Organic waste treatment apparatus and method for recycling as a liquid fertilizer

A technology of organic waste and liquid fertilizer, applied in the preparation of organic fertilizers, organic fertilizers, liquid fertilizers, etc., can solve the problems of inability to eliminate parasites and pathogens, impossible to completely remove odors, and increase costs.

Inactive Publication Date: 2004-11-24

EIB +1

View PDF1 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although the generated odor can be absorbed by deodorizers such as zeolite, it is practically impossible to completely remove the malodor and will increase the cost

[0008] Furthermore, in the mentioned process which belongs to mesophilic fermentation, parasites and pathogens such as Criptostridium cannot be eliminated

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0021] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT

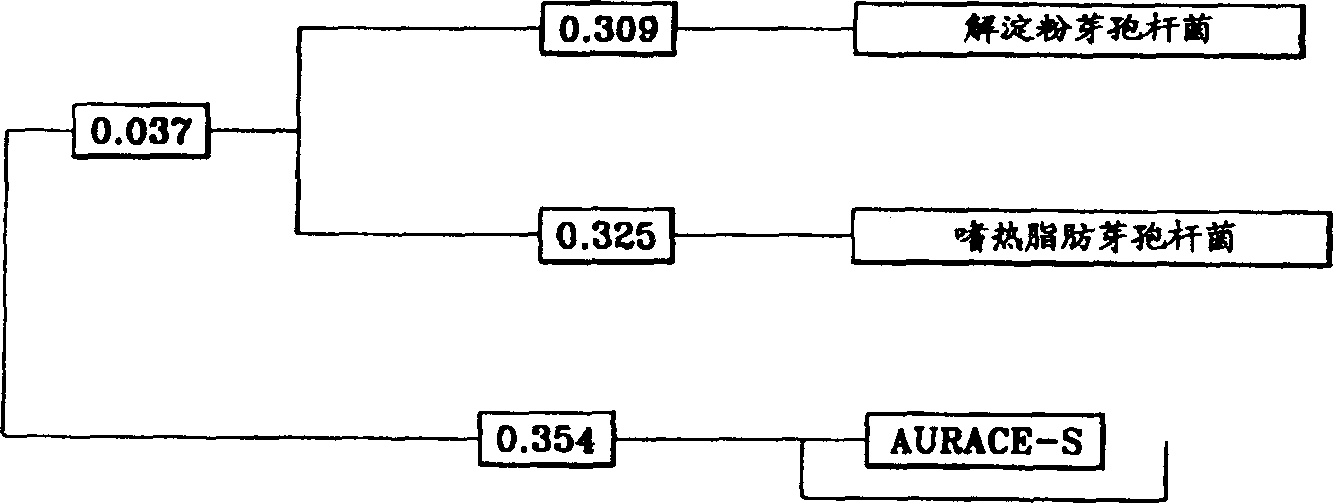

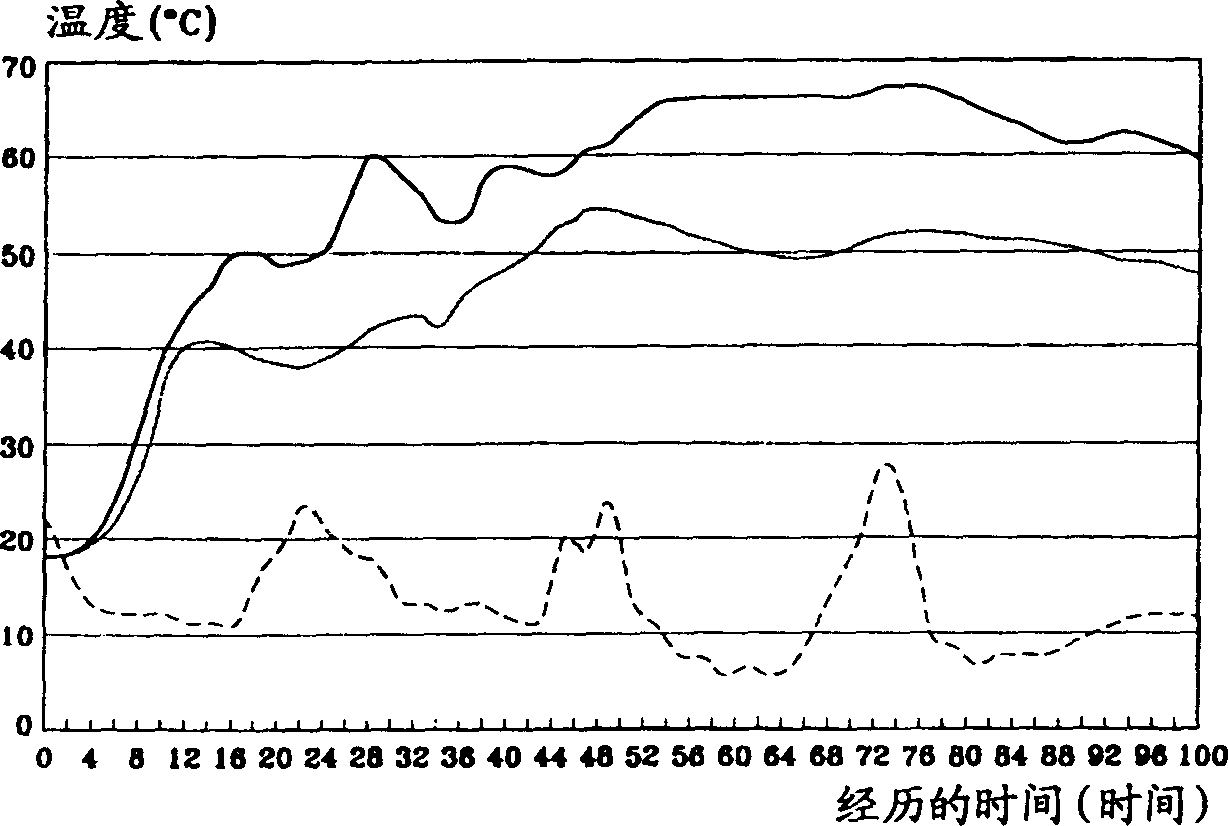

[0022] Aerobic thermophilic digestive bacteria (AURACE-S) are microorganisms present in organic waste, which were extracted to study their properties. The results thus obtained are as follows.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

