Patents

Literature

93results about How to "No foul smell" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Consumer waste innocent treatment comprehensive utilization technique

InactiveCN101249499AReduce volumeGood colorBio-organic fraction processingLighting and heating apparatusNutrientDecomposition

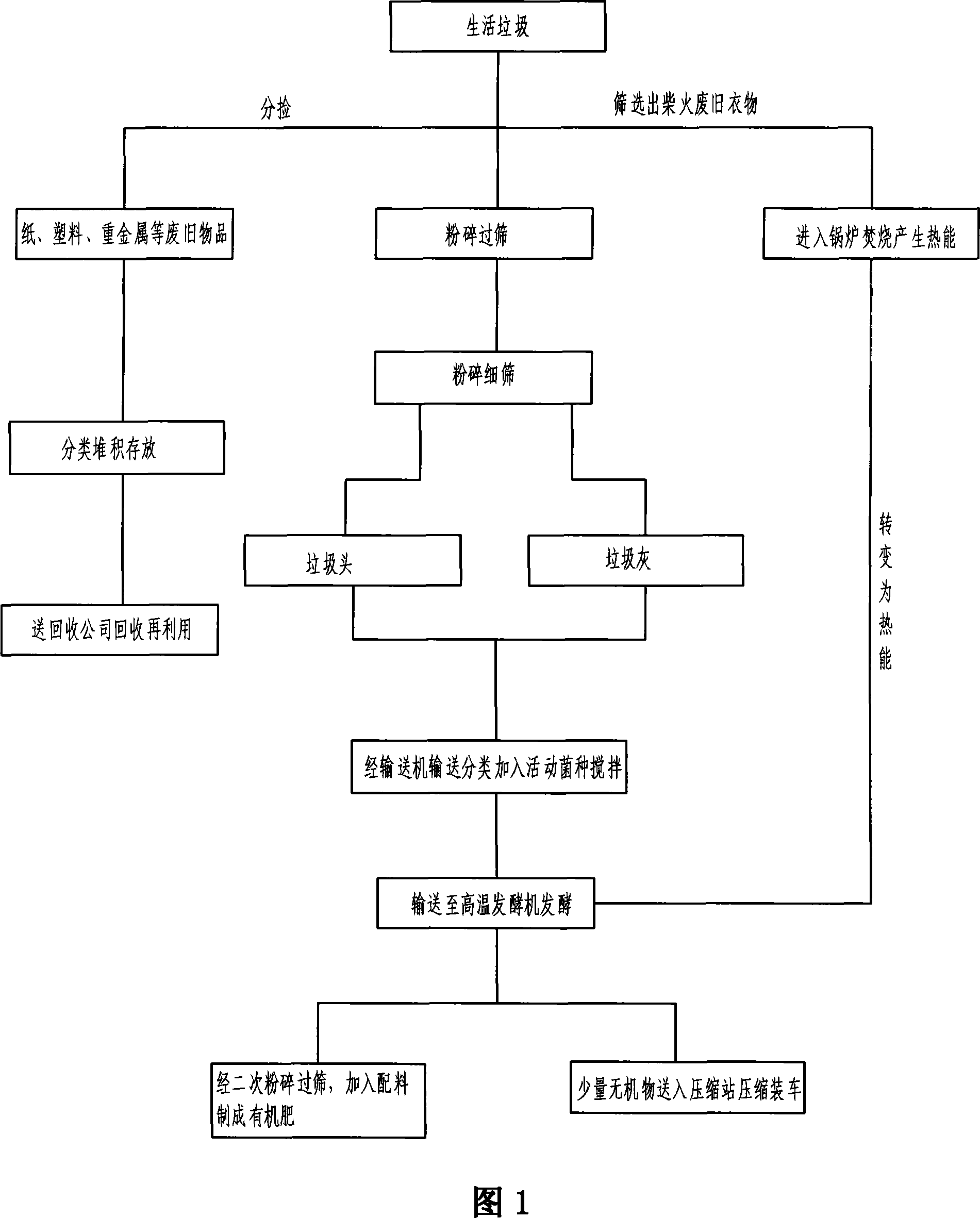

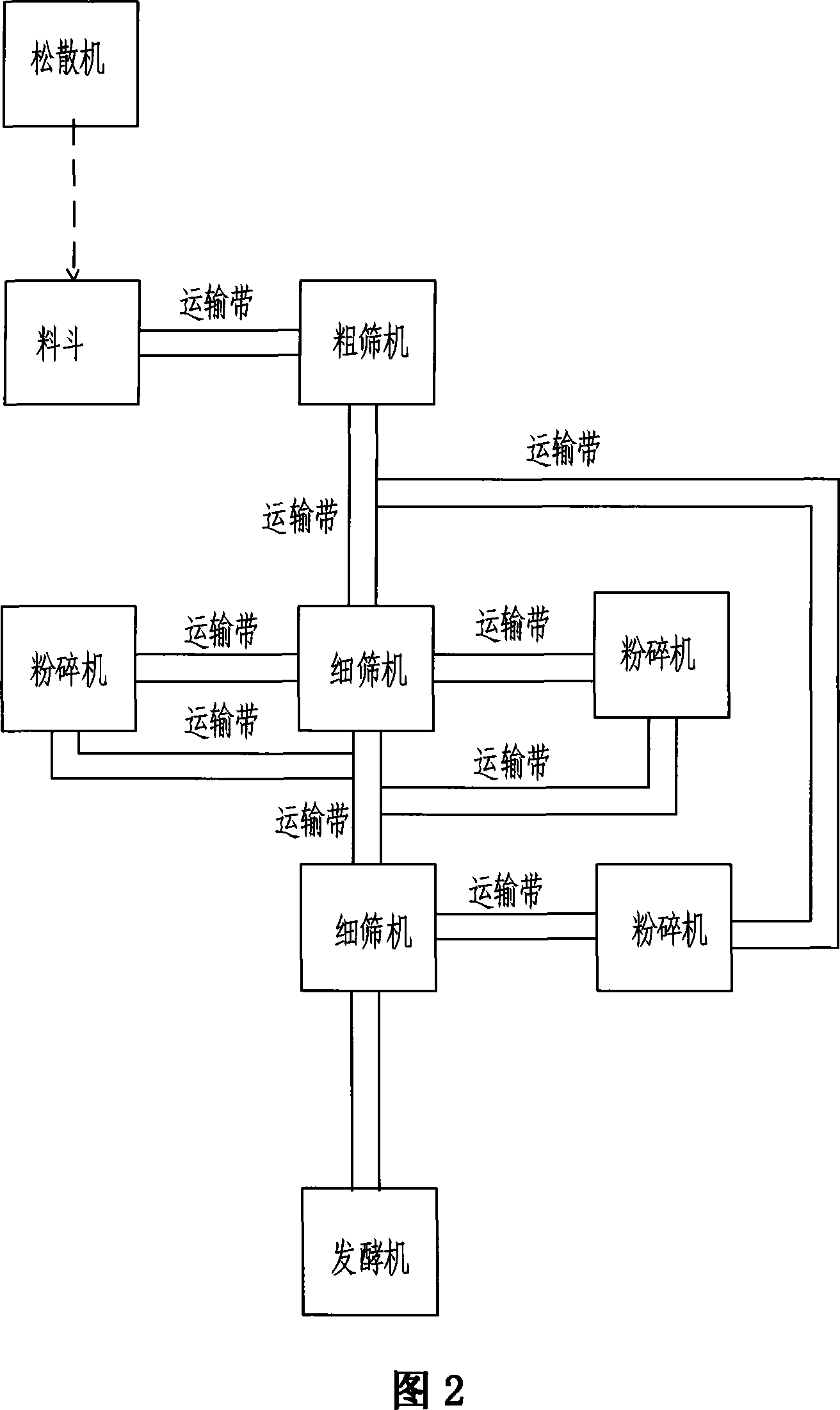

A harmless processing comprehensive utilization technology for life garbage is mainly used for solving the technical problems such as non-environmental protection of prior life garbage processing manner. The technical proposal mainly comprises the following steps of: separating and screening raw life garbage to separate recyclable waste materials such as paper, plastic and heavy metals for recycling and reusing, and combustible materials such as plants and waste clothes for burning in a burner; and then crushing the rest garbage, sieving, sorting, adding active bacteria, stirring completely, feeding into a high-temperature fermenter, and fermenting to obtain organic fertilizer and nutrient soil. According to the invention, the full process for processing the life garbage including fermenting, decomposition, deodorization, sterilization, purification, concentration and discharge only takes 18 to 30 hours, the volume of the waste materials can be reduced by about 30% to 70%, and high-quality organic fertilizer and nutrient organic substrate excellent in color, odor and nutrient can be produced. The process is energy-saving and environment-friendly, and can be widely used to process and reuse the life garbage.

Owner:湘潭闯创环保科技有限公司

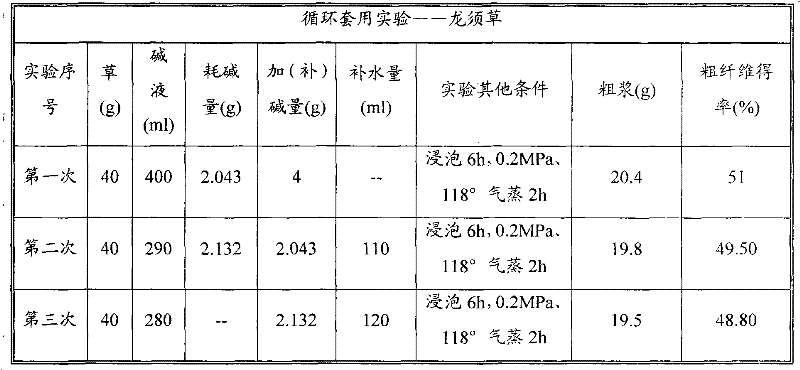

Novel cellulose extraction process

ActiveCN101748633BLight colorPromote growthPretreatment with alkaline reacting compoundsDigestersCelluloseHigh concentration

The invention relates to a novel sectional type process which extracts cellulose from plant bodies, and comprises the following steps: the process is that dilute alkali is first used for soaking the plant bodies, and then pressurizing, steaming, polishing and pulp washing are carried out so that the cellulose is obtained. The sectional type process has the advantages that very dilute alkali can be used for soaking or evaporating the plant bodies, not only the amount of alkali is greatly saved, but also the heating temperature is reduced, the heating time is shortened, the cellulose can be obtained at yield coefficient, and the secondary pollution brought by using sulfide, anthraquinone and other high pollution auxiliary agents is avoided. The soak solution and the cleaning solution can be used together in a cycling way, so liquid or solid organic fertilizer with high concentration can be conveniently obtained.

Owner:BEIJING INSIGHT BIOMASS

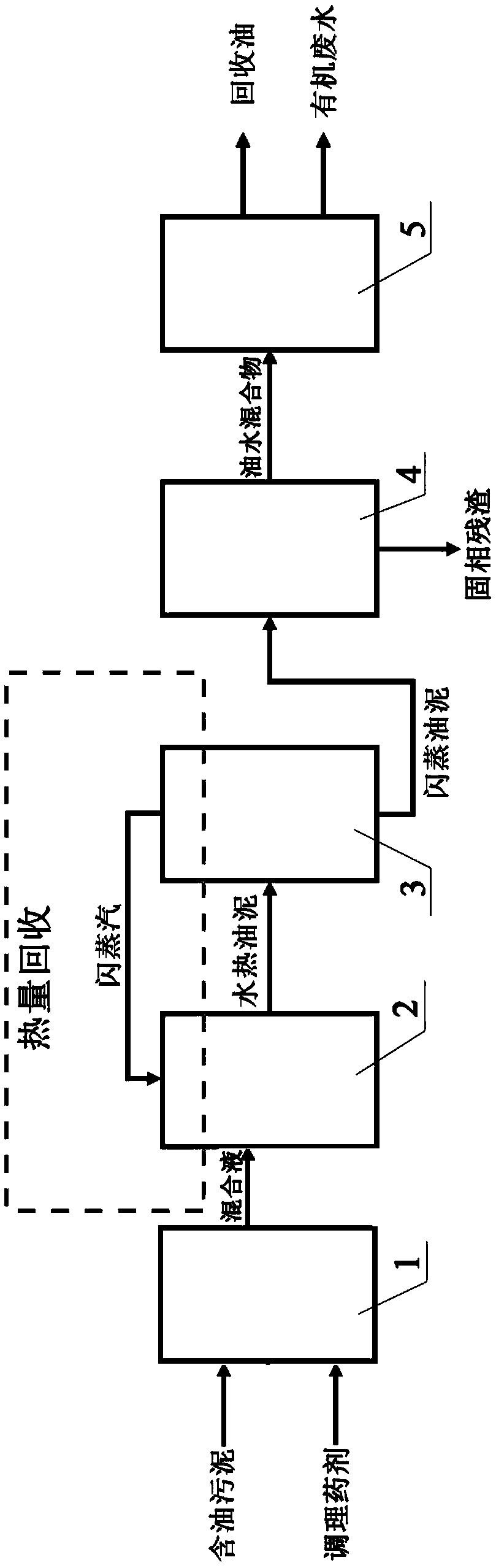

Method and device for synchronously dehydrating and recycling oil from oil-containing sludge

