Method for hydrolytic preparing biological tangeritin by enzyme

A technology for flavonoid monoglycoside and enzymatic preparation, which is applied in the field of enzymatic hydrolysis to prepare citrus bioflavonoid monoglycoside, can solve the problem of difficulty in obtaining naringenin monoglycoside or hesperetin monoglycoside, and achieves convenient separation and purification of products , The enzymatic hydrolysis process is easy and the effect of less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: preparation of solid enzyme

[0023] Aspergillus niger WZ001 (Zhejiang University of Technology Institute of Biology and Environmental Engineering provides) after 5 days of Cha's medium activation, inoculate a loop to the liquid seed medium (4% bran, 3% bean cake powder, 8% bean dregs, and the remainder is water) in 100 mL for 36 h to obtain a seed solution.

[0024] Liquid fermentation medium: 5% bran, 4% bean cake powder, 10% bean dregs, the remaining water, natural pH, 0.1Mpa steam pressure sterilization for 20 minutes, cooling, and adding Aspergillus niger seed liquid to each bottle at a volume ratio of 2%. Fermentation temperature 30-37 ℃, rotation speed 150-200r / min, cultured for 5-7 days, filtered to get the crude enzyme liquid, the enzyme activity of hesperidinase was 14104.9U / g fermentation raw material, the enzyme activity of naringinase The activity is 14799.6U / g fermentation material. Add 270mL of ethanol to 100mL of the obtained crude enzyme...

Embodiment 2

[0025] Embodiment 2: Preparation of immobilized enzyme

[0026] Aspergillus niger WZ001 was activated by Chase medium for 5 days, inoculated one loop into 100 mL of liquid seed medium (4% bran, 3% bean cake powder, 8% bean dregs, and the balance was water) and cultivated for 36 hours to obtain seed liquid.

[0027] Liquid fermentation medium: 5% bran, 4% bean cake powder, 10% bean dregs, the remaining water, natural pH, 0.1Mpa steam pressure sterilization for 20 minutes, cooling, and adding Aspergillus niger seed liquid to each bottle at a volume ratio of 2%. The fermentation temperature is 30-37° C., the rotation speed is 150-200 r / min, and the cultivation is carried out for 5-7 days, and the crude enzyme liquid is obtained by filtration.

[0028] Method (1): Take 10ml of enzyme solution, mix with 50mL of sodium alginate solution with a mass concentration of 1.5%, add 0.02g of tannic acid and 0.02g of polyvinyl alcohol, granulate with a syringe, and drop into 100mL of a mass ...

Embodiment 3

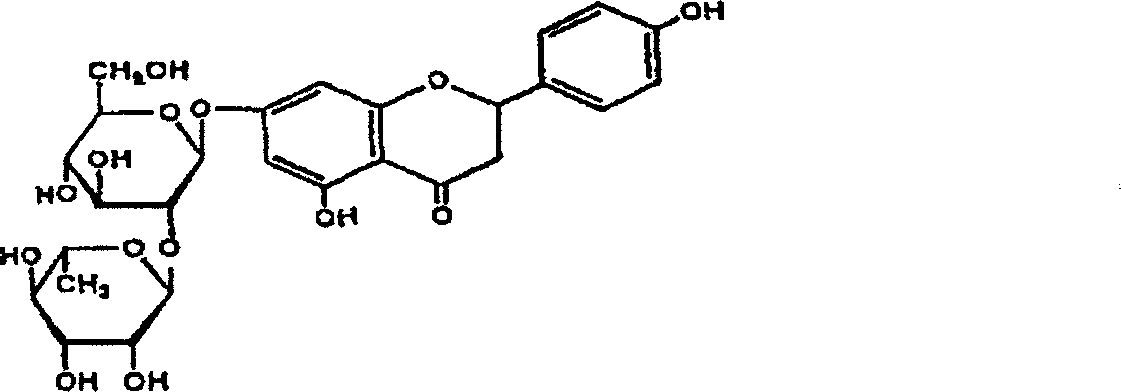

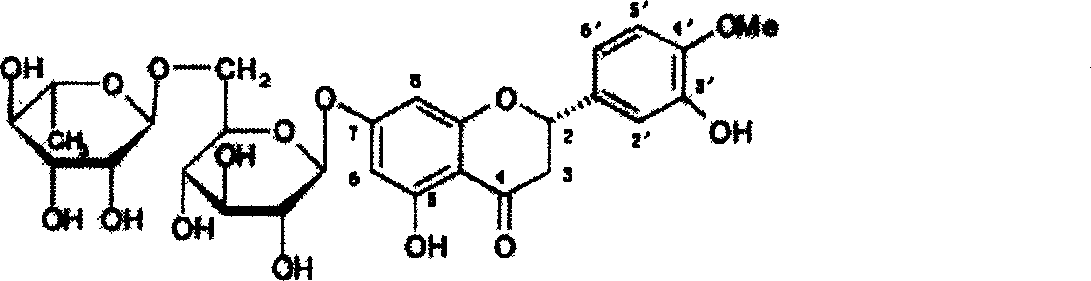

[0031] Embodiment 3: Preparation of naringenin monoglycoside

[0032] 0.2 g of naringin was dissolved in 100 ml of 20% dimethylformamide organic solution with a volume concentration of 20%, so that the concentration of naringin reached 2 g / L. Under the conditions of pH 3.0-6.0 and temperature 20-60°C, add 1-10g of glucose, use free or immobilized naringinase to enzymatically hydrolyze naringin, the enzymatic hydrolysis time is 20-60min, and quantify the product by HPLC Analysis, detection of naringenin monoglycoside and rhamnose content:

[0033]1. Under the conditions of pH 3.5 and temperature 20°C, add the solid enzyme 7U / mg naringin obtained in Example 1, add 1g glucose, and enzymatically hydrolyze it for 20 minutes to obtain 40 mg naringenin monoglycoside and 14.2 mg rhamnose, After enzymatic hydrolysis, the conversion liquid is separated with a macroporous adsorption resin, and eluted with a 30% volume concentration ethanol solution. The obtained substance is naringenin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| embedding rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com