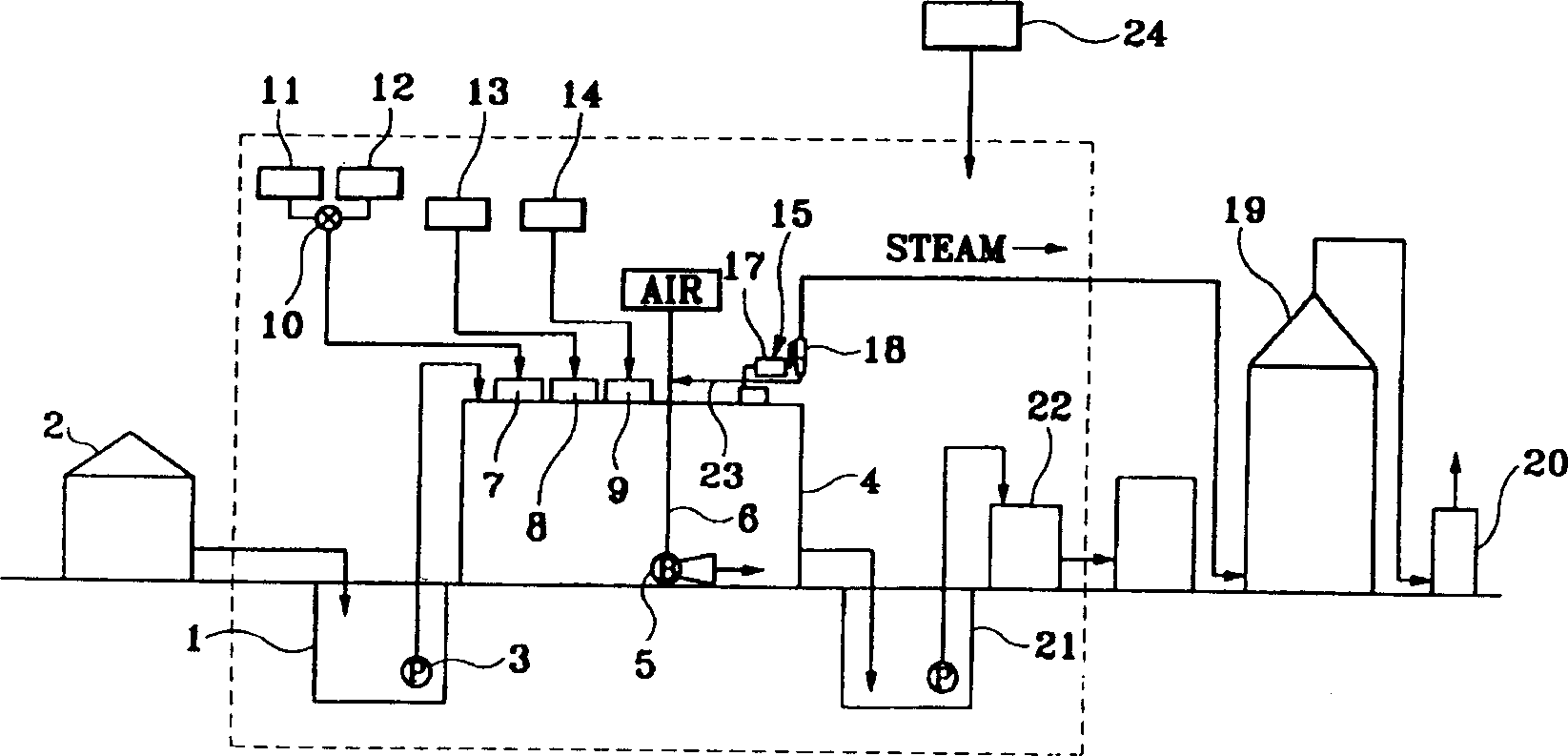

An apparatus for treating organic wastes material and a method for recycling as a liquid fertilizer is disclosed, in which the parasites and pathogens are all annihilated, and the treatment can be carried out at a relatively low cost. The aerobic thermophilic digestion bacteria are added into a closed treatment tank, and the tank accommodates an organic wastes slurry which includes animal manure, kitchen waste, sewage and the like. Then the treatment tank is aerated for promoting the proliferation of the aerobic thermophilic digestion bacteria. Thus, the organic wastes slurry is treated with a thermophilic fermentation. Then photo-tropic bacteria are added to convert the organic waste slurry into a liquid fertilizer. The slurry type organic waste are decomposed by utilizing the aerobic thermophilic digestion bacteria which stably flourishes at about 60 DEG C. Then the decomposing is continued by utilizing the photo-tropic bacteria, thereby finally obtaining the product in the form of a liquid fertilizer. The decomposing treatment can be continued for a long time at a high temperature, and the fermentation can be finished in a relatively short period of time without generating any foul odors. Further, parasites and pathogens can all be annihilated.

Description

field of invention [0001] The present invention relates to a device for treating organic waste and a method for recycling it into liquid fertilizer, wherein the organic waste slurry, such as animal manure, kitchen waste, sewage, etc., is fermented. Background of the invention [0002] Japanese Patent Publication No. Heisei 8-11239 discloses a method for treating organic waste slurries such as animal manure, kitchen waste, sewage and the like. [0003] In this invention, organic waste animal manure is contained in a treatment tank. Then add phototropic bacteria into the tank, and leave the treatment tank exposed to the atmosphere. Foam is then formed on the surface of the treatment tank, to which a decomposition-resistant organic material such as sawdust is added. [0004] The foam is removed by means of a defoamer, and the organic waste slurry containing decomposition-resistant organic materials is also removed from the treatment tank. Organic materials other than decompo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C02F3/02C02F3/34C05F17/00C05G3/00C05F11/08

CPCC02F3/02C02F3/34C05F17/0018C02F2301/106C05G3/0064Y02P20/145C05F17/40C05G5/20Y02W30/40Y02W10/10C05F11/08

Inventor 李明圭

Owner EIB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com