ActiveCN108892348AEfficient recyclingHigh recovery rateWaste water treatment from quariesSludge treatment by de-watering/drying/thickeningChemical oxygen demandEvaporation

The invention provides a method and a device for synchronously dehydrating and recycling oil from oil-containing sludge. The method comprises the following steps: mixing oil-containing sludge with a conditioning chemical, and preheating; further heating the oil-containing sludge and the conditioning chemical to carry out a hydrothermal reaction so as to obtain hydrothermal oil sludge; carrying outflash evaporation rapidly to achieve separation of steam, oil gases and solid-phase residues, wherein generated flash vapor is adopted for preheating to achieve heat recycling; carrying out filter pressing dehydration on separated flash evaporation oil sludge, thereby obtaining a solid-phase residue and liquid-phase oil-water mixture; and standing and layering the oil-water mixture, recycling oilfrom an upper layer, and recycling organic wastewater from a lower layer, wherein the conditioning chemical is composed of a heat-sensitive metal oxide, a catalyst and a demulsifier. By adopting theprocess, good reduction and oil recycling effects can be achieved at a low hydrothermal temperature, the reaction energy consumption can be greatly reduced, the COD (Chemical Oxygen Demand) of a generated waste liquid can be greatly reduced, in addition, the toxicity is degraded, and biochemical treatment can be facilitated.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Method for extracting aroma and flavor-producing substances from splenic edema

ActiveCN101748036ANo foul smellImprove qualityAlcoholic beverage preparationAlcohol contentVacuum pumping

The invention provides a method for extracting aroma and flavor-producing substances from splenic edema, comprising the following steps: obtaining splenic edema liquid through pre-filtering the splenic edema; reducing the pressure of the splenic edema liquid; controlling the negative pressure between 0.5 and 1.0 MPa; maintaining the temperature between 45 and 80 DEG C; extracting the volatile aroma and flavor-producing substances with the alcohol content higher than 10 percent (voL); controlling the negative pressure between 0.8 and 1.2 MPa after the extraction in the first period; maintaining the temperature between 70 and 95 DEG C; extracting the involatile aroma and flavor-producing substances; and using a certain amount of aroma and flavor-producing substances with lower boiling points remained in water used by vacuum pumping as paste adding water after the completion of the extraction. The invention realizes the effective extraction by a pressure reduction vacuum pumping concentration extraction method, improves the extraction efficiency, reduces the cost, and improves the quality of the extraction liquid.

Owner:四川省宜宾市叙府酒业股份有限公司

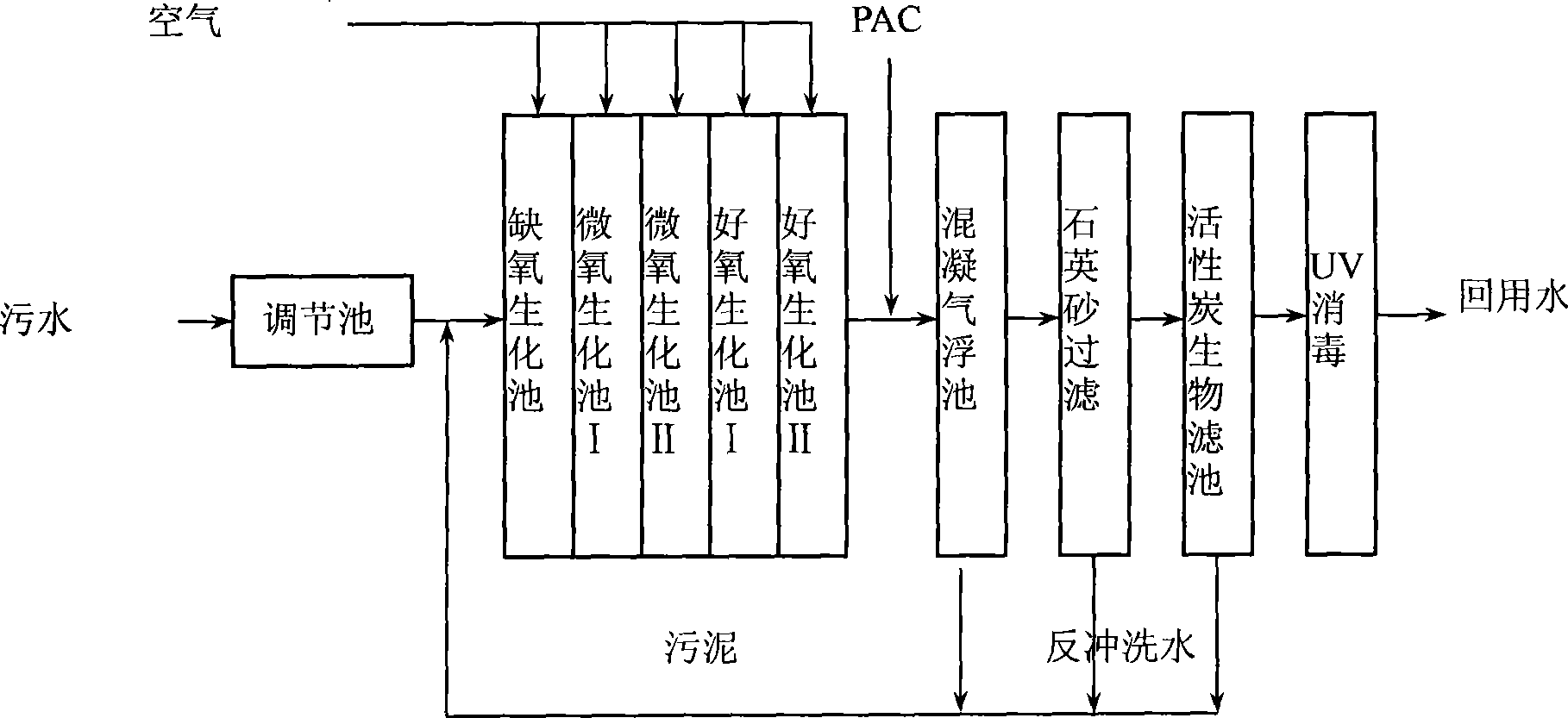

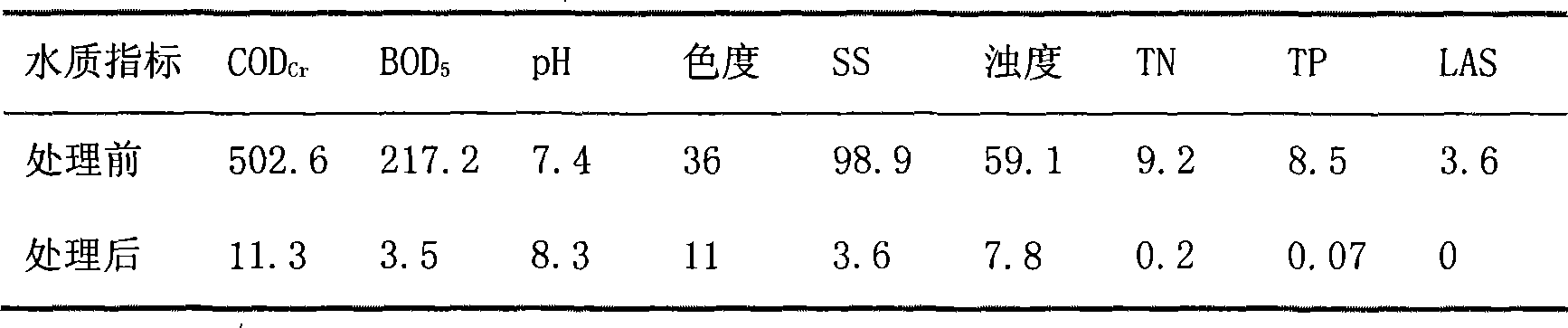

Novel municipal sewage treatment technology without excess sludge discharge

InactiveCN101428942AEliminate pollutionImprove removal efficiencyWater/sewage treatment by irradiationTreatment with aerobic and anaerobic processesWater useActivated carbon filtration

The invention provides a process system for no residual sludge emission in the treatment of municipal sewage, which belongs to a sewage treatment process. The process flow is as follows: the municipal sewage in an adjusting tank orderly is subjected to anoxic biological treatment, microaerophilic biological treatment and aerobic biological treatment, and then orderly undergoes coagulation air-flotation treatment, quartz sand treatment, biological active carbon filtration and subsequent UV sterilization disinfection treatment, and reused as non-potable household water. The process has the advantages of eliminating the odor pollution such as H2S generated in the anaerobic hydrolysis process by the prior A / O method, reducing aeration amount, saving energy consumption, lowering sewage treatment cost, recycling sewage, not causing secondary pollution, completely refluxing the treated system sludge to the anoxic tank, performing the sludge treatment and the sewage biological treatment in the same system, conveniently operating and managing, realizing the residual sludge emission of the system, and improving the discharged water quality of the original treatment system.

Owner:NANJING INST OF GEOGRAPHY & LIMNOLOGY

Lubricating and cooling emulsified oil of copper-alloy fine drawing and its production

InactiveCN101029268AImprove adsorption capacityReduce wearAdditivesBase-materialsOleic Acid TriglycerideMaterials science

A fine pulling lube cooling emulsified oil of copper alloy consists of motor oil 56-60wt%, oleic acid 8-12wt%, mersolates 8-12wt%, zinc naphthenate 4-6wt%, triethyl phosphate 8-10wt%, anhydrous alcohol 1-2wt%, dibutyl phthalate 1-3wt%, non-ionic surface activator 3-6wt% and benamide azole trinitride 0.5-1wt%. The process is carried out by putting motor oil into reactor, heating to 60-70degree, adding mersolates, zinc naphthenate, triethyl phosphate, dibutyl phthalate and oleic acid into motor oil successively, agitating at 600-650 / min for 1-2hrs, dissolving benamide azole trinitride by anhydrous alcohol, adding into mixed solution, adding into non-ionic surface activator, agitating and lowering temperature. It can prevent pulling metal from overheat and oxidation coloring and have better finish degree and brightness.

