolute alcohol, glacial acetic acid and water are mixed in a volume ratio of 10:19:8:4. The method has the following technical effect: the titanium alkoxide has double functions, namely the titanium alkoxide can be used as a titanium source and can also be used as a functional monomer in the hydrolysis process. Other organic functional monomers are not required.

Owner:NANCHANG HANGKONG UNIVERSITY

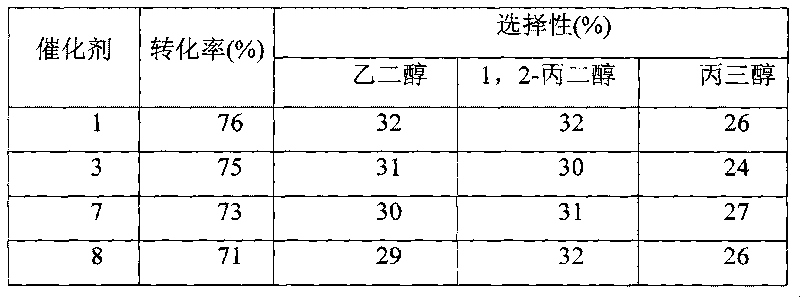

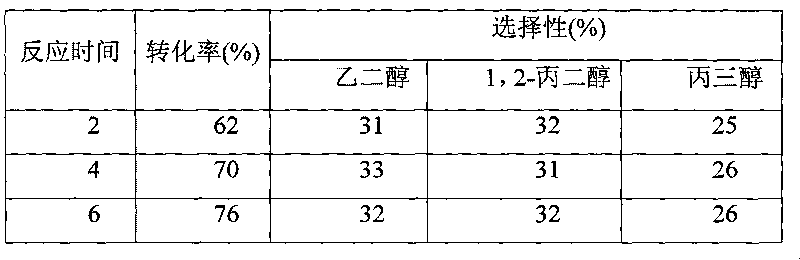

Method for preparing ethylene glycol, propylene glycol and glycerine by carrying out catalytic conversion on corn cobs

ActiveCN101704710ARelieve stressAchieve sustainable useOrganic compound preparationHydroxy compound preparationPolyesterAcid catalyzed

Corn cobs are important biomass resources. For a long time, the corn cobs have low chemical utilization ratio or cannot be utilized sufficiently to cause a great waste of resources. The invention develops a method for preparing ethylene glycol, propylene glycol and glycerine by carrying out catalytic hydrocracking conversion on the corn cobs, wherein the product is an important polyester synthetic chemical raw material. The corn cobs are efficiently converted into low carbon polyol products by the processes of acid-catalyzed hydrolysis, catalytic hydrogenation conversion and cracking. The yield of xylose in the hydrolytic process reaches over 30 percent; the conversion rate in the hydrogenation process reaches over 90 percent; and the selectivity in the hydrogenation process reaches over 90 percent.

Owner:JIANGSU SOPO GRP +1

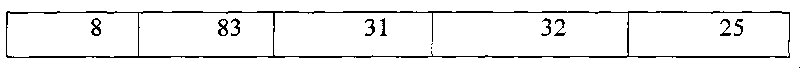

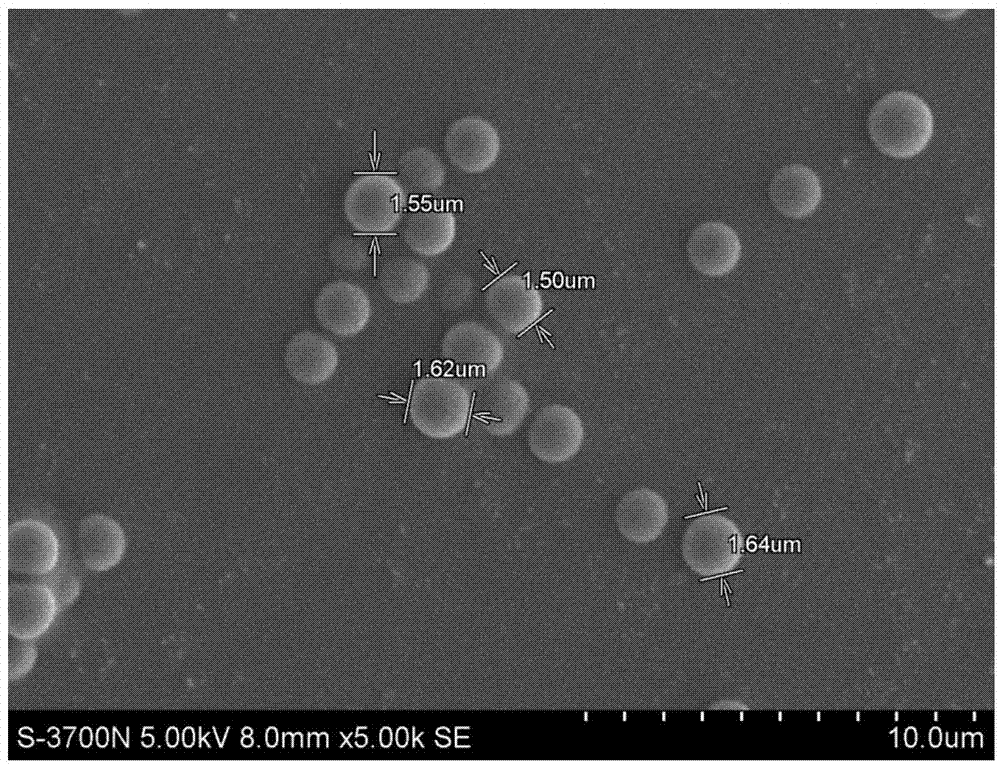

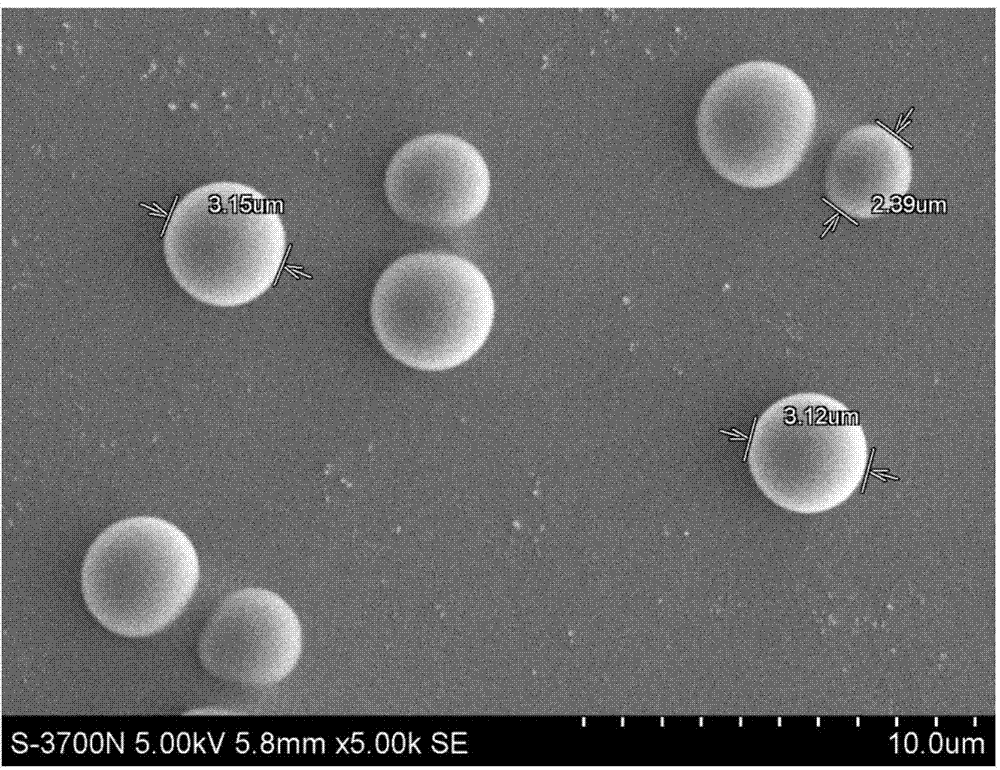

Preparation method of mono-dispersion polysiloxane microspheres with controllable particle size

The invention discloses a preparation method of mono-dispersion polysiloxane microspheres with controllable particle size. The preparation method comprises the following three specific steps: (1) hydrolytic process: adding a certain amount of acidic catalyst into de-ionized water, mechanically mixing uniformly to form an acidic aqueous solution with a certain pH (potential of hydrogen) value, adding siloxane monomers according to a ratio, reacting for a period of time while stirring with a certain rotation speed, to form silanol solution; (2) polycondensation process: adding alkaline solution into the reaction system obtained in the step (1) to adjust the pH value of the system, keeping a certain mechanical rotation speed under a normal temperature condition, stirring and reacting for a period of time; and (3) drying process: centrifugally separating the solution obtained in the step (2), washing by mixed solution of ethanol and de-ionized water, drying in a vacuum drying oven, so as to obtain the polysiloxane microspheres with certain particle size. The method disclosed by the invention is simple, heating and nitrogen protecting device are not required, a toxic solvent is not required, and the controllability of the particle size of the microspheres is realized.

Owner:SOUTH CHINA UNIV OF TECH

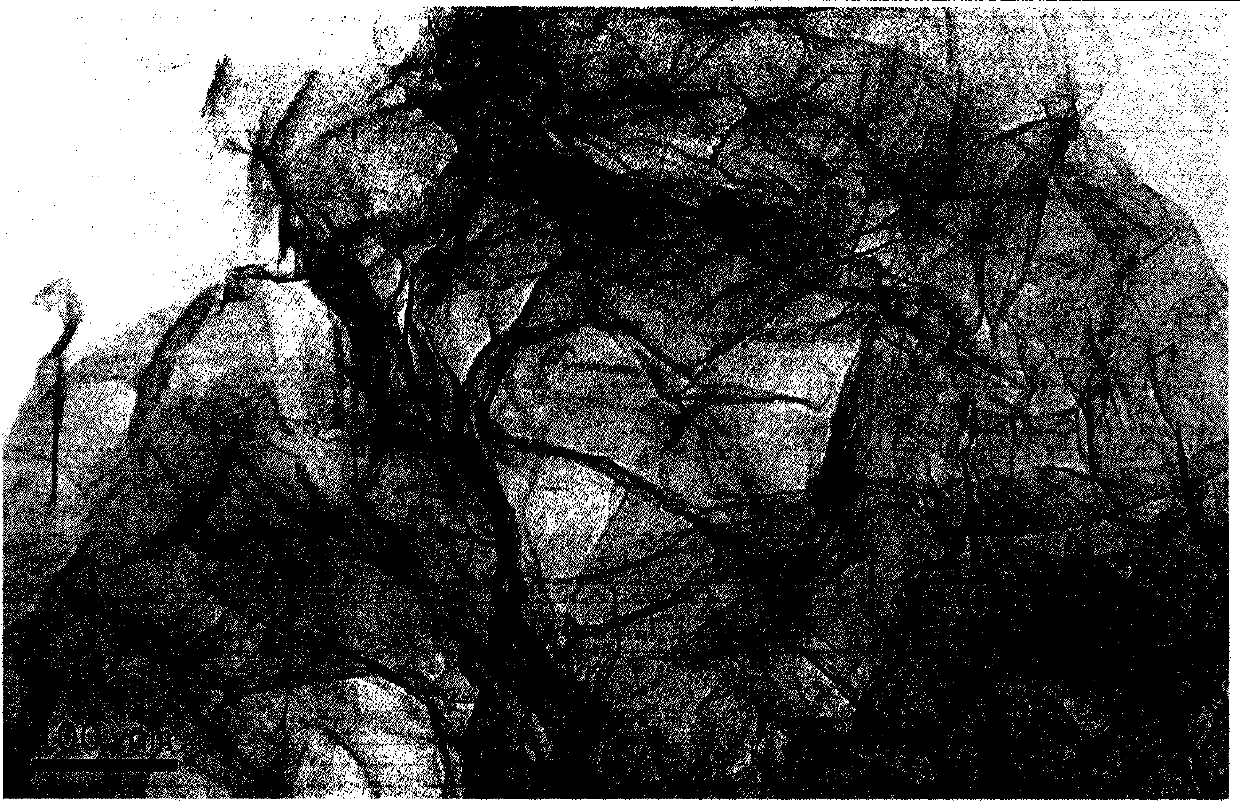

Method for preparing nano cellulose by simultaneous assistance of ultrasonic waves and microwaves

The invention discloses a method for preparing nano cellulose by simultaneous assistance of ultrasonic waves and microwaves, belonging to the field of biomass nano materials. According to the nano material, liquid acid is taken as a catalyst, and the high-efficiency hydrolysis at the amorphous area of cellulose is promoted due to the simultaneous assistance of the ultrasonic waves and microwaves, so that the nano cellulose is rapidly prepared by plant fiber raw materials. The preparation method comprises the steps of acid hydrolysis of plant cellulose, centrifugal recovery of liquid acid and centrifugal separation of nano cellulose. According to the method, the mechanical dispersion action and ultrasonic cavitation effect of the ultrasonic waves, microwave uniform heating effect, catalytic action of the liquid acid and the synergistic effect of the ultrasonic waves and microwaves are utilized sufficiently, and the hydrolytic process of cellulose is enhanced, so that the high-efficiency and rapid preparation of the nano cellulose can be realized. The prepared nano cellulose material can be used for food additives, drug excipients, engineering material additives, specialty paper additives and the like.

Owner:FUJIAN AGRI & FORESTRY UNIV

Process for preparing furfural by using agricultural by-products of high and crude fiber plants

InactiveCN102659723AImprove productivityHigh iodine valueOrganic chemistryCarbon compoundsFiberPhosphoric acid

The invention discloses a process for preparing furfural by using agricultural by-products of high and crude fiber plants. The process includes the steps of 1) conducting pretreatment of raw materials; 2) hydrolyzing pretreated raw materials in a hydrolyzing tank, and using an acid catalyst formed by mixing sulfuric acid and phosphoric acid during the hydrolytic process; 3) introducing high-temperature steam into the hydrolyzing tank, heating up the hydrolyzing tank, and conducting gap stripping for hydrolysis products of furfural; and 4) feeding gas stripped furfural to into a furfural phase splitter to obtain coarse furfural and furfural residues. According to the process, the acid catalyst combining the sulfuric acid and the phosphoric acid is used for hydrolyzing the raw materials, and the hydrolytic process is assisted by ultrasonic treatment simultaneously, so that the productivity of the furfural is improved, the residue amount of the sulfuric acid is a little, the production of sulfur oxides in the subsequent activating process of furfural residues is reduced, and the environmental pollution is reduced. Besides, the invention also provides a process for producing activated carbon adsorbents by using the furfural residues. The process includes the steps of drying the furfural residues, screening, roasting, hardening activating and steam curing, the obtained activated carbon specific surface is large, the iodine value is high and the adsorption capacity is high.

