Harmless treatment method for secondary aluminum ash

A harmless treatment, secondary aluminum technology, applied in chemical instruments and methods, inorganic chemistry, chemical industry and other directions, can solve the problems of high energy consumption, large preparation investment, limited and other problems, achieve high economic benefits, avoid production Safety accidents and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

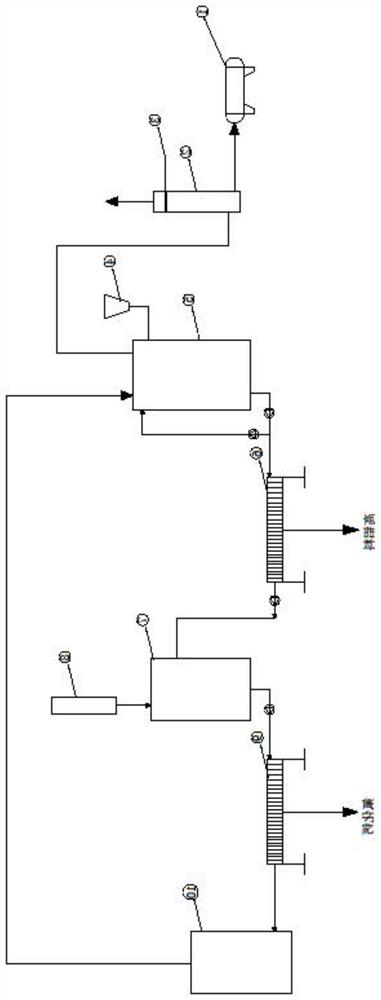

Method used

Image

Examples

Embodiment 1

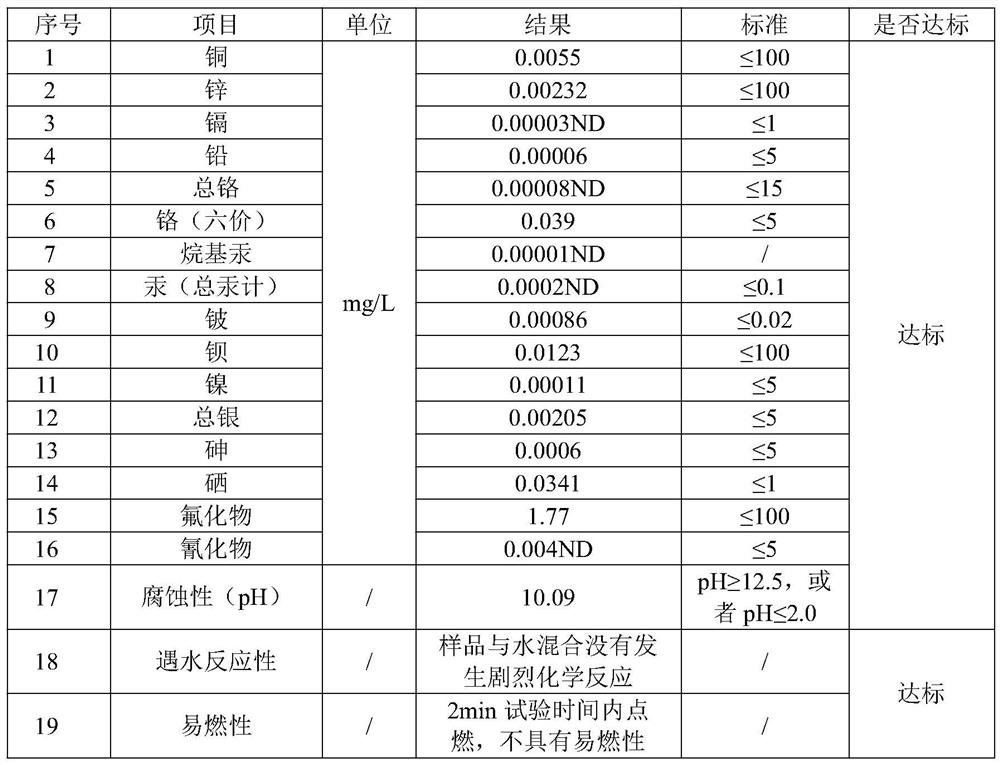

[0033] The reaction experiment of embodiment 1 secondary aluminum ash and water

[0034] ① In experiment 1, 1 kg of secondary aluminum ash and water were mixed in a ratio of 1:3, placed in a reaction vessel at room temperature of 25°C, and timed. It was found that the hydrolysis reaction proceeded slowly and hardly reacted.

[0035] ②Experiment 2 Mix 1 kg of secondary aluminum ash and water in a ratio of 1:3, place it in a reaction vessel at a water temperature of 50°C, and time it. Small bubbles will be generated after 2 minutes, and large bubbles will be generated after 7 minutes. The temperature of the medium solution was about 85°C, the reaction began to decrease after 9 minutes, and the bubbles were less, and the water was almost evaporated after 2 hours, forming a slurry-like mixture. There was no reaction after adding 1 part of 50°C water.

[0036] ③Experiment 3 Mix 1kg of secondary aluminum ash and water according to the ratio of 1:3, place it in a reaction vessel at ...

Embodiment 2

[0042] Embodiment 2 according to the process step of the present invention harmless treatment secondary aluminum ash:

[0043] (1) Raw material preparation

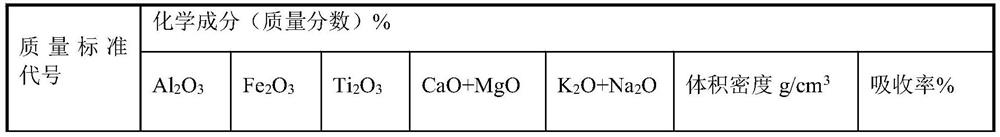

[0044] Collect primary aluminum ash, after two-stage ball milling and sieving to extract elemental aluminum, the particle size of aluminum ash obtained is about 0.125 μm (the screen is 120 mesh), and the secondary aluminum ash is obtained, the main component of which is: alumina (about 60 %), aluminum nitride (about 17.5%), aluminum (about 6%), fluorine (about 1.6%).

[0045] (2) Hydrolysis

[0046] The secondary aluminum ash is sent to the two-level high-level silo, measured by the metering equipment equipped with the second-level high-level silo, and then sent to the closed hydrolysis tank for hydrolysis through the screw conveyor at the lower part of the silo, and the hydrolysis temperature is controlled at 90°C ~100°C; hydrolysis is stirred with an explosion-proof mixer at the same time, the screw machine and the hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com