Novel municipal sewage treatment technology without excess sludge discharge

A technology for urban sewage and excess sludge, applied in water/sludge/sewage treatment, water/sewage multi-stage treatment, flotation water/sewage treatment, etc., to improve effluent water quality, eliminate odor, and reduce aeration volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

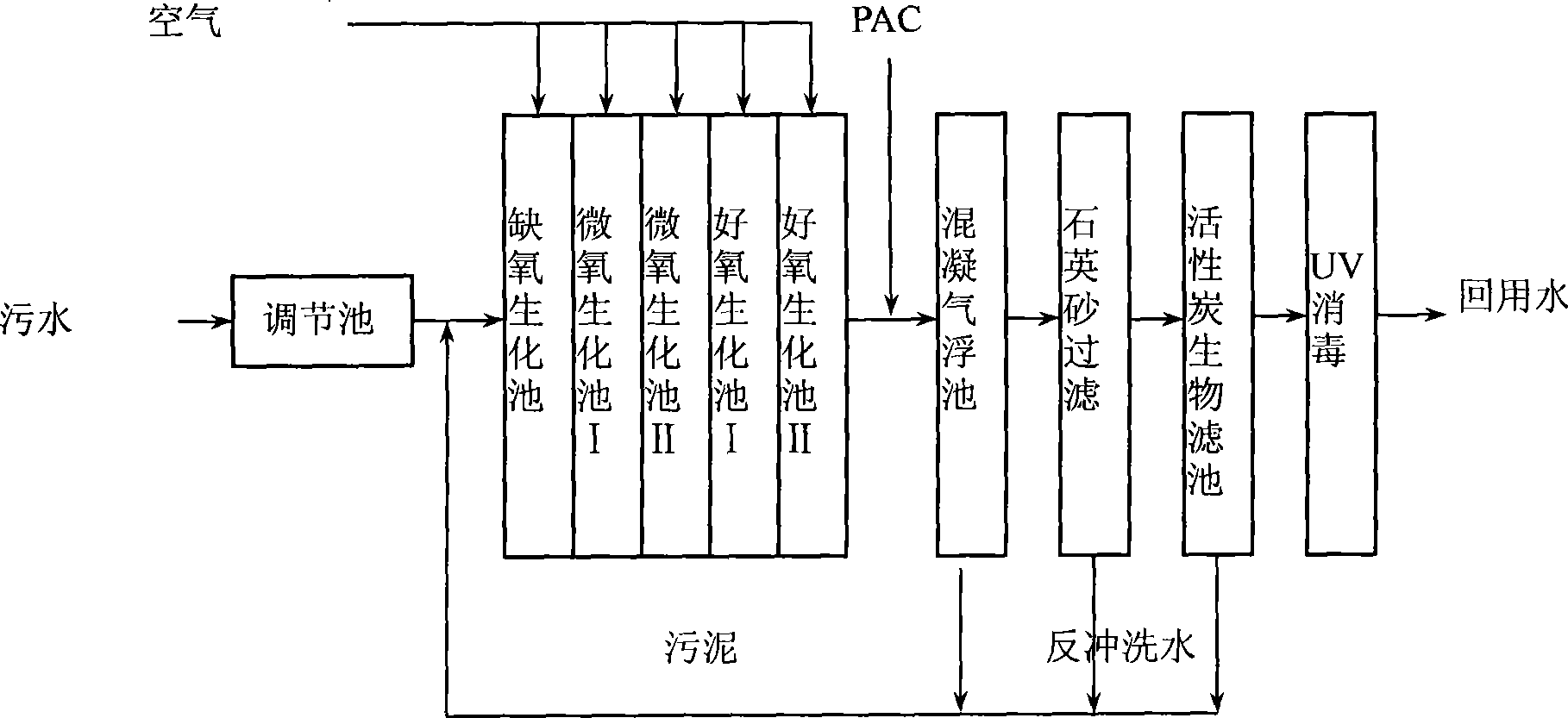

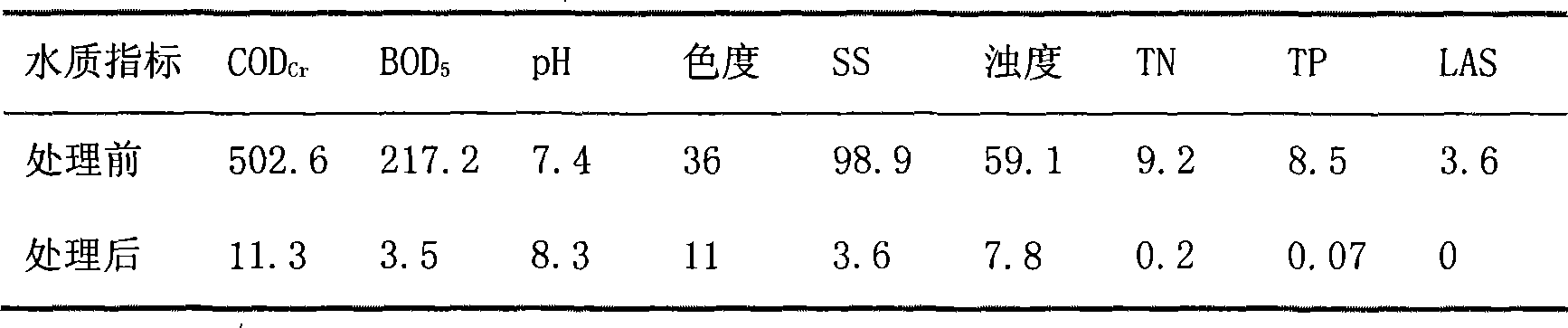

[0014] The water quality characteristics of sewage from a certain urban sewage plant are shown in Table 1. figure 1 Process flow for processing. The HRT in the conditioning tank is 8h; the hypoxic tank is 4h; the HRT of the first-level micro-oxygen tank is 6h, and the DO is 0.3~1mg / L; the HRT of the second-level micro-oxygen tank is 6h, and the DO is 0.8~1.5mg / L; The HRT of the oxygen tank is 4h, and the DO is 1.5~2.0mg / L; the HRT of the secondary aerobic tank is 4h, and the DO is 2~4mg / L; the coagulant is PAC, and the treatment is normally operated under the conditions of 8~15mg / L. , The final effluent is superior to the standards and requirements of domestic miscellaneous water after being filtered by quartz sand, activated carbon and UV sterilization. The treatment results are shown in Table 1. In addition, there is no H during processing 2 When odors such as S appear, the processing system saves energy consumption by about 30% compared with conventional processes. The sludge o...