Owner:北京博能康成科技有限公司

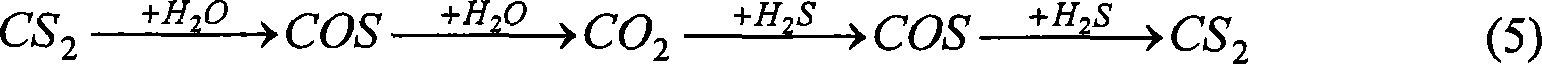

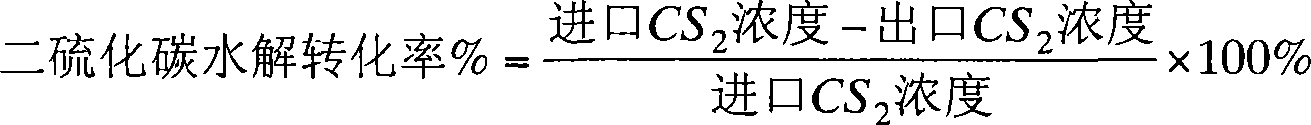

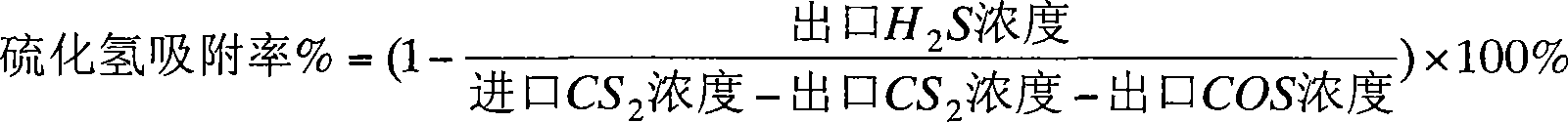

Medium temperature carbon bisulfide hydrolytic catalyst and preparation method and application thereof

InactiveCN101121123AHigh hydrolysis catalytic rateMetal/metal-oxides/metal-hydroxide catalystsIndustrial gasSocial benefits

A medium-temperature carbon disulfide hydrolysis catalyst and its preparation method and application belong to a catalyst for removing organic sulfur in raw material gas, and the purpose is to solve the problem that CS2 is difficult to remove compared with COS in the catalytic hydrolysis of carbon disulfide. It is characterized in that by adding catalyst modifiers ZrO2 and La2O3, a catalyst with high CS2 hydrolysis catalytic rate, anti-coking and no conversion side reactions is obtained at medium temperature, and its preparation method is that the modifier and the activity accelerator are divided into two steps Loading is done by isometric impregnation. Under normal pressure, temperature 200-400°C, space velocity 2000-8000h-1, CO volume content 0-30%, CS2 concentration less than 500mgS / m3, the carbon disulfide hydrolysis conversion rate is above 95%. It is mainly developed for medium-temperature purification of carbon disulfide in industrial gases containing carbon monoxide, and has considerable application value, economic benefits and social benefits.

Owner:TAIYUAN UNIV OF TECH

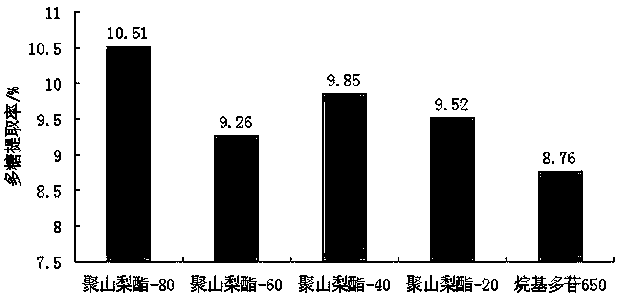

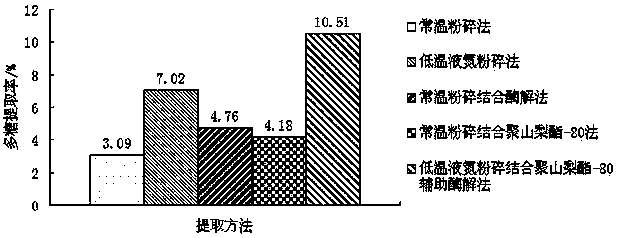

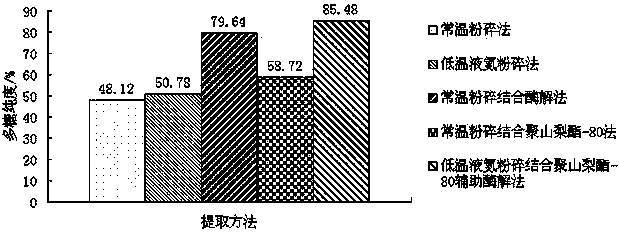

Extraction method for astragalus polysacharin

The invention relates to the health care food processing technology field, and concretely relates to an extraction method for astragalus polysacharin. In the method, polysacharin is extracted by utilization of low temperature liquid nitrogen crushing, non-ionic surface active agent auxiliary and plant compound enzyme enzymolysis. The method is advantaged by easily available raw materials, simple technology, and convenient operation and is suitable for large-scale industrial production. On the one side, the method decreases extraction times, raises yield and purity of the polysacharin, and lowers the production cost, on the other side, the method maintains the stabilization of structures and properties of the polysacharin, and raises trophism, safety and acceptability of the astragalus polysacharin greatly. In addition, the added non-ionic surface active agent is preferably polysorbate-80, polysorbate-80 has promotion effects on cellulase and pectase in hydrolytic process, and has solubilizing effects on the polysacharin at the same time. The pretreatment time and the extraction time are shortened, the time cost is lowered, and economic benefits of enterprises are raised.

Owner:越好生物科技(广州)股份有限公司

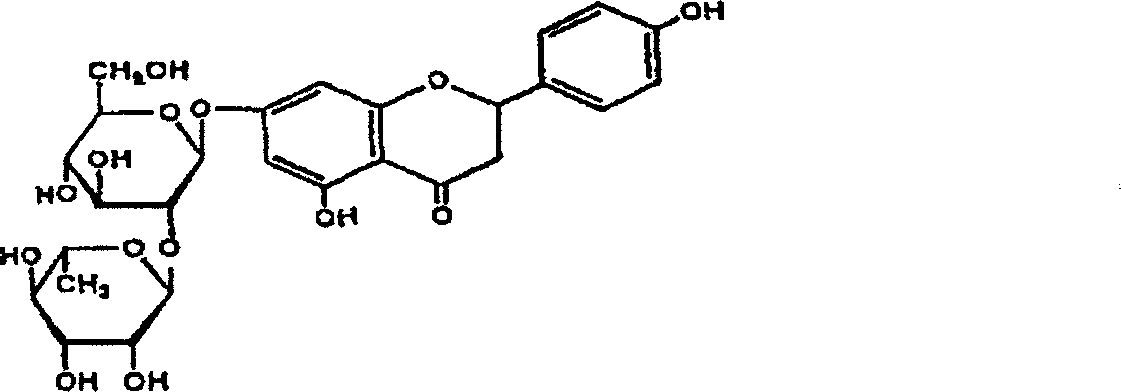

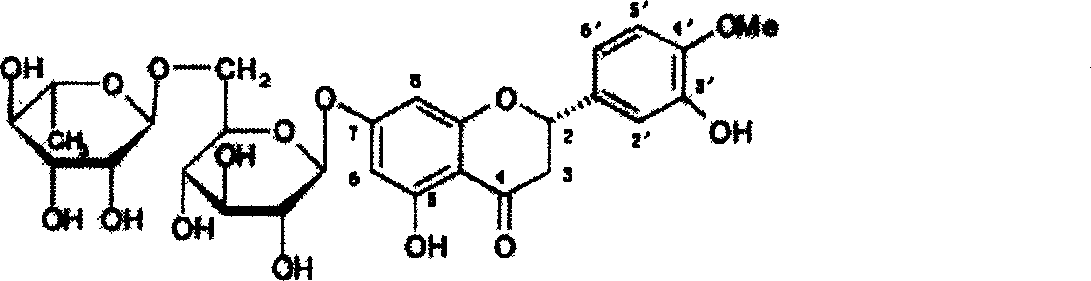

Method for hydrolytic preparing biological tangeritin by enzyme

InactiveCN101089187AControl the hydrolysis processEasy to separate and purifyFermentationNaringinCitrus Bioflavonoids

In the invented method, citrus bioflavonoid and corresponding enzyme are used as raw materials, being dissolved in organic solvent, adding glucoside solution at concentration of 1-100g / L, under pH value of 3.0-7.0 and temperature of 20-65 deg.C for 20-60 min. After separation and purification, obtained is citrus bioflavonoid monoglycoside. With this invention, naringoside enzymolysis and cirmtim enzymolysis method for production of naringen in monoglycoside and hesperetin monoglycoside, compared with chemical method, has advantages of:easily to be controlled of enzymolysis, mild reaction, less by-products and easy to be separated of products. By using this invented method, the enzymolysis of naringoside and cirmtim for production of naringenin monocoside and hesperetin monoglycoside can be effectively controlled, and only the first glycosidic bond is broken, so obtained is highest yield of naringenin monoglycoside, hesperetin monoglycoside and rhamnose.

Owner:ZHEJIANG UNIV OF TECH

Sludge pyrohydrolysis method and sludge pyrohydrolysis system

InactiveCN104355511AEfficient removalShorten digestion timeSpecific water treatment objectivesSludge treatment by pyrolysisDigestion TreatmentSewage

The invention relates to a sludge pyrohydrolysis method and a sludge pyrohydrolysis system, belongs to the field of treatment of a sewage plant, and particularly relates to the field of treatment of sludge of a sewage treatment product. To solve the problem that most of organic matters are not removed with an existing method, the invention provides the sludge pyrohydrolysis method and the sludge pyrohydrolysis system. The method comprises the processes of sludge slurrying, sludge pyrohydrolysis, sludge decompressed flash, sludge digestion, and centrifugal dewatering, wherein the process of sludge slurrying adopts a pump stirring mode, the temperature in a slurrying tank is kept at 97 DEG C; saturated steam heats a pyrohydrolysis tank to rapidly rise the temperature to be 165-190 DEG C in the process of sludge pyrohydrolysis, the pyrohydrolysis process lasts for 90 min, wherein the time for sludge charge is 15 min, the time for sludge discharge is 15 min, the steam is introduced for about 15 min, the pyrohydrolysis reaction is about 30 min, and the air is exhausted for 15 min; in the flash process, the pressure of a flash tank is kept at 0.1-0.3 MPa and the balance temperature is 102 DEG C; the time for sludge digestion is 15 days. The method and the system use the modes of pyrohydrolysis and flash, the organic matters in the sludge are effectively removed, meanwhile, the time for sludge digestion is shortened, and the sludge treatment efficiency is improved.

Owner:XIAN HUALU ENVIRONMENTAL PROTECTION EQUIP

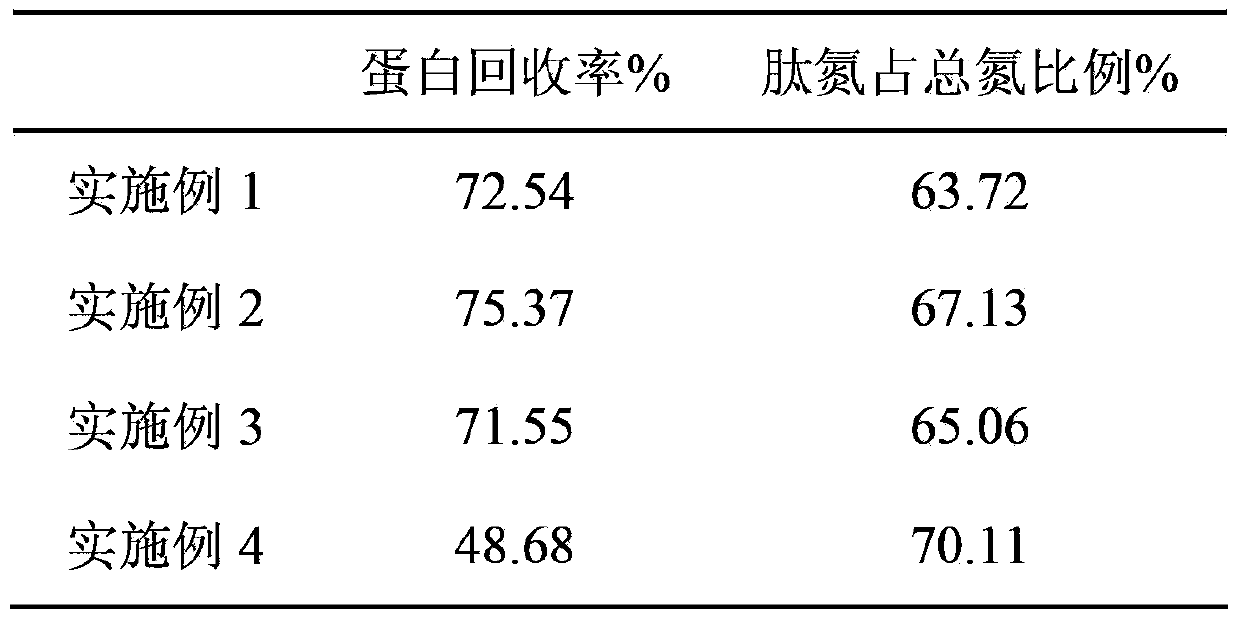

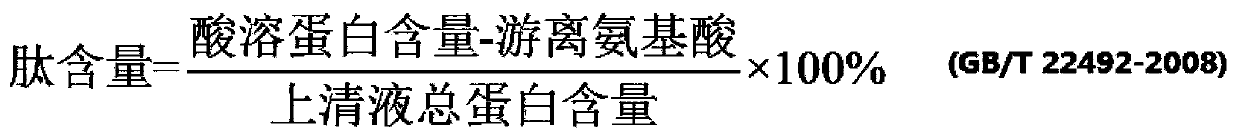

Method for preparing strong antioxidative peptide by using peanut meal

ActiveCN103392902AShort heating timeImprove the heating effectProtein composition from vegetable seedsVegetable proteins working-upFiltrationPeanut meal

The invention discloses a method for preparing strong antioxidative peptide by using peanut meal. The method comprises the following steps of: (1) uniformly mixing the peanut meal and an acidic buffer, carrying out microwave heating, and placing in a powdering machine, thus obtaining powder peanut meal; (2) adding water, protease and cellulase, then adding a surface active agent, hydrolyzing at 45-60 DEG C, and carrying out centrifugal separation to obtain liquid supernatant which is peanut meal enzymatic hydrolysate; and (3) adding an ethanol solution to the peanut meal enzymatic hydrolysate, carrying out ultra-filtration, collecting trapped fluid, and carrying out spray drying to obtain the strong antioxidative peptide. According to the method, the peanut meal is pretreated by adopting microwave heating and the acidic buffer, so that disulfide bonds in peanut meal proteins are converted into sulfydryl bonds, more enzymolysis sites are exposed, and the enzymatic hydrolysis is facilitated. The surface active agent is used for cooperating with the enzymatic hydrolysis, changing the characteristics of an enzymolysis substrate, enlarging a surface on which celluloses can be adsorbed, and sequentially simulating reaction sites to be adsorbed on enzymes; and meanwhile, the surface active agent has stablizing effect on the enzymes, effectively stops the denaturation of enzymes in a hydrolytic process and is beneficial to the improvement of hydrolysis efficiency of the proteases.