Owner:DALIAN SANDAAOKE CHEM

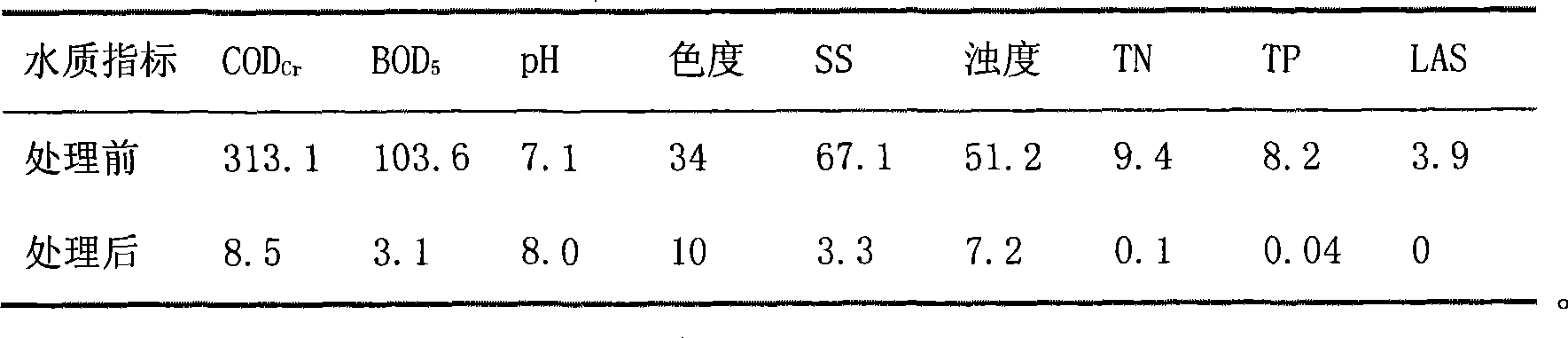

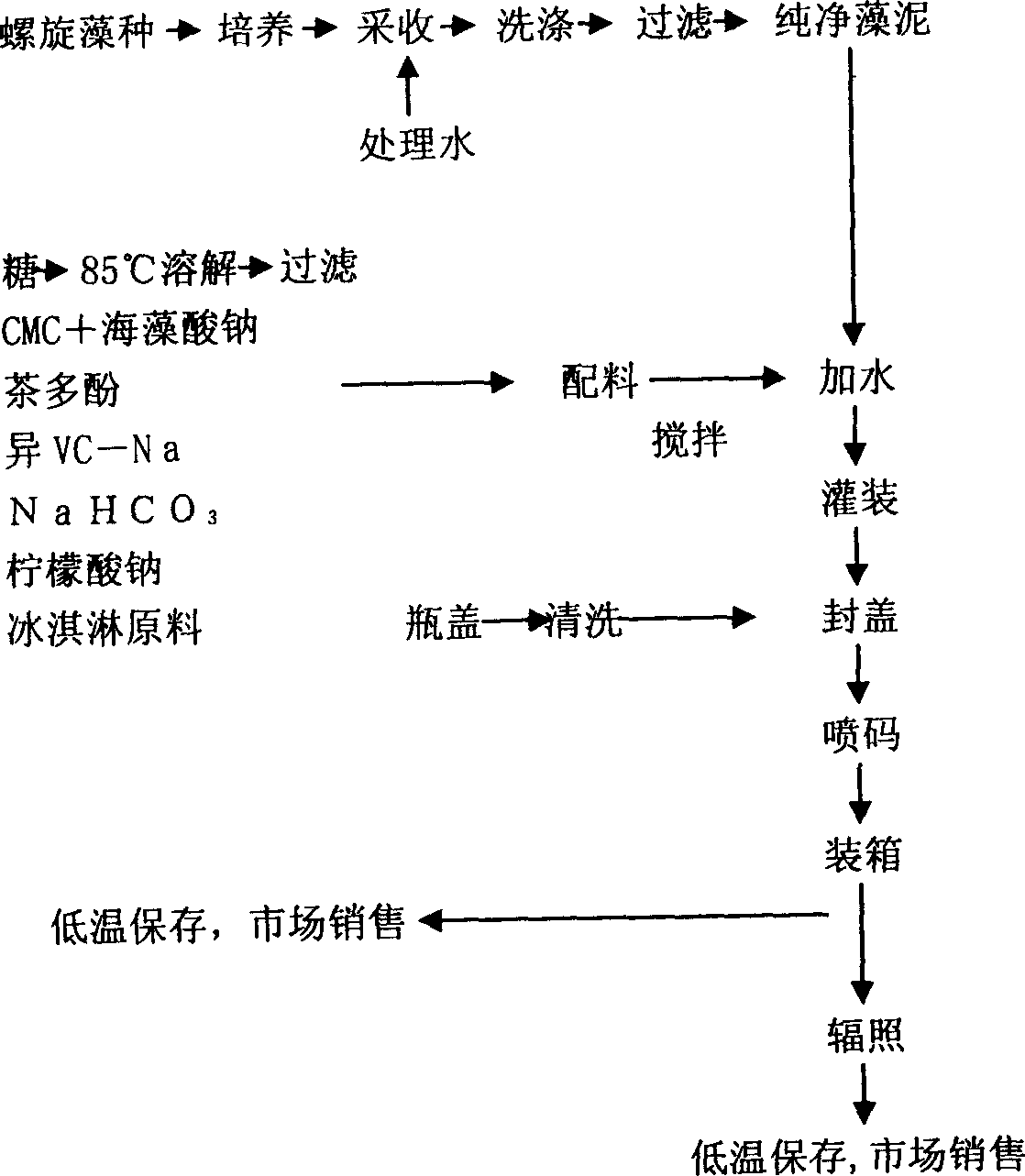

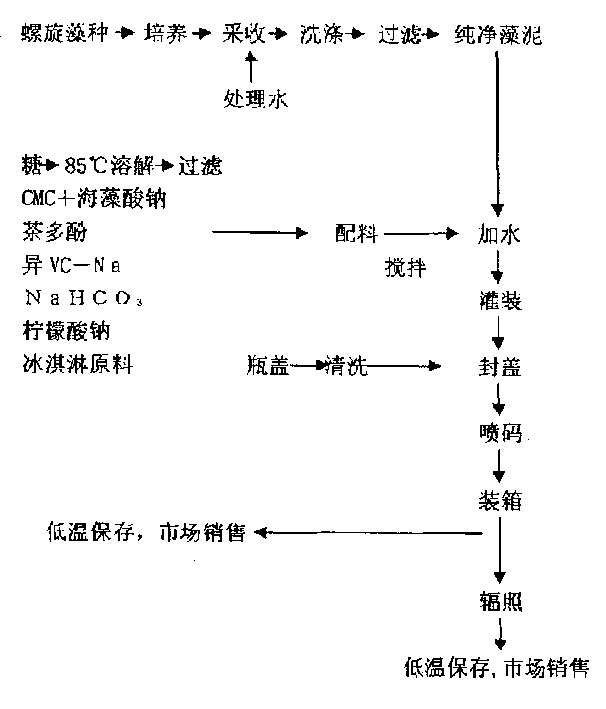

Health foods of new type spirulina and preparation method thereof

A health-care spirulina food in the form of milk, nectar, or ice cream is prepared by biotechnology. Its advantages are no loss of mutrients, and agreeable taste.

Owner:INST OF PHARMACOLOGY & TOXICOLOGY ACAD OF MILITARY MEDICAL SCI P L A

Paper pulping bleaching and waste water purification integration technology

InactiveCN101597871AShort production processProtect environmentPulp liquor regenerationPulp bleachingEnzymePulp bleaching

A paper pulping bleaching and waste purification integration technology comprises two technology stages of paper pulping bleaching and waste water purification; wherein the paper pulping bleaching technology stage comprises: (1) slicing; (2) solution preparing; (3) initial reaction by adding enzyme and medicament; (4) deep reaction by adding medicament; (5) sieving, sedimentation and grinding; and (6) pulp washing, bleaching and stabilizing to obtain paper pulp finished product; and the waste water purification technology stage comprises: (1) purification, sedimentation and separation; and (2) concentration, drying and sediment recovery. The invention combines chemistry and biology, pulping and bleaching are completed in the same container in an integration way, neither chorine element is required nor black liquor is produced during pulping and bleaching, COD, BOD, SS and chrominance in pulping water are reduced to the utmost extent, waste water of pulping can be reused in pulp washing after purification treatment, and finally zero discharge or standard discharge of the whole waste water of pulping is realized.

Owner:XIAN TONGRUN BIOTECH

Technology for biochemical treatment and fertilizer use of tobacco invalidism body

ActiveCN103373867AReduce volumeNo spreadBio-organic fraction processingOrganic fertiliser preparationBiotechnologyNicotiana tabacum

The invention relates to a technology for biochemical treatment and fertilizer use of a tobacco invalidism body. The technology realizes availability of the tobacco through a microbial decomposition and fermentation method, and realizes recycling and fertilizer use of the tobacco invalidism body through steps of pretreatment, sterilization, degradation of nicotine tar, fermentation and postripeness. According to the technology, the problem of recycling the tobacco invalidism body is solved, high quality active organic fertilizer can be produced rapidly, and the contamination problem caused by the tobacco invalidism body in production of tobacco is completely solved.

Owner:湖南碧野农业科技开发有限责任公司

Plant hollow capsule

InactiveCN104127877AReduce usageReduce pollutionCapsule deliveryMacromolecular non-active ingredientsEthyl hydroxybenzoateDisease

The invention discloses a plant hollow capsule which comprises the following ingredients by mass: 20 to 30 parts of hydroxypropyl methyl cellulose, 20 to 30 parts of carrageenan, 10 to 25 parts of alginate, 10 to 25 parts of guar gum, 6 to 12 parts of algal polysaccharides, 2 to 6 parts of carboxyl methyl glucomannan, 1 to 3 parts of a soybean isolate protein, 2 to 6 parts of a malt extract, 1 to 4 parts of starch, 40 to 60 parts of ethyl alcohol, 2 to 5 parts of triethyl ester, 1 to 4 parts of glycerin, 0.5 to 1.5 parts of titanium dioxide, 2 to 5 parts of magnesium stearate, 0.1 to 0.5 part of ethyl hydroxybenzoate, 2 to 5 parts of methyl p-hydroxybenzoate, 0.2 to 0.6 part of methyl silicone oil, 1 to 3 parts of an edible pigment, and 70 to 100 parts of purified water. The plant hollow capsule can reduce environmental pollution, prevents and treats the transmission of diseases, and improves the capsule security.

Owner:ZHEJIANG YILI CAPSULE

Zinc-coated steel-plated punch drawing lube oil and its production

InactiveCN101029271AImprove adsorption capacityReduce wearAdditivesBase-materialsN-butyl vinyl etherParaffin oils

A galvanized steel plate punch stretch lube oil consists of motor oil 45-55wt%, castor oil 2-4wt%, soya oil 25-35wt%, mersolates 0.5-1.5wt%, zinc naphthenate 0.5-1.5wt%, triethyl phosphate 2-4wt%, chlorinated paraffin 3-5wt%, butyl-octanol zinc salt phosphinothioyl 2-4wt%, poly-n-butyl vinyl ether 4-6wt% and bactericide 0.2-0.3wt%. The process is carried out by adding motor oil into reactor, heating to 90-100degree, agitating at 750-850 / min, adding into mersolates, zinc naphthenate, chlorinated paraffin and triethyl phosphate successively, agitating for 1.5-2.5hrs, lowering temperature to 50-60degree, adding into castor oil, soya oil and bactericide, agitating for 0.5-1.5hrs, lowering to normal temperature, adding into butyl-octanol zinc salt phosphinothioyl and poly-n-butyl vinyl ether, and agitating at 75-85 / min and agitating 1.5-2.5hrs. It has better oil-film continuity and adsorption and prevents punch work-piece from being scraped and corrosion.

Owner:DALIAN SANDAAOKE CHEM

Sludge high-temperature aerobic composting treatment method

PendingCN109851399AEasy to operateReduce negative impactBio-organic fraction processingClimate change adaptationFilter pressOxygen

The invention relates to a sludge high-temperature aerobic composting treatment method. The treatment method comprises the following steps: (1) conveying dewatered sludge of a plate-and-frame filter press to a sludge deep treatment workshop, mixing the dewatered sludge with a strain fermentation material, and stacking the mixture in an aerobic fermentation tank of the sludge deep treatment workshop; (2) performing ventilating aeration by an aerator pipe at the bottom in the aerobic fermentation tank to ferment the mixture of the dewatered sludge and the strain fermentation material, turning over the mixture during the fermentation process, and transporting the mixture outwards after the mixture is fermented to be mature. The sludge high-temperature aerobic composting treatment method is simple in steps.

Owner:福州创源同方水务有限公司

Environment-friendly and harmless novel technology for producing organic fertilizers by utilizing agricultural wastes

InactiveCN104725087ANo foul smellSimple processBio-organic fraction processingExcrement fertilisersBiotechnologyAsparagus

The invention discloses an environment-friendly and harmless novel technology for producing organic fertilizers by utilizing agricultural wastes, and relates to a technology for producing the organic fertilizers. The technology comprises three steps of pretreatment, primary fermentation and posttreatment. The specific technological process is as follows: 1, preparing main materials, auxiliary materials and a compound microorganism agent, and mixing and stirring the materials; 2, through adopting a compost aerobic fermentation technology, performing biochemical degradation on organic wastes by utilizing microorganism under an aerobic condition, wherein the critical technology is main fermentation and postfermentation; 3, performing necessary treatment on completely cured organic fertilizers subjected to fermentation process; and 4, spreading the treated fertilizers for air drying, crushing and screening, carrying out quality inspection, weighing and subpackaging. According to the novel technology, the aerobic fermentation technology of microorganism technology is utilized, the high-efficient compound microorganism agent, cow dung and asparagus straws are mixed according to a certain ratio and naturally fermented (heating is not needed) in a fermentation tank, and the high-efficient non-poisonous and harmless organic fertilizers are prepared after 15-20 days.

Owner:SHANGHAI SHENGWEI ORGANIC FERTILIZER CO LTD

Iron-carbon microelectrolysis coupled submerged plant module and application thereof