Embodiment 2

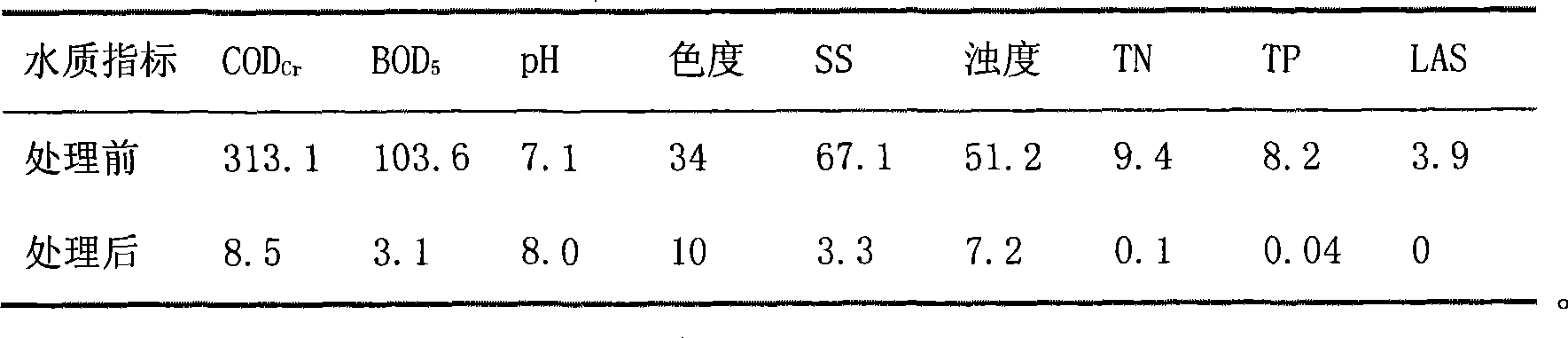

[0018] The water quality characteristics of sewage from a certain living quarter are shown in Table 2. figure 1 Process flow for processing. The HRT in the conditioning tank is 8h; the hypoxic tank is 4h; the HRT of the first-level micro-oxygen tank is 6h, and the DO is 0.3~1mg / L; the HRT of the second-level micro-oxygen tank is 6h, and the DO is 0.8~1.5mg / L; The HRT of the oxygen tank is 4h, and the DO is 1.5~2.0mg / L; the HRT of the secondary aerobic tank is 4h, and the DO is 2~4mg / L; the coagulant is PAC, and the treatment is normally operated under the conditions of 8~15mg / L. , The final effluent is superior to the standards and requirements of domestic miscellaneous water after being filtered by quartz sand, activated carbon and UV sterilization. The treatment results are shown in Table 1. In addition, there is no H during processing 2 When odors such as S appear, the processing system saves 30% of energy consumption compared with conventional processes. The sludge of the trea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com