Owner:广东华肽生物科技有限公司

Production method of liquid medlar

The invention discloses a production method of liquid medlar. Firstly, medlar pulp is prepared, and then liquid medlar is prepared according to the following technical steps: facilitating composite hydrolysis by ultrasonic wave, filtering, or centrifugal separating, strengthening membrane separation by ultrasonic wave, filling and sterilizing, wherein, in the process of facilitating composite enzymolysis by ultrasonic wave, ultrasonic frequency is 20 to 80 kHz, and power is 50 to 300 W, and complex enzyme which is adopted is the compound of 1 part by weight of pectase, 1.5 parts by weight of proteinase and 2.5 parts by weight of cellulase; enzyme adding amount is 0.01 to 0.15% of the total material quantity, enzymolysis temperature is 40 to 65 DEG C, and enzymolysis time is from 15 to 120 minutes. In the hydrolytic process of complex enzyme, the production method of liquid medlar is promoted by ultrasonic technology, which shortens enzymolysis reaction time for 50% and reduces enzyme adding amount by 20%, so that the production method can obviously improve enzymolysis efficiency and lower production cost.

Owner:早康枸杞股份有限公司

Method for rapidly converting animal-poultry faeces into high-efficiency fertilizer

InactiveCN101659582APrevent salt buildupImprove soil qualityClimate change adaptationExcrement fertilisersFertilizerChemistry

The invention discloses a method for rapidly converting animal-poultry faeces into high-efficiency fertilizer, which comprises the following steps: hydrolyzing animal-poultry faeces under the acidity condition and producing amino acid (ova and germina are all killed in the process) to obtain crop synergia fertilizer; adding hydrolyticre agent into dispersant, odor absorbent, adhesive-maintaining agent, coating agent and bulking agent. The fertilizer not only has good fertilizer efficiency, but also has good effects on the proliferation of microbes in soil, can avoid occurrence of the following situations that microbes in soil die out, salt is accumulated and soil is hardened as chemical fertilizer is misused; and the implementation of the method plays a positive role in agricultural non-pollution ecological production and industrial production.

Owner:广西北国生物科技有限公司

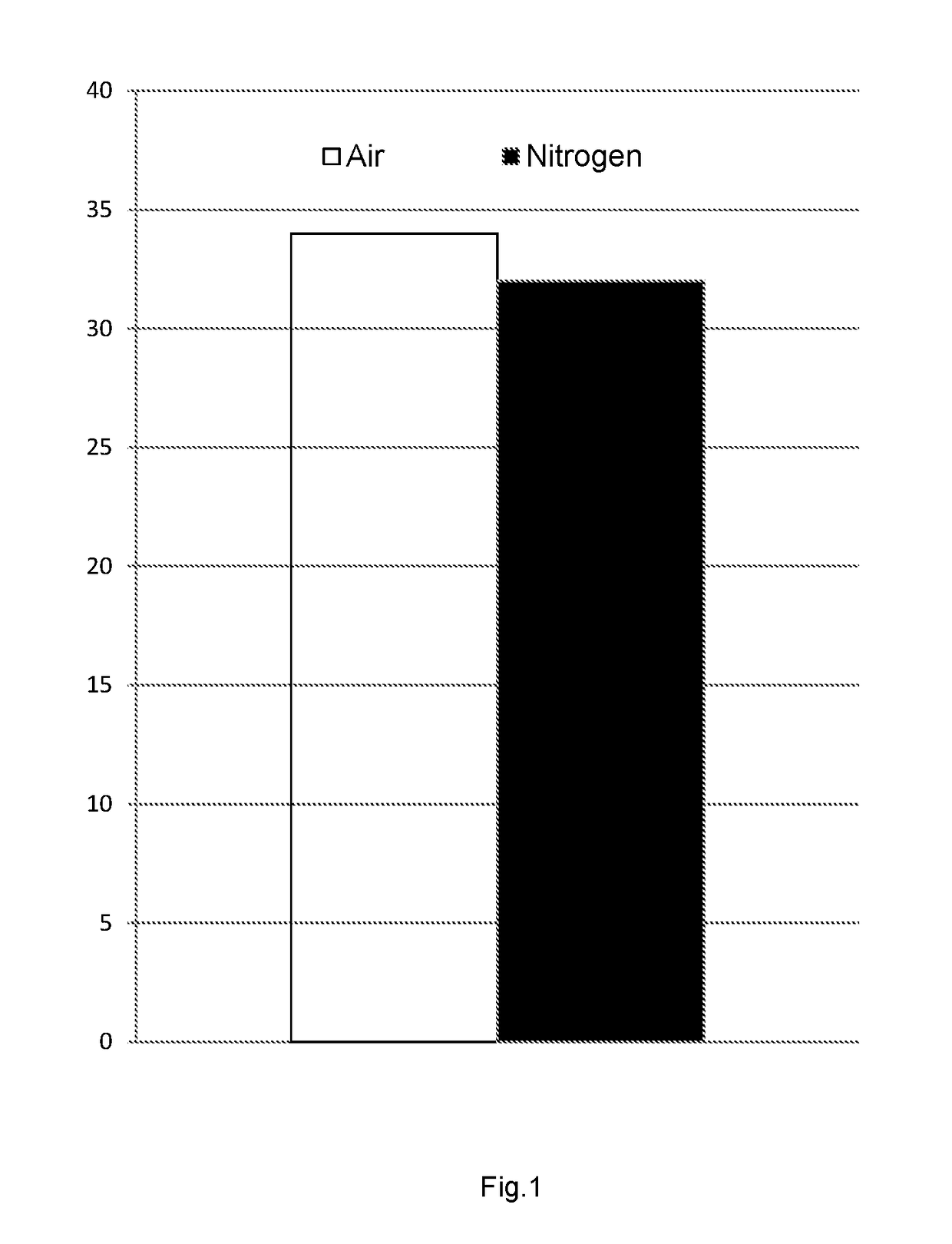

Process and apparatus for enzymatic hydrolysis of lignocellulosic material and fermentation of sugars

ActiveUS10087475B2Reduce processing timeReduce the amount of enzymes usedBioreactor/fermenter combinationsBiological substance pretreatmentsEnzymatic hydrolysisProcess engineering

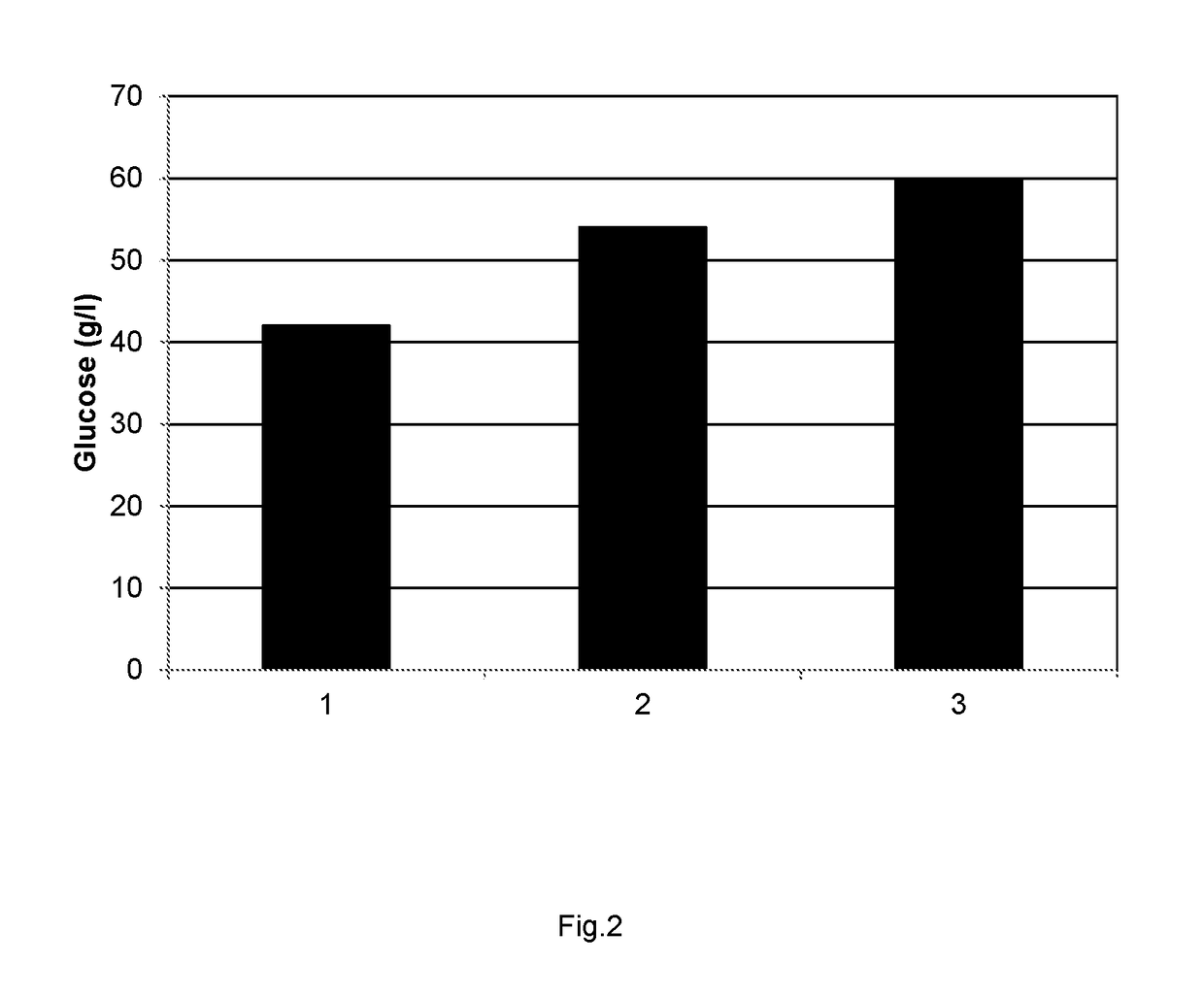

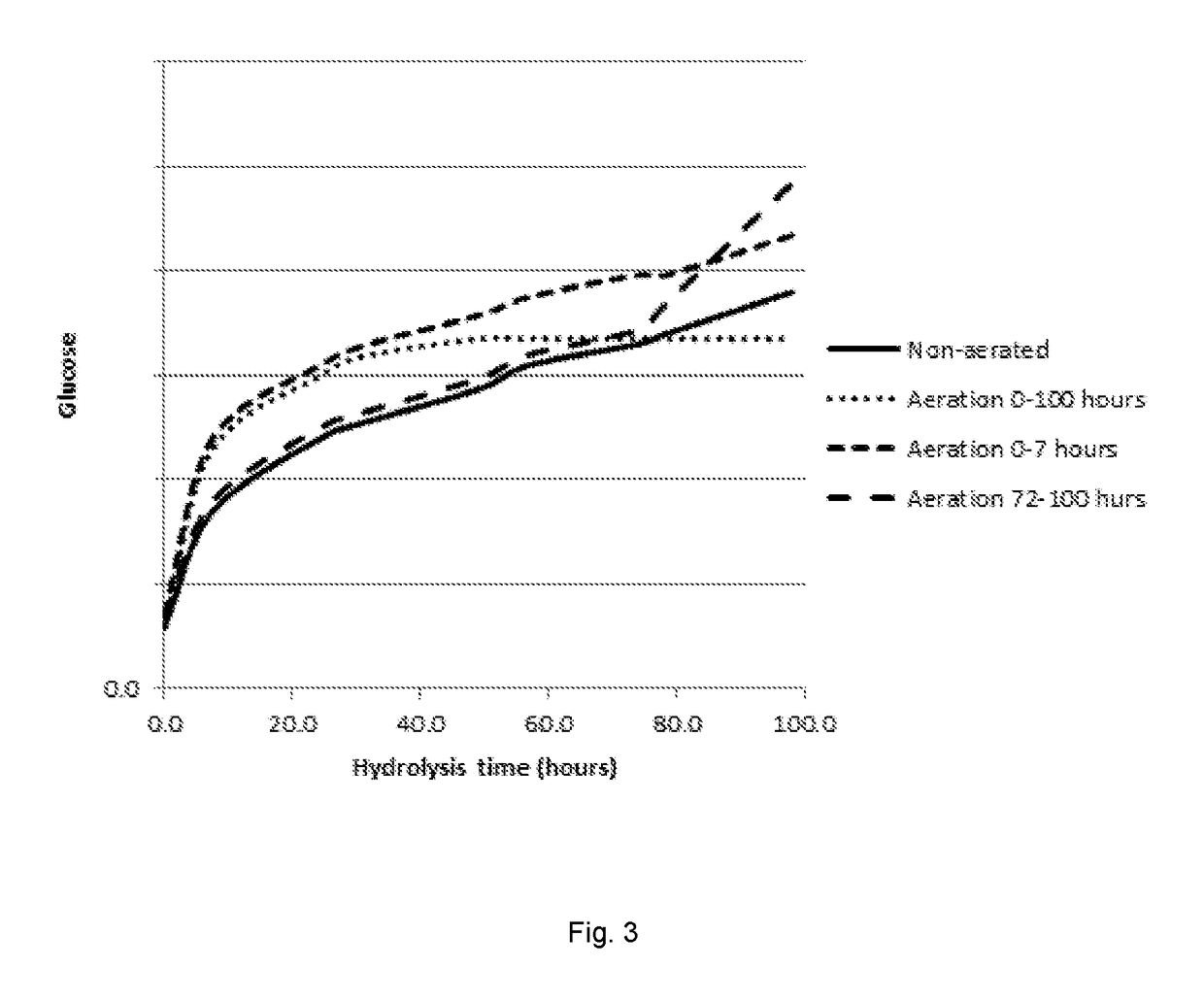

The disclosure relates to a process for the preparation of a sugar product from lignocellulosic material, comprising the following steps:a) optionally, pretreatment of the lignocellulosic material;b) optionally, washing of the optionally pretreated lignocellulosic material;c) enzymatic hydrolysis of the optionally washed and / or optionally pretreated lignocellulosic material in a hydrolysis reactor using an enzyme composition comprising at least two cellulase; andd) optionally, recovery of a sugar product;wherein during the enzymatic hydrolysis oxygen-containing gas is added to the lignocellulosic material in the hydrolysis reactor and wherein part of the oxygen-containing gas, added to the lignocellulosic material, is gas originating from the headspace of the reactor,preferably during part of the time of the enzymatic hydrolysis less oxygen is added to the lignocellulosic material compared to the other part of the time of the enzymatic hydrolysis, or preferably during part of the time of the enzymatic hydrolysis no oxygen is added to the lignocellulosic material.