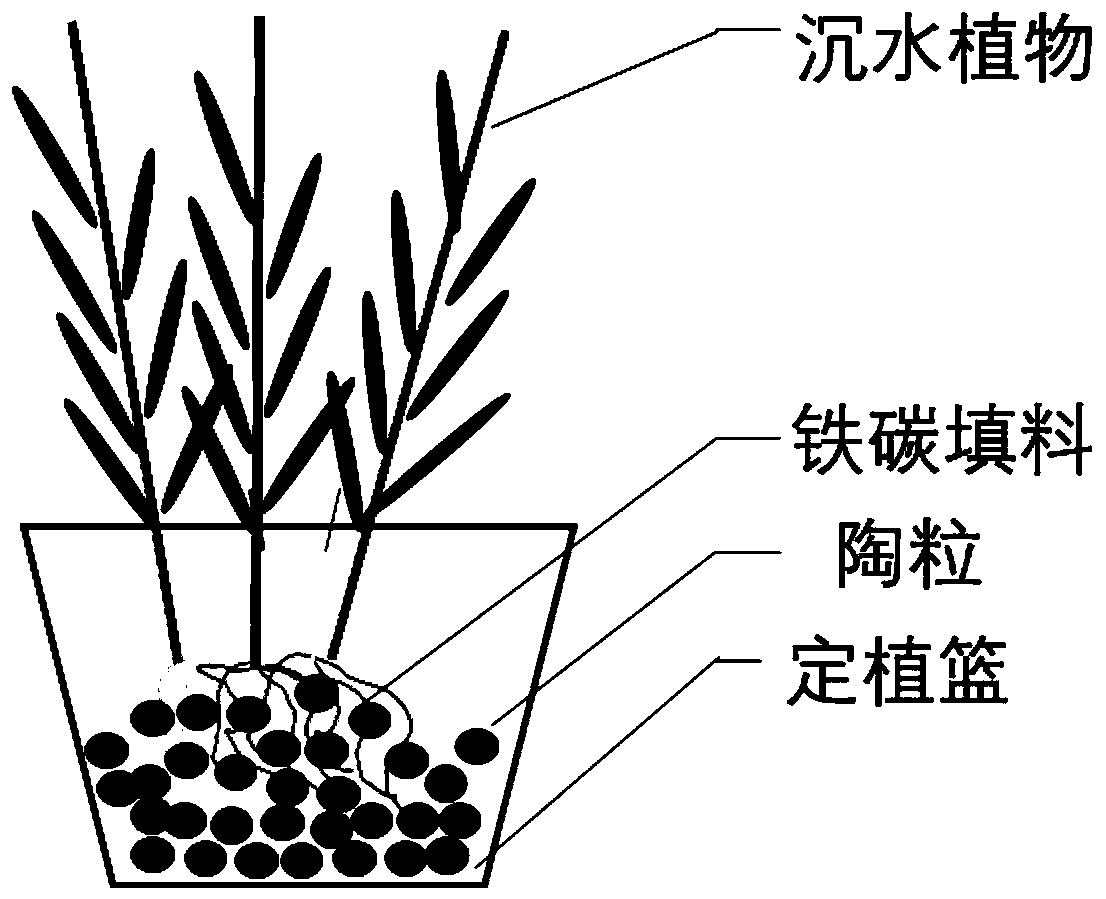

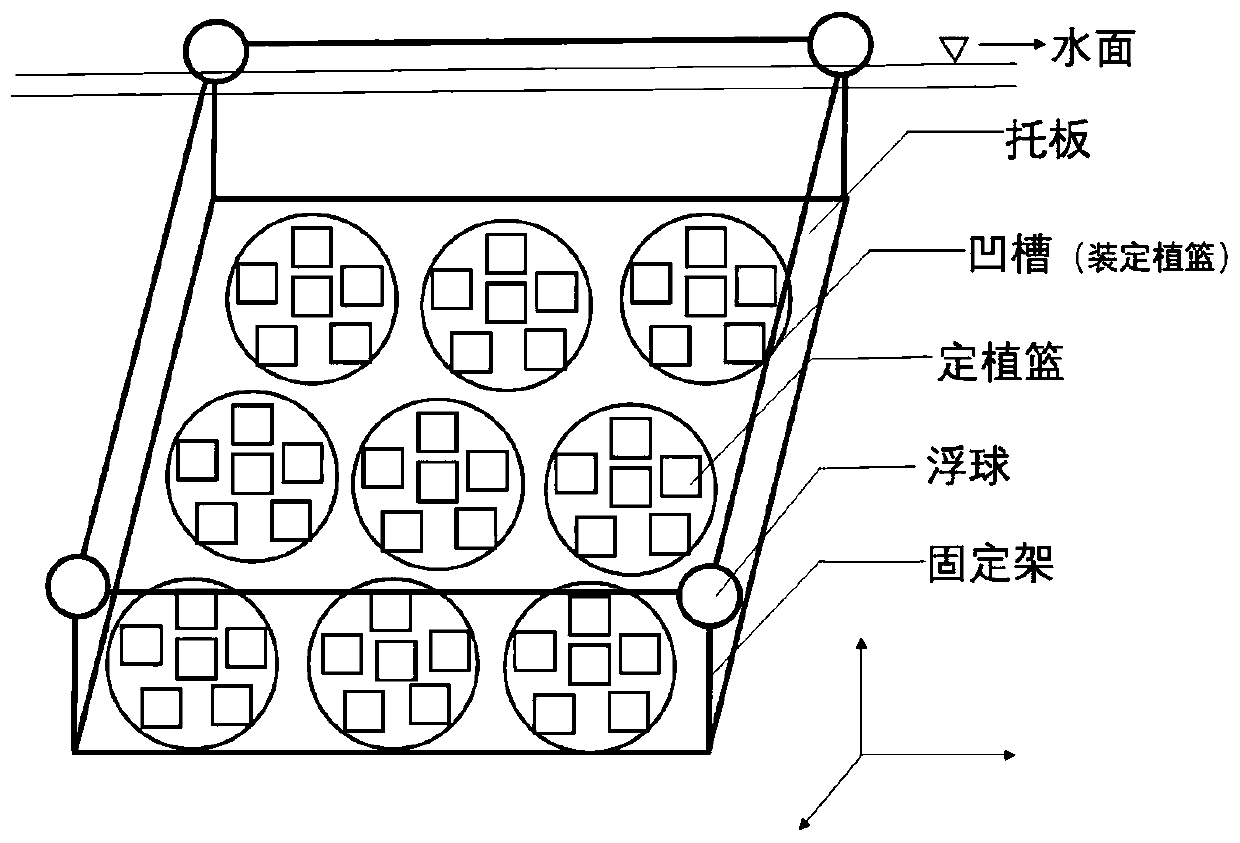

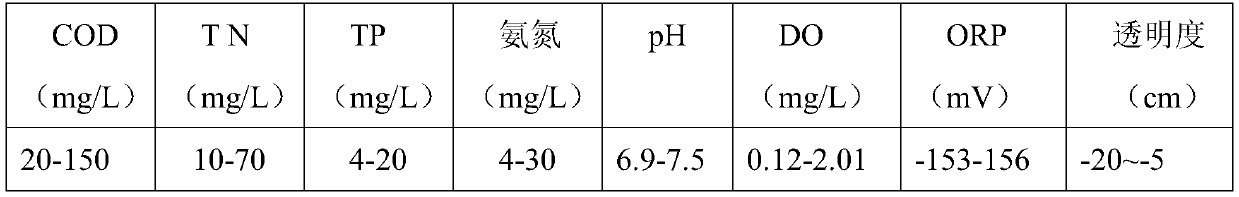

InactiveCN110092475AHigh transparencyIncrease varietyTreatment by combined electrochemical biological processesSpecific water treatment objectivesAeration systemEngineering

The invention discloses an iron-carbon microelectrolysis coupled submerged plant module and an application thereof. The module comprises a submerged plant system and an aeration system, the submergedplant system comprises planting baskets and submerged plants, the submerged plants are fixed in the planting baskets, the roots of the submerged plants are wrapped with an iron-carbon filler and are fixed, and the submerged plants are fixed in the planting baskets by ceramsite; and the aeration system is characterized by underground aeration or surface aeration. The iron-carbon microelectrolysis coupled submerged plant module is applied to the repairing of the black and odorous / eutrophic water to significantly reduce the chroma and odor thresholds of the black and odorous / eutrophic water within 2 d, and achieves no foul odor, significant increase of the transparency of the water, the COD removal rate of 70% or above, the ammonia nitrogen removal rate of 95% or above, the denitrification rate of 60% or above, the phosphorus removal rate of 95% or above, the dissolved oxygen concentration of 2.5-5.5 mg / L, the transparency of 35-70 cm and increase of the number of kinds of microorganismsin the water after 10 d.

Owner:SOUTH CHINA UNIV OF TECH

Microorganism compound organic feed

InactiveCN109497281ADeep degradationMeet daily needsFood processingAnimal feeding stuffBacillus licheniformisPectinase

The invention provides microorganism compound organic feed. The microorganism compound organic feed is prepared from the following raw material components in parts by weight: 15 to 30 parts of soybeanflour, 50 to 80 parts of a microorganism fermentation composition and 0.5 to 1 part of calcium hydrogen phosphate, wherein the microorganism fermentation composition is prepared by carrying out aerobic fermentation on a microorganism mixed bacterium agent, a combined enzyme, an organic raw material and water according to a weight ratio of (1 to 1.5) to (0.5 to 1) to 100 to (10 to 20) at 25 to 50DEG C for 8-12 h; the microorganism mixed bacterium agent is prepared from the following raw material components: bacillus subtilis, bacillus megaterium, bacillus cereus, bacillus licheniformis, aspergillus niger and aspergillus oryzae; the combined enzyme is a mixture of proteinase, cellulase, dextranase and pectinase; the organic raw material is at least one of soybean meal, peanut meal and rapeseed meal. The design provided by the invention has the advantages that deep degradation of organic matters is realized, the immune function in animal bodies is easy to improve, the fermentation period is short and the stink is not generated.

Owner:湖北源清生物科技股份有限公司

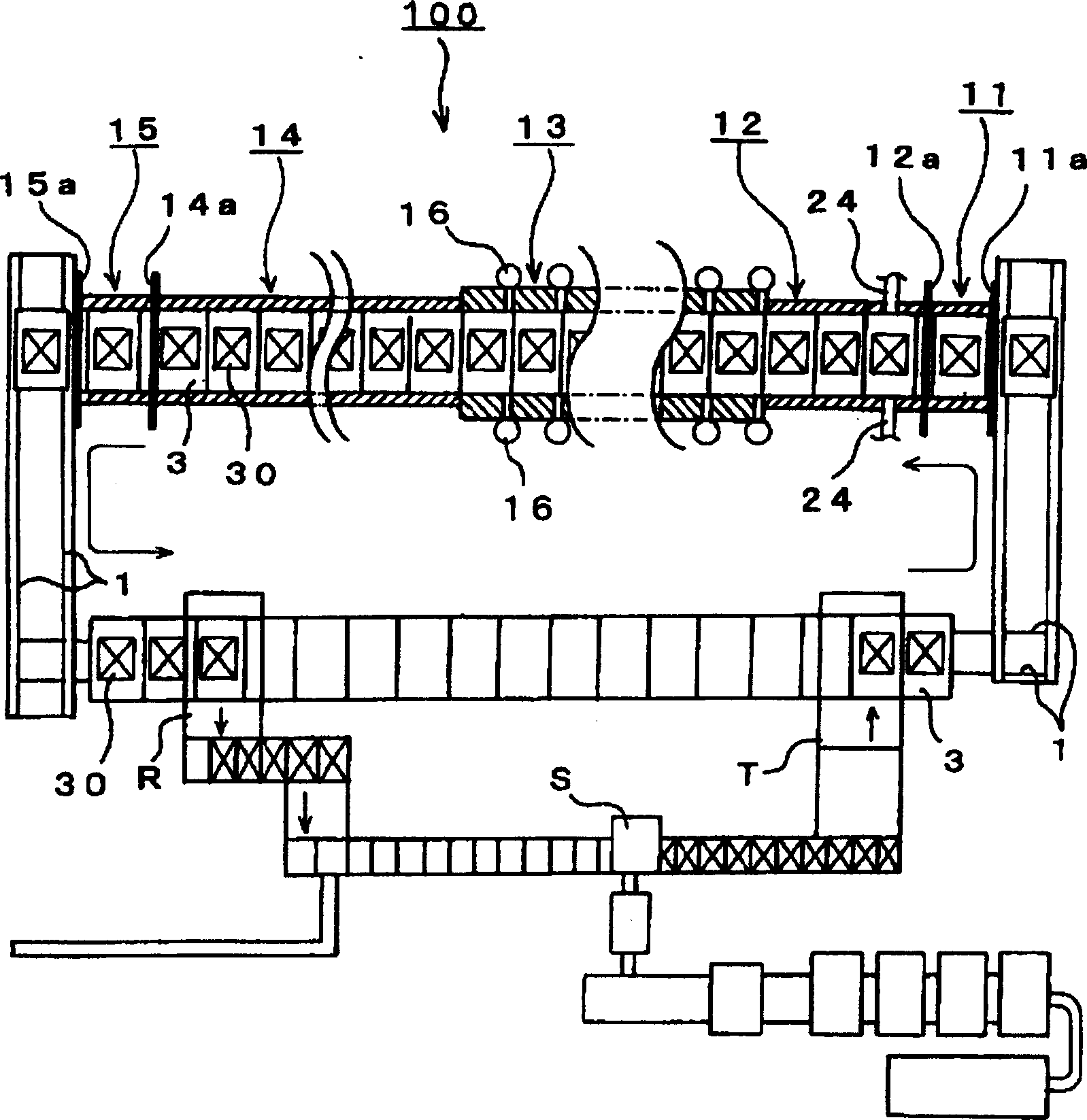

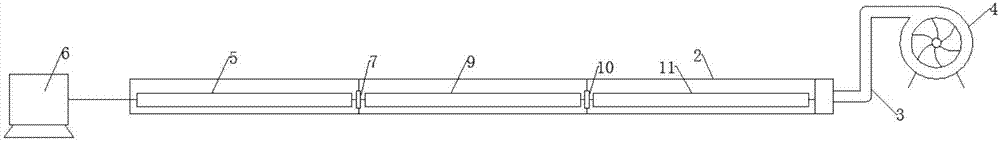

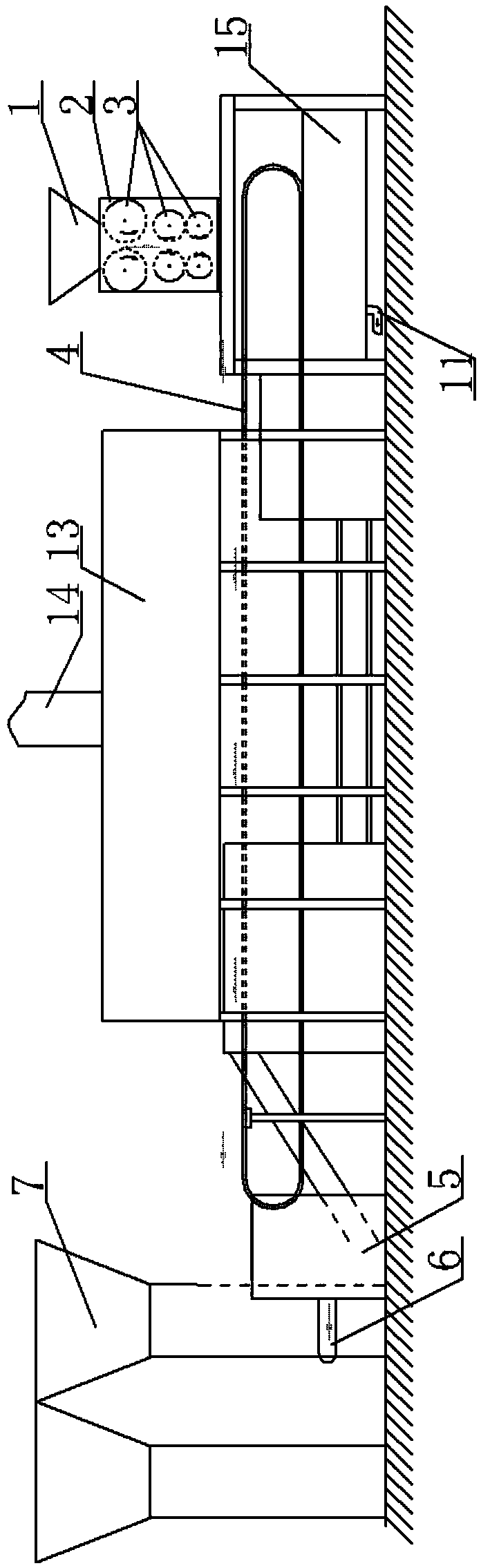

Continuous carbonization apparatus and method

InactiveCN1605797ARapid continuous carbonizationImprove carbonization efficiencyIncinerator apparatusTunnel kilnCarbonization

The present invention provides one kind one continuous carbonizing method and apparatus. The method can treat great amount of matter without generating offensive odor, and has raised carbonizing efficiency, reduced fuel consumption and lowered cost. The continuous carbonizing apparatus includes long horizontal tunnel kiln comprising preparing zone, pre-heating zone, carbonizing zone, cooling zone and conveying zone successively; and re-burning deodorizing furnace performing heat treatment to gas exhausted from the tunnel kiln. The full carbonizing process from loading the matter to be carbonized into the storing boxes to discharging the carbonized matter is completed in the tunnel kiln.