Owner:DSM IP ASSETS BV

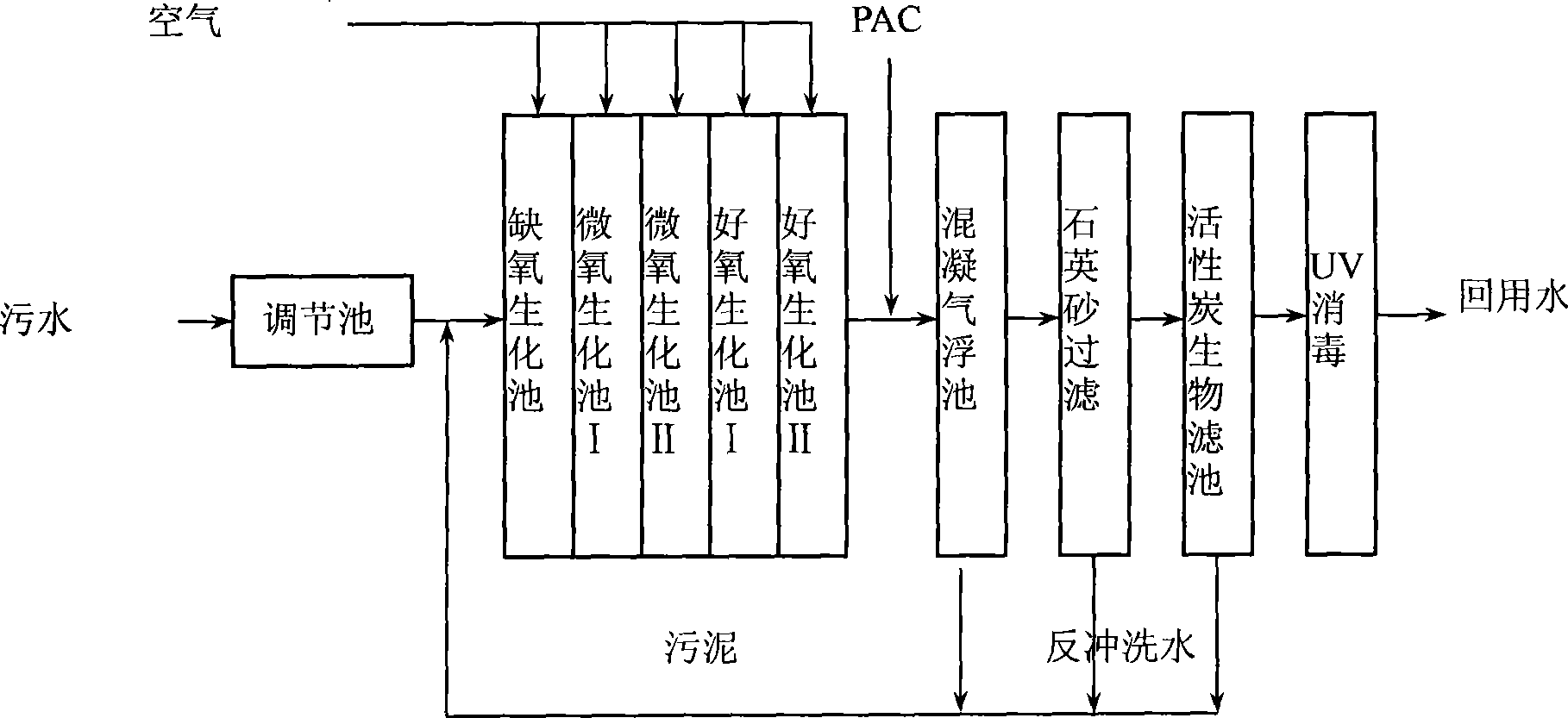

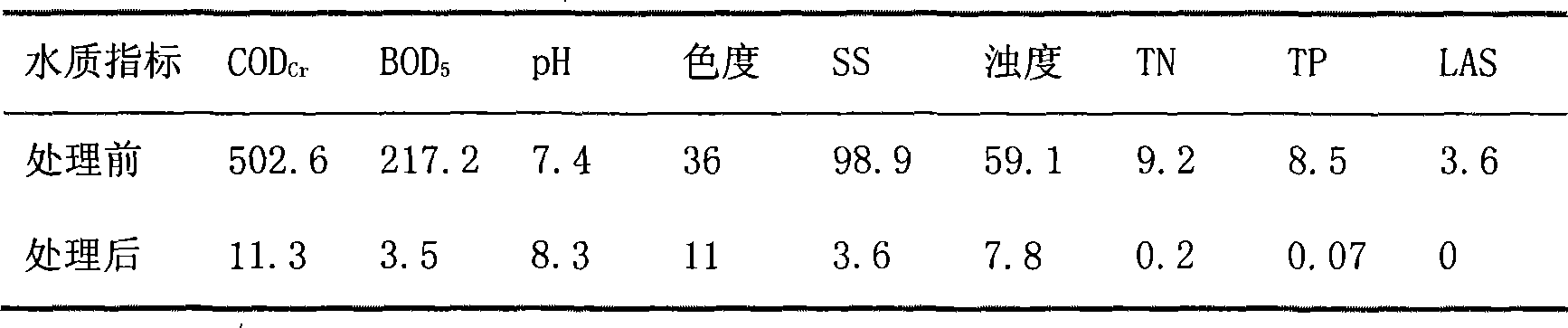

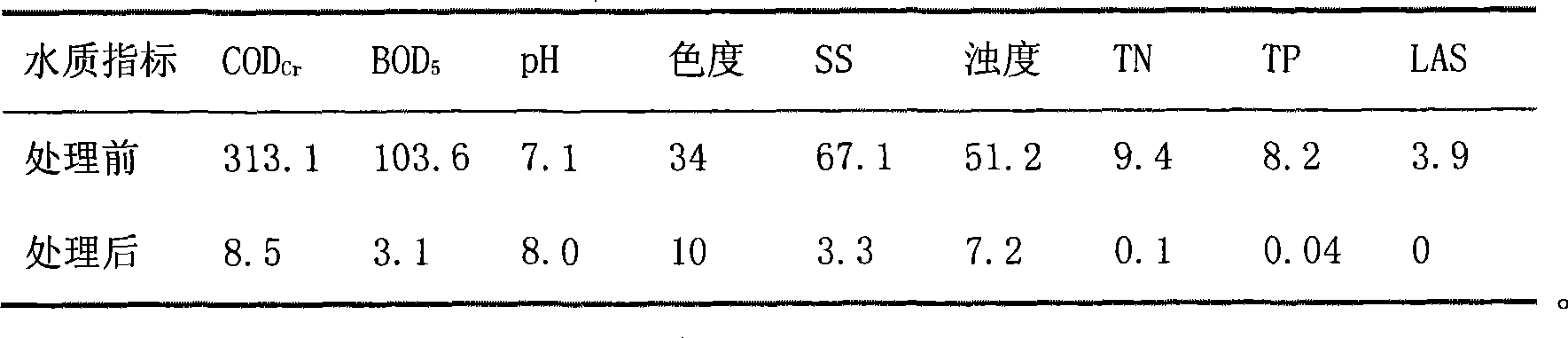

Novel municipal sewage treatment technology without excess sludge discharge

InactiveCN101428942AEliminate pollutionImprove removal efficiencyWater/sewage treatment by irradiationTreatment with aerobic and anaerobic processesWater useActivated carbon filtration

The invention provides a process system for no residual sludge emission in the treatment of municipal sewage, which belongs to a sewage treatment process. The process flow is as follows: the municipal sewage in an adjusting tank orderly is subjected to anoxic biological treatment, microaerophilic biological treatment and aerobic biological treatment, and then orderly undergoes coagulation air-flotation treatment, quartz sand treatment, biological active carbon filtration and subsequent UV sterilization disinfection treatment, and reused as non-potable household water. The process has the advantages of eliminating the odor pollution such as H2S generated in the anaerobic hydrolysis process by the prior A / O method, reducing aeration amount, saving energy consumption, lowering sewage treatment cost, recycling sewage, not causing secondary pollution, completely refluxing the treated system sludge to the anoxic tank, performing the sludge treatment and the sewage biological treatment in the same system, conveniently operating and managing, realizing the residual sludge emission of the system, and improving the discharged water quality of the original treatment system.

Owner:NANJING INST OF GEOGRAPHY & LIMNOLOGY

Method of using TiCl4 to prepare high-activity double-effect crystal seed and control titanium dioxide particle size

InactiveCN104129813AReduce usageSmall particle sizeTitanium dioxidePhysical chemistryHydrolytic Process

The invention provides a method of using TiCl4 to prepare a high-activity double-effect crystal seed and control titanium dioxide particle size. Specifically, the method employs TiCl4 as a raw material, a precipitate is prepared through a certain proportion and rapid neutralization of a dilute base solution, the precipitate is subjected to peptizing, curing and quenching and then is adjusted to have a proper pH value, then soluble salt compositions are removed through washing, so that the high-activity double-effect crystal seed, which is applied to hydrolysis process and calcining process of production of sulfuric-acid-process titanium dioxide, is prepared. The prepared crystal seed is uniform in particle size and high in activity, and also during application of hydrolysis of a titanium solution, by adjusting the addition amount of the seed crystal and cooperating with addition of a proper salt treating agent and control on calcining intensity, rutile type titanium dioxide with different particle sizes can be prepared, and thus the particle size demands on different products are satisfied. The preparation technology is simple, not high in equipment investment and high in operation controllability, and the prepared double-effect crystal seed is capable of producing titanium dioxide hydrate primary particles with uniform particle size, so that the uniformity of calcined product particle size is guaranteed, and optical performances and pigment performances of titanium dioxide are perfectly exhibited.

Owner:SICHUAN LOMON TITANIUM IND CO LTD

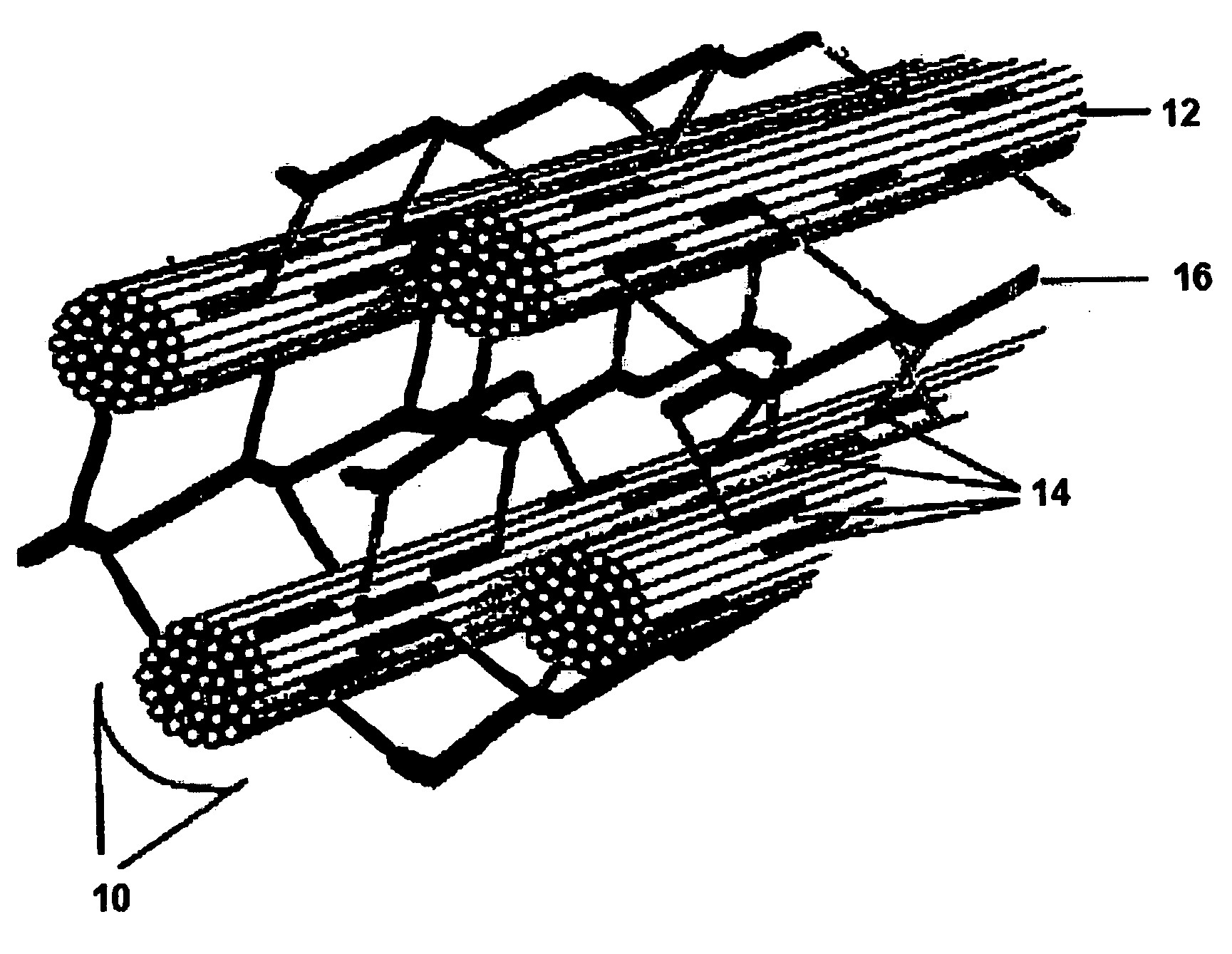

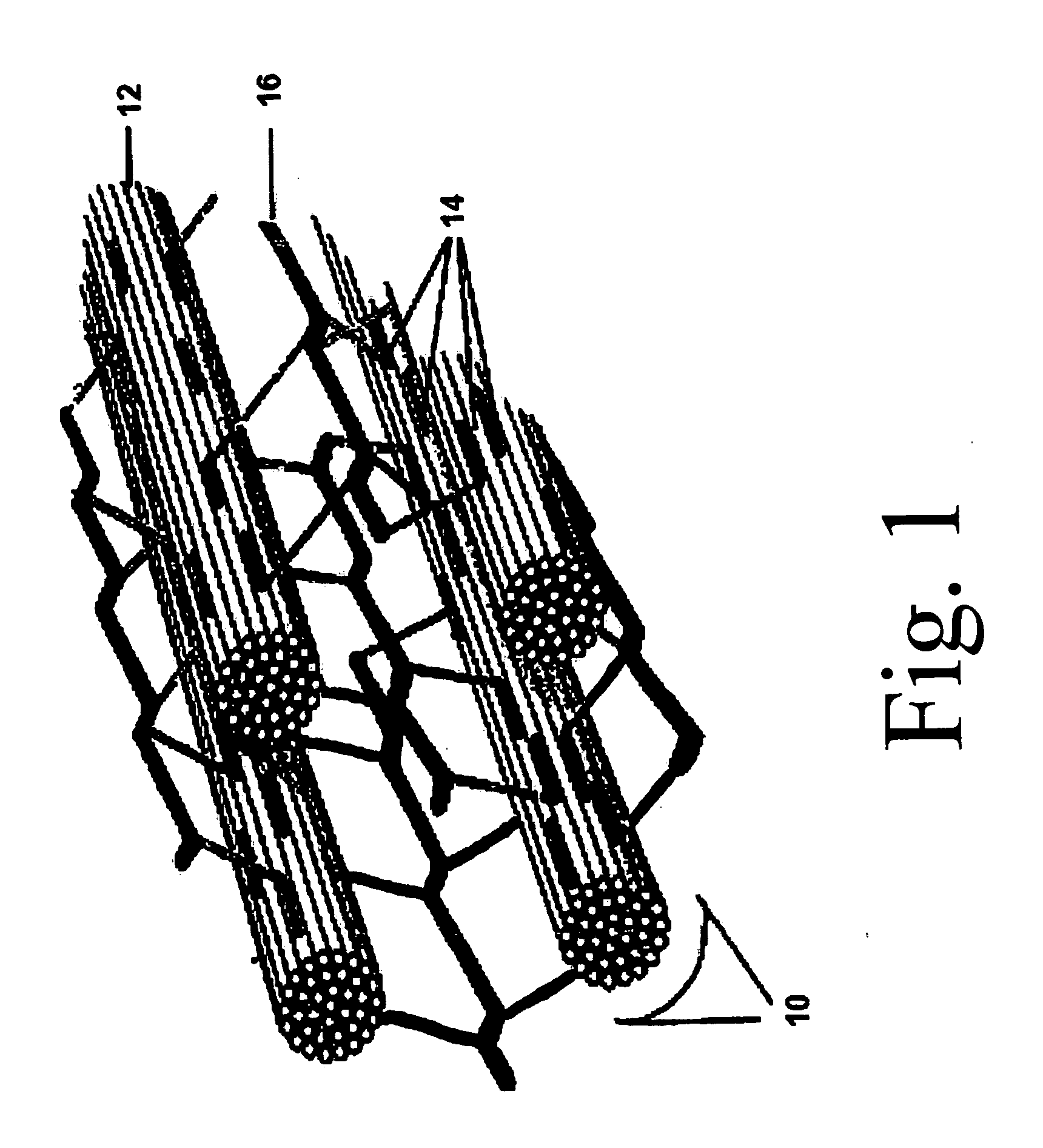

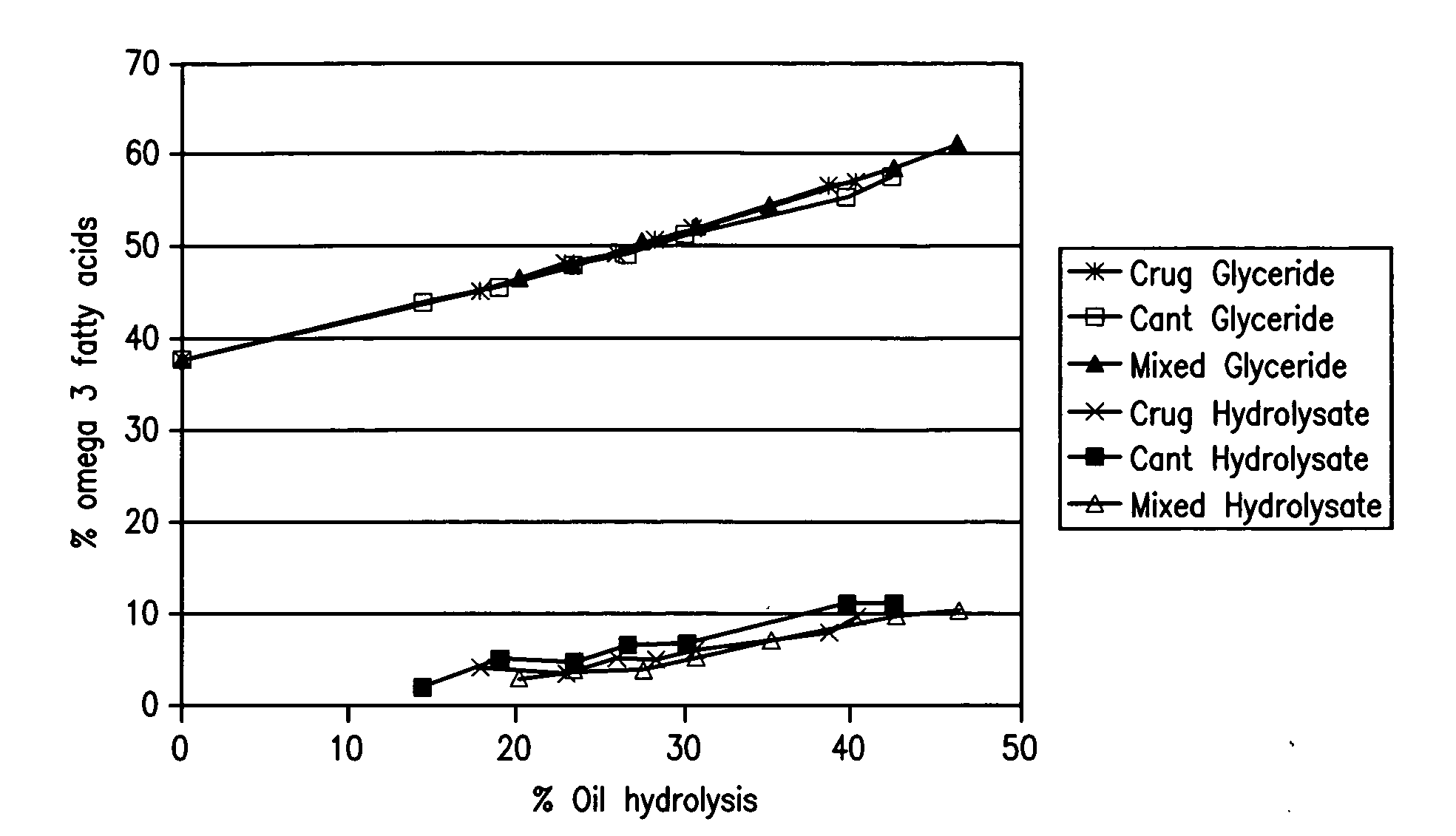

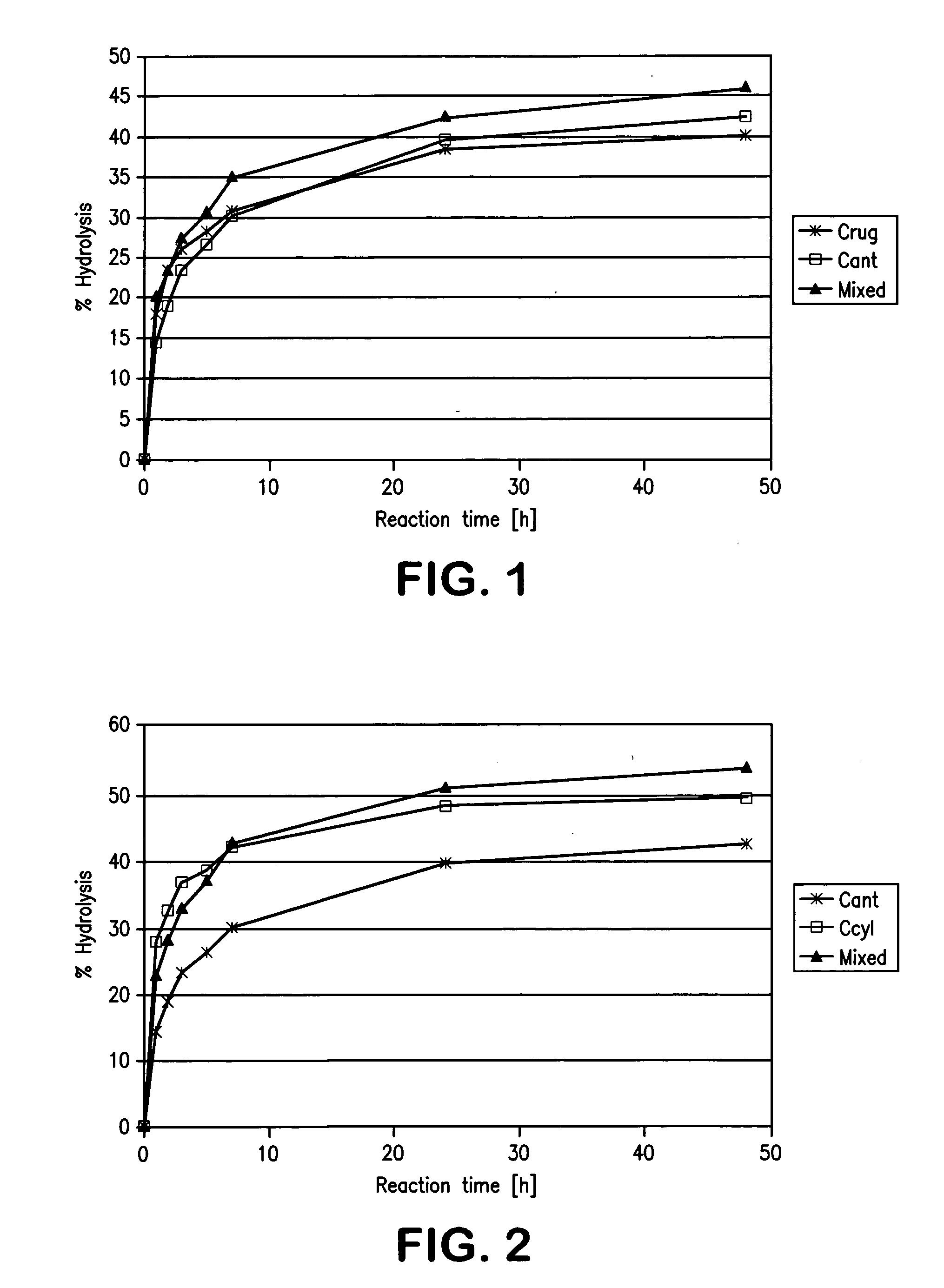

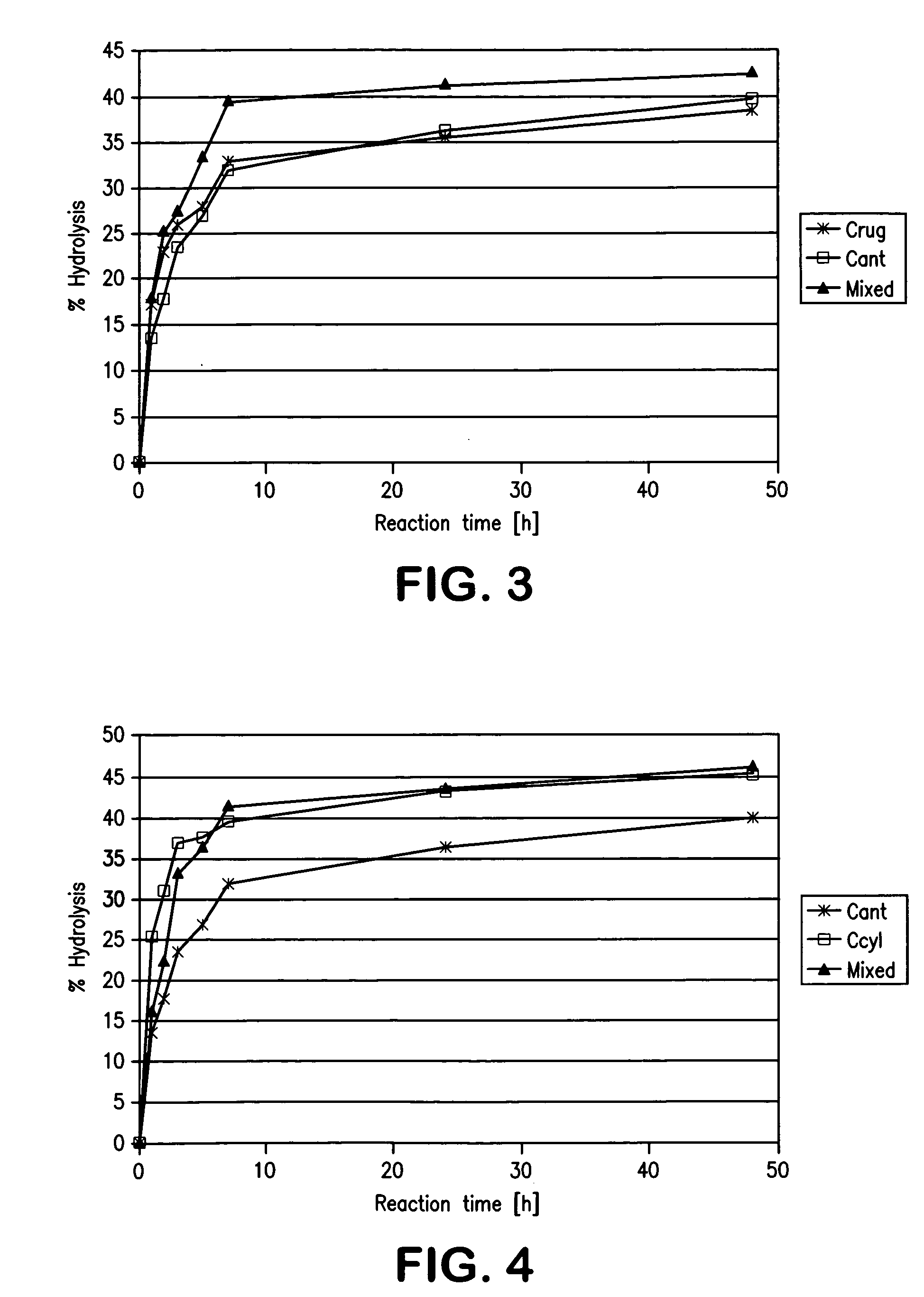

Mixture containing fatty acid glycerides

InactiveUS20080248187A1Increased PUFA concentrationReduce concentrationOrganic chemistryFatty acid esterificationAlcoholAcyl group

A mixture containing fatty acid glycerides which has a high percentage content of PUFA acyl groups and a low percentage content of saturated fatty acid acyl groups is described. A process which enables the PUFA acyl groups in a mixture containing fatty acid glycerides (for example a fish oil) to be enriched and, at the same time, the content of saturated fatty acid acyl groups to be maintained at a low content is described. The process is a hydrolytic process or an alcoholysis in which the fatty acid acyl groups to be enriched are hydrolytically or alcoholytically released from the fatty acid glycerides slowly, if at all, the process being carried out in the presence of a lipase.