Owner:C Y C +1

Faint scent-type cat litter added with camellia japonica and processing technology of faint scent-type cat litter

The invention relates to faint scent-type cat litter added with camellia japonica. The faint scent-type cat litter is characterized by comprising the following components: 50 to 85 parts of plant wood chips, 5 to 10 parts of starch, 3 to 5 parts of an antimicrobial agent, 8 to 10 parts of sodium bicarbonate, 4 to 5 parts of a binder, 1 to 2 parts of super absorbent resin, 2 to 4 parts of camellia japonica and 5 to 10 parts of water. The cat litter provided by the invention has the beneficial effects of small density, high expansion and hygroscopicity, biodegradability, high antibacterial property, low bacterium breeding possibility, faint scent of camellia japonica, and capability of absorbing urine and feces without generating stink.

Owner:YANTAI CHINA PET FOODS GRP

Biological organic fertilizer using orange peel residue as main raw material and preparation method thereof

InactiveCN102249756BUniform sizePromote growth and developmentBio-organic fraction processingOrganic fertiliser preparationNavel orangeToxic industrial waste

The invention discloses a biological organic fertilizer using orange peel residue as a main raw material and a preparation method thereof. The biological organic fertilizer comprises the following raw materials in percentage by weight: 65 to 75 percent of orange peel residue, 5 to 8 percent of rice husk, 4 to 5 percent of wood dust, 0 to 5 percent of stevia rebaudiana filter residue, 10 to 20 percent of animal manure, and 1 to 2 percent of micro fertilizer and biological strains. The biological organic fertilizer is prepared by the steps of orange peel residue pretreatment, proportioning, primary degradation, compost ageing treatment, adding of biological functional bacteria at the rear end and the like. Various indexes of the biological organic fertilizer prepared by the method are totally superior to the biological organic fertilizer standards issued by the state; after the biological organic fertilizer is applied to the soil, the water, fertilizer, gas and heat conditions of the soil can be effectively improved, so that the soil becomes loose and fertile and is favorable for cultivation and growth and development of crop roots, the yield is increased, and the product quality is improved; the biological organic fertilizer is particularly suitable to be used as a special biological organic fertilizer for navel orange; and the industrial waste residue of orange juice is changed into valuable, the environment is protected, the comprehensive benefit is improved, and the invention has good economic benefit and ecological benefit.

Owner:GANNAN NORMAL UNIV +1

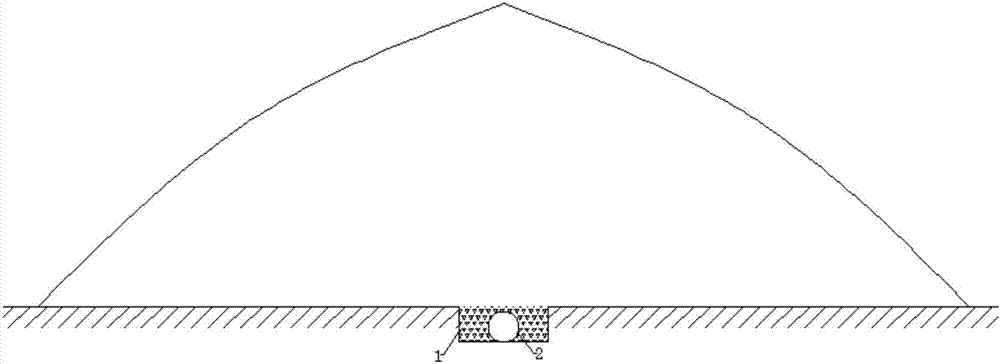

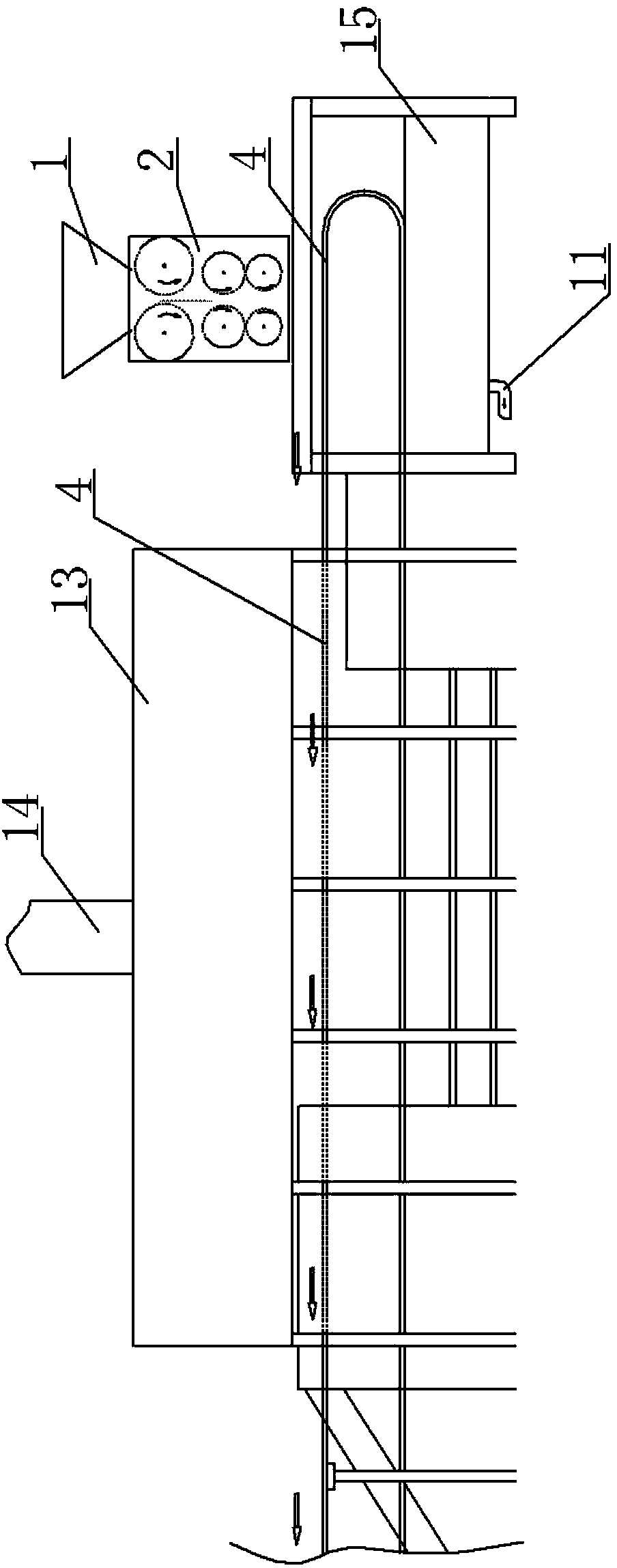

Windrow composting aeration system

ActiveCN107382403ADoes not affect walkingDoes not affect flippingBio-organic fraction processingOrganic fertiliser preparationAeration systemHusk

The invention discloses a windrow composting aeration system which comprises a groove and a gas pipe, wherein the groove is formed in a pre-composting ground along a windrow orientation and has a width smaller than that of wheels of a turning and throwing machine; the gas pipe is laid at the bottom of the groove; a plurality of aeration notches are formed in a pipe wall of the gas pipe; other parts in the groove are filled with rice husks. The windrow composting aeration system provided by the invention has the functions that gas is supplied by the gas pipe rather than the groove; the gas pipe does not interfere with turning and throwing, can supply gas without blockage, can discharge accumulated water automatically, and the like, so that the windrow composting aeration system is more sufficient in the amount of supplied oxygen, rapid to heat up, high in fermentation temperature, short in fermentation period, rapid in material turnover, and high in productivity.