Owner:COGNIS IP MANAGEMENT GMBH

Preparation method of cobalt-nickel double metal hydroxide nano composite

ActiveCN103433044AFerromagneticEasy to separateOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsCatalytic effectSolvent

The invention provides a method for preparing a cobalt-nickel double metal hydroxide nano composite through a hydrolytic process, belonging to the technical field of nano material preparation. The method is carried out under the condition of room temperature, dispenses with heating and temperature control devices and takes distilled water as a solvent, hydrolysis of sodium borohydride is utilized to provide an alkaline environment for reaction, the synthetic steps are simple, the yield is high and the obtained cobalt-nickel double metal hydroxide nano composite is a grapheme-like structure. The method is simple and energy-saving in preparation process and is suitable for industrial production. The obtained cobalt-nickel double metal hydroxide nano composite has good catalytic effects on hydrogenation of p-nitrophenol.

Owner:广东中科智道热源科技有限公司

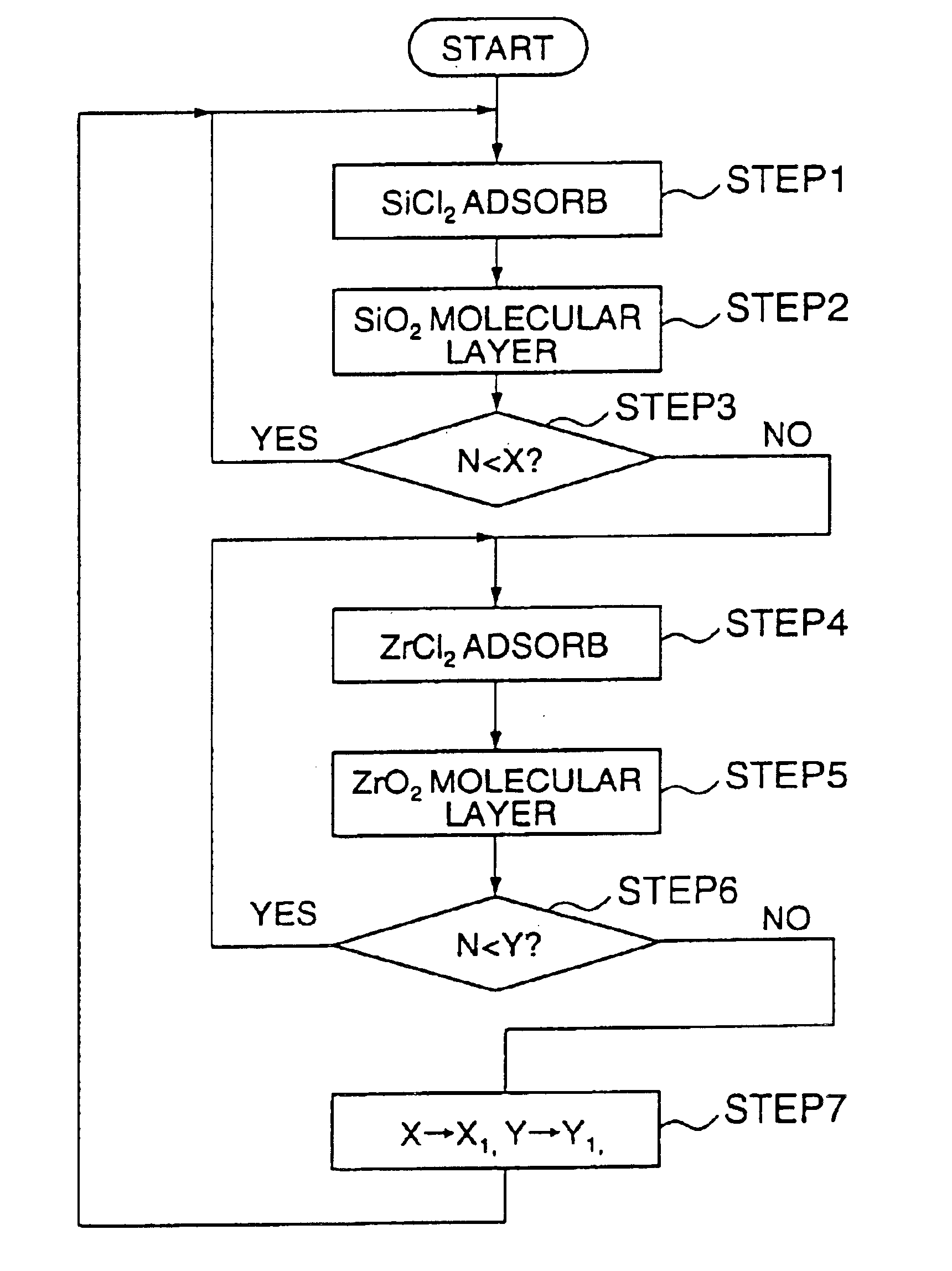

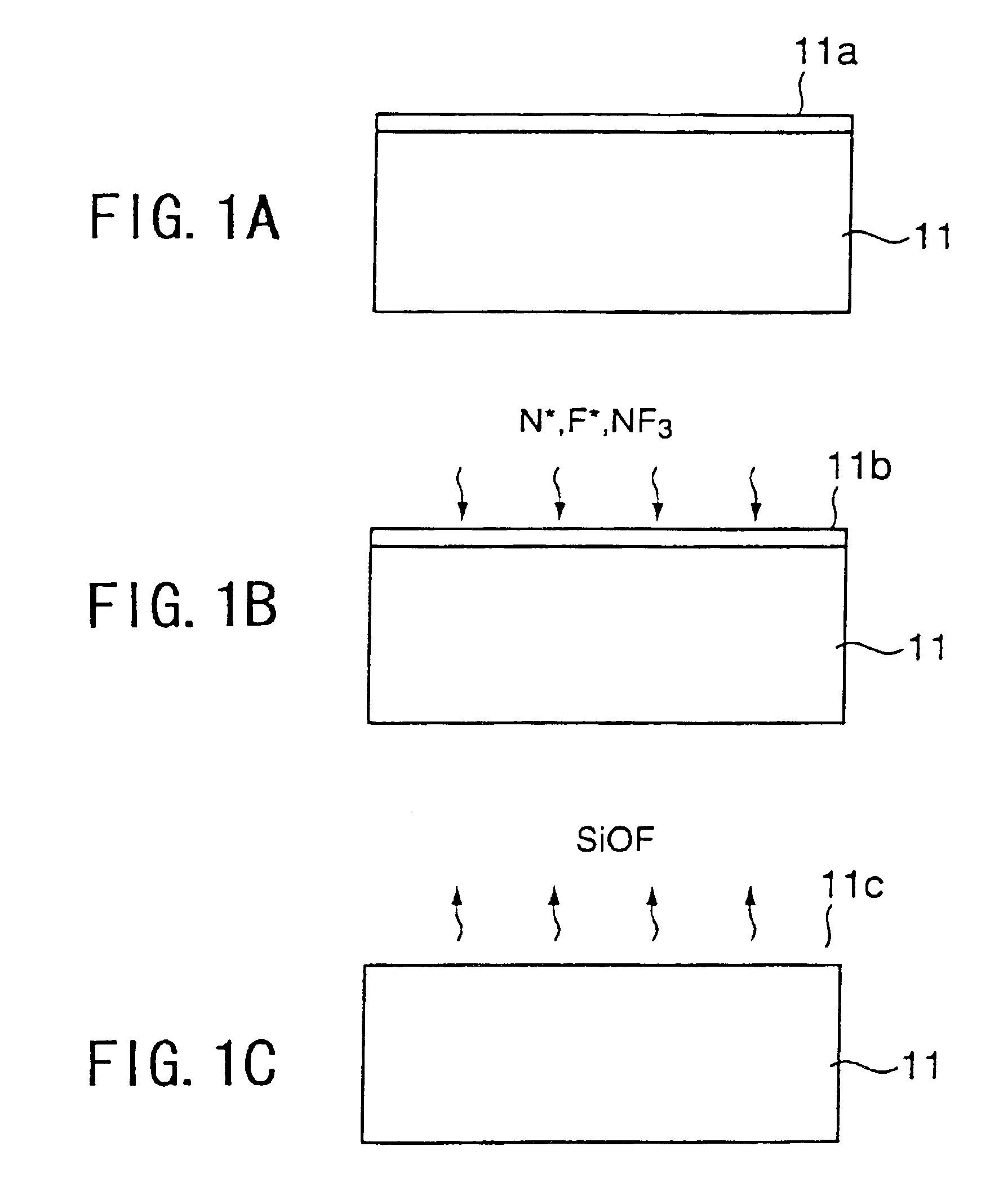

Method of forming a dielectric film

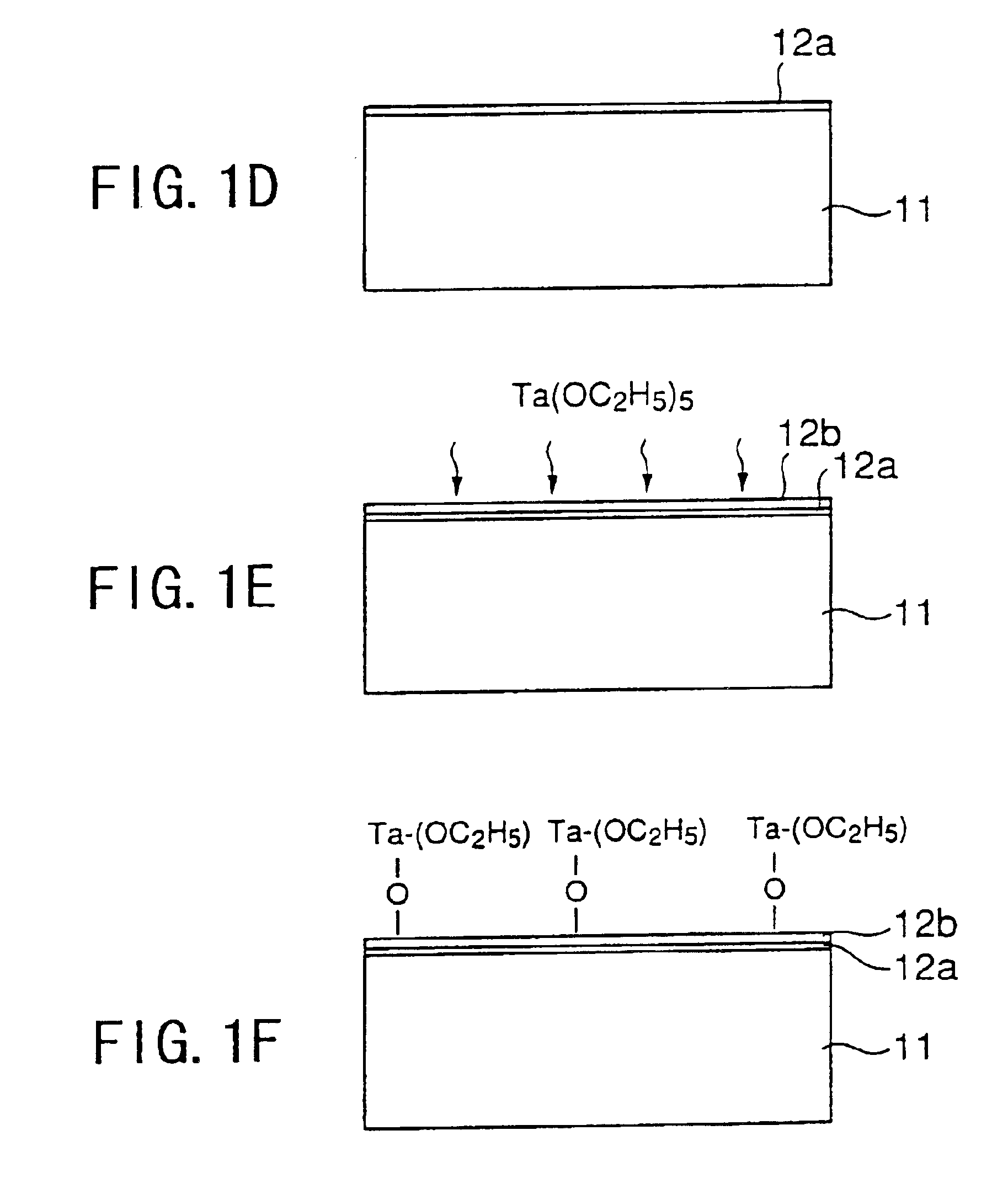

InactiveUS6866890B2Eliminate the problemReduce surface roughnessPretreated surfacesSemiconductor/solid-state device manufacturingDecompositionHydrolytic Process

A method of forming a dielectric film on a Si substrate comprises the steps of adsorbing a gaseous molecular compound of a metal element constituting a dielectric material on a Si substrate, and causing a decomposition of the gaseous molecular compound thus adsorbed by a hydrolysis process or pyrolytic decomposition process or an oxidation process.

Owner:TOKYO ELECTRON LTD

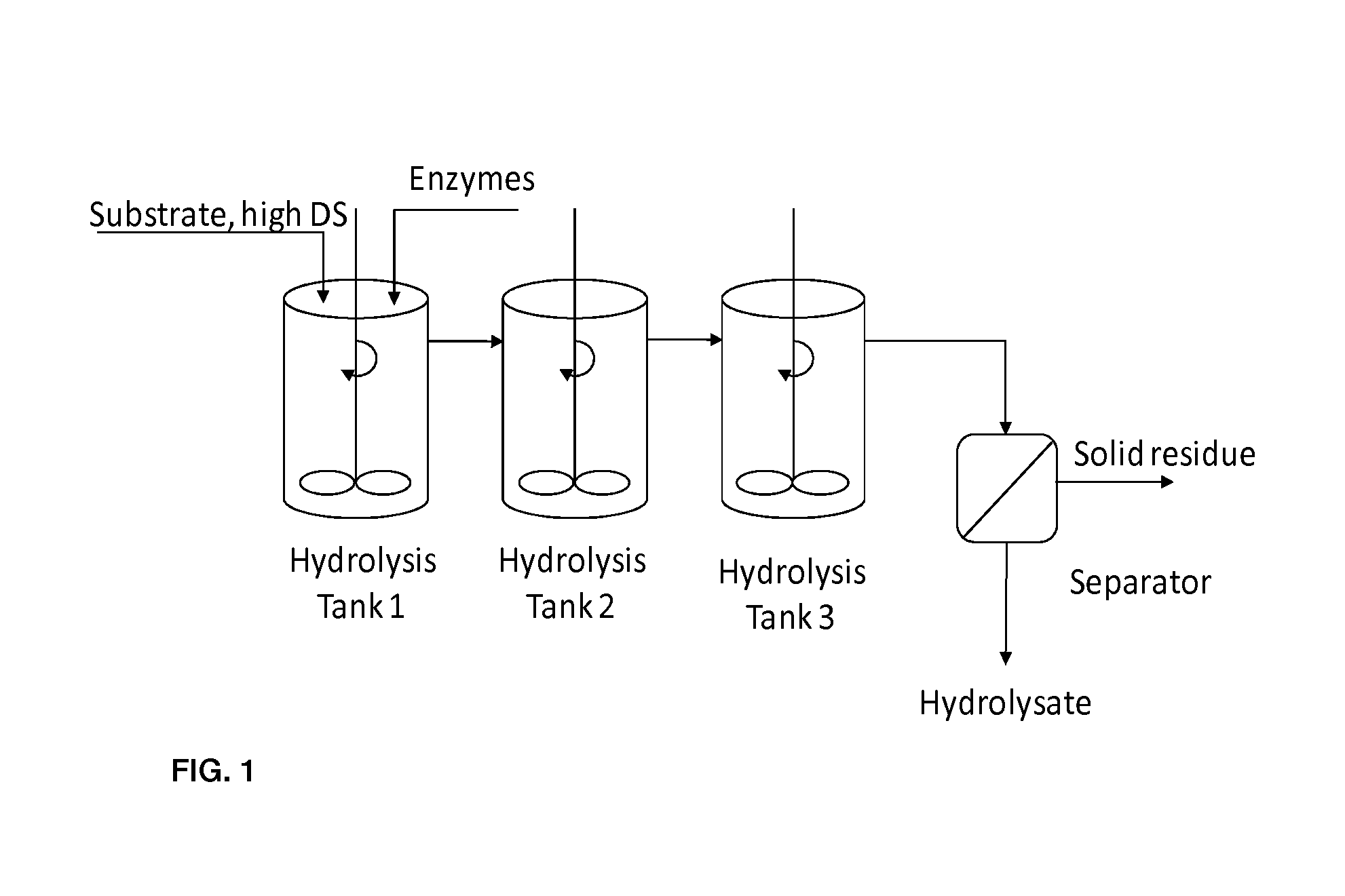

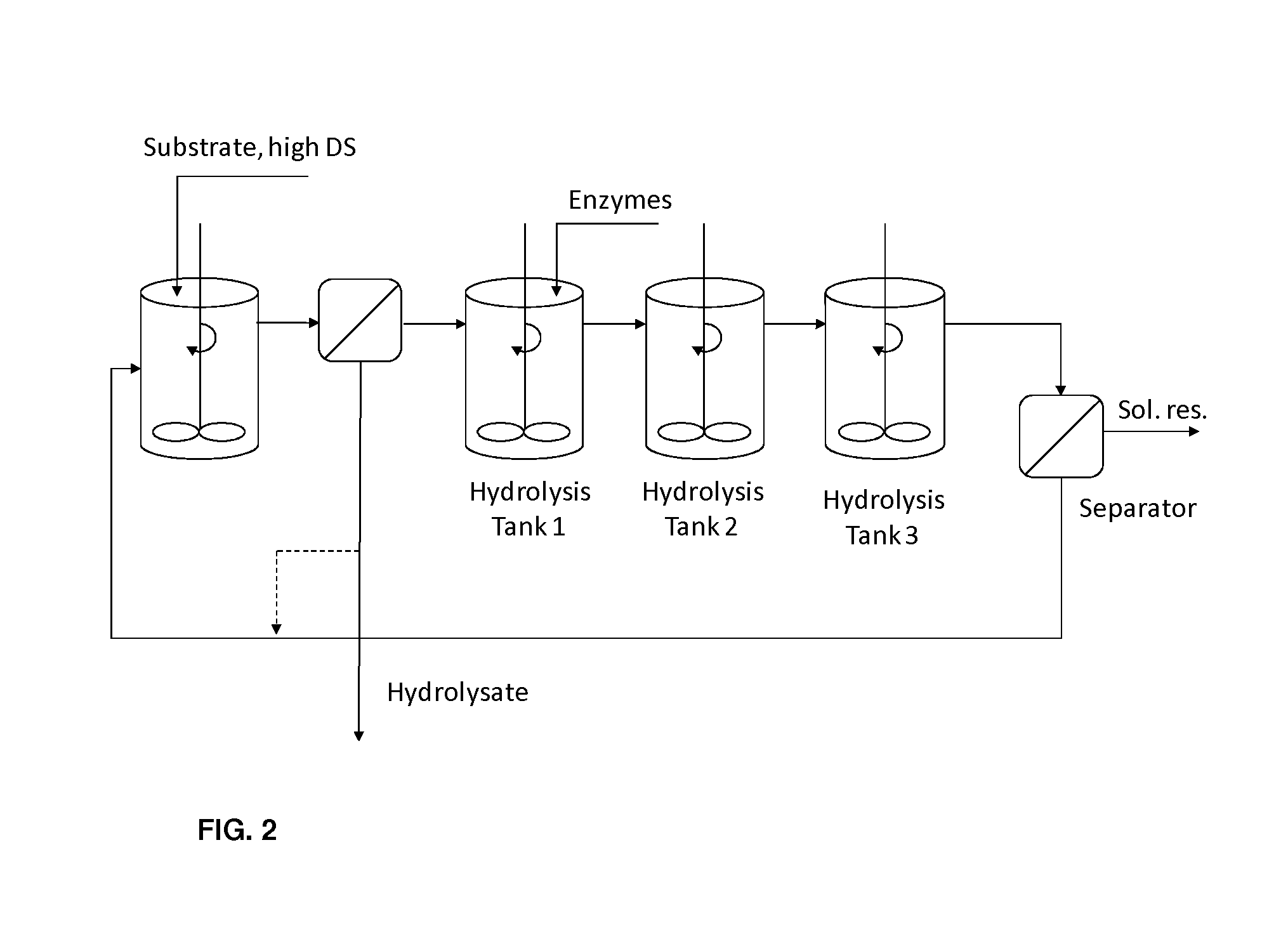

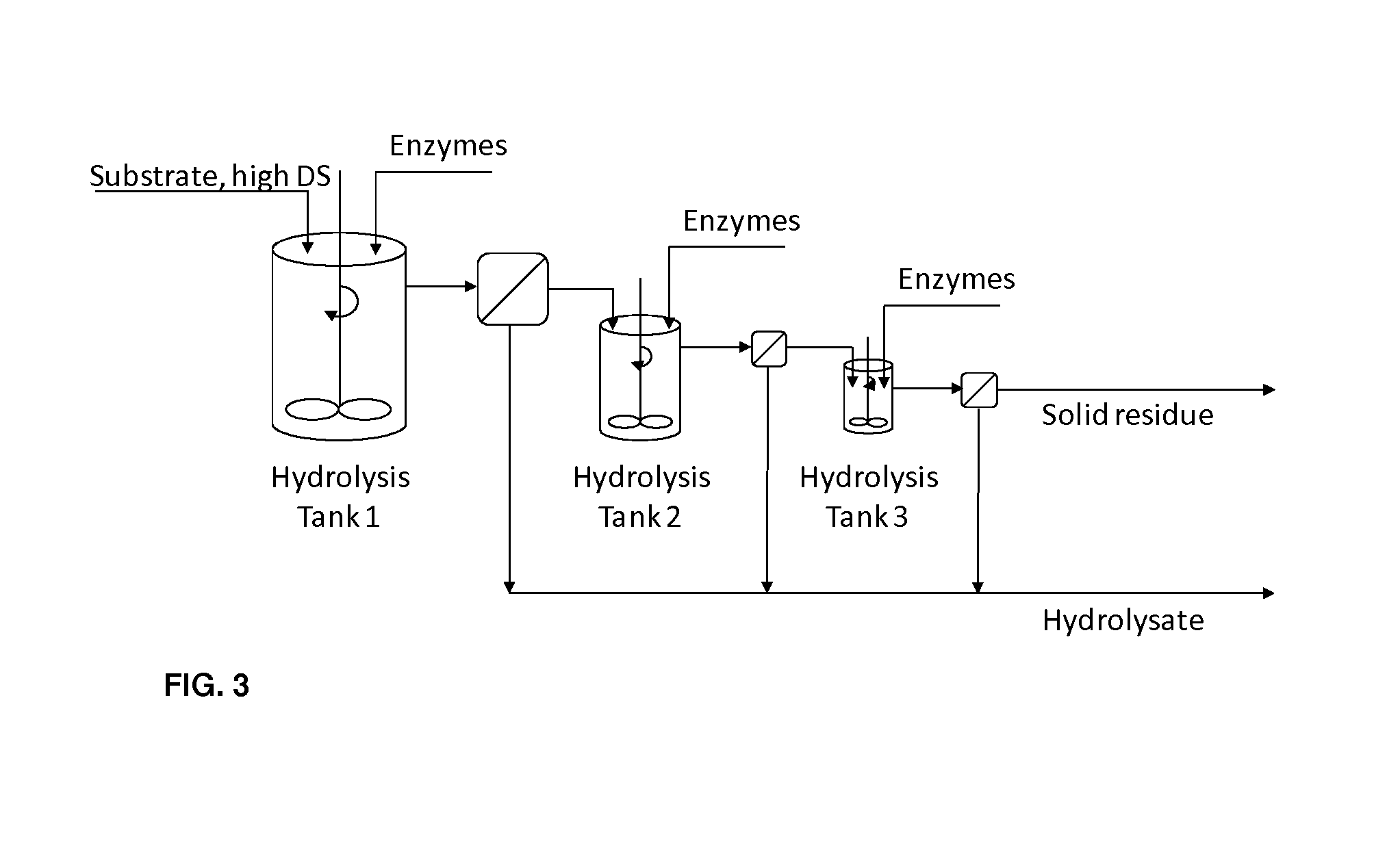

Enzymatic hydrolysis of cellulose

ActiveUS9193982B2High viscosityIncrease loadBioreactor/fermenter combinationsBiological substance pretreatmentsEnzymatic hydrolysisPartial hydrolysis

The present invention relates to a continuous process for the enzymatic hydrolysis of cellulosic biomass and to an apparatus for conducting said process. According to the present invention, a steady state is achieved in a reactor in regard to the hydrolysis reaction. Therein, cellulosic biomass of a high total solids content (preferably 10% or higher, further preferably between 15 and 30%) is continually added to said reactor, while at least partially hydrolyzed cellulosic biomass is continually removed from said reactor. The steady state is adjusted, i.e. the amount of cellulosic biomass added and the amount of at least partially hydrolyzed cellulosic biomass removed is adjusted, so that the retention time of a given portion of added cellulosic biomass in the reactor is longer than its “liquefaction time”, i.e. the time period required to transform a solid slurry into a pumpable liquid during hydrolysis, i.e. the time required to lower the viscosity of the slurry to a value, which is acceptable for further processing.

Owner:BORREGAARD

Pretreatment method capable of improving saccharification efficiency of lignocellulose

ActiveCN110760552AImprove enzymatic hydrolysis and saccharification efficiencyLow equipment requirementsPulping with organic solventsFermentationCelluloseGlycerol

The invention discloses a pretreatment method capable of improving saccharification efficiency of lignocellulose. According to the method, ethanedioic acid, choline chloride and glycerol are added towater for reaction to obtain a modified deep-eutectic solvent (DES), and a lignocellulose raw material is pretreated with the modified DES. The method can realize pretreatment of the lignocellulose under a lower-temperature condition, is more beneficial to improvement of the saccharification efficiency of the lignocellulose and can substantially increase the total quantity of carbohydrates released in a lignocellulose hydrolytic process.

Owner:XIANGTAN UNIV

Prepn and application of high-activity titanium catalyst

InactiveCN1403193AHigh catalytic activityHigh activityCatalyst activation/preparationOrganic solventTitanium

The present invention relates to polyester catalyst. The high-activity titanium catalyst is prepared through dissolving alcoholate of titanium in organic solvent, hydrolysis to obtain TiO2 deposit, washing and filtering, organically modifying TiO2 by setting the deposit in organic modifier solution to obtain modified TiO2. The catalyst is used in preparing saturated polyester resin with relative molecular weight smaller than 10,000 or thermoplastic polyester and copolyester with relative molecular weight greater than 10,000. The organic modifier modified TiO2 has high activity and no trouble of resulting in yellow polyester.