Owner:GUANGXI JINSUI ECOLOGICAL TECH CO LTD

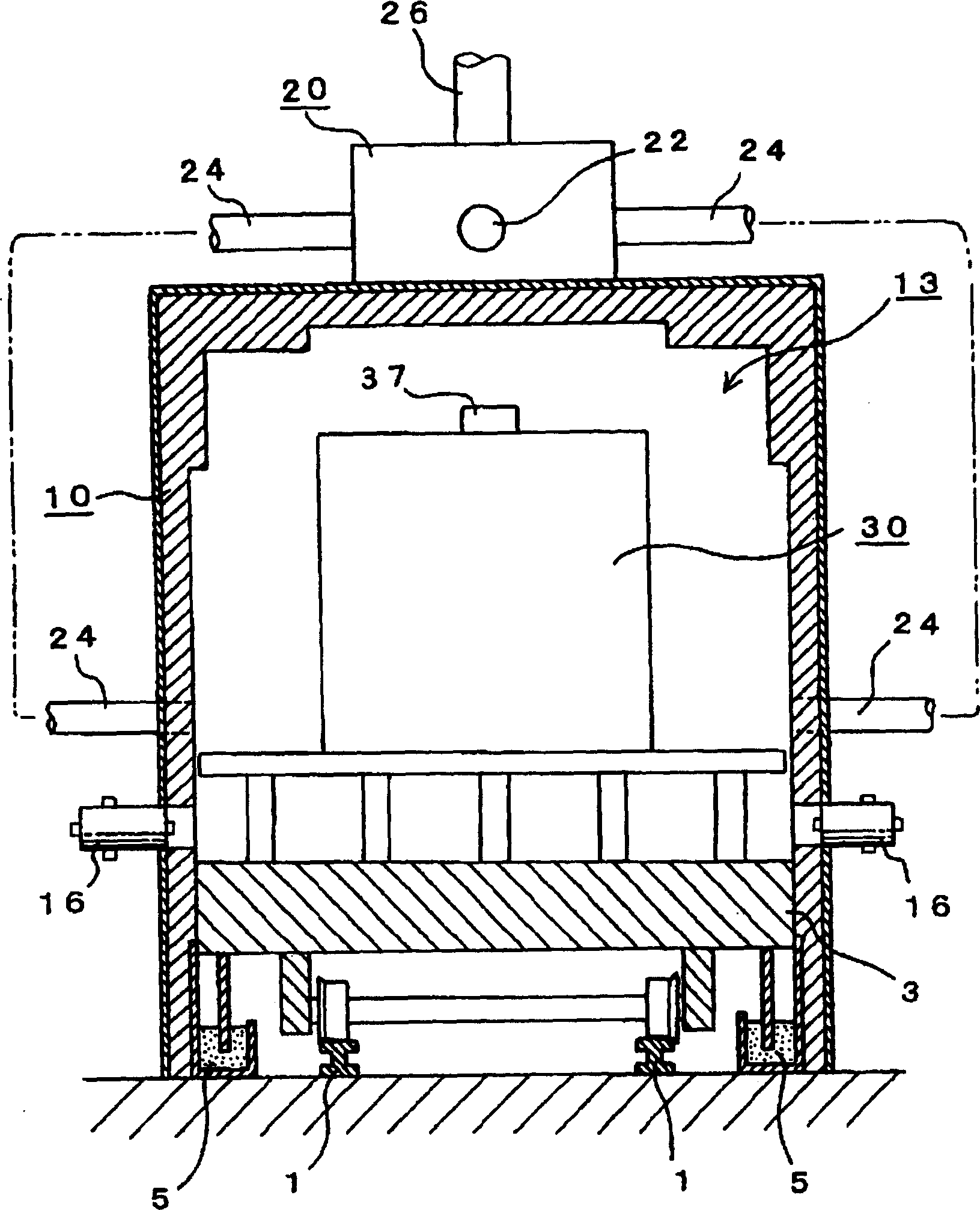

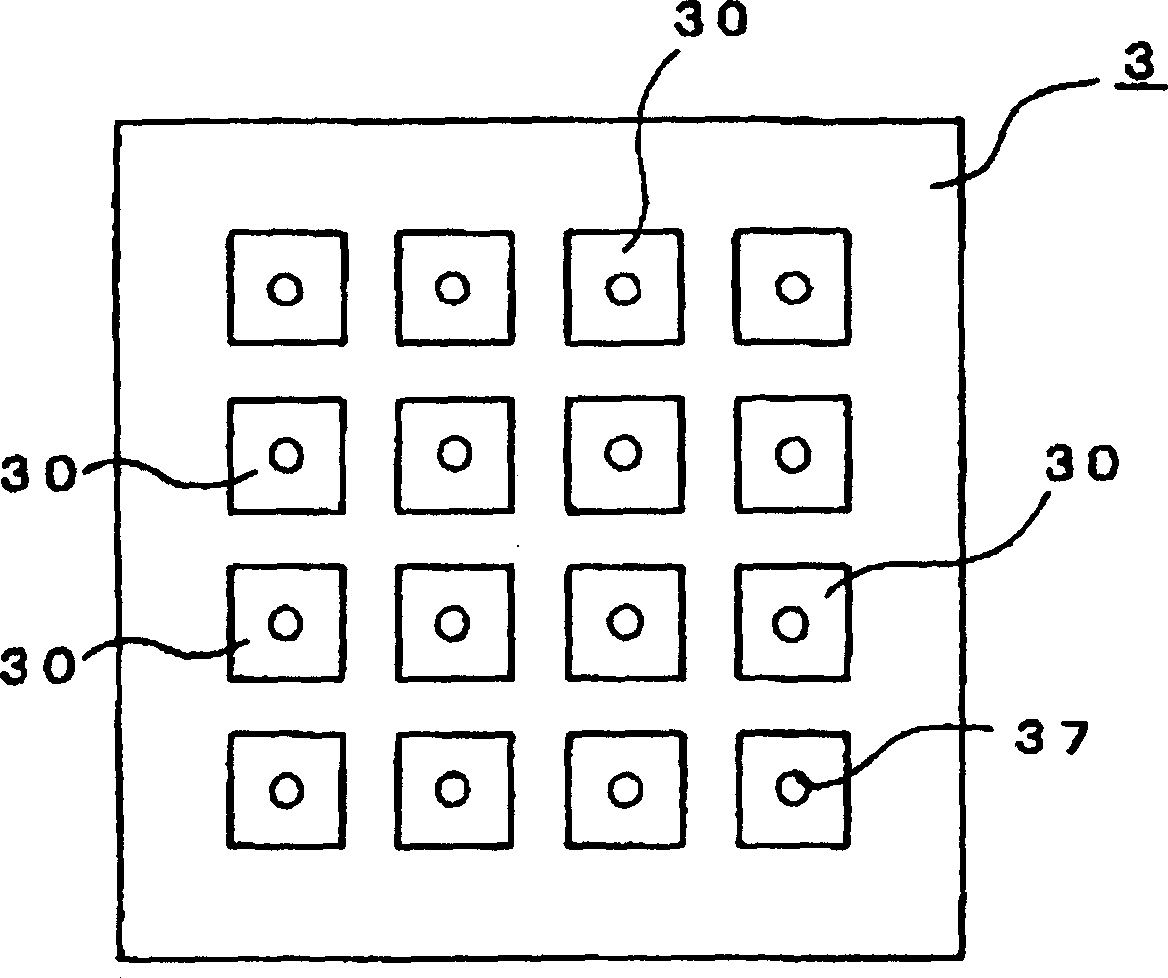

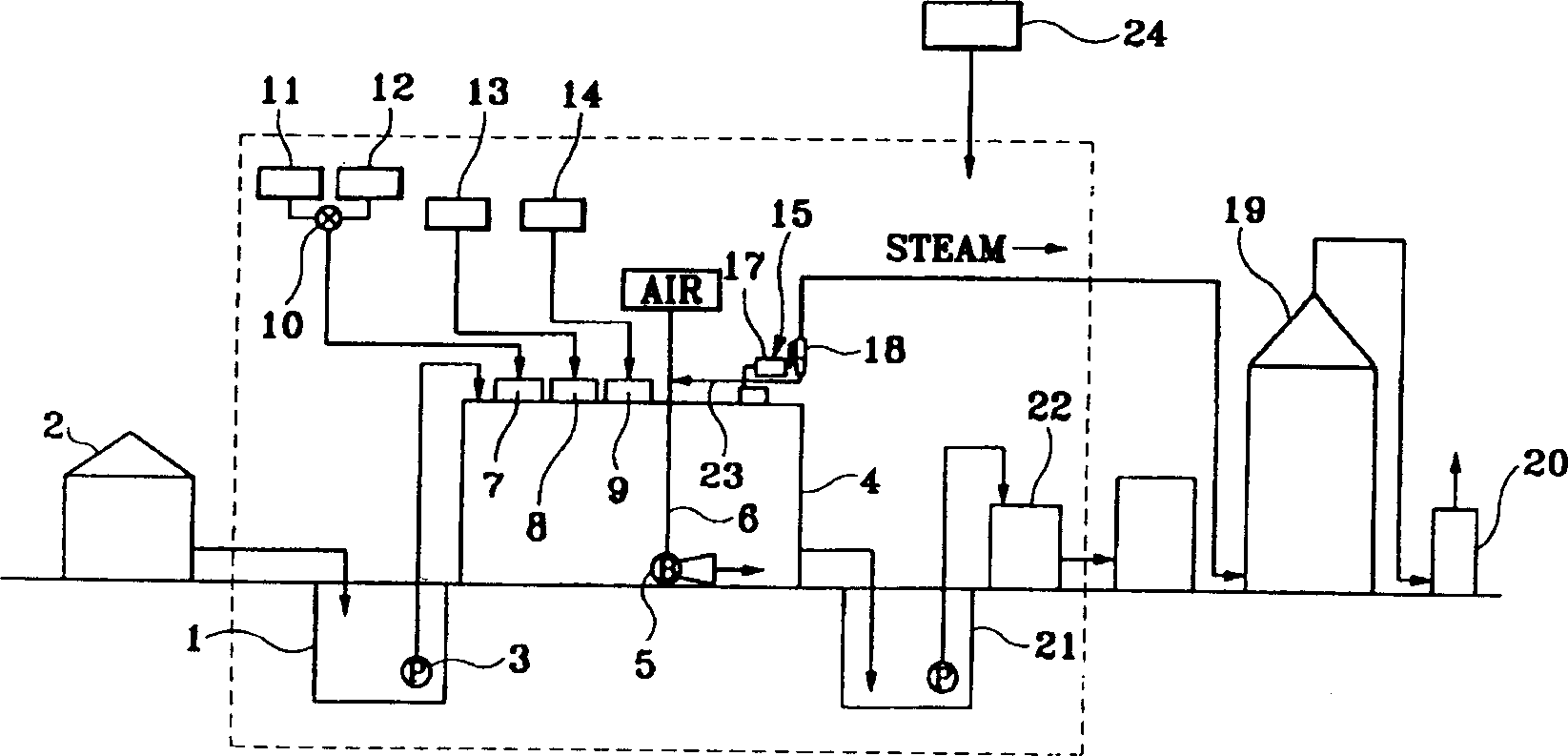

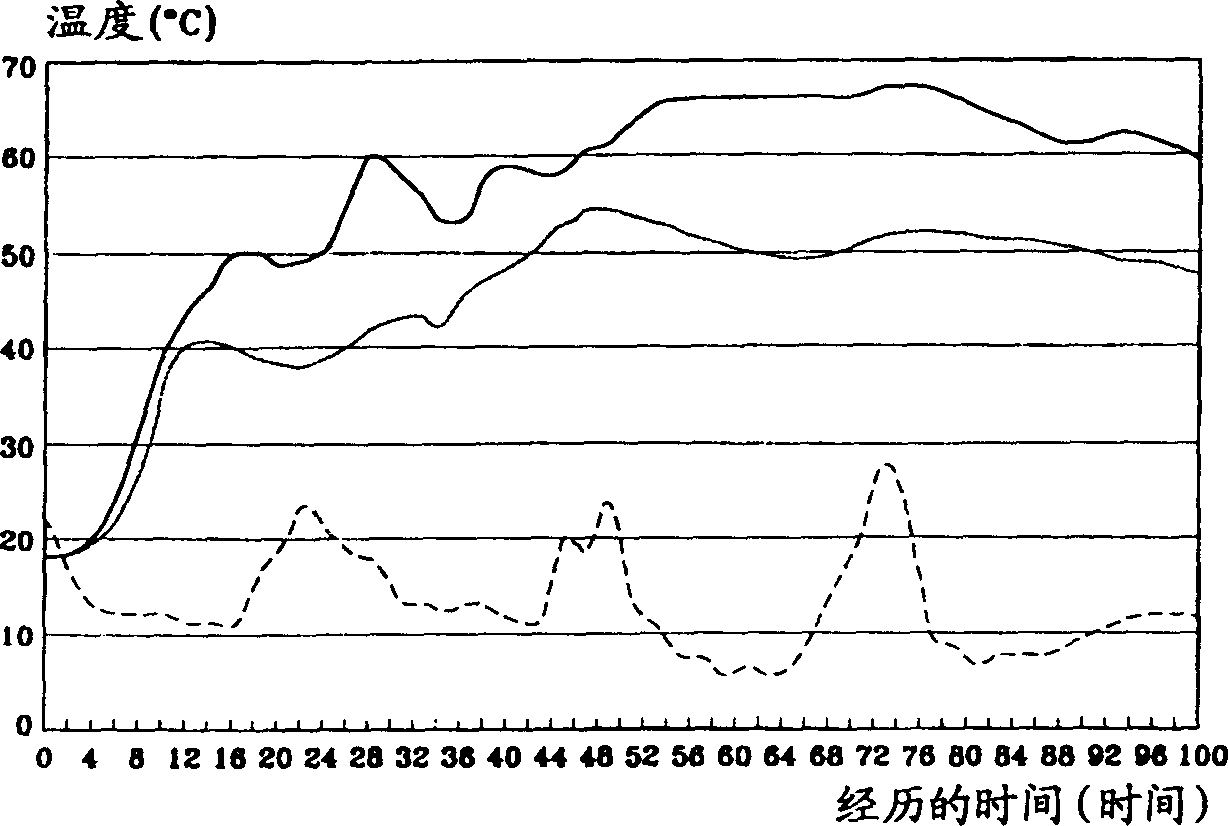

Organic waste treatment apparatus and method for recycling as a liquid fertilizer

InactiveCN1548406ANo foul smellReduce volumeProductsBio-organic fraction processingFertilizerPathogen

An apparatus for treating organic wastes material and a method for recycling as a liquid fertilizer is disclosed, in which the parasites and pathogens are all annihilated, and the treatment can be carried out at a relatively low cost. The aerobic thermophilic digestion bacteria are added into a closed treatment tank, and the tank accommodates an organic wastes slurry which includes animal manure, kitchen waste, sewage and the like. Then the treatment tank is aerated for promoting the proliferation of the aerobic thermophilic digestion bacteria. Thus, the organic wastes slurry is treated with a thermophilic fermentation. Then photo-tropic bacteria are added to convert the organic waste slurry into a liquid fertilizer. The slurry type organic waste are decomposed by utilizing the aerobic thermophilic digestion bacteria which stably flourishes at about 60 DEG C. Then the decomposing is continued by utilizing the photo-tropic bacteria, thereby finally obtaining the product in the form of a liquid fertilizer. The decomposing treatment can be continued for a long time at a high temperature, and the fermentation can be finished in a relatively short period of time without generating any foul odors. Further, parasites and pathogens can all be annihilated.