Owner:SHANGHAI JIAO TONG UNIV

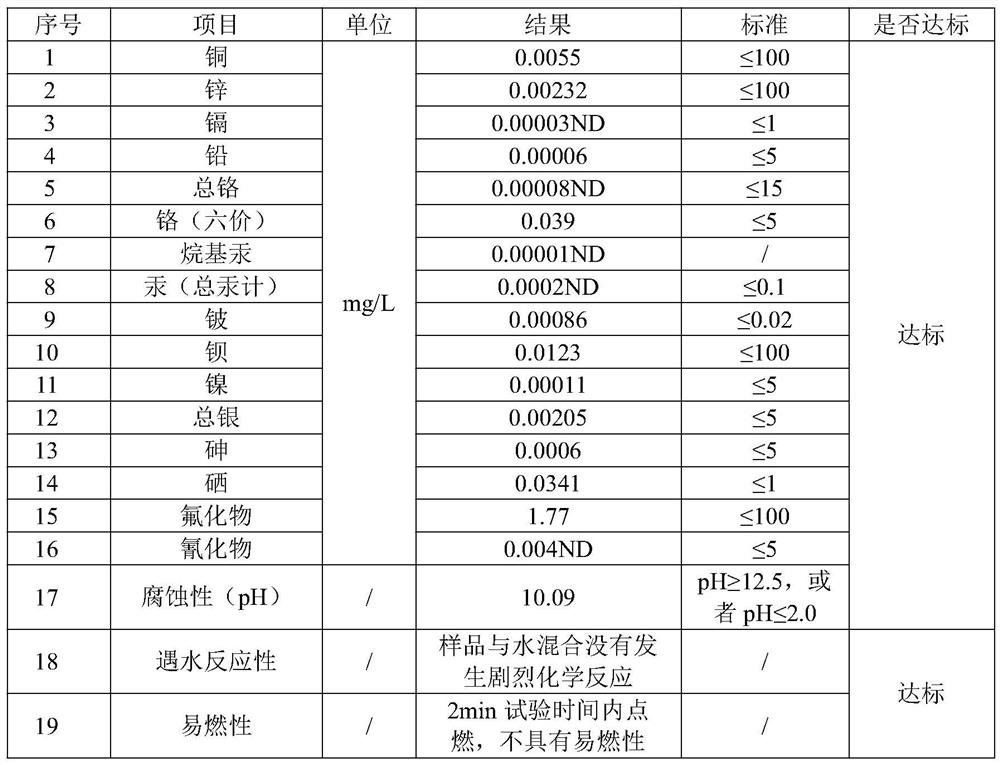

Harmless treatment method for secondary aluminum ash

PendingCN113578927AAvoid explosionAvoid mixingSolid waste disposalCalcium/strontium/barium fluoridesCalcinationChemistry

A harmless treatment method for secondary aluminum ash comprises the following five process steps: (1) preparing raw materials, namely preparing the secondary aluminum ash; (2) carrying out hydrolysis in a hydrolytic tank; (3) carrying out filter pressing by using a filter press and washing; (4) fixing fluorine by using calcium hydroxide; and (5) washing ammonia gas generated by reaction in a third-stage leaching tower. The method disclosed by the invention has the following advantages: firstly, aiming at the ammonia gas and hydrogen gas generated in a secondary aluminum ash hydrolysis process, a hydrolytic tank sealing form is adopted to prevent air from being mixed in, and a continuous feeding form and a continuous discharging form are adopted, so that explosion accidents of a large amount of ammonia gas and hydrogen gas generated instantly are effectively avoided, and the method is a safe and reliable recovery process; secondly, the whole technological process consumes less equipment, so that the energy consumption is low; the production cost of the method is lower than that of calcination, acid leaching and other processes, the product high-aluminum material, the by-product fluorite calcium fluoride and dilute ammonia water can be comprehensively utilized, and the economic benefit is high. The method is suitable for treating aluminum ash by-products in the electrolytic aluminum industry.

Owner:邵冰 +1

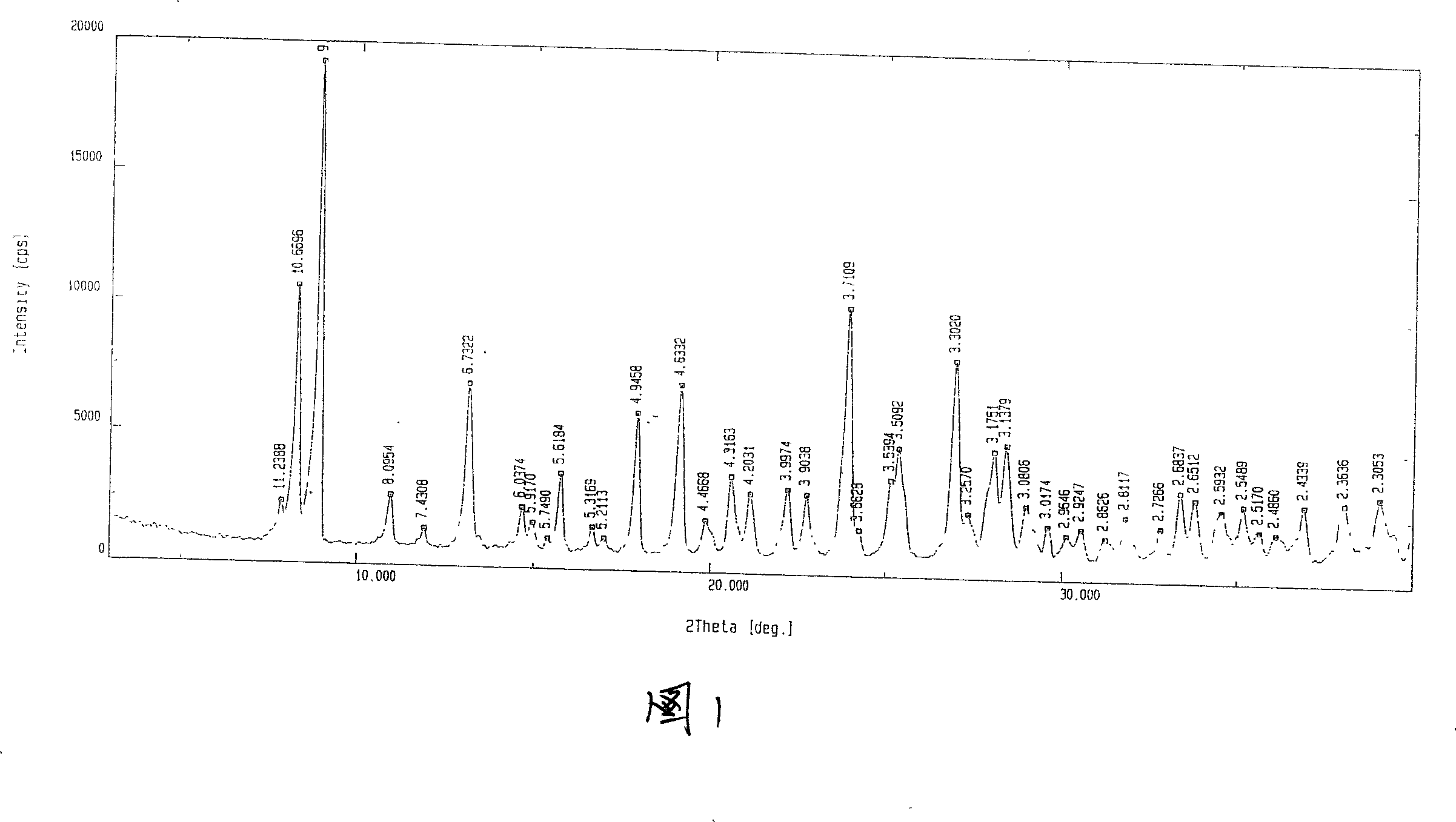

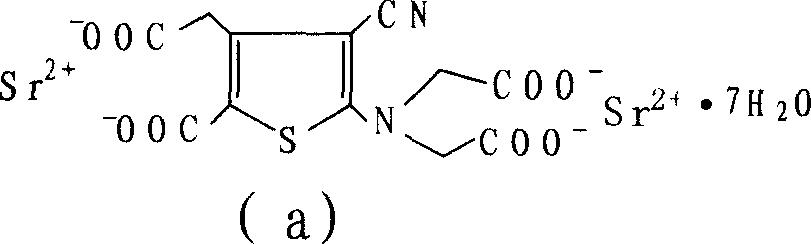

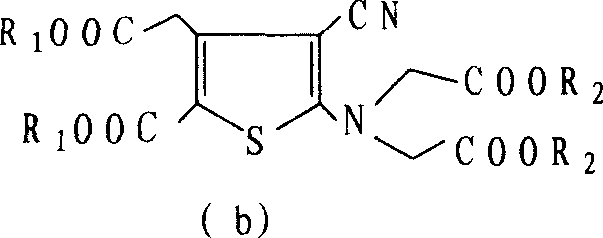

Novel method of producing strontium ranelate heptahydrate

The invention relates to a new preparation method of strontium ranelate heptahydrate. The products produced by the method have water content of 19.0 per cent to 20.4 per cent and the relevant substances are lower than 0.5 per cent. The strontium ranelate heptahydrate produced by the method is stable under room temperature, has little water content differences between batches and is kept for a long time under natural environment with unchangeable moisture, content and relevant substances. The method is characterized in that: (1) the reflux of the 2-[N, N- 2(carboxymethyl)amino]-3-cyano-group-4-thiopheneacetic-5-carboxylic acid tetra ester (b) is carried out in the proper sodium hydroxide aqueous solution of alcohol for 5h to 6h and the pH value is kept over 10 during hydrolysis; (2) the ethanol of 20 per cent to 60 per cent is added and then the strontium chloride aqueous solution with 2times to 2.5times molal weight is directly added, precipitates the crystal, is filtered and dried; (3) water is added to carry out the reflux and the little salt packed in the crude product is removed, and the product is collected through heat filtration. The invention discloses the drug combination containing the strontium ranelate heptahydrate which is used for the treatment of osteoporosis of women after menopause.

Owner:TIANJIN INSTITUTE OF PHARMA RESEARCH

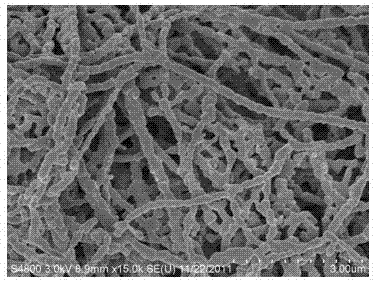

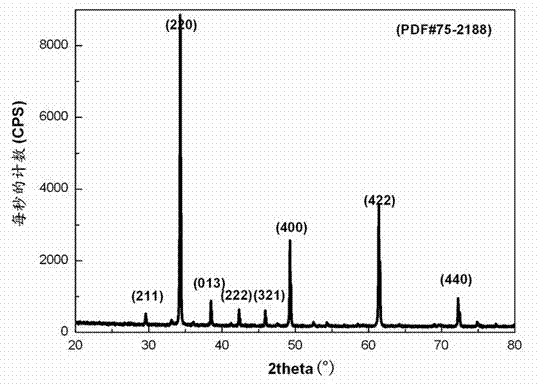

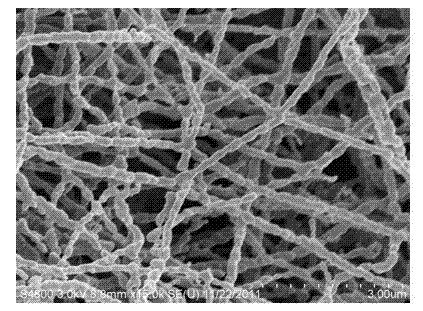

CaCu3Ti4O12 micro nano sized fiber and its preparation method

InactiveCN102515744AControl the hydrolysis processThe electrospinning process went smoothlyFilament/thread formingSpinning solutions preparationFiberCalcium nitrate tetrahydrate

The invention discloses a CaCu3Ti4O12 micro nano sized fiber and its preparation method, which belongs to the inorganic material technical field. The CaCu3Ti4O12 micro nano sized fiber comprises the elements of Ca, Cu, Ti and O with the mol ratio of 13412, and the diameter is 200-300 nanometers. The preparation method comprises the following steps mixing anhydrous ethyl alcohol, calcium nitrate tetrahydrate and copper acetate monohydrate to obtain a solution A; mixing anhydrous ethanol, butyl titanate and a spinning auxiliary agent to obtain a solution B; slowly adding the solution B in the solution A, and using a static spinning technology to prepare the CaCu3Ti4O12 micro nano sized fiber. The method of the invention can effectively control the hydrolysis process of the raw materials by selecting and adjusting the ratio of raw materials and the spinning auxiliary agent, the obtained static spinning solution possesses spinnability, and the method of the invention provides the novel CaCu3Ti4O12 micro nano sized fiber. The preparation method has the advantages of simple process, mild condition, easy control and wide applicability.

Owner:SUZHOU UNIV

Method for preparing glucosamine hydrochloride

InactiveCN101775045AShort reaction timeInhibit side effectsSugar derivativesSugar derivatives preparationGas explosionChemistry

The invention relates to a method for preparing glucosamine hydrochloride, which is characterized by comprising the following steps: 1) treatment of chitin in a gas explosion expanding method: feeding chitin as a raw material into a gas explosion expanding tank, and injecting a gas explosion expanding medium into the gas explosion expanding tank, wherein the gas explosion expanding medium is one of the four substances, namely, steam, water, ammonium hydroxide and ethanol; and instantly releasing the pressure of the gas explosion expanding tank, and discharging the raw material chitin into an atmospheric vessel, thereby obtaining chitin concentrate; 2) hydrolysis with hydrochloric acid; 3) decolorization; 4) filtration; 5) concentration and crystallization; and 6) secondary crystallization. Compared with the prior art, the invention has the following advantages that: 1) the chitin pretreated in the gas explosion expanding method is used as the raw material, and due to the high chemical activity thereof, the invention can achieve a higher product yield; 2) almost no 'coking' can be caused in the process of hydrolysis; 3) the extraction of GAH can be completed at one step during the technological process of technology, thereby simplifying the preparation of GAH; and 4) the hydrochloric acid can be recycled, thereby realizing the clean production of GAH.

Owner:汪昔奇 +1

Chitosan preparation method

The invention relates to a chitosan preparation method, which is characterized in that the method comprises the following steps: 1) gas explosion swelling: loading chitin raw materials into a gas explosion swelling tank, injecting a gas explosion swelling medium which adopts one kind of materials of water vapor, water, ammonia water and ethanol, instantaneously releasing pressure in the gas explosion swelling tank, and spraying the chitin raw materials into a normal pressure container to obtain fine chitin materials; 2) hydrolysis; 3) filtration; 4) soaking and water washing; 5) filtration; and 6) drying. Compared with the prior art, the invention has the characteristics that the chitin pretreated by a gas explosion swelling method is adopted as raw materials, the raw materials have high chemical activity, and low reaction temperature and short reaction time can be adopted in the hydrolysis process, so the generation of the secondary reaction is inhabited, and the decomposition of the chitosan is avoided. Thereby, the invention has the following advantages: 1) the consumption of alkali and energy sources is little;2) the reaction time is short; 3) the yield is high; 4) the production cost is low; 5) the pollutant discharge is little; and 6) the product quality is stable.

Owner:汪昔奇 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com