Owner:EIB +1

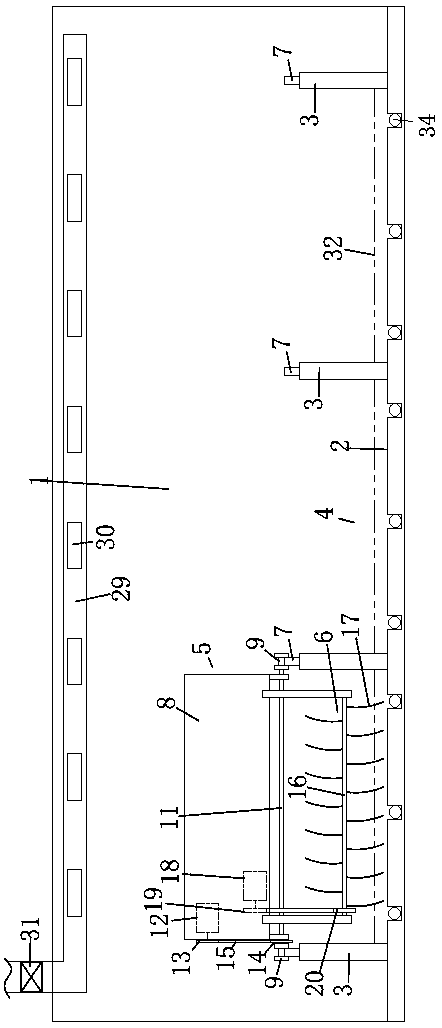

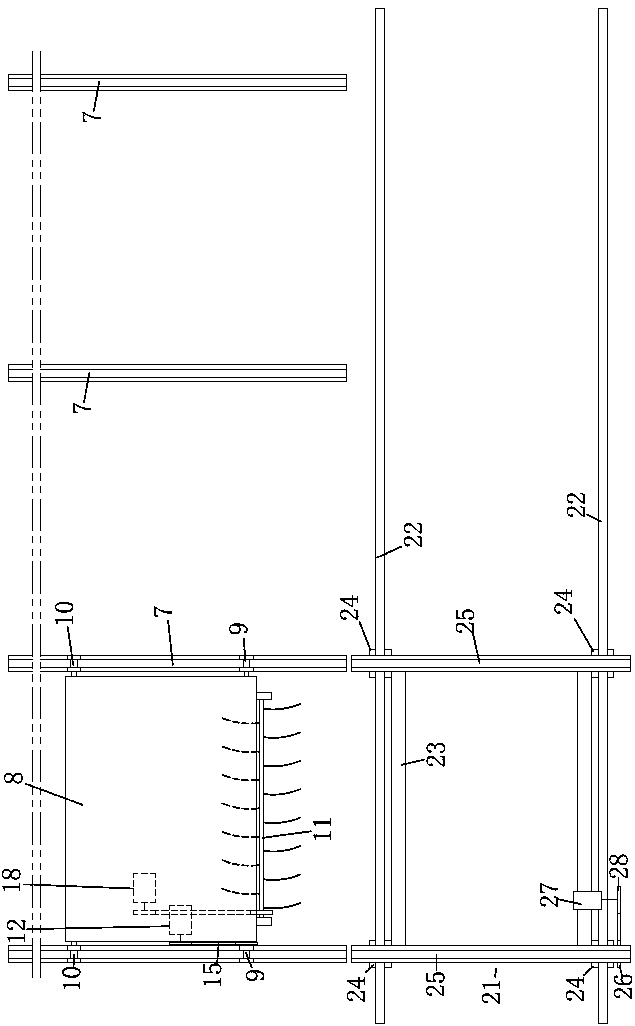

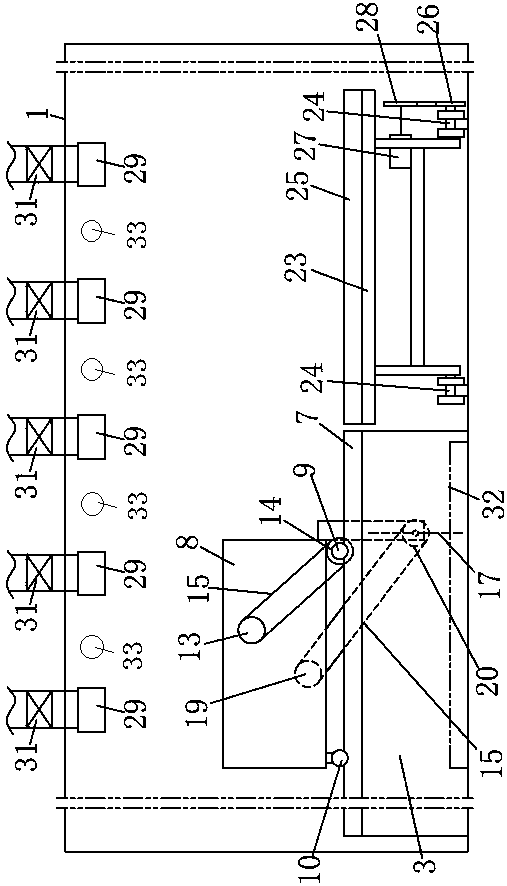

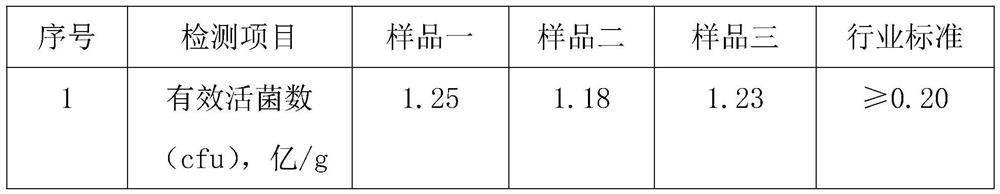

Method for preparing biological organic fertilizer by using fermentation tank

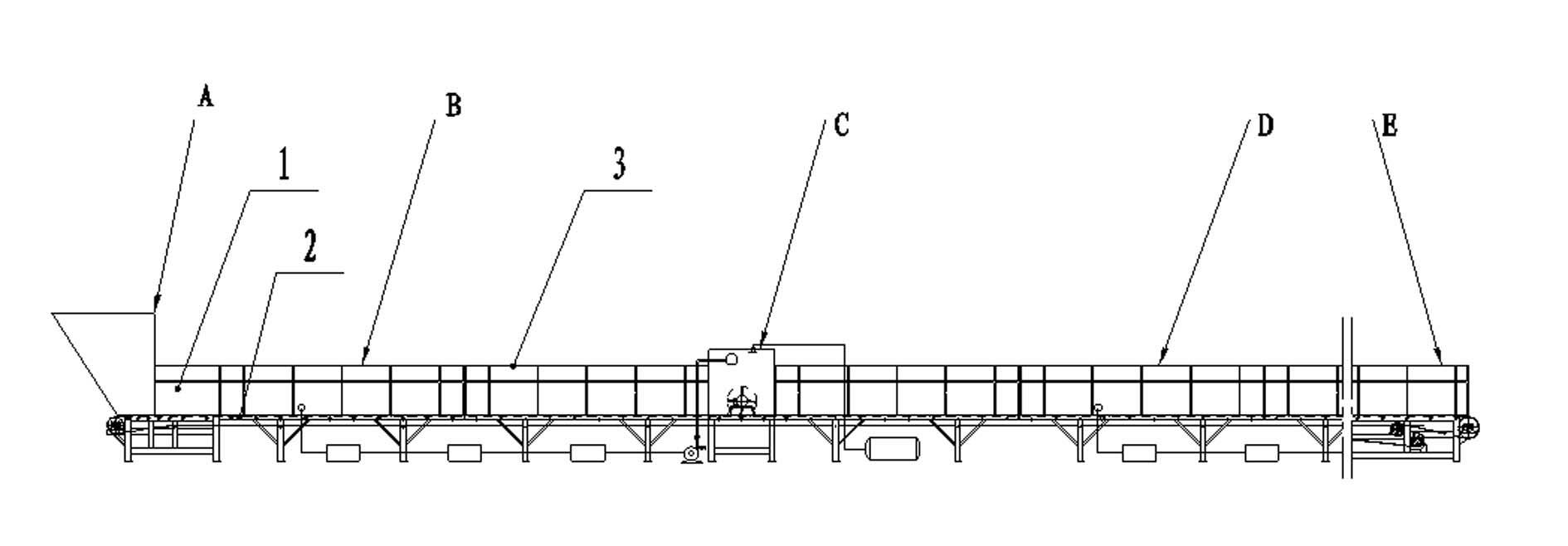

ActiveCN102584379AShort fermentation timeOut of fatClimate change adaptationOrganic fertiliser preparationAutomatic controlControl system

The invention discloses a method for preparing a biological organic fertilizer by using a fermentation tank. The method comprises the following steps of: (1) preparing a biological organic fertilizer fermentation tank; (2) mixing 60 to 70 weight percent of sludge, 30 to 40 weight percent of organic matters and 2 to 8 kinds of beneficial strains; (3) feeding the mixed materials into the fermentation tank, and fermenting in a sealed negative pressure environment; (4) controlling a heating mechanism, a humidifying mechanism, a turning, polishing and aerating mechanism and a strain adding mechanism to heat and humidify the materials, add the strains and turn, polish and aerate the materials in a reaction tank by using an automatic control system; and (5) extracting stink generated in the reaction tank by using an air extractor, feeding into environment-friendly equipment for treating, and fermenting and decomposing the materials in the reaction tank for 15 to 17 hours to obtain the biological organic fertilizer. By the method for preparing the biological organic fertilizer, fermentation time is short, the fertilizer is quickly discharged, production efficiency is high, the materials are driven to move forwards by a conveying belt, feeding, fermenting and discharging are connected, and the method is suitable for industrial production; and the stink is not generated in the production process, so the method is environment-friendly.

Owner:桂林润泰生物科技有限公司 +1

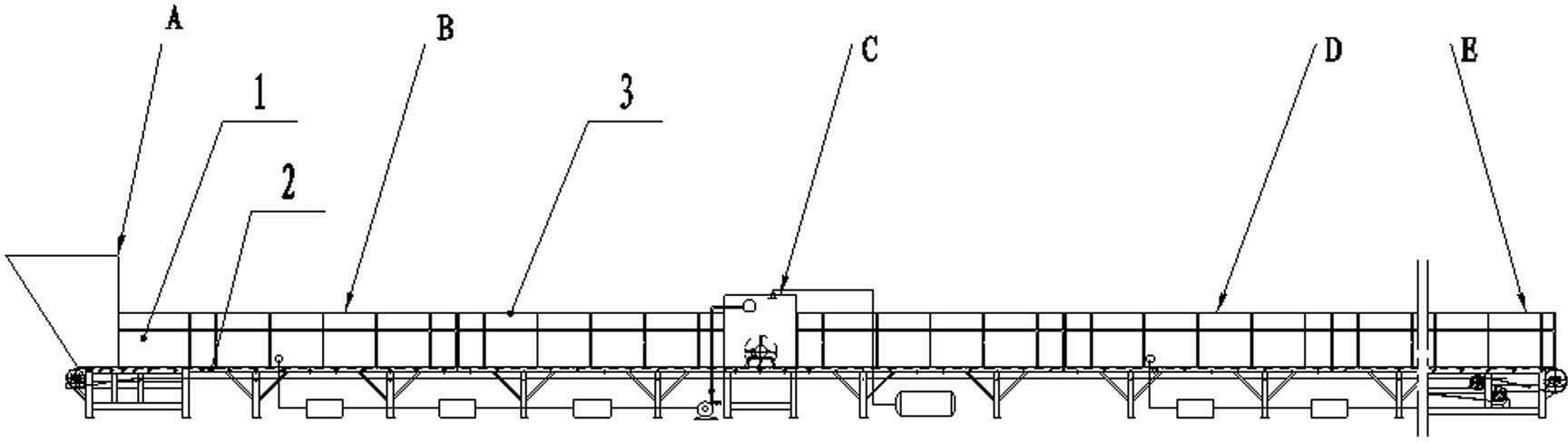

Three-phase catalytic deodorization process for RTO emission exhaust

PendingCN106984189ALow costReduce processing costsGas treatmentOrganic-compounds/hydrides/coordination-complexes catalystsCooling towerFlue gas

The invention relates to the field of exhaust treatment and relates to a three-phase catalytic deodorization process for RTO emission exhaust. The method is as follows: gas obtained after RTO is burn passes through a flue gas cooling tower and a three-phase catalytic deodorization device to achieve the effect of purifying the exhaust, wherein the flue gas cooling tower can be used for reducing the temperature of the gas while removing acid gas in the exhaust so as to ensure that subsequent devices can continuously and stably operate. The three-phase catalytic deodorization device is used for performing coupling catalysis gas, liquid, solid phases to degrade odor matters in the exhaust to achieve deodorization effect. The method has the advantages of being easy to operate, low in processing cost, small in device investment, and the like.

Owner:NJTECH ENVIRONMENT TECH CO LTD

Preparation method of microalgae nutritional brown algae gel

InactiveCN108113000ANo foul smellHigh acceptabilityFood shapingFood ingredient as encapsulating agentCholesterolAqueous solution

The present invention discloses a preparation method of microalgae nutritional brown algae gel and belongs to the technical field of food. Firstly, a certain amount of sodium alginate is dissolved ina microalgae solution to form a uniform solution; then, the uniform solution is added to a molding solution for embedding microalgae to obtain pre-embedded brown algae gel; a certain amount of a sodium alginate aqueous solution is added to the pre-embedded brown algae gel to be mixed uniformly, and then the molding solution is added; and stirring, calcifying, still putting, and cooling are conducted to obtain the microalgae nutritional brown algae gel. The prepared microalgae nutritional brown algae gel is good in mouthfeel, free of any smelly and odor smell, and intact in kept nutritious components, and has nutritional effects on moistening intestines and relaxing bowels, lowering cholesterol and improving human body immunity.

Owner:QINGDAO BRIGHT MOON SEAWEED GROUP

Rose-added cat sand with fresh scent and processing technology for same

The invention relates to a type of rose-added cat sand with a fresh scent. The cat sand is characterized by comprising constituents including 50-85 parts of plant wood bits, 5-10 parts of starch, 3-5 parts of antibacterial agent, 8-10 parts of sodium bicarbonate, 4-5 parts of binder, 1-2 parts of super absorbent resin, 2-4 parts of roses and 5-10 parts of water. The cat sand provided by the invention has the beneficial effects that the density of the cat sand is low; expansion moisture absorptivity is high; the cat sand is biodegradable and has a high anti-bacterial property; bacteria breeding does not take place easily; and the cat sand has the fresh rose scent, so that no foul smell is generated after the cat sand adsorbs urine and faeces.

Owner:YANTAI CHINA PET FOODS GRP

Lepidoptera pest attractant and preparation method thereof

InactiveCN106172500ALong lastingReduce replacement frequencyBiocidePest attractantsTrappingOrder Lepidoptera

The invention discloses a trapping agent for lepidopteran pests, which belongs to the technical field of agriculture. The trapping agent is composed of brown sugar, vinegar, water, gelatin, pectin and agar. The field is resistant to rain erosion, hot sun exposure, long-lasting effect, reduced replacement frequency, and reduced labor input; simple formula, good trapping effect, ecological environmental protection, inheriting the traditional concept of safety and greenness, low cost of raw materials, and the trap after use can be recycled Therefore, the input cost is reduced; when the trapping agent of the present invention is used, the worm body will not appear in the net-like trapping device, and the phenomenon of foul smell will not occur after soaking in water for a long time, and the trapping effect will be increased; the preparation method of the present invention is simple to operate, convenient to prepare, Low cost and suitable for industrialized mass production.

Owner:SICHUAN JINXIANG KIWI FRUIT IND TECH RES CO LTD

Detergent for removing sulfur scales

The invention discloses a detergent for removing sulfur scales. The detergent comprises a main solvent, a co-solvent, a phase activator and a phase stabilizer. The above product combines the advantages of a physical solvent and chemical cleaning, and the obtained detergent has the advantages of no offensive odor, no irritation, little corrosion to stainless steel and carbon steel, and realizationof stable phase system after dissolving the sulfur scales. The detergent subjected to sulfur removal allows sulfur in the system to form crystallized sulfur precipitated from the detergent system through cooling and other simple operating means; and the detergent can be continuously recycled, so the cleaning cost is reduced. The detergent also has the advantages of simplicity in preparation, no dangerous reaction, extremely small environmental influences, convenience in use, and convenience in onsite operation.

Owner:CHINA PETROLEUM & CHEM CORP +1

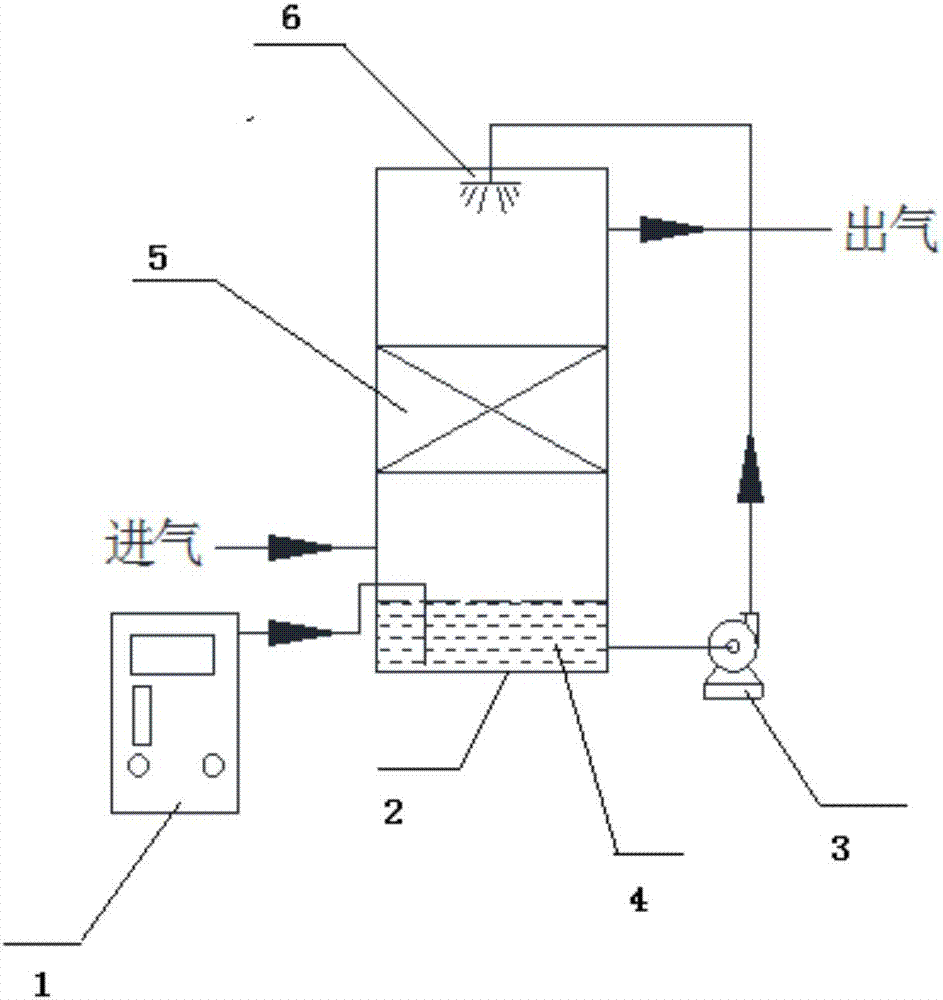

Method for preparing organic fertilizer by taking wet garbage as raw material

InactiveCN111704486AAchieve reductionHarmlessClimate change adaptationEnergy inputSlurryRefuse Disposals

The invention relates to the technical field of garbage treatment, and discloses a preparation method of an organic fertilizer by taking wet garbage as a raw material, which comprises the following steps: S1, pulverizing the wet garbage by a pulverizer, and forming slurry by a material preparation tank; S2, performing a hydrothermal oxidation reaction on the slurry through an oxidation reaction tank; S3, separating gas in the wastewater through a gas-liquid separation tank; S4, carrying out filter pressing on the wastewater by virtue of a filter press; and S5, drying the filter cake through adryer. The pulverizer disclosed by the invention is used for pulverizing wet garbage; carrying out hydrothermal oxidation reaction on the wet garbage in sequence through an oxidation reaction tank ina high-temperature and high-pressure environment; the organic matters in the wet garbage decompose humic acid, formic acid, acetic acid, lactic acid and the like and are dissolved in the wastewater, the wastewater is sequentially subjected to filter pressing and drying through the filter press and a dryer, water fertilizer and solid organic fertilizer particles are obtained, the reaction time is short, the processing efficiency is high, no foul smell exists, waste heat can be recycled, and the production cost is low.

Owner:淄博询知方技术开发有限公司

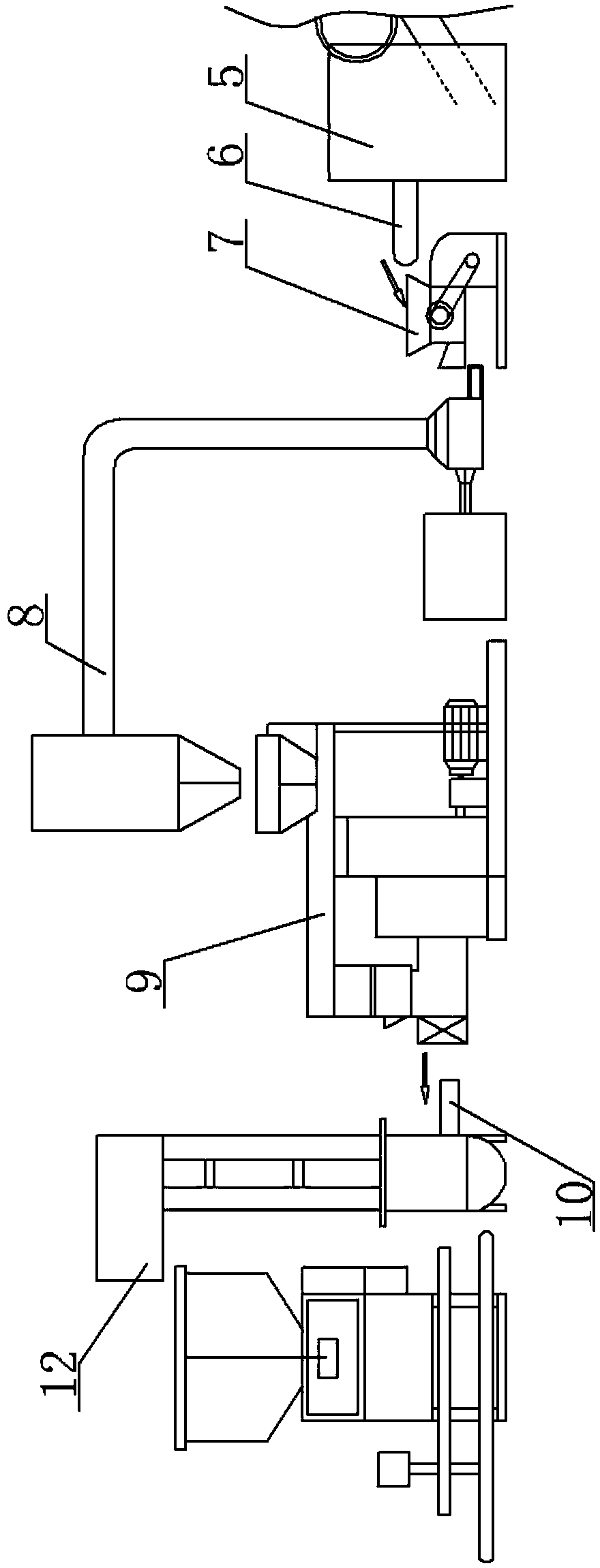

Method and production line for preparing biomass particles by adopting aquatic plants

ActiveCN104194858AEasy to handleTake advantage ofBiofuelsSolid fuelsProduction lineReduction treatment

The invention provides a method and production line for preparing biomass particles by adopting aquatic plants. According to the method, the fished aquatic plants can be subjected to rapid reduction treatment in situ, the biomass particles prepared at the later stage can serve as biomass fuel and also can serve as feed base stock for animals and organic fertilizer base stock for plants, so that the aquatic plants are fully utilized. In addition, after the aquatic plants are treated by the method, stink is avoided, and the environmental quality is ensured. The method comprises the following steps: sequentially squeezing, drying, grinding and granulating the aquatic plants, thus obtaining biomass particles.

Owner:SUZHOU DEXINYUAN ENEGRGY SAVING ENVIRONMENTAL SCI & TECH CO LTD

Fresh scent type cat litter added with folium artemisiae argyi and processing process thereof

The invention relates to fresh scent type cat litter added with folium artemisiae argyi. The fresh scent type cat litter is characterized by comprising the following components: 50 to 85 parts of plant sawdust, 5 to 10 parts of starch, 3 to 5 parts of an antibacterial agent, 8 to 10 parts of sodium bicarbonate, 4 to 5 parts of a binding agent, 1 to 2 parts of super absorbent resin, 2 to 4 parts of the folium artemisiae argyi and 5 to 10 parts of water. The fresh scent type cat litter added with the folium artemisiae argyi has the beneficial effects that the cat litter provided by the invention has the characteristics of small density, high expansion hygroscopic property, biodegradable property, high antibacterial property, uneasiness of breeding bacteria, fresh scent of the folium artemisiae argyi and no odor after urine and excrement are adsorbed.

Owner:YANTAI CHINA PET FOODS GRP

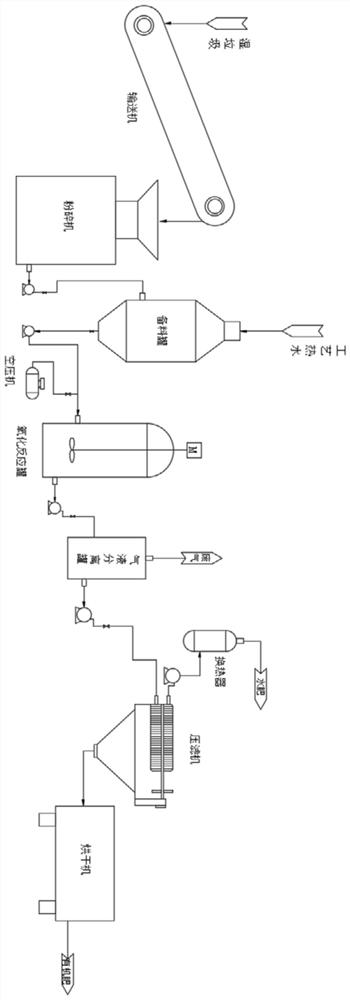

Harmless treatment technology for household garbage

InactiveCN107520226AReduce volumeGood colorSolid waste disposalTransportation and packagingNutrientHeavy metals

The invention discloses a harmless treatment technology for household garbage. The harmless treatment technology mainly solves the technical problems that an existing household garbage treatment method is not environment-friendly and the like. According to the technical scheme of the harmless treatment technology, firstly, a raw material of the household garbage is sorted and screened, recyclable waste articles such as paper, plastic and heavy metal are sorted out and recycled, a combustible such as plants and waste clothes are sorted out and are conveyed to a combustor to be combusted; and then the rest of the garbage is crushed and screened and then is classified, active bacteria are added into the classified garbage, and the active bacteria and the classified garbage are uniformly stirred and then are conveyed to a high-temperature fermentation machine to be fermented so as to prepare organic fertilizer nutrient soil. The harmless treatment technology has the advantages that the whole process that the household garbage is fermented, decomposed, deodorized, sterilized, purified, concentrated and discharged only needs 18-30 hours, the volume of the garbage can be decreased by about 30-70%, and a high-quality organic fertilizer with excellent color, smell and nutrients and a nutritional type organic matrix can be produced; and the harmless treatment technology is energy-saving and environment-friendly and can be widely applied to treatment and reutilization of the household garbage.

Owner:王立兵

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com